设计简介

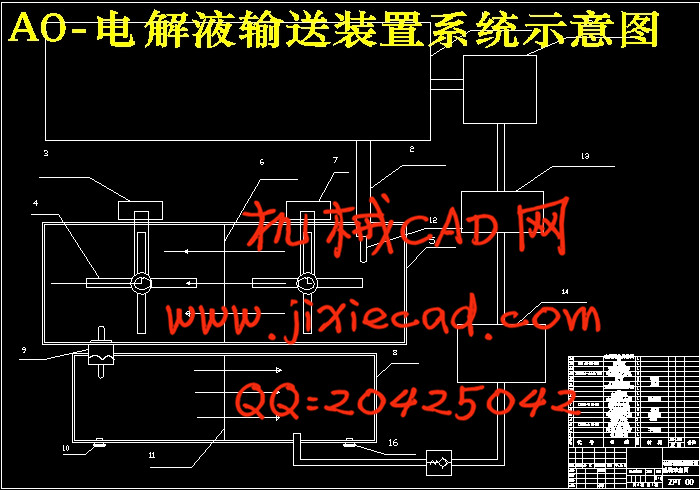

本课题主要是为了推广电解加工技术,对现有数控电解机床及其电解液循环过滤系统进行改造。电解加工由于加工效率高、无工具损耗等显著优点,在难切削材料复杂型面、型腔加工方面获得了越来越广泛的应用,而多轴联动数控机床一般都是针对具体加工对象进行设计,且进口设备价格昂贵,因此,基于实验室现有设备进行改造设计,并对电解液输送系统在保证现有循环过滤的基础上,增加恒温及压力控制装置,使得加工过程中电解液参数易于精确控制,从而提高电解加工精度,对于电解加工工程应用具有重要意义。

本课题中,设计了电解液槽的方案,电解液的过滤,搅拌,增加了温度控制系统,用电子程序对温度进行控制,选择了合适的泵,可以保证电解加工对电解液的要求。加入了搅拌系统可以控制电解液的浓度,以保证加工质量。

关键词 电解加工 电解液 过滤 温度控制 电解液槽

Abstract

This issue is mainly to promote the electrochemical machining technology to the existing NC machine tools and electrolyte electrolytic recycling system to reform. Since ECM high efficiency, no tool wear and other significant advantages, in hard cutting materials of complex surface cavity machining gained more and more widespread concerns applications other multi-axis NC machine tools are generally designed for specific processing of object and imported equipment is expensive, therefore, to renovate existing equipment based on laboratory design, and electrolyte delivery system in ensuring the existing, increased temperature and pressure control equipment, making process in the electrolyte parameters easy precise control, thereby enhancing the electrochemical machining precision engineering applications for ECM is important.

The projects are in the trough of the program is designed electrolyte, electrolyte filtering, mixing, increasing the temperature control system, electronic temperature control program to select the appropriate pump, you can ensure the electrochemical machining of the electrolyte requirements. Joined the agitation system can control the concentration of electrolyte in order to ensure processing quality.

Keywords ECM Electrolyte Filter Temperature Control Electrolyte tank

目 次

1 引言 1

2电解液输送装置的总体设计思路 3

2.1 电解液输送装置总体方案论证 3

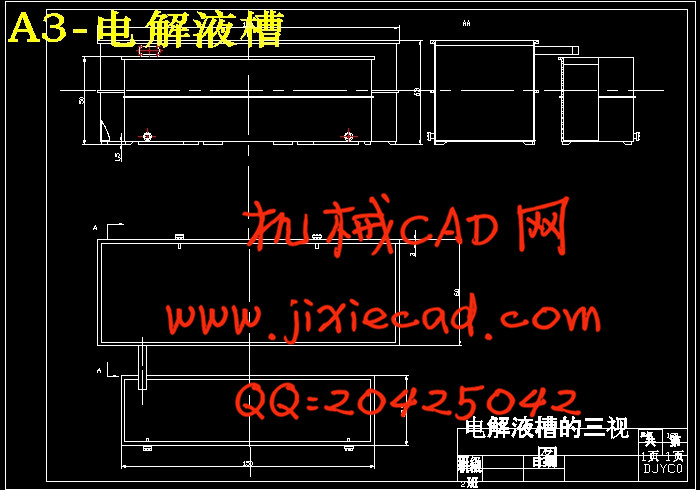

3 电解液槽总体结构设计 6

3.1 设计基础及分析 6

3.2 电解液槽材料的选择 6

3.3 电解液槽结构设计 6

3.4电解液过滤器的设计和选择 7

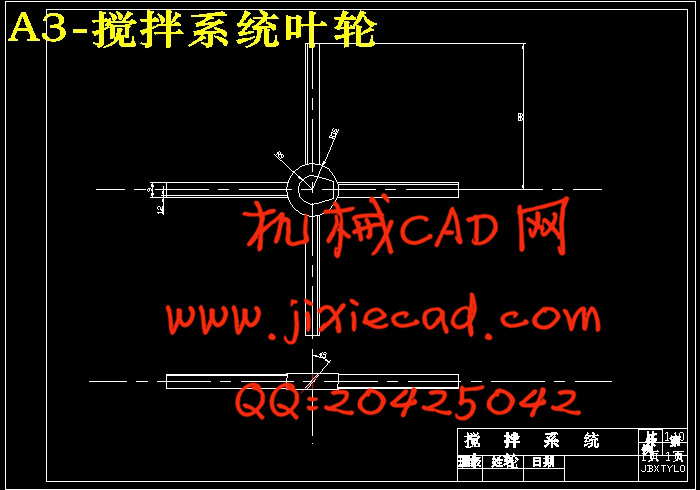

4 电解液搅拌装置设计 9

4.1 搅拌叶轮的选用 10

4.2 搅拌系统传动方案设计 12

4.3 搅拌支架的结构设计 14

5 温度控制系统设计 18

5.1 温度控制硬件电路的设计 18

5.2 温度控制的算法 21

5.3 温度控制程序设计 22

结论 33

致谢 34

参考文献 35

本课题中,设计了电解液槽的方案,电解液的过滤,搅拌,增加了温度控制系统,用电子程序对温度进行控制,选择了合适的泵,可以保证电解加工对电解液的要求。加入了搅拌系统可以控制电解液的浓度,以保证加工质量。

关键词 电解加工 电解液 过滤 温度控制 电解液槽

Abstract

This issue is mainly to promote the electrochemical machining technology to the existing NC machine tools and electrolyte electrolytic recycling system to reform. Since ECM high efficiency, no tool wear and other significant advantages, in hard cutting materials of complex surface cavity machining gained more and more widespread concerns applications other multi-axis NC machine tools are generally designed for specific processing of object and imported equipment is expensive, therefore, to renovate existing equipment based on laboratory design, and electrolyte delivery system in ensuring the existing, increased temperature and pressure control equipment, making process in the electrolyte parameters easy precise control, thereby enhancing the electrochemical machining precision engineering applications for ECM is important.

The projects are in the trough of the program is designed electrolyte, electrolyte filtering, mixing, increasing the temperature control system, electronic temperature control program to select the appropriate pump, you can ensure the electrochemical machining of the electrolyte requirements. Joined the agitation system can control the concentration of electrolyte in order to ensure processing quality.

Keywords ECM Electrolyte Filter Temperature Control Electrolyte tank

目 次

1 引言 1

2电解液输送装置的总体设计思路 3

2.1 电解液输送装置总体方案论证 3

3 电解液槽总体结构设计 6

3.1 设计基础及分析 6

3.2 电解液槽材料的选择 6

3.3 电解液槽结构设计 6

3.4电解液过滤器的设计和选择 7

4 电解液搅拌装置设计 9

4.1 搅拌叶轮的选用 10

4.2 搅拌系统传动方案设计 12

4.3 搅拌支架的结构设计 14

5 温度控制系统设计 18

5.1 温度控制硬件电路的设计 18

5.2 温度控制的算法 21

5.3 温度控制程序设计 22

结论 33

致谢 34

参考文献 35