设计简介

中文摘要

内容:改革开放以来,随着人民生活水平的提高,人们对生活中的生活用品的质量要求也提出了更高的要求。童车是现在人们生活中必不可少的用品之一,儿童推车在带来方便的同时,也会给婴幼儿带来伤害,为此世界各国和地区均制订了严格的安全性能标准,以最大限度地为婴幼儿提供安全的儿童推车产品。其质量的合格与否直接影响到儿童的安全。所以本课题主要针对现实生活中人们对童车的安全性的考虑设计了用于试验童车滚轮疲劳强度的试验机。本课题主要根据检测标准,设计一个童车滚轮强度疲劳试验机,该试验机以童车滚轮为试验对象,夹持童车手把,模拟道路环境滚动,直到童车滚轮破坏或达到规定试验时间为止。设计要求设计的试验机能按照试验标准要求进行连续运行,运动动力源采用电动机,其运动的时间可以设定。

关键词:改革开放,生活水平,疲劳,试验机,安全。

Abstract

In view of the positioning of this product, the first is for the purpose of fitness, then one must reflect the car's interesting. At design time, to fully play entertainment purposes. Car or bicycle-like general fitness, often large amount of movement, while the entire exercise boring. This makes it difficult to attract interest, and then a positioning in the market, mainly for urban white-collar. Because of the white-collar work pressure, and they generally do not have a lot of time to participate in some exercise activities. The ordinary fitness is difficult to arouse their interest, such a set of fun and exercise in one of the fitness equipment will have a good response in the market.

The beginning of the article summarizes some of the existing features of the car, and describes the development of the car at home and abroad fitness, this fitness car market outlook, come to the car at home or have a very broad market; later in the article, according to the principles of the movement of the mechanical principle on some bodies of the analysis, combined to achieve the function of the fitness car come to a main part of a car steering system and forward system using structure, steering gear drive, forward is the rack and pinion drive, can exercise the three main parts of the body; analysis of the force of the car as a whole, and the key components of the car checking of strength and life.

目录

第一章 概述 3

1.1童车概述 3

1.2童车的组成 4

1.3 国内外的发展现状 5

1.4童车行业发展潜力巨大 7

1.4童车的发展趋势 9

1.5本课题的意义 9

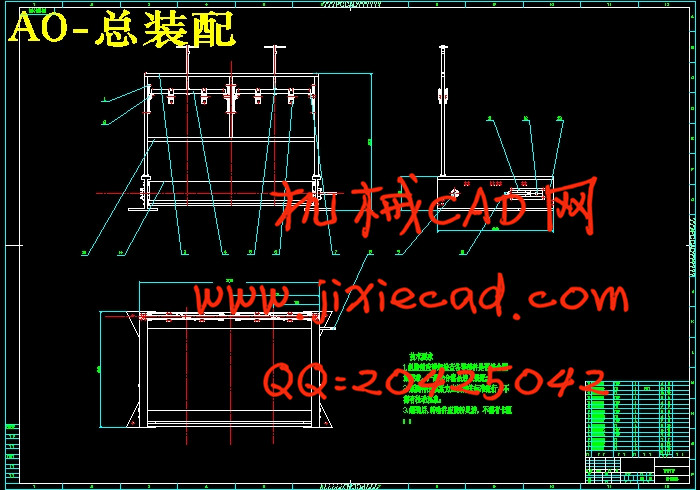

第二章 总体设计方案比较 11

2.1 总体设计方案一 11

2.2 总体设计方案二 12

2.3 总体设计方案三 13

2.4设计方案比较 14

第三章 零件结构设计 16

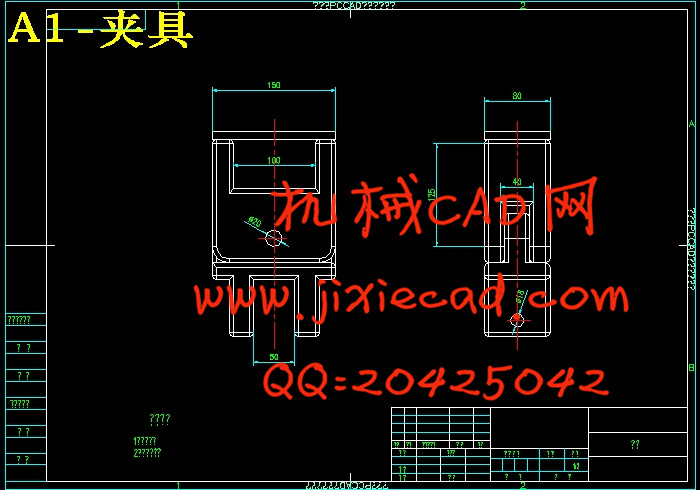

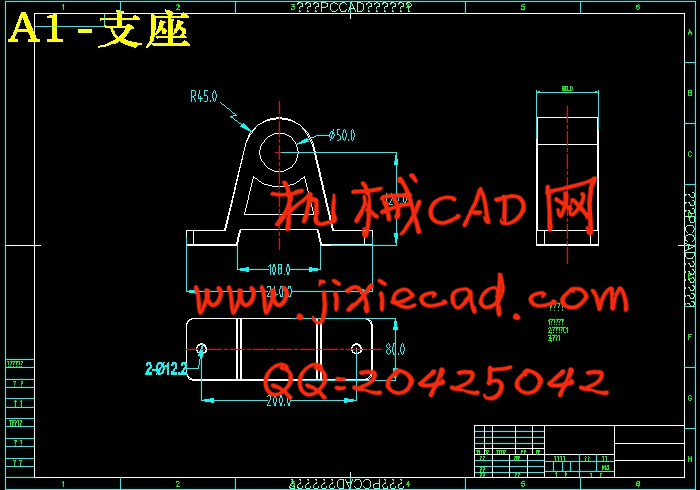

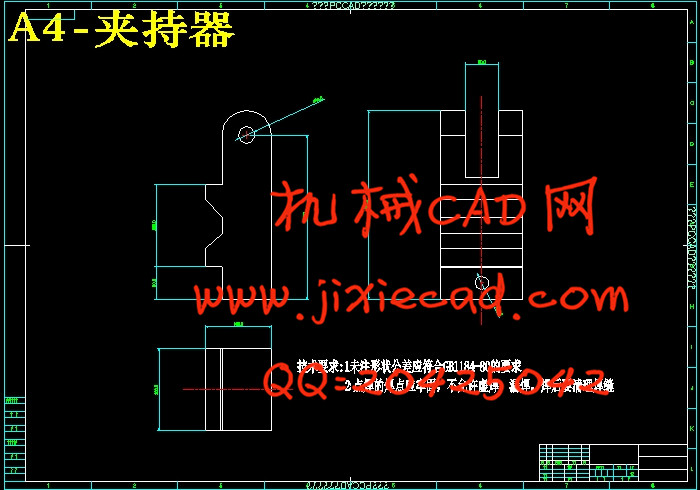

3.1夹持机构设计 16

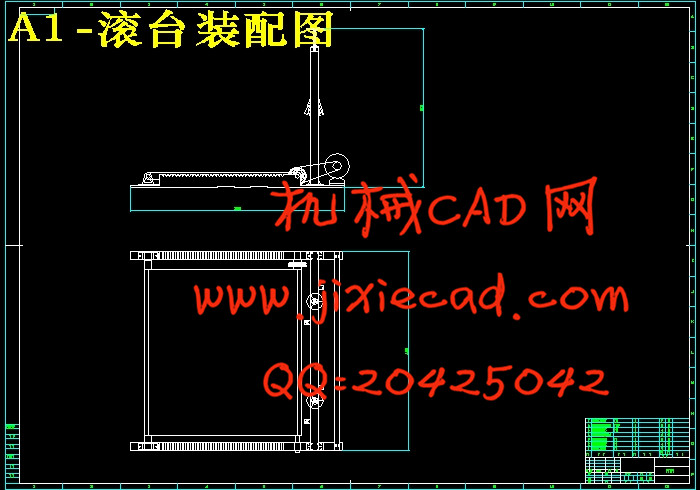

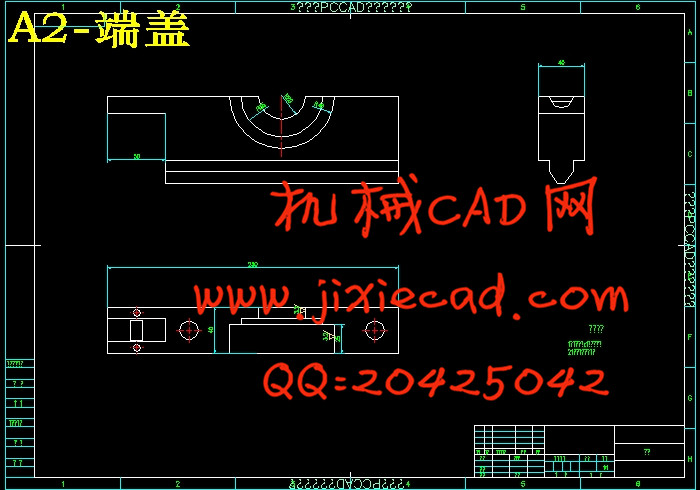

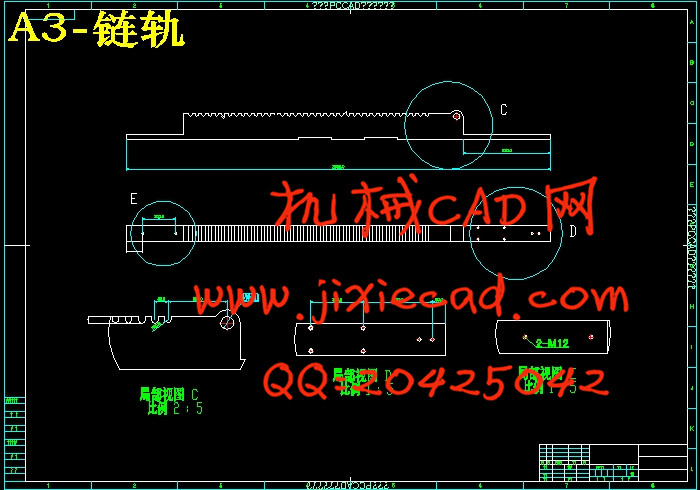

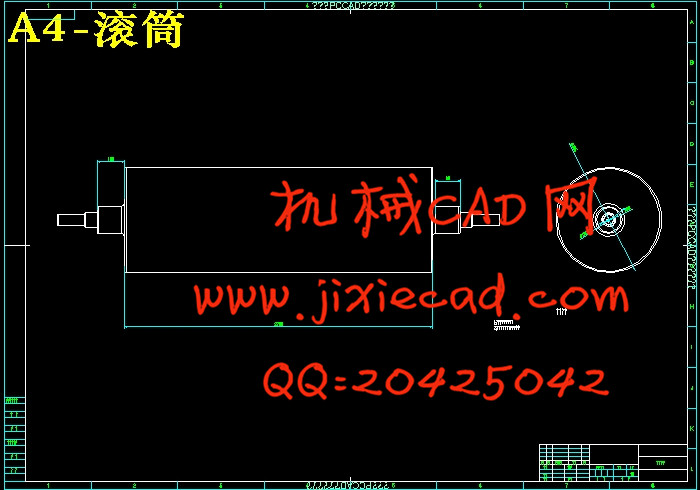

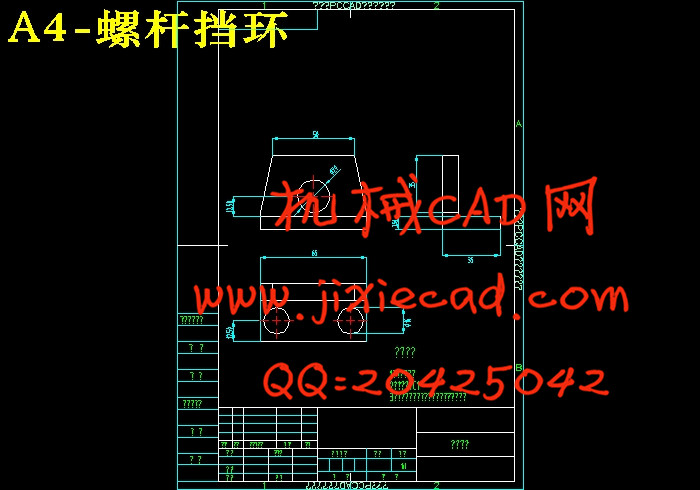

3.2张紧机构的结构设计 19

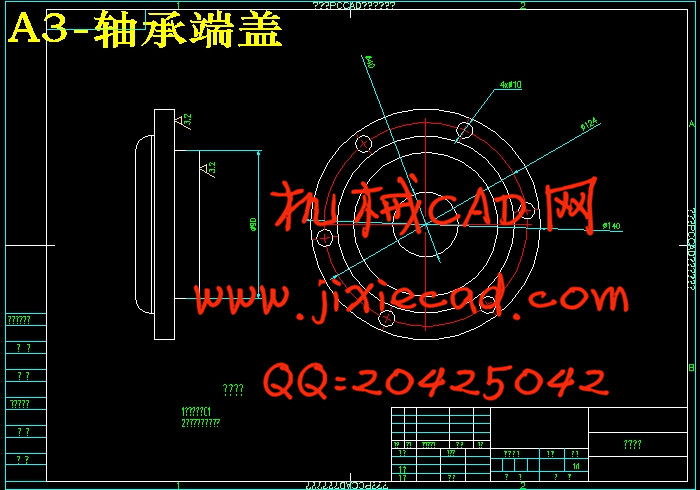

3.3 滚动轴承的选择 20

3.4 电机的选择 21

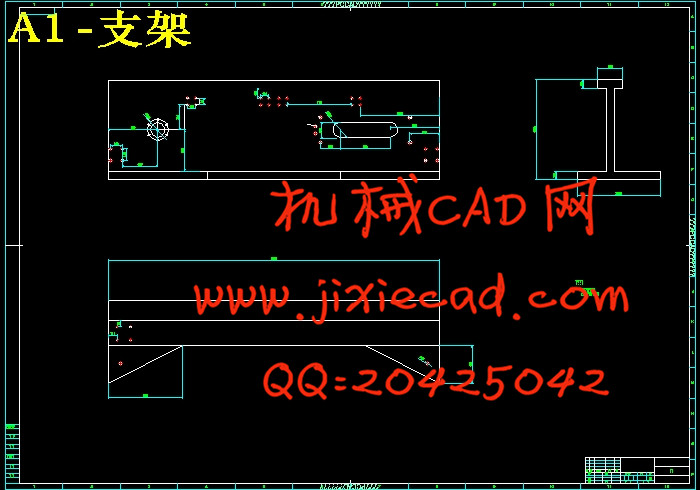

第四章 强度校核计算 22

4.1 疲劳机前轴的校核 22

4.2 轴承的寿命校核 23

4.3 轴上上键的强度的校核 24

结论 25

致谢 27

参考文献 28

内容:改革开放以来,随着人民生活水平的提高,人们对生活中的生活用品的质量要求也提出了更高的要求。童车是现在人们生活中必不可少的用品之一,儿童推车在带来方便的同时,也会给婴幼儿带来伤害,为此世界各国和地区均制订了严格的安全性能标准,以最大限度地为婴幼儿提供安全的儿童推车产品。其质量的合格与否直接影响到儿童的安全。所以本课题主要针对现实生活中人们对童车的安全性的考虑设计了用于试验童车滚轮疲劳强度的试验机。本课题主要根据检测标准,设计一个童车滚轮强度疲劳试验机,该试验机以童车滚轮为试验对象,夹持童车手把,模拟道路环境滚动,直到童车滚轮破坏或达到规定试验时间为止。设计要求设计的试验机能按照试验标准要求进行连续运行,运动动力源采用电动机,其运动的时间可以设定。

关键词:改革开放,生活水平,疲劳,试验机,安全。

Abstract

In view of the positioning of this product, the first is for the purpose of fitness, then one must reflect the car's interesting. At design time, to fully play entertainment purposes. Car or bicycle-like general fitness, often large amount of movement, while the entire exercise boring. This makes it difficult to attract interest, and then a positioning in the market, mainly for urban white-collar. Because of the white-collar work pressure, and they generally do not have a lot of time to participate in some exercise activities. The ordinary fitness is difficult to arouse their interest, such a set of fun and exercise in one of the fitness equipment will have a good response in the market.

The beginning of the article summarizes some of the existing features of the car, and describes the development of the car at home and abroad fitness, this fitness car market outlook, come to the car at home or have a very broad market; later in the article, according to the principles of the movement of the mechanical principle on some bodies of the analysis, combined to achieve the function of the fitness car come to a main part of a car steering system and forward system using structure, steering gear drive, forward is the rack and pinion drive, can exercise the three main parts of the body; analysis of the force of the car as a whole, and the key components of the car checking of strength and life.

目录

第一章 概述 3

1.1童车概述 3

1.2童车的组成 4

1.3 国内外的发展现状 5

1.4童车行业发展潜力巨大 7

1.4童车的发展趋势 9

1.5本课题的意义 9

第二章 总体设计方案比较 11

2.1 总体设计方案一 11

2.2 总体设计方案二 12

2.3 总体设计方案三 13

2.4设计方案比较 14

第三章 零件结构设计 16

3.1夹持机构设计 16

3.2张紧机构的结构设计 19

3.3 滚动轴承的选择 20

3.4 电机的选择 21

第四章 强度校核计算 22

4.1 疲劳机前轴的校核 22

4.2 轴承的寿命校核 23

4.3 轴上上键的强度的校核 24

结论 25

致谢 27

参考文献 28