设计简介

双圆盘开沟机的设计和研究

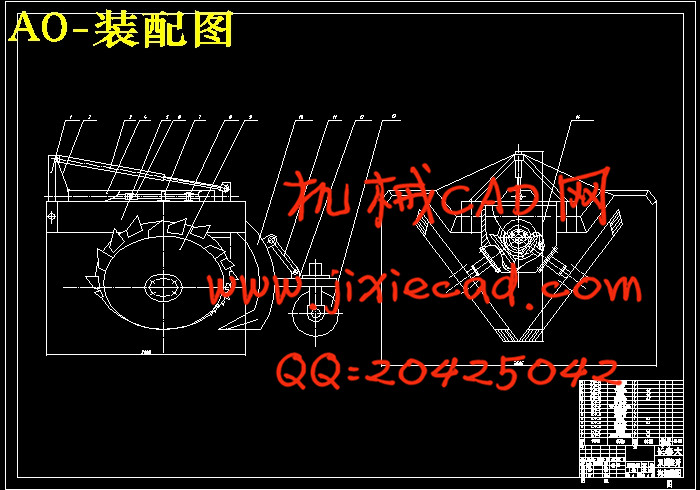

[摘要] 通过对现有开沟机的比较研究,确定了双圆盘开沟机的总体结构,并对该机的主要参数、工作原理、工作部件做了分析。该机结构紧凑,整体布局合理,设计可达到预定效果,具有良好的推广前景。

双圆盘开沟机不同于链式开沟机,它采用了铣削原理,通过圆盘部件对土壤进行铣削,具有效率高,开沟沟型完整,土壤抛洒均匀等优点,大大提高了生产率并降低了劳动强度。双圆盘开沟机适用于开挖沟渠鱼塘以及铺设电缆的工作,是农业工程机械中不可或缺的一部分。

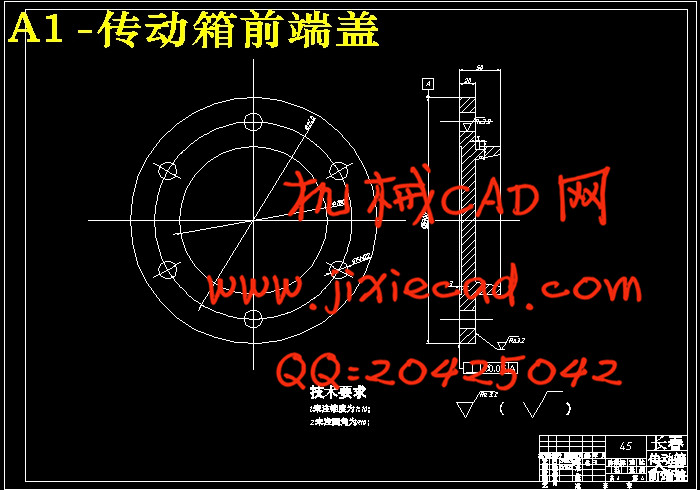

本次设计运用了液压、机械等方面的知识完成了双圆盘开沟机的设计,包括开沟机传动箱、机身、液压等部分。对传动箱进行了设计,包括齿轮的设计和校核及轴的校核,使该机的设计更加完整,设计中参考了许多国家标准使得双圆盘开沟机在使用中更加方便。

[关键词]: 农业工程机械 双圆盘开沟机 设计

Design and Research of the Double-disk Trencher

[Abstract] Through the comparative research of existing ditching machines, we have confirmed the ensemble structure of the double-disk trencher and analys its main parameters, operation principle, working components. It has proved that this machine’s structure is compact and is rationally and entirely distributed. The design could attains the anticipated result and has good popularization prospects.

Unlike chain trencher, which uses the milling principle components of the soil by disc milling, high efficiency, open Gully type complete, the advantages of uniform soil spilled, greatly improving the productivity and reduce labor intensity. Double-disc trencher for digging and laying cable pond work . It is an integral part of agriculture construction machinery.

This design used a hydraulic and mechanical knowledge to complete the double disc ditching machine design, including ditching machine's gear box, body, hydraulic and other parts. Carried out on the gear box design, including gear and shaft design and verification check of the machine's design is more perfect, the design reference to a number of national standard makes double-disc trencher more convenient in using.

[Keywords] agriculture engineering double-disc trencher design

目 录[摘要] 通过对现有开沟机的比较研究,确定了双圆盘开沟机的总体结构,并对该机的主要参数、工作原理、工作部件做了分析。该机结构紧凑,整体布局合理,设计可达到预定效果,具有良好的推广前景。

双圆盘开沟机不同于链式开沟机,它采用了铣削原理,通过圆盘部件对土壤进行铣削,具有效率高,开沟沟型完整,土壤抛洒均匀等优点,大大提高了生产率并降低了劳动强度。双圆盘开沟机适用于开挖沟渠鱼塘以及铺设电缆的工作,是农业工程机械中不可或缺的一部分。

本次设计运用了液压、机械等方面的知识完成了双圆盘开沟机的设计,包括开沟机传动箱、机身、液压等部分。对传动箱进行了设计,包括齿轮的设计和校核及轴的校核,使该机的设计更加完整,设计中参考了许多国家标准使得双圆盘开沟机在使用中更加方便。

[关键词]: 农业工程机械 双圆盘开沟机 设计

Design and Research of the Double-disk Trencher

[Abstract] Through the comparative research of existing ditching machines, we have confirmed the ensemble structure of the double-disk trencher and analys its main parameters, operation principle, working components. It has proved that this machine’s structure is compact and is rationally and entirely distributed. The design could attains the anticipated result and has good popularization prospects.

Unlike chain trencher, which uses the milling principle components of the soil by disc milling, high efficiency, open Gully type complete, the advantages of uniform soil spilled, greatly improving the productivity and reduce labor intensity. Double-disc trencher for digging and laying cable pond work . It is an integral part of agriculture construction machinery.

This design used a hydraulic and mechanical knowledge to complete the double disc ditching machine design, including ditching machine's gear box, body, hydraulic and other parts. Carried out on the gear box design, including gear and shaft design and verification check of the machine's design is more perfect, the design reference to a number of national standard makes double-disc trencher more convenient in using.

[Keywords] agriculture engineering double-disc trencher design

前言…………………………………………………………………………………1

第1章 双圆盘开沟机概述 ………………………………………………………2

1.1 双圆盘开沟机概念…………………………………………………………2

1.2 双圆盘开沟机发展及现状…………………………………………………2

1.2.1 日美俄开沟机发展状况………………………………………………3

1.2.2 我国开沟机发展状况…………………………………………………3

1.3 双圆盘开沟机研究意义……………………………………………………4

第2章 双圆盘开沟机总体设计……………………………………………………5

2.1 双圆盘开沟机结构组成……………………………………………………5

2.2 双圆盘开沟机工作原理……………………………………………………5

2.3 动力机………………………………………………………………………5

2.4 工作部件……………………………………………………………………5

2.4.1结构……………………………………………………………………………5

2.4.2 运动分析………………………………………………………………5

2.4.3 参数选择………………………………………………………………6

2.5 传动部件……………………………………………………………………8

2.5.1 传动总轴………………………………………………………………8

2.5.2 传动箱…………………………………………………………………8

2.6 液压部分……………………………………………………………………8

2.7 机身…………………………………………………………………………8

2.8 悬挂装置……………………………………………………………………8

2.9 附属装置……………………………………………………………………9

第3章 双圆盘开沟机传动箱设计计算……………………………………………10

3.1 直齿圆柱齿轮设计计算……………………………………………………10

3.1.1 Ⅰ轴直齿圆柱齿轮设计计算………………………………………10

3.1.2 Ⅱ轴直齿圆柱齿轮设计计算………………………………………13

3.2 直齿锥齿轮设计计算……………………………………………………16

3.2.1 Ⅳ轴直齿锥齿轮设计计算…………………………………………16

3.2.2 Ⅴ轴直齿锥齿轮设计计算…………………………………………19

3.3 齿轮轴强度校核计算………………………………………………………19

3.3.1 Ⅱ轴强度校核计算…………………………………………………19

3.3.2 Ⅴ轴强度校核计算…………………………………………………21

结论…………………………………………………………………………………22

致谢…………………………………………………………………………………23

参考文献……………………………………………………………………………24