设计简介

摘 要

装备工业的技术水平和现代化程度决定着整个国民经济的水平和现代化程度,数控技术及装备是发展新兴高新技术产业和尖端工业(如信息技术及其产业、生物技术及其产业、航空、航天等国防工业产业)的使能技术和最基本的装备。随着数控技术的发展,考虑到它的控制方式和使用特点,才对机床的生产率、加工精度和寿命提出了更高的要求。本课题主要研究的是数控机床的主体机构。并将研究重点放在以下两个方面:1)由于采用了高性能的无级变速主轴及伺服传动系统,数控机床的极限传动结构大为简化,传动链也大大缩短。2)为适应连续的自动化加工和提高加工生产率,数控机床机械结构具有较高的静、动态刚度和阻尼精度,以及较高的耐磨性,而且热变形小。

关键词:数控机床,主轴,无级变速

Abstract

The engineering level of equipment industry and modernized intensity are determining the level of the whole national economy and modernized intensity, numerical control technology and equip, develop new developing new high-tech industry and most advanced industry To can make technology and basic equipment most (national defense industry industries, such as information technology and their industry, biotechnology, industry, aviation, space flight, etc.).With the development of technology of numerical control, consider its control method and use characteristic, have just put forward higher requirement for the productivity, machining accuracy and life span of the machine tool. That originally designed main research is the subject organization of the numerical control machine tool. And will study and place on two following respects especially: 1) Because of adopting the high-performance infinitely variable speeds spindle and servo transmission, the terminal transmission structure of the numerical control machine tool is greatly simplified, the drive chain is shortened greatly too. 2) For meet continuous automation process and improve productivity of processing, numerical control lathe mechanical structure have high quiet, dynamic rigidity and damping precision, and higher wear ability, and hot and out of shape and small.

Keyword: Numerical control machine tool, spindle, infinitely variable speeds

目 录

摘 要 I

Abstract II

第一章 前言 1

1.1数控机床的发展概况 1

1.2 数控机床的发展方向 1

1.3 数控机床的主传动系统 1

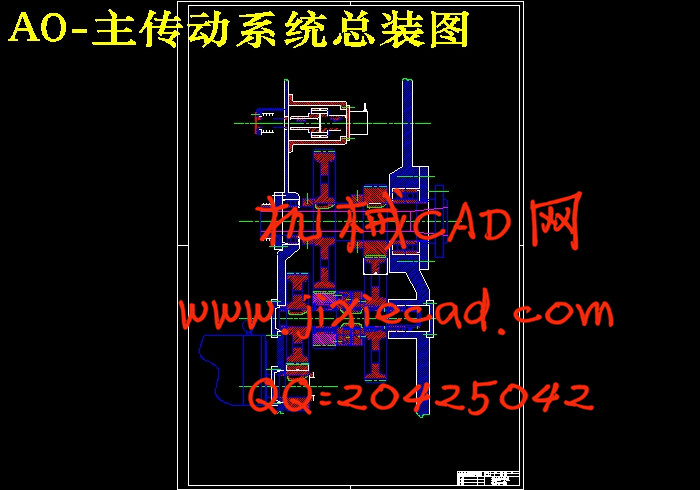

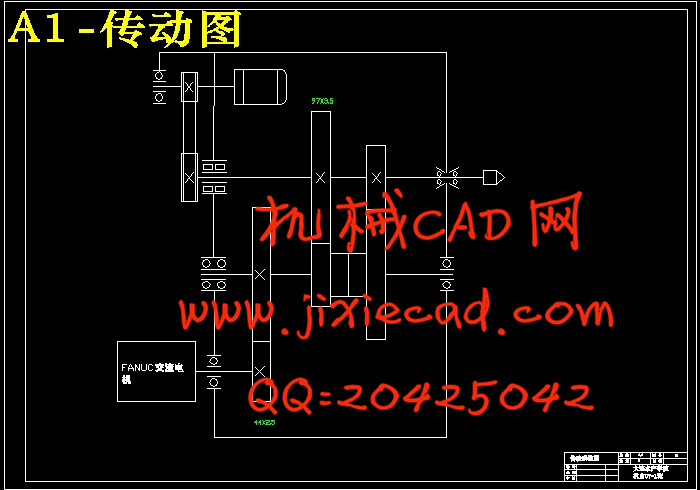

第二章 主传动系统的运动设计 2

2.1 主运动系统驱动电机的选择 2

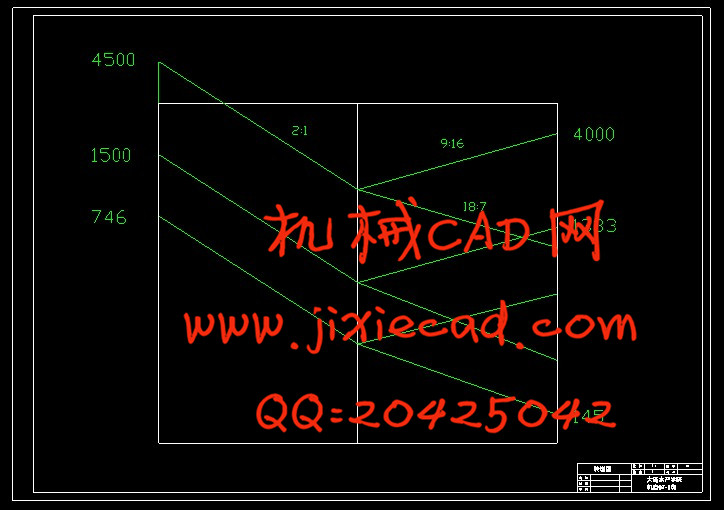

2.2拟定转速图 5

2.3 拟定传动方案 6

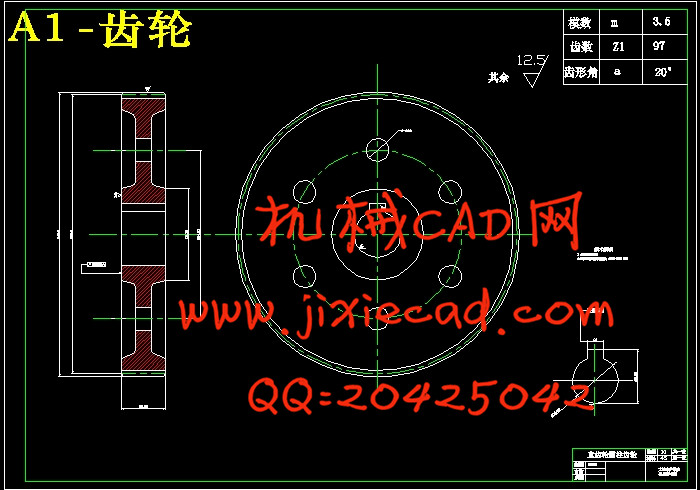

第三章轴的结构设计 8

3.1轴的结构设计及齿轮尺寸参数 8

3.2电磁摩擦离合器的计算和选择 16

3.3轴承的选择 21

第四章 主轴结构设计 22

4.1主轴组件的性能要求 22

4.2 编码器的选择与安装 24

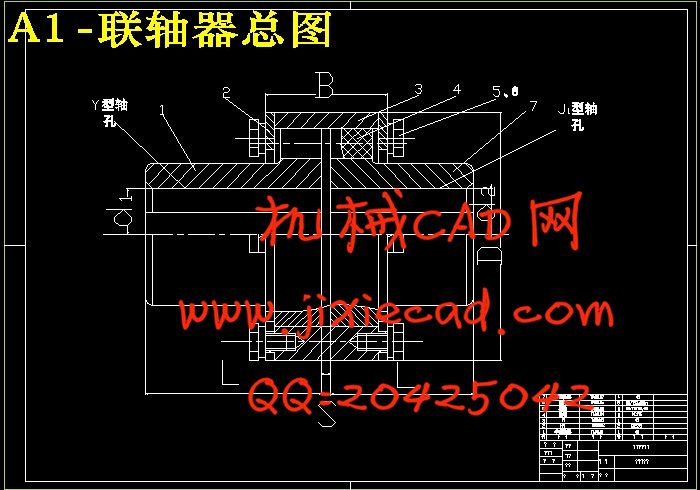

4.3联轴器的选择及带轮参数 25

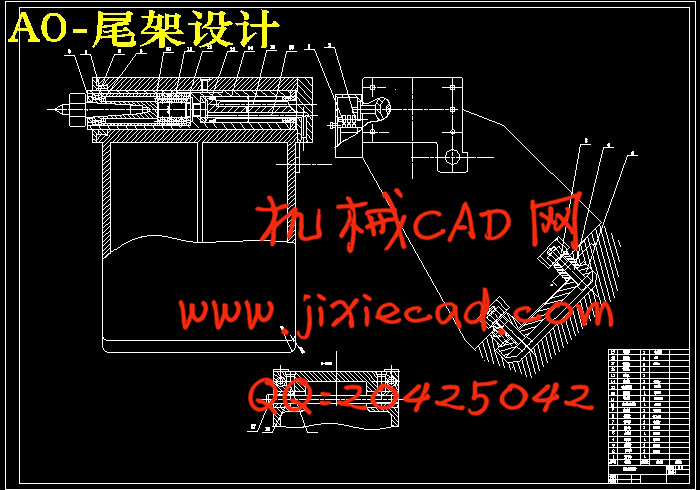

第五章尾架的设计 27

5.1 尾架的结构设计 27

5.2尾架的工作原理 27

结束语 28

致 谢 29

参 考 文 献 30