设计简介

摘要

随着人们环境意识的日益增强,对环境的要求越来越高,城市废弃树枝的随意堆放

及焚烧被逐渐禁止,废弃树枝的处理及综合利用成了城市园林及环卫部门亟待解决的问题。目前采用的主要技术方案是将树枝粉碎后堆肥,用作城市植被、盆栽花卉及树苗移栽的底肥。机身作为粉碎机的一个组成部分,是粉碎装置的基本载体,对粉碎装置的使用寿命有很大的保护作用。而粉碎后物料的输送设备也是连接粉碎后物料与成型室的一个重要装置,能保物料能够连续不断的,稳定的输送到成型室中进行成型。

粉碎室机身是粉碎树枝后的载体是将物料输送到成型室的首要环节,同时机身的设计对于粉碎装置的最大效率的实现有很大的辅助意义。它的结构优化,噪音的处理,粉碎装置的稳定性,都具有重要的意义。

对于螺旋输送机,在工程设计及使用中还存在一些的缺陷,如参数选择不合理等。目前,螺旋公式计算输送机的设计仍是依靠经验,在经验公式中许多参数的选择是在一定范围内凭经验选取的,这使得螺旋输送机的设计较落后,无法提高其设计水平和提高产品的性能。

文中对螺旋输送机进行了较全面论述,了解了螺旋输送机的类型、发展现状。阐明了螺旋输送机的工作原理。并根据螺旋输送机的工作原理、工作条件、输送要求等设计一螺旋输送机。该螺旋输送机用于树枝粉碎料的水平输送,根据输送量以及输送路程设计出螺旋直径。

最后对螺旋输送机的安装及平时保养做出了总结。整个设计对今后的设计工作将有实际指导意义和价值。

关键词: 机身;上壳体;下壳体;螺旋输送机;连续运输机械;螺旋直径

Abstract

As people's environmental awareness increasing, the requirement to the environment is more and more high, the city deserted branch random stacking and burning was gradually abandoned the ban, the treatment and comprehensive utilization of the city landscape and environmental sanitation departments problems to be solved.At present the main technical proposal is that the branch crushing after composting, as city vegetation, potted flowers and seedlings transplanting fertilizer.The fuselage as the mill is an integral part of, is a basic carrier of crushing device for crushing device, the service life is very protective effect.The crushed material conveying device is also connected crushed material and the molding chamber is an important device, can guarantee the material can be continuous, stable conveying to the molding chamber for forming.

Crushing chamber body is crushed branches after the carrier is the material is transported to the molding chamber is the important link, at the same time the design for grinding device for maximum efficiency achievement greatly assisted significance.Its structure is optimized, noise processing, grinding device stability, have important sense.

The text of the screw conveyor in a more comprehensive discussion about the type of screw conveyor, the development of the status quo. To clarify the working principle of the screw conveyor. Screw conveyor in accordance with the working principle, working conditions, transportation requirements to design a screw conveyor. The screw conveyor for conveying the level of cement, according to throughput and transmission distance diameter spiral design, computing power, as well as a spiral in accordance with the power to choose a motor, reducer and coupling to solve practical problems.

At last, some research work is made about the influences of parameters during screw conveyors conveying bulks. This can direct later research work about screw conveyors design work, and has practical significance.

Key Words: screw conveyor; continuous transportation machine; screw diameter

目录随着人们环境意识的日益增强,对环境的要求越来越高,城市废弃树枝的随意堆放

及焚烧被逐渐禁止,废弃树枝的处理及综合利用成了城市园林及环卫部门亟待解决的问题。目前采用的主要技术方案是将树枝粉碎后堆肥,用作城市植被、盆栽花卉及树苗移栽的底肥。机身作为粉碎机的一个组成部分,是粉碎装置的基本载体,对粉碎装置的使用寿命有很大的保护作用。而粉碎后物料的输送设备也是连接粉碎后物料与成型室的一个重要装置,能保物料能够连续不断的,稳定的输送到成型室中进行成型。

粉碎室机身是粉碎树枝后的载体是将物料输送到成型室的首要环节,同时机身的设计对于粉碎装置的最大效率的实现有很大的辅助意义。它的结构优化,噪音的处理,粉碎装置的稳定性,都具有重要的意义。

对于螺旋输送机,在工程设计及使用中还存在一些的缺陷,如参数选择不合理等。目前,螺旋公式计算输送机的设计仍是依靠经验,在经验公式中许多参数的选择是在一定范围内凭经验选取的,这使得螺旋输送机的设计较落后,无法提高其设计水平和提高产品的性能。

文中对螺旋输送机进行了较全面论述,了解了螺旋输送机的类型、发展现状。阐明了螺旋输送机的工作原理。并根据螺旋输送机的工作原理、工作条件、输送要求等设计一螺旋输送机。该螺旋输送机用于树枝粉碎料的水平输送,根据输送量以及输送路程设计出螺旋直径。

最后对螺旋输送机的安装及平时保养做出了总结。整个设计对今后的设计工作将有实际指导意义和价值。

关键词: 机身;上壳体;下壳体;螺旋输送机;连续运输机械;螺旋直径

Abstract

As people's environmental awareness increasing, the requirement to the environment is more and more high, the city deserted branch random stacking and burning was gradually abandoned the ban, the treatment and comprehensive utilization of the city landscape and environmental sanitation departments problems to be solved.At present the main technical proposal is that the branch crushing after composting, as city vegetation, potted flowers and seedlings transplanting fertilizer.The fuselage as the mill is an integral part of, is a basic carrier of crushing device for crushing device, the service life is very protective effect.The crushed material conveying device is also connected crushed material and the molding chamber is an important device, can guarantee the material can be continuous, stable conveying to the molding chamber for forming.

Crushing chamber body is crushed branches after the carrier is the material is transported to the molding chamber is the important link, at the same time the design for grinding device for maximum efficiency achievement greatly assisted significance.Its structure is optimized, noise processing, grinding device stability, have important sense.

The text of the screw conveyor in a more comprehensive discussion about the type of screw conveyor, the development of the status quo. To clarify the working principle of the screw conveyor. Screw conveyor in accordance with the working principle, working conditions, transportation requirements to design a screw conveyor. The screw conveyor for conveying the level of cement, according to throughput and transmission distance diameter spiral design, computing power, as well as a spiral in accordance with the power to choose a motor, reducer and coupling to solve practical problems.

At last, some research work is made about the influences of parameters during screw conveyors conveying bulks. This can direct later research work about screw conveyors design work, and has practical significance.

Key Words: screw conveyor; continuous transportation machine; screw diameter

摘要 I

Abstract II

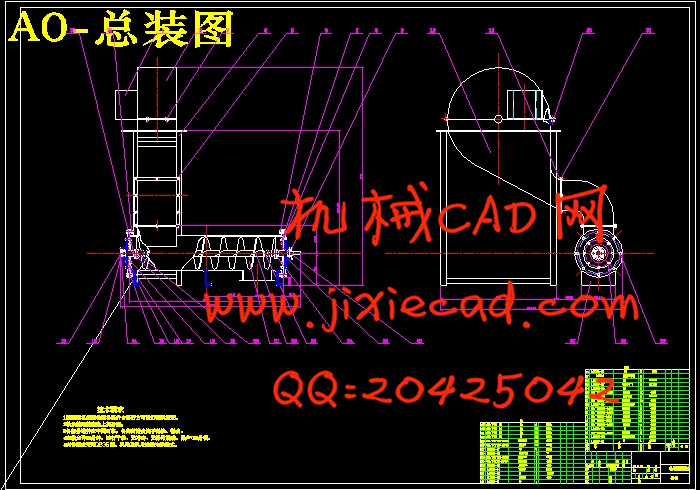

第1章 粉碎机机身的结构设计 1

1.1树枝粉碎机的结构设计与参数 1

1.1.1机身的设计要求 1

1.1.2 机身材料的选取 1

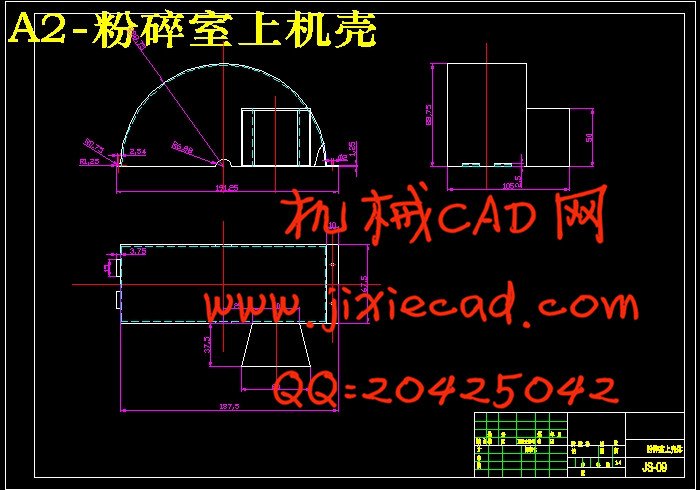

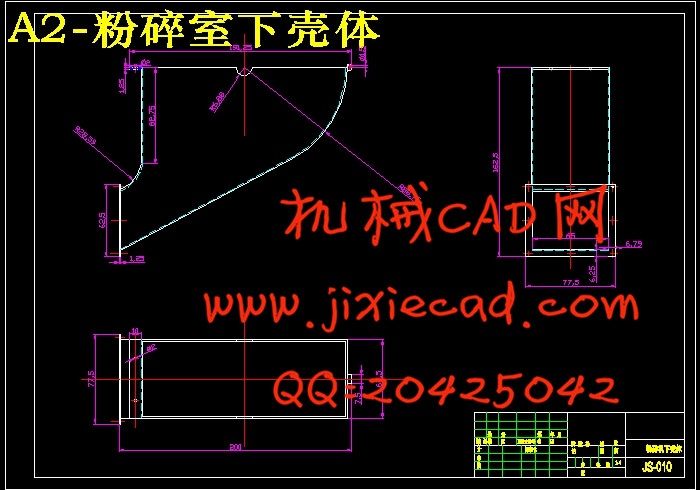

1.2机身粉碎室结构尺寸的确定 2

1.2.1粉碎室宽度B的确定 2

1.2.2粉碎室上壳体尺寸的确定 2

1.2.3粉碎室下壳体尺寸的确定 3

1.2.4粉碎室下壳体出料口尺寸确定 4

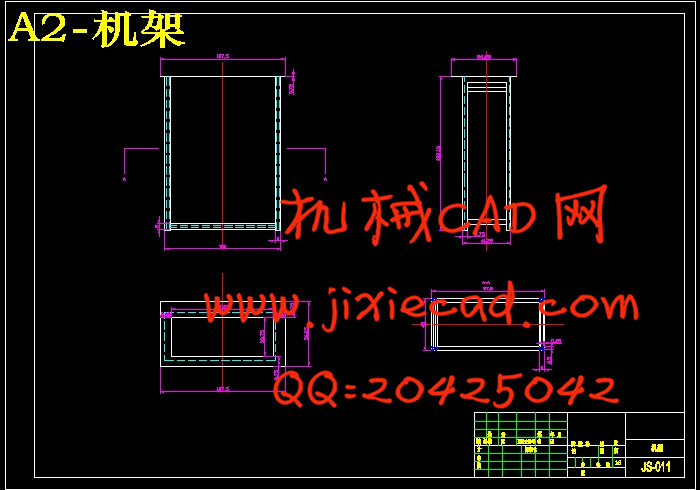

1.3机身机架结构尺寸 4

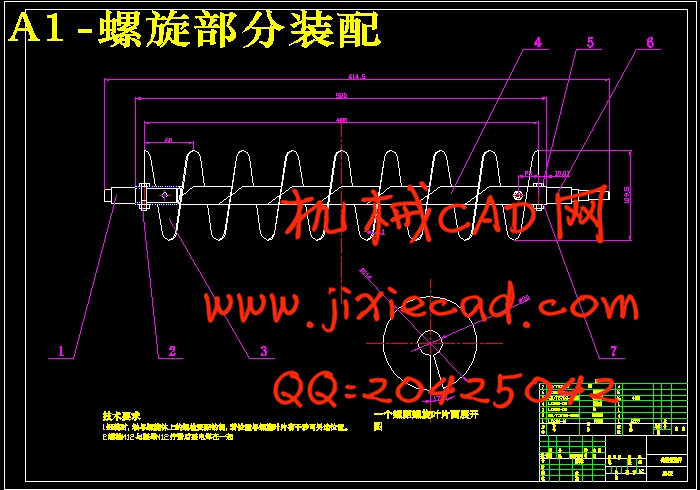

第2章 粉碎机螺旋输送机的设计 5

2.1螺旋输送机的工作原理及特点 5

2.2螺旋输送机发展历史及趋势 6

2.2.1螺旋输送机的发展历史 6

2.2.2螺旋输送机的发展趋势 9

2.2.3螺旋输送机的应用范围 10

2.3螺旋输送机的发展现状 10

第3章 螺旋输送机的设计与参数选用 12

3.1螺旋输送机的设计方法 12

3.1.1 螺旋输送机的现代设计方法 13

3.1.2 螺旋输送机的常规设计 14

3.2螺旋输送机的具体设计 15

3.2.1螺旋输送机的选型 15

3.2.2螺旋输送机的设计计算 17

3.2.3 螺旋输送机外形尺寸 27

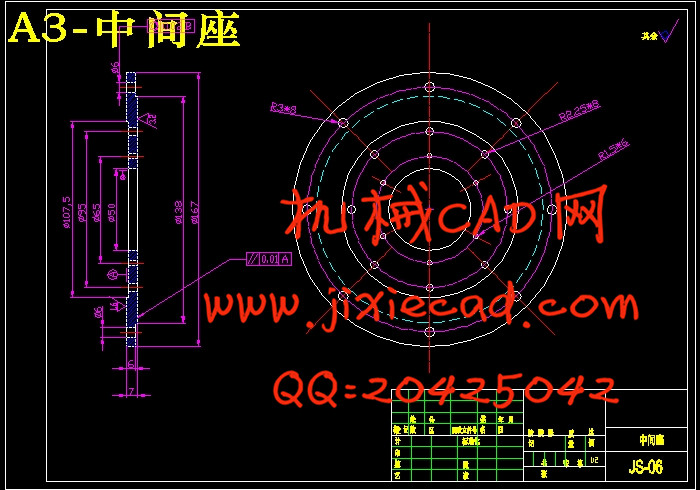

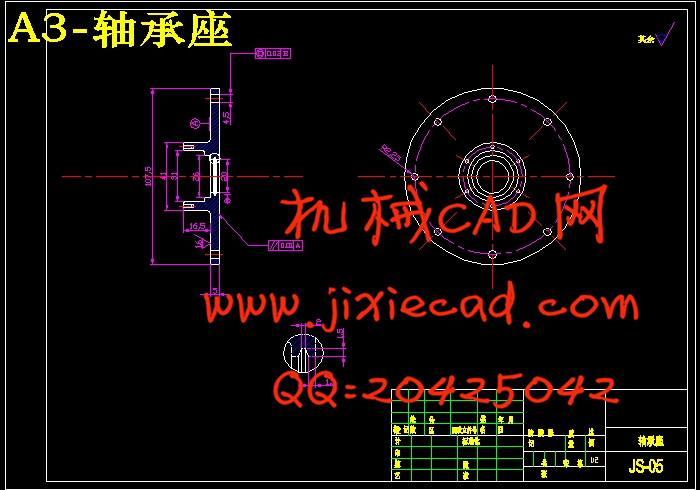

3.2.4 螺旋输送机轴承选择 27

3.2.5 螺旋输送机进出料口装置 28

第4章 螺旋输送机的安装使用及维护 28

4.1 螺旋输送机安装技术条件 28

4.2 螺旋输送机的使用与维护 29

总结 31

参考文献 32