设计简介

摘 要

射性和其他有毒、有污染环境条件上进行操作。更显其优越性,有着广阔的发展前途。在中国工业韧带发展中,很多高生产率高精度的机械加工设备从国外引进,比如数控车床和铣床等,还有把几种机床的功能集中在一起的加工中心等。总之这类 CNC机床大大的提高了工作速度,产品的加工精度,降低了工作的劳动强度,所以大受欢迎。但是这类设备引进费用也是相当的昂贵,所以国内很多企业的技术人员在原先的旧机床上进行改进,来达到提高生产率和降低工人的劳动强度,实现工业自动化,这类改进同样也大受欢迎。

我由引想到为普通机床配套设计一套上料机械手,来起到减少上料的时间,减轻工人劳动强度的目的。机械手是一种模仿人体上肢运动的机器,它能按照预定要求输送工种或握持工具进行操作的自动化技术设备,对实现工业生产自动化,推动工业生产的进一步发展起着重要作用。因而具有强大的生命力,受到人们的广泛重视和欢迎。

工业机械手可以代替人手的繁重劳动,显著减轻工人的劳动强度,提高 劳动生产率和自动化水平。工业生产中经常出现的笨重工件的搬运和长期频繁,单调的操作,如果没有机械手那么工人的劳动强度是很高的,有时候还要用行车员工件,生产速度大大延缓,这种情况采用机械手是很有效的。此外,它能在高温、低温、深水、宇宙、反

关键词:加工工艺;机床;机械手

ABSTRACT

In China, many industrial ligament developing productivity high precision machining equipments imported from abroad, such as CNC lathe, milling machine, etc, and have several function of machine together in processing center, etc. In this kind of CNC machine greatly enhanced the work product machining accuracy, speed and reduce the labor intensity of work, so popular. But this kind of equipment, the introduction is also very expensive, so many domestic enterprises in the technical personnel of the original old machine, to improve productivity and reduce labor intensity, industrial automation, this kind of improvement is also very popular.

I think for ordinary led by a set of machine design on the manipulator, to reduce feeding time, reduce labor intensity. Manipulator is a kind of imitation of the upper body movement machine, it can be scheduled according to request type or holds the automation tool operation of technical equipment, industrial automation, promote the production of industrial production of the further development plays an important role. The powerful vitality and the extensive attention by people, and welcome.

Industrial robots can replace the hands of heavy labor, significantly reduce labor intensity, and improve labor productivity and automation level. Industrial production often appears in the heavy work frequently, handling and long-term operation, if not drab robots that labor intensity is high, sometimes even with employees, driving speed greatly retard, this kind of circumstance using manipulator is very effective. In addition, it can be in high temperature, low temperature, water, the universe, reflective and other toxic, environmental pollution condition on the operation. More show its superiority, has broad prospects.

Keywords: Process the craft,Fixed position,Clip tight,Appropriation tongs

目 录

摘 要······································································································································Ⅰ

Abstract····································································································································Ⅱ

前言··········································································································································· 1

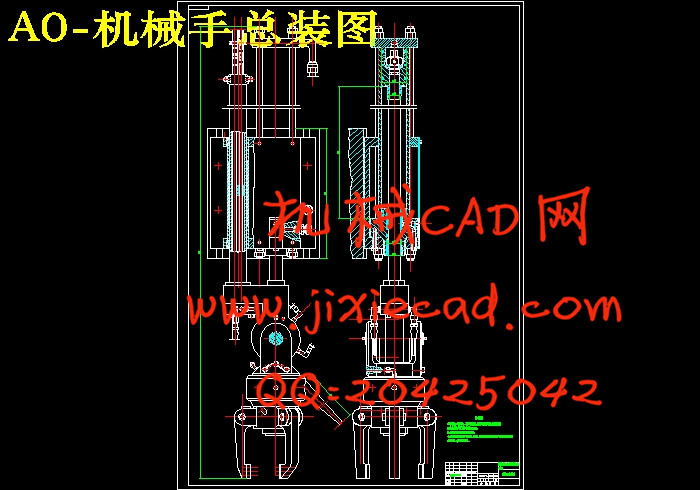

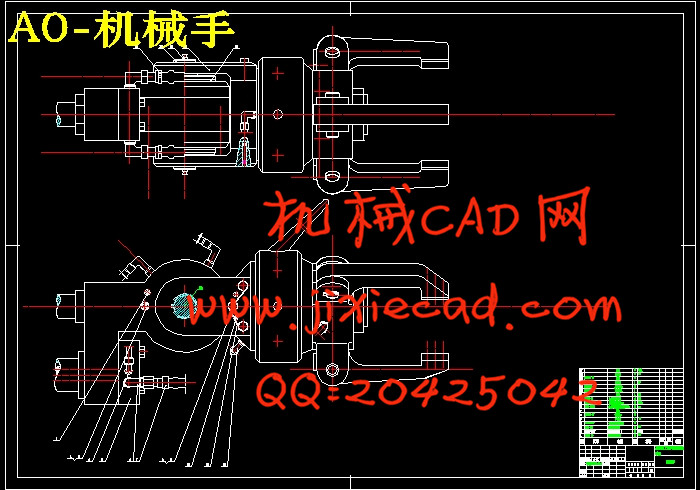

1.机械部分

1-1 确定机械手的结构及拟定工作原理·················································································2

1-2 夹紧油缸的设计·················································································································3

一.夹紧缸的设计·················································································································3

1.夹紧缸的结构设计············································································································3

2.手指选择···························································································································3

3. 三指夹紧力计算················································································································3

4. 夹紧缸计算························································································································4

5. 实际液压力的计算······ ·····································································································5

6.夹紧缸的结构设计··············································································································5

7.顶料杯的计算 ····················································································································6

1-3腕部计算······························································································································7

1.腕部总重力··························································································································7

2.回转油缸的转矩验算··········································································································7

3.驱动力矩的计算··················································································································8

4.回转缸内径的计算··············································································································8

5回转缸壁厚可根据腕部结构和工艺性选择······································································9

6.选用的轴承··························································································································9

7.回转油缸密封形式的确定··································································································9

8.回转缸螺栓的验算··············································································································9

9.花键的强度校核················································································································10

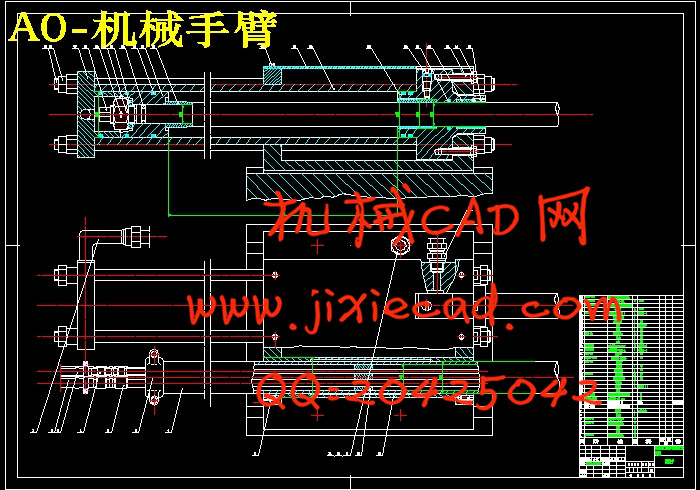

1-4手臂缸的设计和计算·········································································································12

1.手臂缸内径的确定············································································································12

2.油缸的壁厚························································································································12

3.活塞杆的计算及验算········································································································13

4.缸盖的设计························································································································14

5.活塞的结构设计················································································································15

6.油缸端盖的连接方式及强度计算····················································································16

7.液压缸的固定形式及放置································································································17

8.手臂下盖缓冲装置的设计································································································17

9.节流孔直径的确定············································································································18

10.导向套的设计··················································································································19

11.回转缸轴的校核··············································································································19

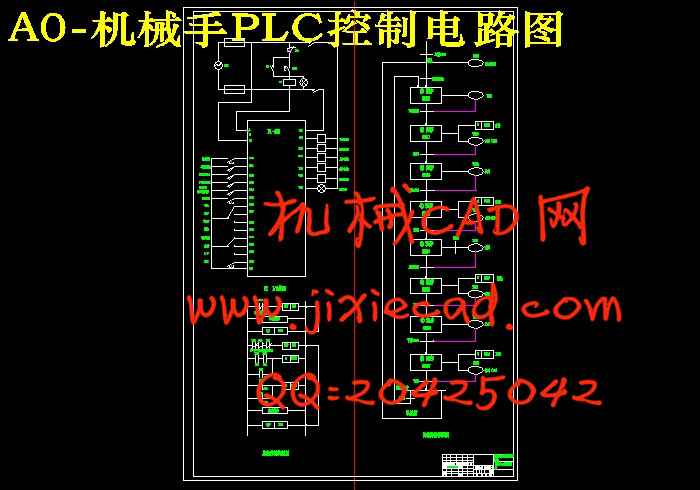

2.电气部分

2-1机械手电气部分的设计概述·····························································································24

2-2传感器的选择·····················································································································24

2-3放射式红外检测开关·········································································································26

2-4根据工艺过程分析控制要求·····························································································27

2-5确定用户输入/输出设备及pc的选择···············································································28

2-6 pc程序设计························································································································28

2-7外部电源·····························································································································32

结论··········································································································································33

致谢··········································································································································34

参考文献···································································································································35

射性和其他有毒、有污染环境条件上进行操作。更显其优越性,有着广阔的发展前途。在中国工业韧带发展中,很多高生产率高精度的机械加工设备从国外引进,比如数控车床和铣床等,还有把几种机床的功能集中在一起的加工中心等。总之这类 CNC机床大大的提高了工作速度,产品的加工精度,降低了工作的劳动强度,所以大受欢迎。但是这类设备引进费用也是相当的昂贵,所以国内很多企业的技术人员在原先的旧机床上进行改进,来达到提高生产率和降低工人的劳动强度,实现工业自动化,这类改进同样也大受欢迎。

我由引想到为普通机床配套设计一套上料机械手,来起到减少上料的时间,减轻工人劳动强度的目的。机械手是一种模仿人体上肢运动的机器,它能按照预定要求输送工种或握持工具进行操作的自动化技术设备,对实现工业生产自动化,推动工业生产的进一步发展起着重要作用。因而具有强大的生命力,受到人们的广泛重视和欢迎。

工业机械手可以代替人手的繁重劳动,显著减轻工人的劳动强度,提高 劳动生产率和自动化水平。工业生产中经常出现的笨重工件的搬运和长期频繁,单调的操作,如果没有机械手那么工人的劳动强度是很高的,有时候还要用行车员工件,生产速度大大延缓,这种情况采用机械手是很有效的。此外,它能在高温、低温、深水、宇宙、反

关键词:加工工艺;机床;机械手

ABSTRACT

In China, many industrial ligament developing productivity high precision machining equipments imported from abroad, such as CNC lathe, milling machine, etc, and have several function of machine together in processing center, etc. In this kind of CNC machine greatly enhanced the work product machining accuracy, speed and reduce the labor intensity of work, so popular. But this kind of equipment, the introduction is also very expensive, so many domestic enterprises in the technical personnel of the original old machine, to improve productivity and reduce labor intensity, industrial automation, this kind of improvement is also very popular.

I think for ordinary led by a set of machine design on the manipulator, to reduce feeding time, reduce labor intensity. Manipulator is a kind of imitation of the upper body movement machine, it can be scheduled according to request type or holds the automation tool operation of technical equipment, industrial automation, promote the production of industrial production of the further development plays an important role. The powerful vitality and the extensive attention by people, and welcome.

Industrial robots can replace the hands of heavy labor, significantly reduce labor intensity, and improve labor productivity and automation level. Industrial production often appears in the heavy work frequently, handling and long-term operation, if not drab robots that labor intensity is high, sometimes even with employees, driving speed greatly retard, this kind of circumstance using manipulator is very effective. In addition, it can be in high temperature, low temperature, water, the universe, reflective and other toxic, environmental pollution condition on the operation. More show its superiority, has broad prospects.

Keywords: Process the craft,Fixed position,Clip tight,Appropriation tongs

目 录

摘 要······································································································································Ⅰ

Abstract····································································································································Ⅱ

前言··········································································································································· 1

1.机械部分

1-1 确定机械手的结构及拟定工作原理·················································································2

1-2 夹紧油缸的设计·················································································································3

一.夹紧缸的设计·················································································································3

1.夹紧缸的结构设计············································································································3

2.手指选择···························································································································3

3. 三指夹紧力计算················································································································3

4. 夹紧缸计算························································································································4

5. 实际液压力的计算······ ·····································································································5

6.夹紧缸的结构设计··············································································································5

7.顶料杯的计算 ····················································································································6

1-3腕部计算······························································································································7

1.腕部总重力··························································································································7

2.回转油缸的转矩验算··········································································································7

3.驱动力矩的计算··················································································································8

4.回转缸内径的计算··············································································································8

5回转缸壁厚可根据腕部结构和工艺性选择······································································9

6.选用的轴承··························································································································9

7.回转油缸密封形式的确定··································································································9

8.回转缸螺栓的验算··············································································································9

9.花键的强度校核················································································································10

1-4手臂缸的设计和计算·········································································································12

1.手臂缸内径的确定············································································································12

2.油缸的壁厚························································································································12

3.活塞杆的计算及验算········································································································13

4.缸盖的设计························································································································14

5.活塞的结构设计················································································································15

6.油缸端盖的连接方式及强度计算····················································································16

7.液压缸的固定形式及放置································································································17

8.手臂下盖缓冲装置的设计································································································17

9.节流孔直径的确定············································································································18

10.导向套的设计··················································································································19

11.回转缸轴的校核··············································································································19

2.电气部分

2-1机械手电气部分的设计概述·····························································································24

2-2传感器的选择·····················································································································24

2-3放射式红外检测开关·········································································································26

2-4根据工艺过程分析控制要求·····························································································27

2-5确定用户输入/输出设备及pc的选择···············································································28

2-6 pc程序设计························································································································28

2-7外部电源·····························································································································32

结论··········································································································································33

致谢··········································································································································34

参考文献···································································································································35