设计简介

摘要

本文是关于双头车床液压系统设计过程的阐述。主要包括系统方案的确定、液压集成块与控制系统的设计和总体布局的设计几个方面的内容。双头车床加工时,由于零件较长,拟采用零件固定,刀具旋转和进给的加工方式,其加工动作循环方式是:快进→工进→快退→停止,同时要求各个车削头能单独调整。显而易见,采用双头车床能使原需多道工序的产品能一次切削完成,使工序简化,生产效益大大提高。且这种设计所产生的产品对成均匀,精度高。对于双头车床的动力执行部分,本设计采用液压伺服机构。液压伺服机构较其他机构有传动平稳、噪音小、驱动力大等优点,同时也存在漏油、爬行、体积大等缺点。

为了尽量避免液压系统的上述缺点,系统设计时用集成块来代替管路,在液压系统采用液压阀集成配置,可以显著减少管路联接和接头,降低系统的复杂性,增强现场添加和更改回路的柔性,具有结构紧凑、安装维护方便、泄漏少、振动小、利于实现典型液压系统的集成化和标准化等优点。

关键词:双头车床 液压系统 液压伺服机构Abstract

This text is a concerning of hydraulic system of the double-head lathe. In this text ,it primarily includes the determination of hydraulic system program, the design of the hydraulic manifold block and control system, and the design of the total layout of the contents.本文是关于双头车床液压系统设计过程的阐述。主要包括系统方案的确定、液压集成块与控制系统的设计和总体布局的设计几个方面的内容。双头车床加工时,由于零件较长,拟采用零件固定,刀具旋转和进给的加工方式,其加工动作循环方式是:快进→工进→快退→停止,同时要求各个车削头能单独调整。显而易见,采用双头车床能使原需多道工序的产品能一次切削完成,使工序简化,生产效益大大提高。且这种设计所产生的产品对成均匀,精度高。对于双头车床的动力执行部分,本设计采用液压伺服机构。液压伺服机构较其他机构有传动平稳、噪音小、驱动力大等优点,同时也存在漏油、爬行、体积大等缺点。

为了尽量避免液压系统的上述缺点,系统设计时用集成块来代替管路,在液压系统采用液压阀集成配置,可以显著减少管路联接和接头,降低系统的复杂性,增强现场添加和更改回路的柔性,具有结构紧凑、安装维护方便、泄漏少、振动小、利于实现典型液压系统的集成化和标准化等优点。

关键词:双头车床 液压系统 液压伺服机构Abstract

When we use the double-head lathe to work the components, because they are relatively long, we plan adopt the way of components fixing, cutting tool revolving and aheading. The circulate pattern of working movement is speeding→aheading→withdrawing→halting. Meanwhile, each turning head is required to adjust solely. Tell its own tale, it can made the produce needed several working procedure formerly cut completely only once , predigest the working procedure and improve the manufacture benefit enormously. And the produce manufactured by the design may be symmetry ,uniformity and high precision. For the drive perform part of the double-head lathe ,the design adopts hydraulic pressure servo mechanism. When compared to other institutions,it has many advances such as driving calmly, small noise, drive power greatcontemporary, it exists several shortcomings such as leaking oil,creeping big vulume.

In order to avoid the above shortcomings as far as possible,during the design of hydraulic system .I use the hydraulic manifold block to replace the oil tube.So that it can use less oil tube and tube joint, decrease complexity of the system, increase the flexibility of appending and altering the system on the spot, tight the system,install and uphold handily, littler seeping oil, lower vibration, and help for accomplish the integration and standardization of the characteristic hydraulic system.

Keywords: Double-head lathe;Hydraulic system;Hydraulic servo

目 录

引 言 1

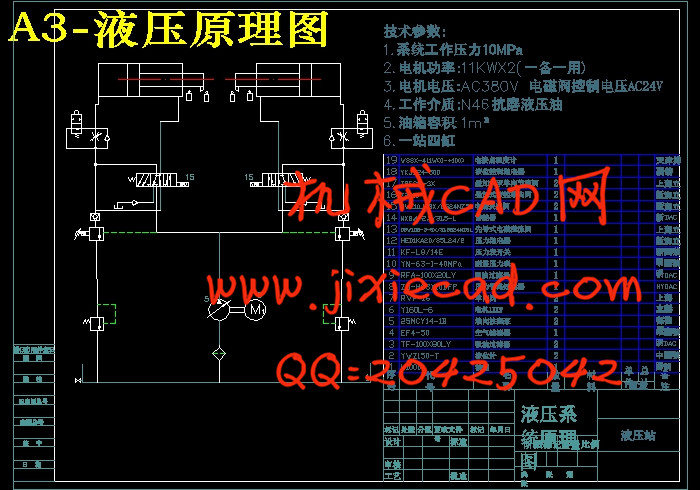

第一章 制定基本方案及绘制液压系统原理图 5

1.1确定对液压系统的工作要求 5

1.1.1 执行机构 5

1.1.2 方向回路 5

1.1.3 调速回路 6

1.2拟定液压系统工作原理图 7

第二章 计算和选择液压元件 11

2.1原始数据 11

2.2工作负载及惯性负载计算 11

2.2.1密封阻力的计算 12

2.2.2导轨摩擦阻力的计算 ..12

2.2.3回油背压造成的阻力计算 13

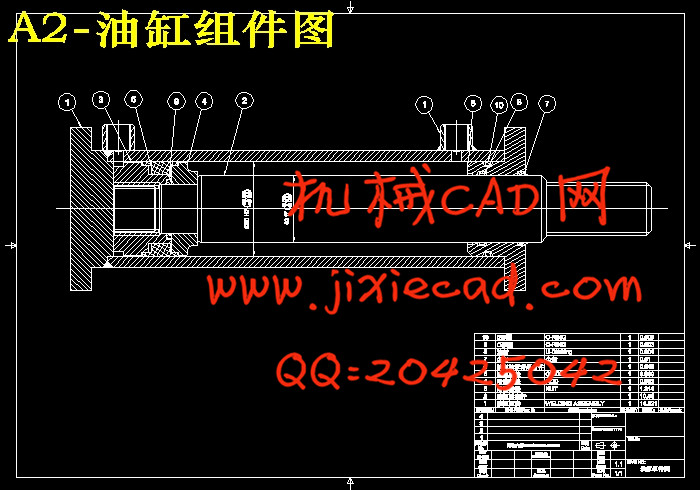

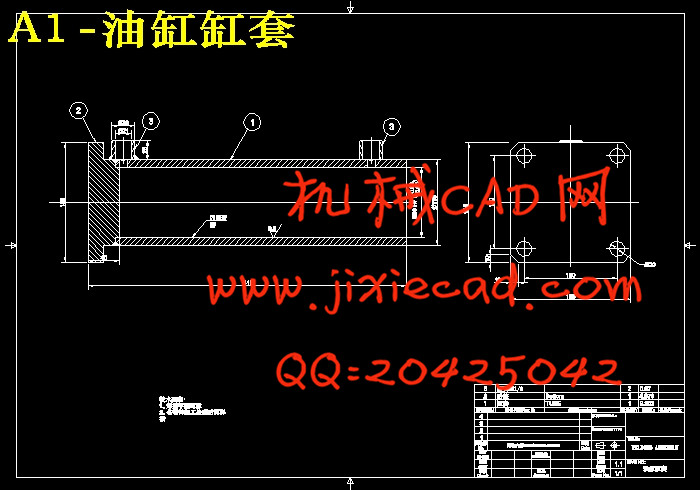

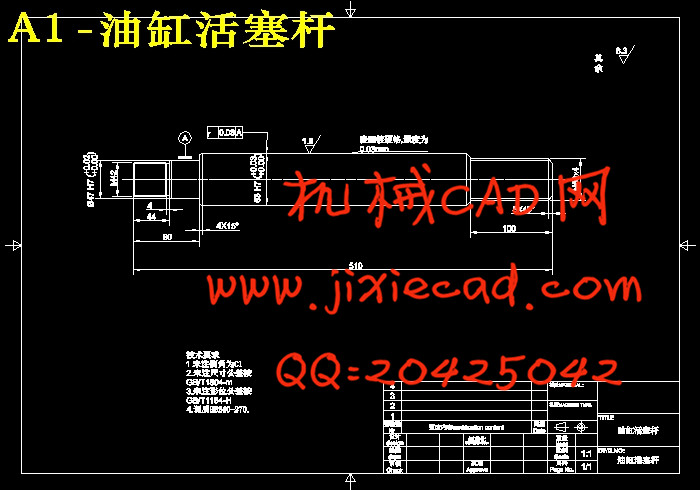

2.2.4确定液压缸的结构尺寸和工作压力 14

2.3油泵的计算 18

2.3.1确定油泵的实际工作压力,选择油泵 18

2.3.2确定液压泵电机的功率 19

第三章 液压元件计算与选择 20

3.1选择控制元件 20

3.2油管的计算和选择 22

3.3管接头的选择 24

3.4油箱的设计 24

3.5液压油的选择 27

第四章 液压系统性能的验算 27

4.1计算液压缸各运动阶段的进、排油量 28

4.1.2验算进给油路在快进、工进和快退时的压力损失 28

4.1.3计算液压泵各运动阶段的输出压力 32

4.1.4计算回路效率 34

4.1.5验算系统温升 34

结 论 35

致 谢 36

参考文献: 37