设计简介

数控机床自动夹持搬运装置的液压系统设计

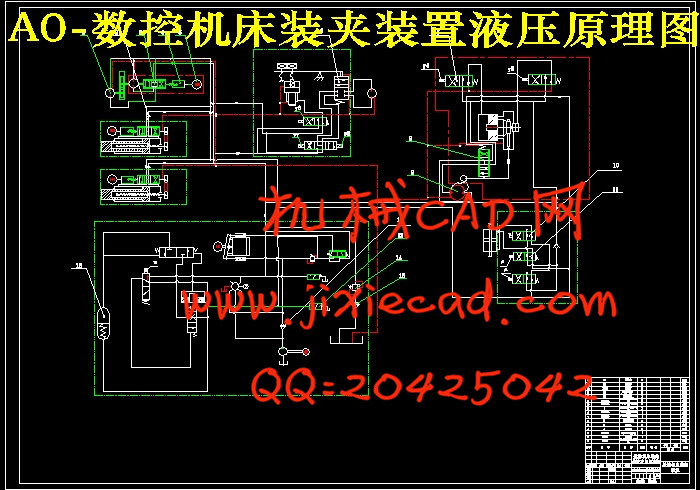

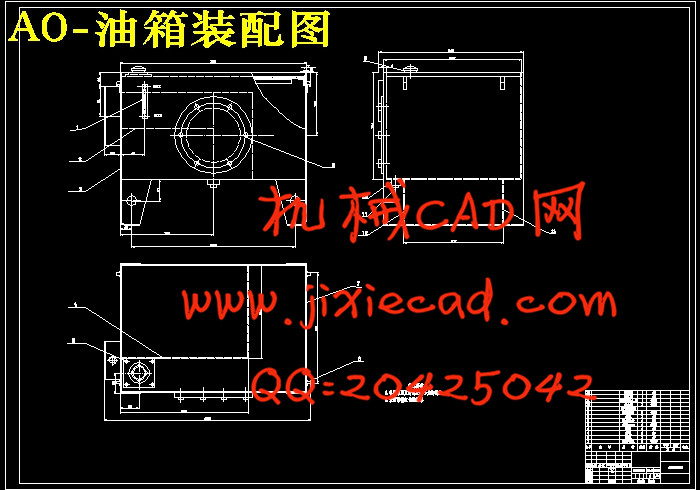

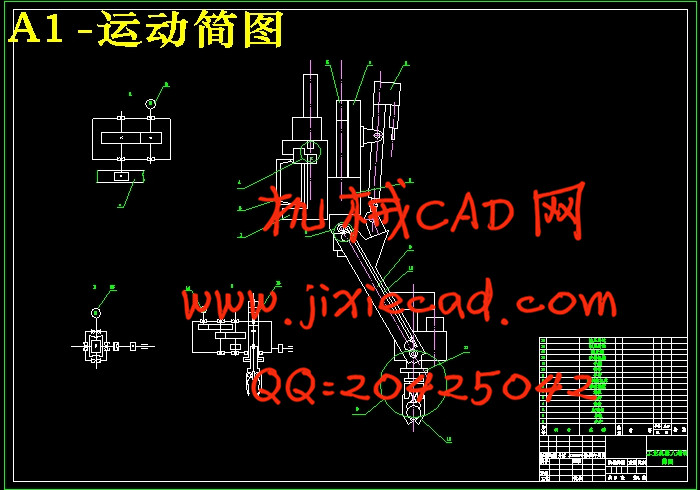

摘 要:数控机床上专用于工件和零件的夹持和自动运转的装置,其运动自由度多,且有严格的动作顺序要求。用液压驱动可实现动作自动循环,利于自动化和高效率等要求。机械手用于各种工艺装备上,其中包括组成柔性自动化系统的数控金属切削机床。工业机器人装备有自动可换夹持装置,其中双夹持器的装置用来保证同时操作毛坯和在加工的零件。本设计主要针对机械手的液压系统,确定液压系统中各个部分的功能,并且对各种执行元件进行计算分析,最终完成液压原理图。

关键词:可换夹持装置 液压元件 双夹持器

Numerically Controlled Machine Tools Automatically Handling Devices Hydraulic Rescue System Design

Abstract: Numerically controlled machine tools, spare parts and dedicated to her rescue and automatic operation of the device, the more freedom of movement and strict action sequence. Driven by hydraulic achievable moves automatically cycle for automation and high efficiency. Mechanical hand for various processes and equipment, including the digital automation system composed soft metal cutting machine tools. Industrial robots are equipped with automatic convertible rescue devices, including devices used to ensure that double-rescue devices at the same time and in the processing operation blank parts. The design of the hydraulic system mainly mechanical hand, identifying the functions of the various parts of the hydraulic system, and implementation of various components in the calculation of analysis, and ultimately complete hydraulic principles maps.

Keywords: Convertible rescue devices ; Hydraulic components; Double-rescue vehicles

目 录

1 概述……………………………………………………………………………………… 1

1.1课题背景……………………………………………………………………… 1

1.2课题内容………………………………………………………………………… 1

1.3课题的意义………………………………………………………………………… 2

1.4课题的创新点………………………………………………………………………… 2

2 机械手的功能设计…………………………………………………………………… 2

2.1机械手液压系统的各部分功能…………………………………………………………… 2

2.2 机械手液压系统的功能综合…………………………………………………………5

2.3机械手电磁铁动作循环表…………………………………………………………… 6

2.4 机械手液压系统方案设计……………………………………………………… 6

3 机械手液压系统机构设计计算……………………………………………………… 6

3.1负载分析………………………………………………………………………………… 6

3.2 液压马达的负载…………………………………………………………………………9

3.3 执行元件主要参数的确定…………………………………………………………………10

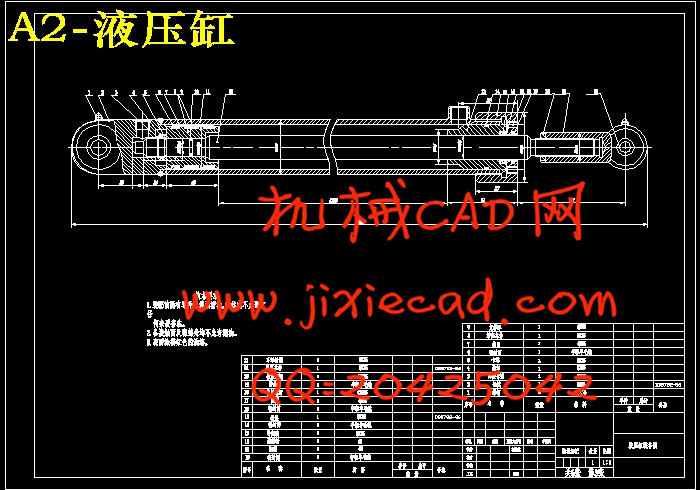

3.4 计算液压缸各工作阶段的工作压力、流量、功率………………………………………11

3.5 拟定液压原理图………………………………………………………………………11

3.6选择液压元件………………………………………………………………………………12

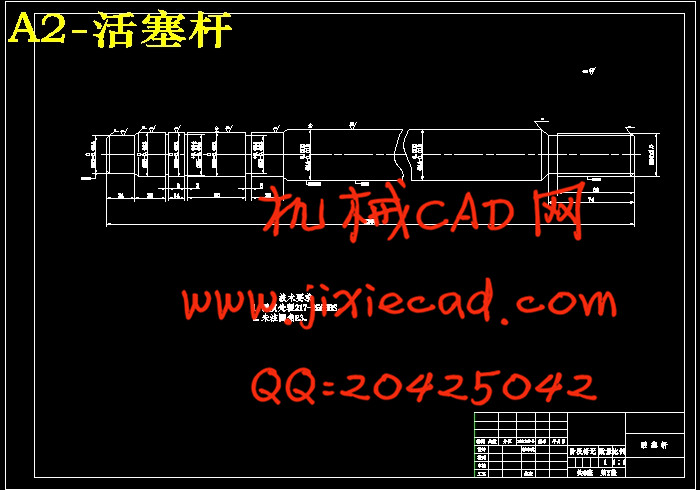

3.7液压缸基本参数的确定……………………………………………………………………14

3.8液压缸结构强度计算和稳定校验…………………………………………………………17

3.9液压传动用油的选择………………………………………………………………………22

4 验算系统液压性能………………………………………………………………………23

4.1压力损失的验算及泵压力的调整…………………………………………………………23

4.2液压系统发热和温升验算…………………………………………………………………26

4.3滤油器的选择………………………………………………………………………………26

结论 …………………………………………………………………………………… 30

致谢 …………………………………………………………………………………… 31

参考文献………………………………………………………………………………32

摘 要:数控机床上专用于工件和零件的夹持和自动运转的装置,其运动自由度多,且有严格的动作顺序要求。用液压驱动可实现动作自动循环,利于自动化和高效率等要求。机械手用于各种工艺装备上,其中包括组成柔性自动化系统的数控金属切削机床。工业机器人装备有自动可换夹持装置,其中双夹持器的装置用来保证同时操作毛坯和在加工的零件。本设计主要针对机械手的液压系统,确定液压系统中各个部分的功能,并且对各种执行元件进行计算分析,最终完成液压原理图。

关键词:可换夹持装置 液压元件 双夹持器

Numerically Controlled Machine Tools Automatically Handling Devices Hydraulic Rescue System Design

Abstract: Numerically controlled machine tools, spare parts and dedicated to her rescue and automatic operation of the device, the more freedom of movement and strict action sequence. Driven by hydraulic achievable moves automatically cycle for automation and high efficiency. Mechanical hand for various processes and equipment, including the digital automation system composed soft metal cutting machine tools. Industrial robots are equipped with automatic convertible rescue devices, including devices used to ensure that double-rescue devices at the same time and in the processing operation blank parts. The design of the hydraulic system mainly mechanical hand, identifying the functions of the various parts of the hydraulic system, and implementation of various components in the calculation of analysis, and ultimately complete hydraulic principles maps.

Keywords: Convertible rescue devices ; Hydraulic components; Double-rescue vehicles

目 录

1 概述……………………………………………………………………………………… 1

1.1课题背景……………………………………………………………………… 1

1.2课题内容………………………………………………………………………… 1

1.3课题的意义………………………………………………………………………… 2

1.4课题的创新点………………………………………………………………………… 2

2 机械手的功能设计…………………………………………………………………… 2

2.1机械手液压系统的各部分功能…………………………………………………………… 2

2.2 机械手液压系统的功能综合…………………………………………………………5

2.3机械手电磁铁动作循环表…………………………………………………………… 6

2.4 机械手液压系统方案设计……………………………………………………… 6

3 机械手液压系统机构设计计算……………………………………………………… 6

3.1负载分析………………………………………………………………………………… 6

3.2 液压马达的负载…………………………………………………………………………9

3.3 执行元件主要参数的确定…………………………………………………………………10

3.4 计算液压缸各工作阶段的工作压力、流量、功率………………………………………11

3.5 拟定液压原理图………………………………………………………………………11

3.6选择液压元件………………………………………………………………………………12

3.7液压缸基本参数的确定……………………………………………………………………14

3.8液压缸结构强度计算和稳定校验…………………………………………………………17

3.9液压传动用油的选择………………………………………………………………………22

4 验算系统液压性能………………………………………………………………………23

4.1压力损失的验算及泵压力的调整…………………………………………………………23

4.2液压系统发热和温升验算…………………………………………………………………26

4.3滤油器的选择………………………………………………………………………………26

结论 …………………………………………………………………………………… 30

致谢 …………………………………………………………………………………… 31

参考文献………………………………………………………………………………32