设计简介

摘 要

随着现代化饲料工业的发展, 饲料厂规模不断扩大,对混合机混合均匀度的要求不断提高 随着饲制液体添加量增加, 传统的卧式双螺带混合机已不能满足上述要求.于是新一代高性能双轴桨叶式混合机便应运而生从而双轴桨叶式混合机应运而生。该机器广泛用于饲料、粮食、化工、医药、农药等行业中粉状、颗粒状、片状、杂状及粘稠状物料的混合; 混合周期短、混合均匀度高:一般物料在50~90S时间内混合均匀度CV≤5%,减少了混合时间,提高了饲料厂生产效率; 装填量可变范围大:装填系数可变范围为0.3~0.8,适用与多行业中不同比重、粒度等物料的混合; 混合不产生偏析:该机在1分钟内混合均匀后,继续混合物料不发生分级现象,且不会因为比重、粒度等物性差别大而产生偏析; 出料快、残留量小:底部采用四开门结构,排料迅速、残留少; 液体添加量大:添加30%的液体仍能将物料混合均匀,即能混合粘稠物料; 采用独特的链条张紧机构,装拆、调节快捷而方便; 排料门密封可靠:排料门采用气囊密封,密封可靠、使用寿命长,更换方便; 采用W形混合室,内置风道,整体式机座,侧置检修门,造型美观,装拆检修方便。

关键词:桨叶式 饲料 混合机

Biaxial blades efficient mixing machine

Abstract: Along with the development of modern industry, animal feed factory continues to expand the scale of mixer, mixing with requirement of improving forage additive quantity of liquid, traditional horizontal double screw with mixer already cannot satisfy the requirement of new generation of high performance. Then biaxial blades mixer produce and biaxial blades mixer arises at the historic moment. This machine is widely used in the food, feed, chemical, pharmaceutical, pesticide, and other industries powder, granule, flake, miscellaneous and mixed sticky materials, Mixed cycle is short, mixed uniformity: general materials in 50 ~ 90S time mixing degree than 5%, reduce CV hybrid time and improve production efficiency, animal feed factory. Loading quantity variable range: loading coefficient for 0.3 ~ 0.8 variable range, and many different proportion and granularity in materials such as mixing, Mixing machine: do not produce segregation in 1 minute after mixing, continue to mix materials not occurred phenomenon, and not because of classification, such as sexual difference is big size and segregation, A fast, residues by four small: bottom door structure, discharging quick, residues, Liquid add quantity: 30% of the liquid can still be mixing materials, which can be mixed sticky materials, Adopt unique chain tensioner, installation, fast and convenient adjustment, Discharging door sealing is reliable, discharging the airbag seal, sealing is reliable, long service life, easy to change, Adopting W shaped the mixing chamber, built-in duct, the integral base-plate, side for the access door, beautiful modelling, installation maintenance convenience.

Key words: Biaxial blades mixing machine

目录

前言 5

第一章 设计任务 5

第二章 设计内容 6

2.1 结构与原理 6

2.2 混合机壳体的计算 6

2 2.1 容积(V)的计算 6

2 2.2 混合室有效容积各部分尺寸的确定 7

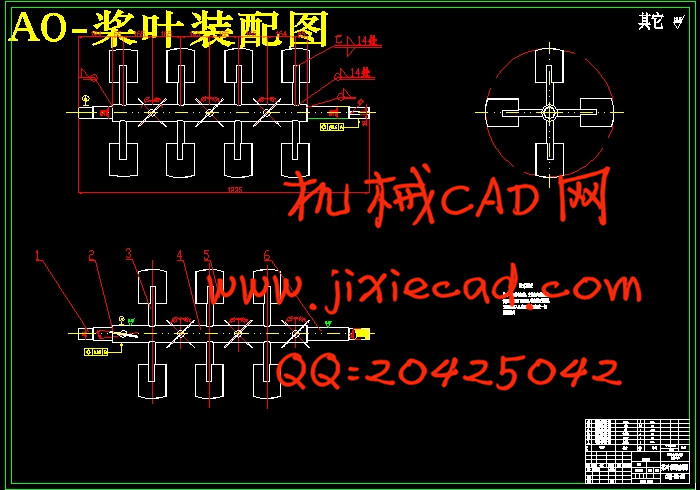

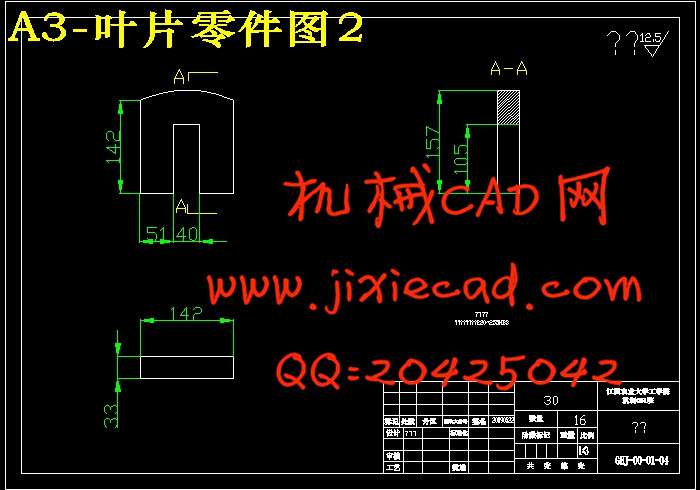

2.3 叶片设计 7

2 3.1桨叶的形状的设计 7

2 3.2 叶片的安装方式 7

2 3.3 叶片参数的确定 8

2 3.4 叶片安装角的确定 8

2 3.5 桨叶与轴的配合 9

2 3.6桨叶与轴的材料选择和连接方式 10

2.4 转子设计 10

2 4.1 两转子的安装关系 10

2 4.2 转子转速n的确定 10

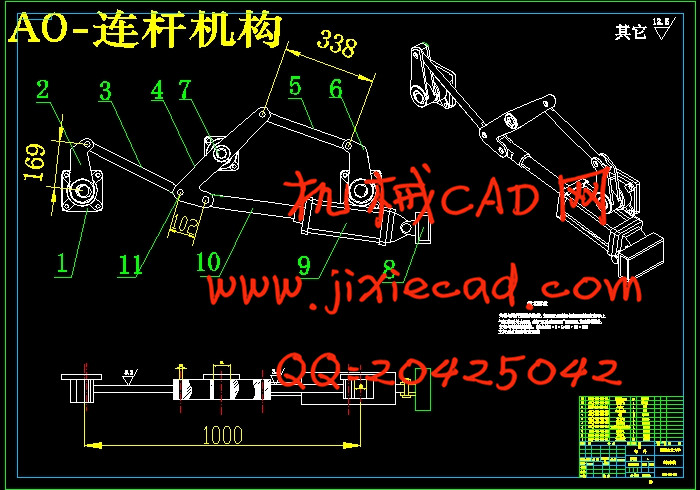

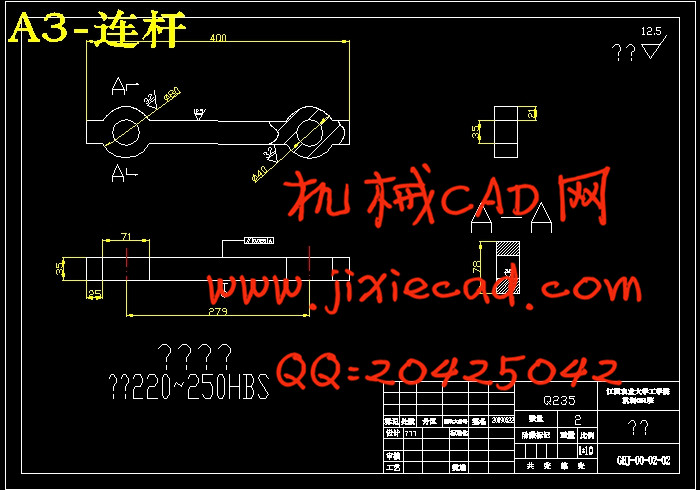

2.5 出料机构设计 11

2 5.1出料机构工作原理 11

2 5.2 放料机构各零件的设计和选择 12

2.6 链传动方式的设计 15

2 .7电动机的选择及叶片轴转速的确定 16

第三章 工艺效果 16

3.1 混合时间短,混合均匀度高 16

3.2 液体添加量大 16

3. 3产品的成型图 17

第四章 总结 18

参 考 文 献 19

致谢 19

随着现代化饲料工业的发展, 饲料厂规模不断扩大,对混合机混合均匀度的要求不断提高 随着饲制液体添加量增加, 传统的卧式双螺带混合机已不能满足上述要求.于是新一代高性能双轴桨叶式混合机便应运而生从而双轴桨叶式混合机应运而生。该机器广泛用于饲料、粮食、化工、医药、农药等行业中粉状、颗粒状、片状、杂状及粘稠状物料的混合; 混合周期短、混合均匀度高:一般物料在50~90S时间内混合均匀度CV≤5%,减少了混合时间,提高了饲料厂生产效率; 装填量可变范围大:装填系数可变范围为0.3~0.8,适用与多行业中不同比重、粒度等物料的混合; 混合不产生偏析:该机在1分钟内混合均匀后,继续混合物料不发生分级现象,且不会因为比重、粒度等物性差别大而产生偏析; 出料快、残留量小:底部采用四开门结构,排料迅速、残留少; 液体添加量大:添加30%的液体仍能将物料混合均匀,即能混合粘稠物料; 采用独特的链条张紧机构,装拆、调节快捷而方便; 排料门密封可靠:排料门采用气囊密封,密封可靠、使用寿命长,更换方便; 采用W形混合室,内置风道,整体式机座,侧置检修门,造型美观,装拆检修方便。

关键词:桨叶式 饲料 混合机

Biaxial blades efficient mixing machine

Abstract: Along with the development of modern industry, animal feed factory continues to expand the scale of mixer, mixing with requirement of improving forage additive quantity of liquid, traditional horizontal double screw with mixer already cannot satisfy the requirement of new generation of high performance. Then biaxial blades mixer produce and biaxial blades mixer arises at the historic moment. This machine is widely used in the food, feed, chemical, pharmaceutical, pesticide, and other industries powder, granule, flake, miscellaneous and mixed sticky materials, Mixed cycle is short, mixed uniformity: general materials in 50 ~ 90S time mixing degree than 5%, reduce CV hybrid time and improve production efficiency, animal feed factory. Loading quantity variable range: loading coefficient for 0.3 ~ 0.8 variable range, and many different proportion and granularity in materials such as mixing, Mixing machine: do not produce segregation in 1 minute after mixing, continue to mix materials not occurred phenomenon, and not because of classification, such as sexual difference is big size and segregation, A fast, residues by four small: bottom door structure, discharging quick, residues, Liquid add quantity: 30% of the liquid can still be mixing materials, which can be mixed sticky materials, Adopt unique chain tensioner, installation, fast and convenient adjustment, Discharging door sealing is reliable, discharging the airbag seal, sealing is reliable, long service life, easy to change, Adopting W shaped the mixing chamber, built-in duct, the integral base-plate, side for the access door, beautiful modelling, installation maintenance convenience.

Key words: Biaxial blades mixing machine

目录

前言 5

第一章 设计任务 5

第二章 设计内容 6

2.1 结构与原理 6

2.2 混合机壳体的计算 6

2 2.1 容积(V)的计算 6

2 2.2 混合室有效容积各部分尺寸的确定 7

2.3 叶片设计 7

2 3.1桨叶的形状的设计 7

2 3.2 叶片的安装方式 7

2 3.3 叶片参数的确定 8

2 3.4 叶片安装角的确定 8

2 3.5 桨叶与轴的配合 9

2 3.6桨叶与轴的材料选择和连接方式 10

2.4 转子设计 10

2 4.1 两转子的安装关系 10

2 4.2 转子转速n的确定 10

2.5 出料机构设计 11

2 5.1出料机构工作原理 11

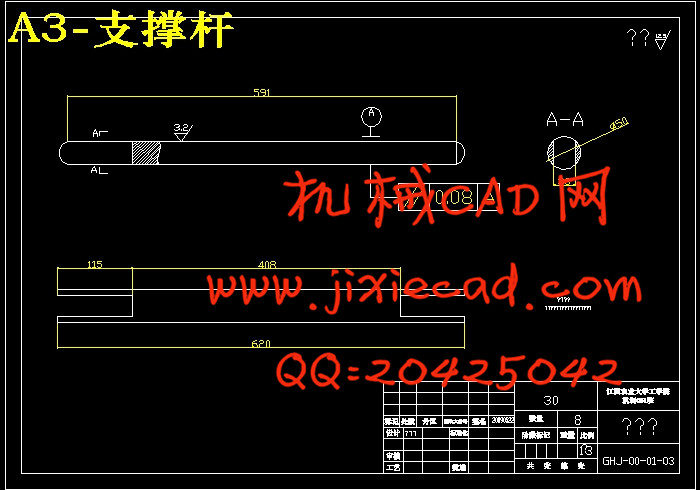

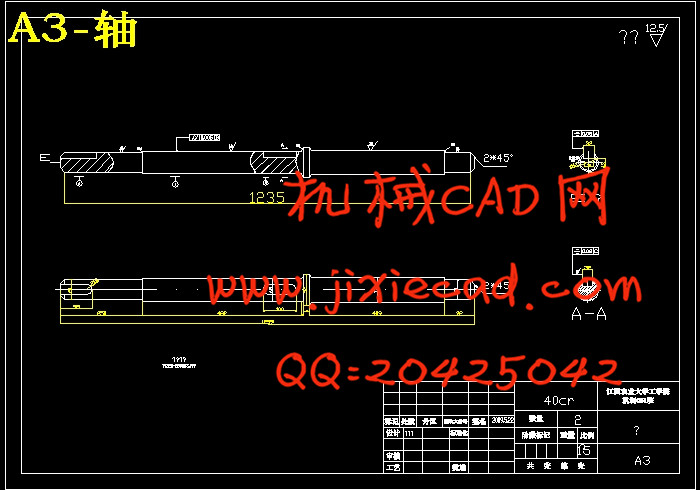

2 5.2 放料机构各零件的设计和选择 12

2.6 链传动方式的设计 15

2 .7电动机的选择及叶片轴转速的确定 16

第三章 工艺效果 16

3.1 混合时间短,混合均匀度高 16

3.2 液体添加量大 16

3. 3产品的成型图 17

第四章 总结 18

参 考 文 献 19

致谢 19