设计简介

摘 要

选煤厂的筛分机数量很多,所以对筛分机的要求也越来越高。不但要求它具有较高的生产率、较好的筛分效率或脱水效果、较低的动力消耗;而且还要具备结构简单、制造容易、安装维修方便等机械性能。由于滚轴筛、圆筒筛上述性能较差,在使用上受到了限制,逐渐被工艺效果好、构造简单、维修方便的振动筛所代替。

自同步振动筛是一种广泛用于散体物料分级的设备。在选煤等工业领域,用于分级、脱水、脱泥和脱介。其筛分性能尤其重要。

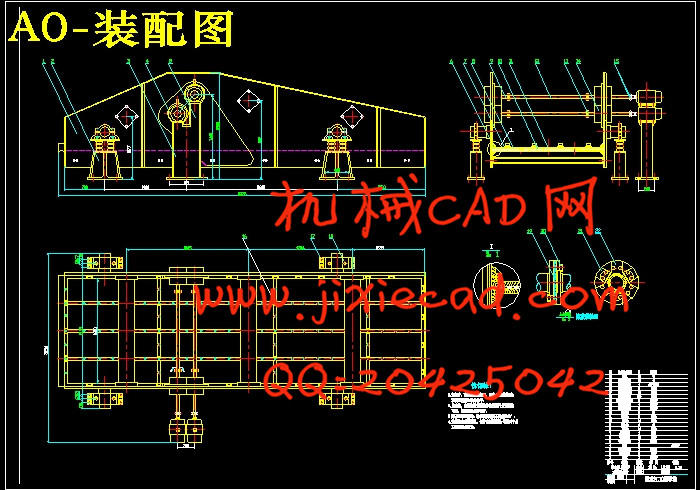

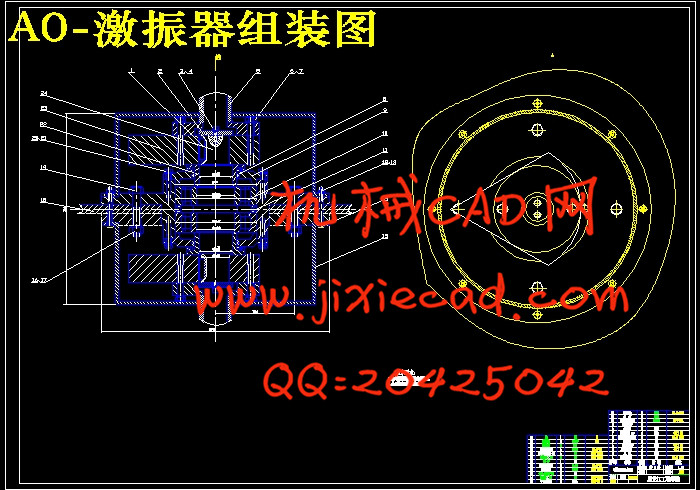

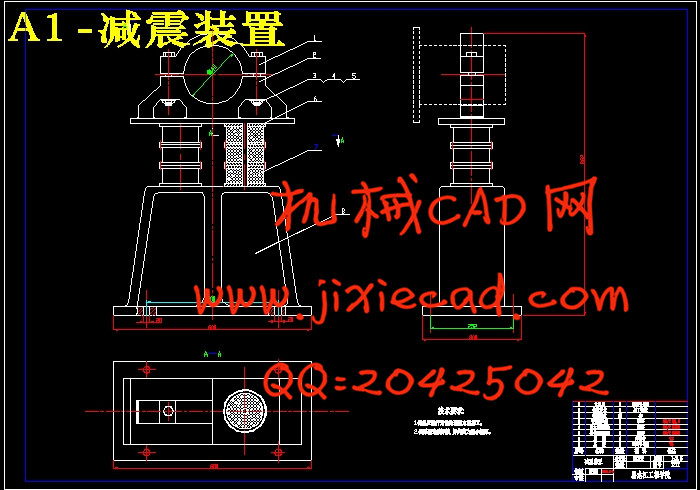

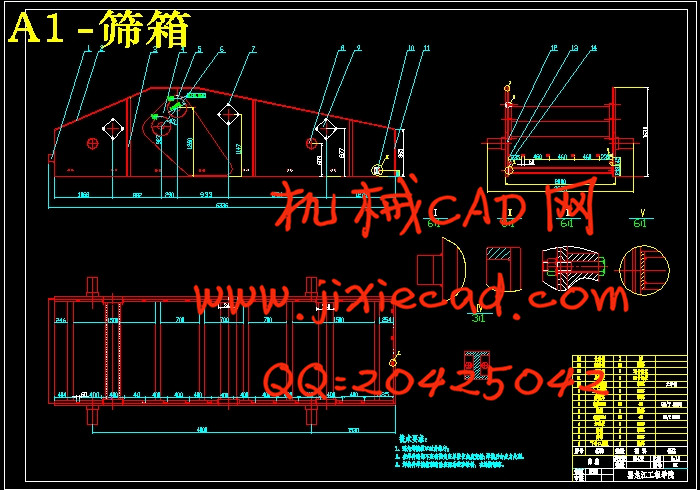

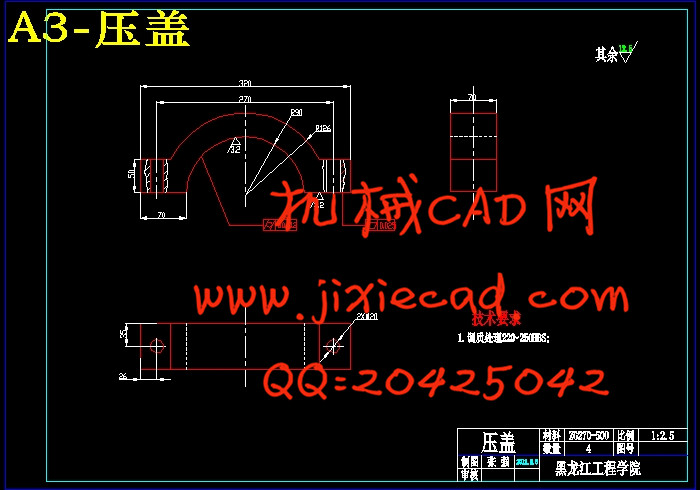

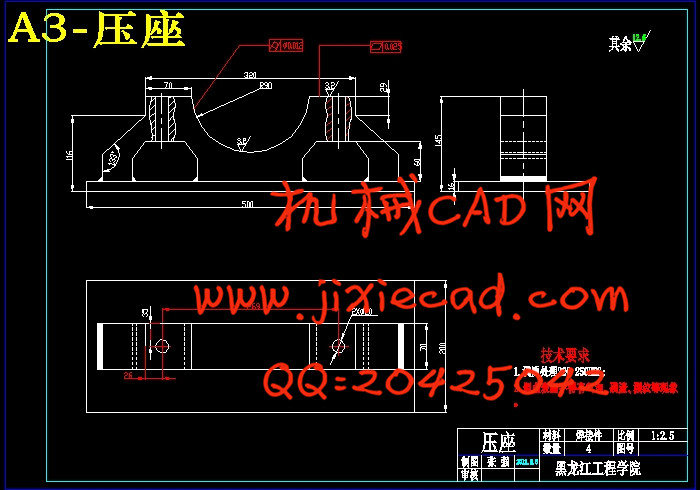

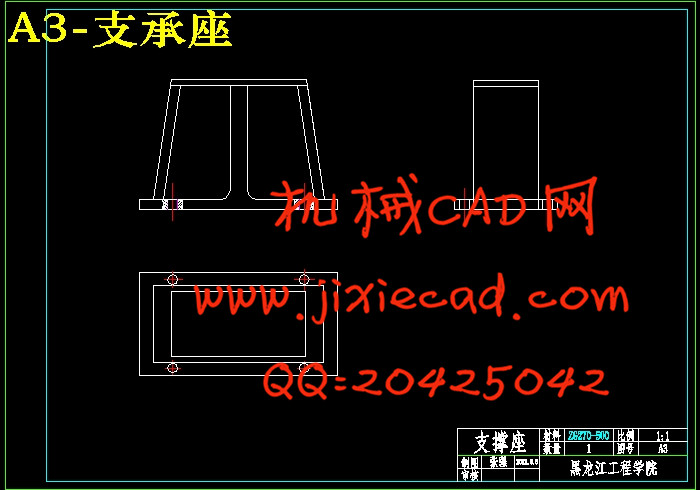

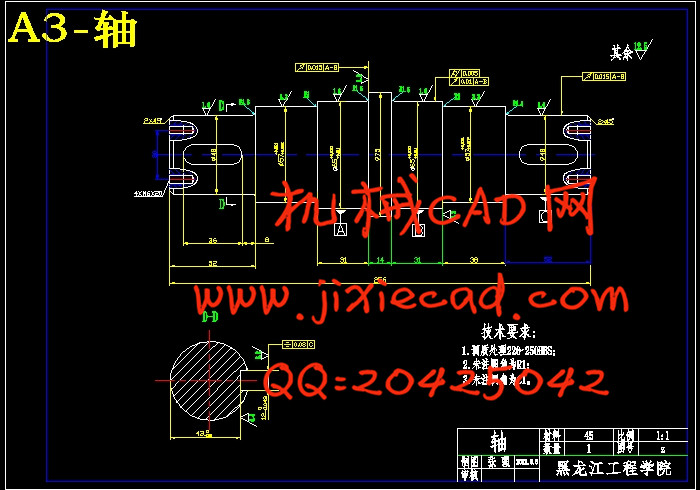

本文系统地阐述了双电机自同步振动筛的应用现状和发展趋势,论述了设计高效双电机自同步振动筛的必要性;同时对双电机自同步振动筛的原理进行了分析,计算了振动筛的动力学参数、运动学参数,设计计算了激振器的轴、偏振块的参数和结构,减震装置,筛框的设计,并进行联轴器的选型等。

关键词:双电机;自同步振动筛;激振器

Abstract

The number of Washery screening machine is very large . So the demands on the screening machine also getting higher and higher. It is not only demand its higher productivity, better screening efficiency or effectiveness dehydration and low power consumption, but also with mechanical properties of simple structure, easy to manufacture, convenient to installation and maintenance and so on .As such properties of the roller sieve and sieve cylinder is very poor, it has became the restrictions of the fields of use. And it has been gradually replaced by the shaker because of its good process effect, simple structure and easy to maintenance .

Synchronization shaker is a widely used equipment in the classification of bulk materials. In the fileds of industrial such as coal chosen ,it has been used for grading, dewatering, desliming and sculping. Its properties of screening is particularly important.

In this paper, systematically expounded the application status and the trends of the design of the the two-synchronous motor,discussing the necessity of the two-synchronous motor. While analysising the principles of the two-synchronous motor, Calculating the kinetic parameters of the shaker,the parameters of kinematics, designing and calculating the structure and parameters of the shaft and the polarization block of the exciter, finishing the design of shock absorber and screen frame and also finishing selection of the coupling .

Key words:double motor;self-synchronous motor;shaker vibrator

选煤厂的筛分机数量很多,所以对筛分机的要求也越来越高。不但要求它具有较高的生产率、较好的筛分效率或脱水效果、较低的动力消耗;而且还要具备结构简单、制造容易、安装维修方便等机械性能。由于滚轴筛、圆筒筛上述性能较差,在使用上受到了限制,逐渐被工艺效果好、构造简单、维修方便的振动筛所代替。

自同步振动筛是一种广泛用于散体物料分级的设备。在选煤等工业领域,用于分级、脱水、脱泥和脱介。其筛分性能尤其重要。

本文系统地阐述了双电机自同步振动筛的应用现状和发展趋势,论述了设计高效双电机自同步振动筛的必要性;同时对双电机自同步振动筛的原理进行了分析,计算了振动筛的动力学参数、运动学参数,设计计算了激振器的轴、偏振块的参数和结构,减震装置,筛框的设计,并进行联轴器的选型等。

关键词:双电机;自同步振动筛;激振器

Abstract

The number of Washery screening machine is very large . So the demands on the screening machine also getting higher and higher. It is not only demand its higher productivity, better screening efficiency or effectiveness dehydration and low power consumption, but also with mechanical properties of simple structure, easy to manufacture, convenient to installation and maintenance and so on .As such properties of the roller sieve and sieve cylinder is very poor, it has became the restrictions of the fields of use. And it has been gradually replaced by the shaker because of its good process effect, simple structure and easy to maintenance .

Synchronization shaker is a widely used equipment in the classification of bulk materials. In the fileds of industrial such as coal chosen ,it has been used for grading, dewatering, desliming and sculping. Its properties of screening is particularly important.

In this paper, systematically expounded the application status and the trends of the design of the the two-synchronous motor,discussing the necessity of the two-synchronous motor. While analysising the principles of the two-synchronous motor, Calculating the kinetic parameters of the shaker,the parameters of kinematics, designing and calculating the structure and parameters of the shaft and the polarization block of the exciter, finishing the design of shock absorber and screen frame and also finishing selection of the coupling .

Key words:double motor;self-synchronous motor;shaker vibrator

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1课题研究的目的及意义 1

1.1.1课题研究的目的 1

1.1.2课题的意义 1

1.2国内外振动筛分机械的发展 3

1.3本次设计的内容 4

第2章 整体结构设计 6

2.1传动方式的选择 6

2.2设计方案介绍与选择 7

2.3减振装置的确定 8

2.4激振器结构设计 9

2.4.1激振器结构类型的选择 9

2.4.2工作原理分析 9

2.5本章小结 11

第3章 双电机自同步振动筛参数确定 12

3.1自同步筛的工艺参数的确定 12

3.2振动筛动力参数计算 13

3.2.1惯性振动筛参振质量的计算 13

3.2.2计算隔振弹簧刚度 14

3.2.3所需激振力力幅及质量矩的计算 14

3.2.4振动筛传给地基的负荷 15

3.3电动机功率的计算与电机选择 15

3.4本章小结 17

第4章 激振器的设计计算 18

4.1偏心块的设计 18

4.2激振器传动轴的设计与计算 22

4.3 键的强度校核 25

4.4轴承的校核 25

4.5 轴承的润滑 26

4.6 本章小结 26

第5章 筛箱的设计分析与计算 27

5.1 筛面选择 27

5.2 筛面固定方法的确定 29

5.3筛框的设计 31

5.4本章小结 31

结论 32

参考文献 33

致谢 34