设计简介

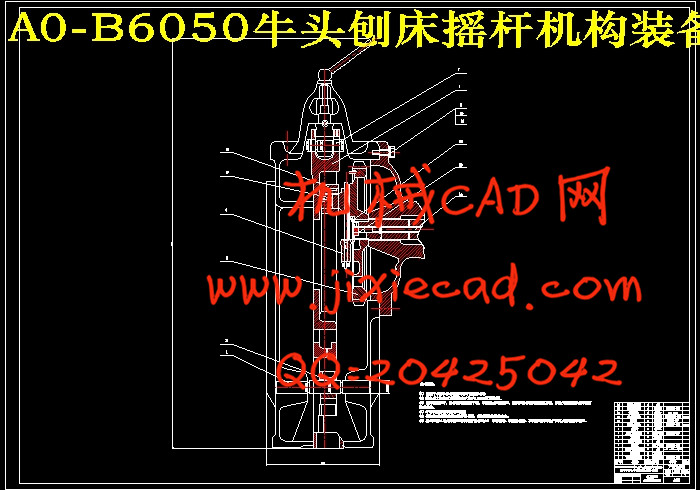

双向刨削牛头刨床的机构改造设计

摘 要

针对传统牛头刨床的空行程和工作效率低这两个缺陷,采用机械传动方式,对牛头刨床进行机构改造设计。使改进后的牛头刨床既能恒力切削,又能是滑枕做匀速直线运动,既能消除空行程,又能变单向切削为双向切削。不仅提高了工作效率,也降低了能耗,而且机构简单,容易进行改造。

关键词:牛头刨床 单行程 空行程 双向刨削。

Abstract:

A simplified calculation scheme for the equivalent stress of vortex dedendum under the effect of uniform internal ores sure was brought forward. Simulation has been carried out on the being established 72 finite element models of vortex body with the exertion of fixed end..surface constraint and different interior pres.. sures.The simplified formula was obtained through planning from the analysis of simulated result.The research indicated that the distribution rules of equivalent stress of vortex dedendum with different parameters were basically identical and presented an exponential distribution along with the involute angles and revealed a linear relationship with the vortex addendum an d interior pressures.There is evident diference in stress distribution between the portion of end segment of vortex tooth.which corresponds to approximately 1r/2 of the portion of involute angle,and the rest portion.The portion that coresponds with the theoretical initial involute angle o/of the vortex tooth at the end segment had rapid changes in Stress.Under the circumstances of no consideration on the stress concentration at root of vortex tooth,the equivalent stress at the root of vortex toth can be carried out by simplified calculation of segm entation.Large numbers of living examples testified that except the o/portion of end segm ent,there was less eror between the result of simplified calculation and that of the finite element simulation,and the maximum eror was not more then 5% .Key words:vortex machinery;vortex dedendum;equivalent

stress;simplified calculation

目录

1、选题审批表

2、任务书

3、评审表

4.答辩记录

文摘……………………………………………………………………………… 1

英文文摘……………………………………………………………………… 1

第一章 绪论………………………………………………………………… 2

第二章 设计方案的拟定

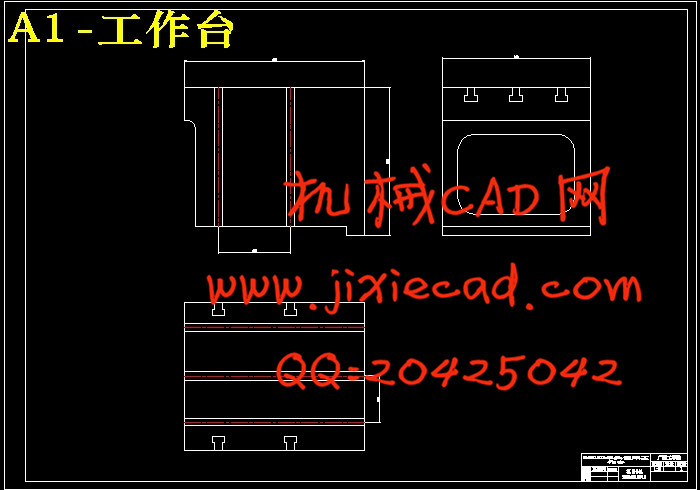

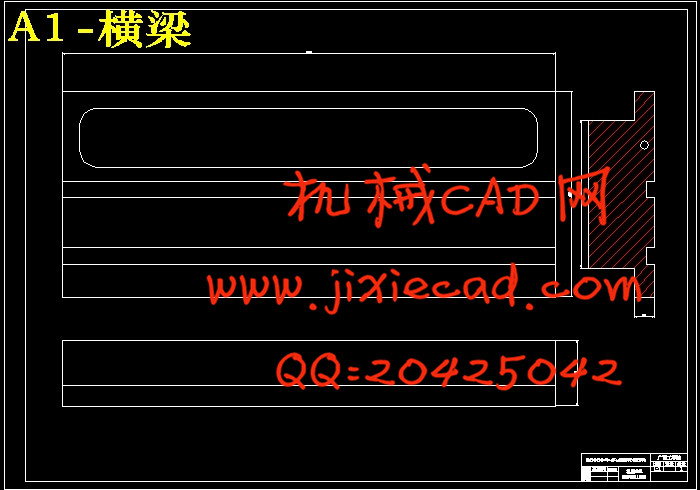

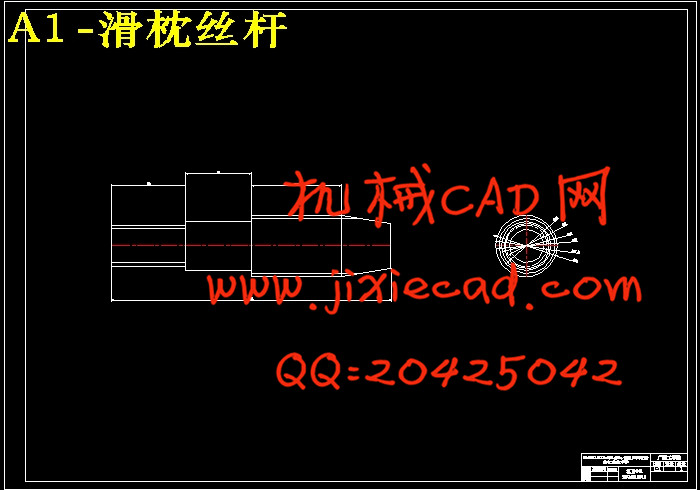

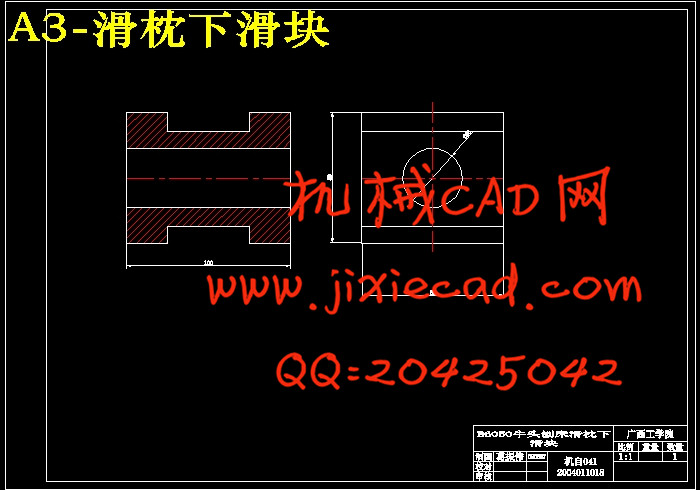

2.1 刨床整体和各部件的拟订和分析…………………… 3

2.1.1工作原理与机构组成………………………………… 4

2.1.2 牛头刨床及其组成部分的名称和作用……… 13

2.1.3牛头刨床的典型机构及其调整…………………… 14

2. 2 牛头刨床尺寸参数的确定…………………………… 15

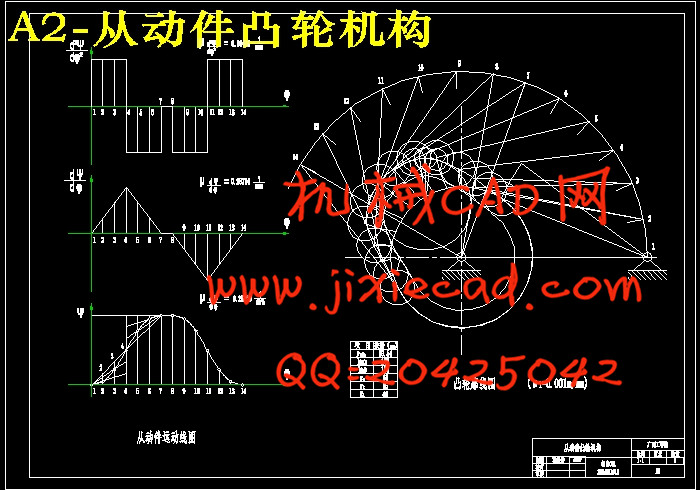

2.3 运动设计 …………………………………………………29

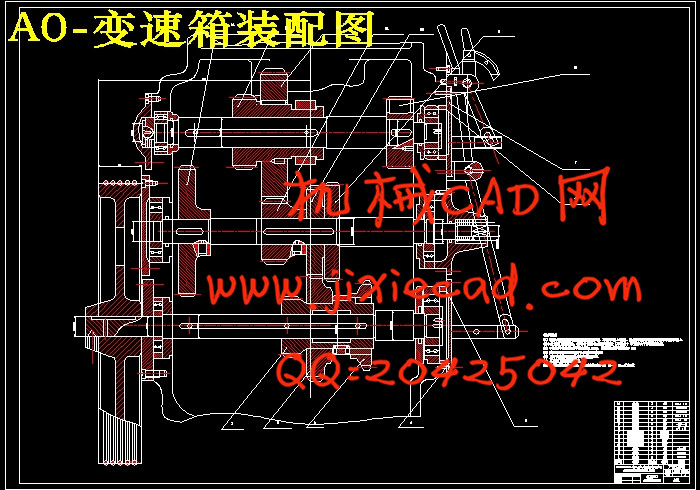

2 . 4 B6050牛头刨床的传动系统…………………………31

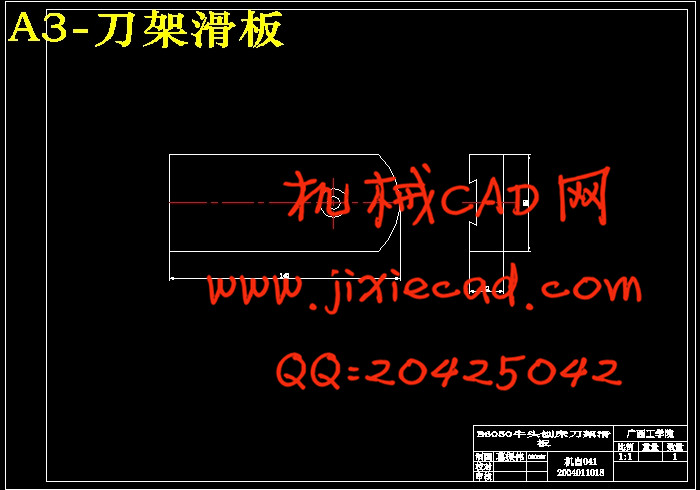

第三章 系统和刀架的分析设计 ………………………………… 42

第四章 经济性分析 ………………………………………………… 44

第五章 结论和展望 ……………………………………………………46

参考文献

致谢

摘 要

针对传统牛头刨床的空行程和工作效率低这两个缺陷,采用机械传动方式,对牛头刨床进行机构改造设计。使改进后的牛头刨床既能恒力切削,又能是滑枕做匀速直线运动,既能消除空行程,又能变单向切削为双向切削。不仅提高了工作效率,也降低了能耗,而且机构简单,容易进行改造。

关键词:牛头刨床 单行程 空行程 双向刨削。

Abstract:

A simplified calculation scheme for the equivalent stress of vortex dedendum under the effect of uniform internal ores sure was brought forward. Simulation has been carried out on the being established 72 finite element models of vortex body with the exertion of fixed end..surface constraint and different interior pres.. sures.The simplified formula was obtained through planning from the analysis of simulated result.The research indicated that the distribution rules of equivalent stress of vortex dedendum with different parameters were basically identical and presented an exponential distribution along with the involute angles and revealed a linear relationship with the vortex addendum an d interior pressures.There is evident diference in stress distribution between the portion of end segment of vortex tooth.which corresponds to approximately 1r/2 of the portion of involute angle,and the rest portion.The portion that coresponds with the theoretical initial involute angle o/of the vortex tooth at the end segment had rapid changes in Stress.Under the circumstances of no consideration on the stress concentration at root of vortex tooth,the equivalent stress at the root of vortex toth can be carried out by simplified calculation of segm entation.Large numbers of living examples testified that except the o/portion of end segm ent,there was less eror between the result of simplified calculation and that of the finite element simulation,and the maximum eror was not more then 5% .Key words:vortex machinery;vortex dedendum;equivalent

stress;simplified calculation

目录

1、选题审批表

2、任务书

3、评审表

4.答辩记录

文摘……………………………………………………………………………… 1

英文文摘……………………………………………………………………… 1

第一章 绪论………………………………………………………………… 2

第二章 设计方案的拟定

2.1 刨床整体和各部件的拟订和分析…………………… 3

2.1.1工作原理与机构组成………………………………… 4

2.1.2 牛头刨床及其组成部分的名称和作用……… 13

2.1.3牛头刨床的典型机构及其调整…………………… 14

2. 2 牛头刨床尺寸参数的确定…………………………… 15

2.3 运动设计 …………………………………………………29

2 . 4 B6050牛头刨床的传动系统…………………………31

第三章 系统和刀架的分析设计 ………………………………… 42

第四章 经济性分析 ………………………………………………… 44

第五章 结论和展望 ……………………………………………………46

参考文献

致谢