设计简介

摘 要

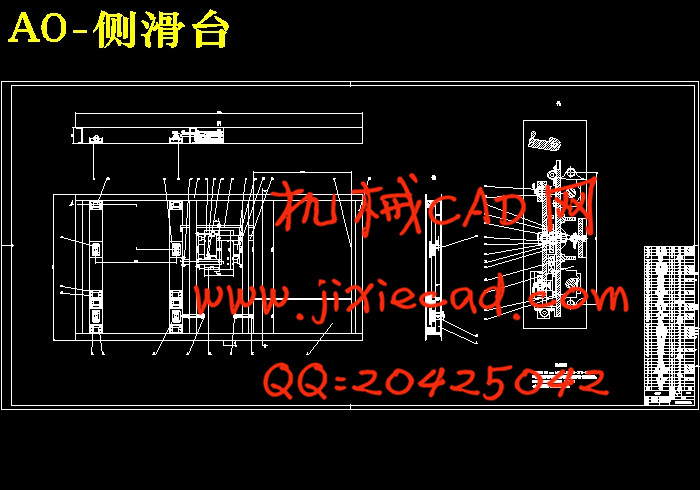

随着我国交通运输业的迅猛发展,建设项目的增多,双前轴转向汽车的使用越来越普遍。而车轮侧滑引起轮胎异常磨损是双前转向汽车普遍存在的问题,因此通过检测车轮侧滑量的大小可以间接评价轮胎磨损。双前轴转向汽车车轮侧滑检测包括轮间和轴间侧滑检测。为了达到准确、快速、自动化检测的目的,本文探讨了一种新的检测方法。这种检测方法可直接检测出轮间和轴间侧滑量,其机械系统建立在原有双板联动式侧滑台的基础上,通过增加等摇臂轴平移机构,加装两支位移传感器。通过对轮间-轴间侧滑检测系统进行了详细的研究和设计,目的是实现对轮间侧滑量和轴间侧滑量的一体化检测。本设计主要是轮间-轴间侧滑台机械组成部分,包括框架、滑板装置、等摇臂杠杆机构、等摇臂轴平移机构、锁定装置等。

关键词:双前轴转向; 车轮定位; 车轮侧滑; 轮间侧滑; 轴间侧滑

ABSTRACT

With rapidly developing of traffic and transport as well as rising of constructing item in our country, the number of double-front-axle steering automobile is also increasing.But the unusual tyre abrasion by wheel sideslip is the most prominent prolem about double-front-axle steering automobile,so by detection of wheel sideslip can estimate the tyre abrasion. Detection of double-front-axle steering automobile’s wheel sideslip includes detection of sideslip between wheels and detection of sideslip between axles. The paper discusses a new detection method which achieves aim of accurate and fast detection.

The detection method which bases on double-board- linkage sideslip tester by adding a equal-rocker-axle shift machine and two lining sensors can detect sideslip between wheels and sideslip between axles directly. By researching and designing detection system of wheel sideslip in detail, aim of which is to realize integrative detection for sideslip between wheels and sideslip between axles. Designation of mechanism involves frame, release device,slip-board device, equal-rocker-leverage machine, equal-rocker-axle shift machine,

comeback device, oriented device, locked device and so on.

Keywords: double-front-axle steering ; wheel location ; wheel sideslip ; sideslip between wheels ; sideslip between axles

目录

1 绪 论 1

1.1 汽车性能检测的意义及发展状况 1

1.2 车轮侧滑检测的重要意义 2

1.3 车轮侧滑性能检测的规定 3

1.4 本设计的重要意义 3

1.5 本设计的内容 4

2 车轮侧滑检测原理与方法 5

2.1 轮间侧滑检测方法 5

2.2 轴间侧滑检测方法 6

2.2.1 双板分动式侧滑检验台检测轴间侧滑量 6

2.2.2 轮间-轴间侧滑检测系统检测轴间侧滑 7

3 轮间-轴间侧滑检测系统机械部份设计 10

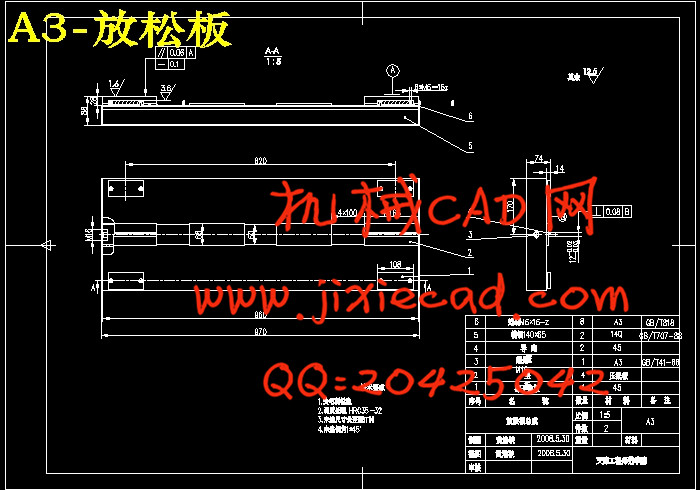

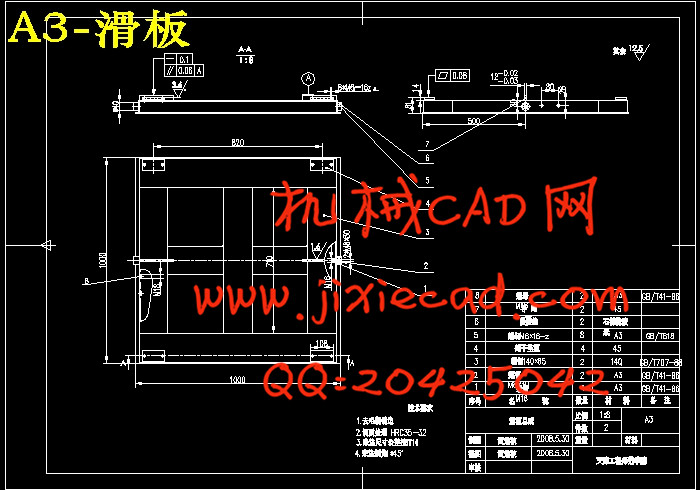

3.1 放松板和滑板 11

3.2 等摇臂杠杆机构 12

3.3 等摇臂轴平移机构 13

3.4 回位装置 13

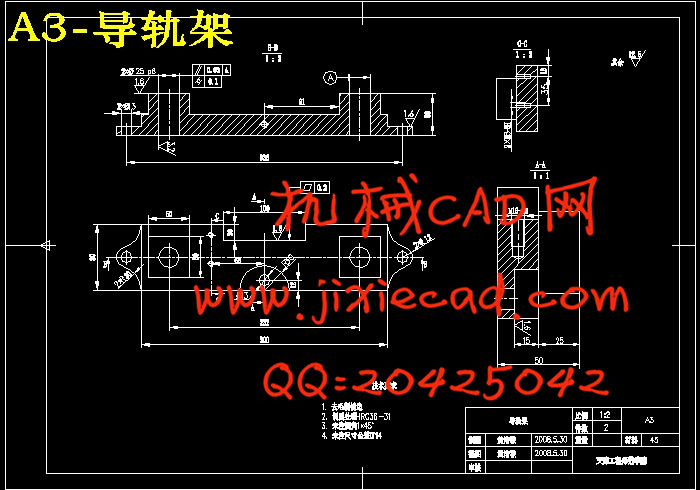

3.5 导向装置 14

3.6 锁定装置 15

3.7 滑动机构 16

3.8 测量装置 16

3.9 轮间-轴间侧滑检测台机械总成和特点 17

4 部分零件的选择与校核 18

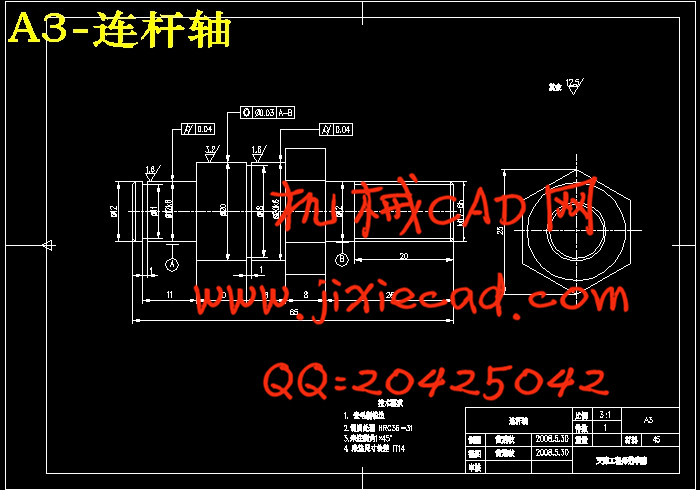

4.1 连杆轴的计算与校核 18

4.2 轴承的选择与计算 19

4.2.1 轴承的选择 19

4.2.2 轴承的寿命计算 20

4.3 槽钢的计算与校核 20

4.4 位移传感器的选型 21

5 应用可行性效果分析 23

6 总 结 24

参考文献 25

致 谢 26

随着我国交通运输业的迅猛发展,建设项目的增多,双前轴转向汽车的使用越来越普遍。而车轮侧滑引起轮胎异常磨损是双前转向汽车普遍存在的问题,因此通过检测车轮侧滑量的大小可以间接评价轮胎磨损。双前轴转向汽车车轮侧滑检测包括轮间和轴间侧滑检测。为了达到准确、快速、自动化检测的目的,本文探讨了一种新的检测方法。这种检测方法可直接检测出轮间和轴间侧滑量,其机械系统建立在原有双板联动式侧滑台的基础上,通过增加等摇臂轴平移机构,加装两支位移传感器。通过对轮间-轴间侧滑检测系统进行了详细的研究和设计,目的是实现对轮间侧滑量和轴间侧滑量的一体化检测。本设计主要是轮间-轴间侧滑台机械组成部分,包括框架、滑板装置、等摇臂杠杆机构、等摇臂轴平移机构、锁定装置等。

关键词:双前轴转向; 车轮定位; 车轮侧滑; 轮间侧滑; 轴间侧滑

ABSTRACT

With rapidly developing of traffic and transport as well as rising of constructing item in our country, the number of double-front-axle steering automobile is also increasing.But the unusual tyre abrasion by wheel sideslip is the most prominent prolem about double-front-axle steering automobile,so by detection of wheel sideslip can estimate the tyre abrasion. Detection of double-front-axle steering automobile’s wheel sideslip includes detection of sideslip between wheels and detection of sideslip between axles. The paper discusses a new detection method which achieves aim of accurate and fast detection.

The detection method which bases on double-board- linkage sideslip tester by adding a equal-rocker-axle shift machine and two lining sensors can detect sideslip between wheels and sideslip between axles directly. By researching and designing detection system of wheel sideslip in detail, aim of which is to realize integrative detection for sideslip between wheels and sideslip between axles. Designation of mechanism involves frame, release device,slip-board device, equal-rocker-leverage machine, equal-rocker-axle shift machine,

comeback device, oriented device, locked device and so on.

Keywords: double-front-axle steering ; wheel location ; wheel sideslip ; sideslip between wheels ; sideslip between axles

目录

1 绪 论 1

1.1 汽车性能检测的意义及发展状况 1

1.2 车轮侧滑检测的重要意义 2

1.3 车轮侧滑性能检测的规定 3

1.4 本设计的重要意义 3

1.5 本设计的内容 4

2 车轮侧滑检测原理与方法 5

2.1 轮间侧滑检测方法 5

2.2 轴间侧滑检测方法 6

2.2.1 双板分动式侧滑检验台检测轴间侧滑量 6

2.2.2 轮间-轴间侧滑检测系统检测轴间侧滑 7

3 轮间-轴间侧滑检测系统机械部份设计 10

3.1 放松板和滑板 11

3.2 等摇臂杠杆机构 12

3.3 等摇臂轴平移机构 13

3.4 回位装置 13

3.5 导向装置 14

3.6 锁定装置 15

3.7 滑动机构 16

3.8 测量装置 16

3.9 轮间-轴间侧滑检测台机械总成和特点 17

4 部分零件的选择与校核 18

4.1 连杆轴的计算与校核 18

4.2 轴承的选择与计算 19

4.2.1 轴承的选择 19

4.2.2 轴承的寿命计算 20

4.3 槽钢的计算与校核 20

4.4 位移传感器的选型 21

5 应用可行性效果分析 23

6 总 结 24

参考文献 25

致 谢 26