设计简介

摘 要

镗模是一种机械零件加工设备,在箱体类零件加工特别是孔系加工中有着相当广泛的应用。本设计是在一些现有镗模设计的基础上设计而成的。在设计中结合了生产实践中的宝贵经验和先进技术的有关信息,并从生产实际及经济性等角度出发,进行了研究和论证。其设计原理是在保证箱体在加工过程中定位和夹紧安全、可靠、操作方便的基础上,通过对镗孔工艺方案的分析,进行镗模和孔加工刀具的设计和选用。由本设计制造而成的镗模主要用于台式车床车头箱孔系加工。本设计能够做到结构稳定、工作可靠、使用维修方便,当产品更新的时候,通用部件、标准件还可以重新利用,不需要重新制造,具有广阔的市场前景。

关键词:镗模 箱体 孔系加工 镗孔工艺 车床车头箱

Abstract

Bore mould is a machine components process equipment, there is quite extensive application when processed in the body part processing of case especially hole department. It designs to be existing to bore foundation that the mould is designed design and succeed in some originally. In the design,it has combined the relevant information of valuable experience and advanced technology in the production practices in the design, and set out from producing the angles, such as real and economy,etc. study and prove. Its design principle is guaranteeing that the case body makes a reservation and clamps safe, reliably in the course of processing, on the foundation easy to operate, through an analysis of craft scheme of bore hole, bore the design and exertion that the model and hole processed the cutter, used in the desk-top lathe locomotive case the hole department to process mainly. Originally design and can accomplish the structure steadily, the work is reliable, convenient to use and maintain.When the products are upgraded, part in common use, the standard component can also be utilized again, do not need to make again,so it has wide market prospects.

Keywords: bore mould case body hole department processing

bore hole craft locomotive case of the lathe

目 录

0 引言 …………………………………………………………………………………………… 1

1 箱体孔系加工工艺 ………………………………………………………………………… 3

1.1 平行孔系的加工 ………………………………………………………………………… 3

1.2 同轴孔系的加工 ………………………………………………………………………… 3

2 箱体的定位方案 …………………………………………………………………………… 5

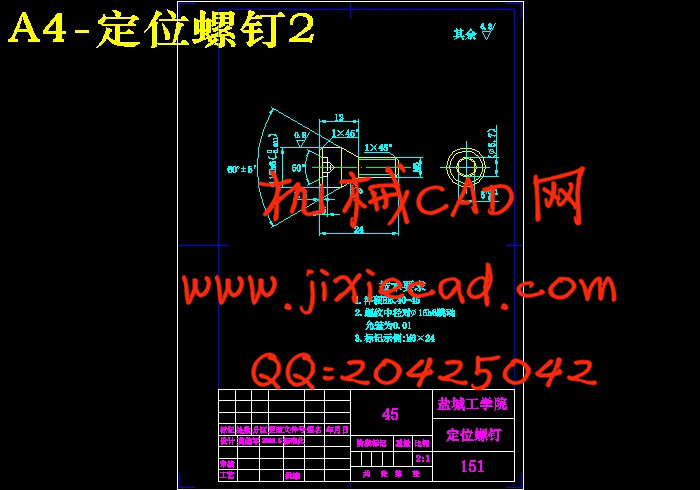

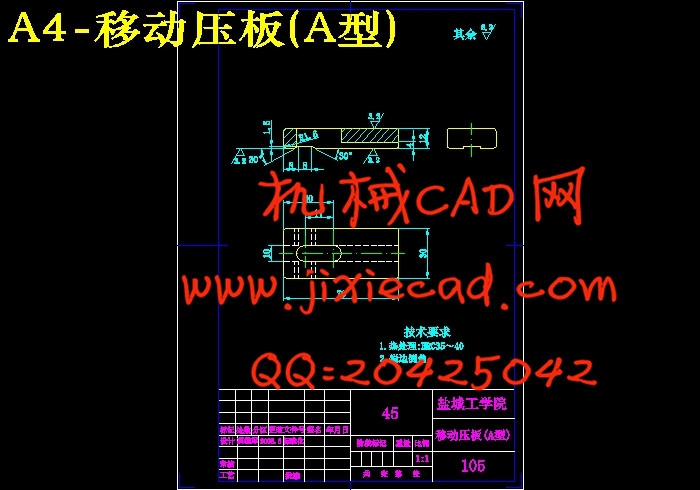

3 箱体的夹紧方案 …………………………………………………………………………… 7

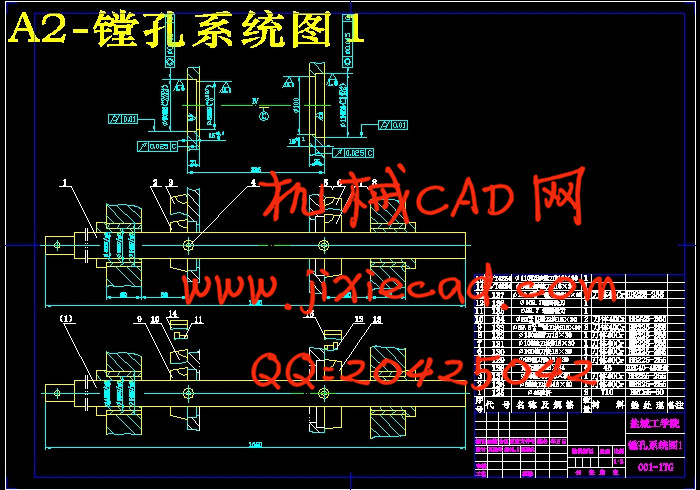

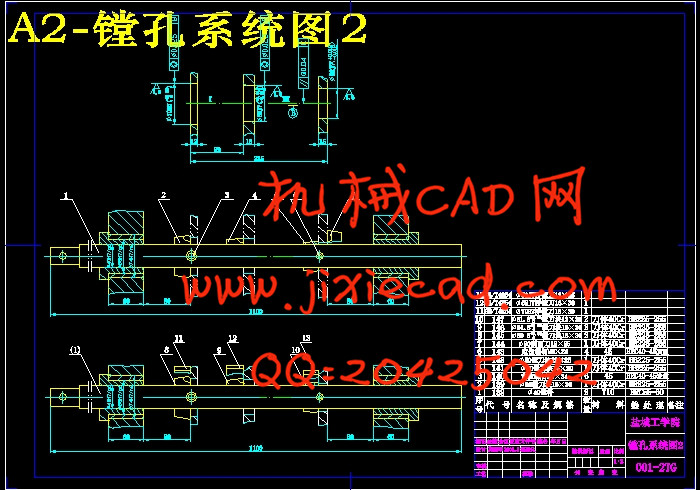

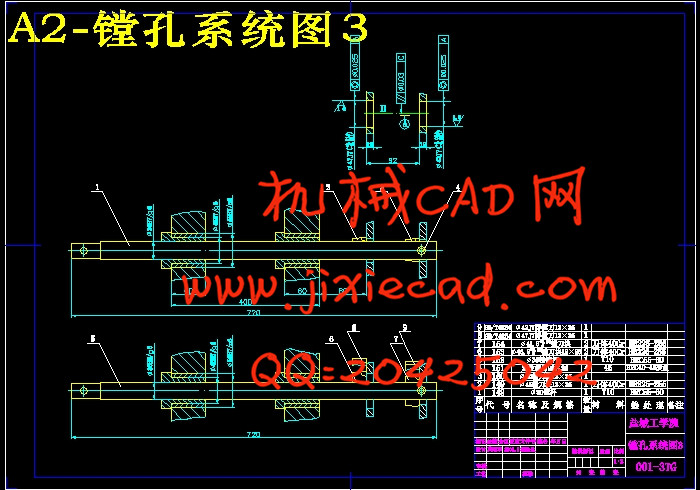

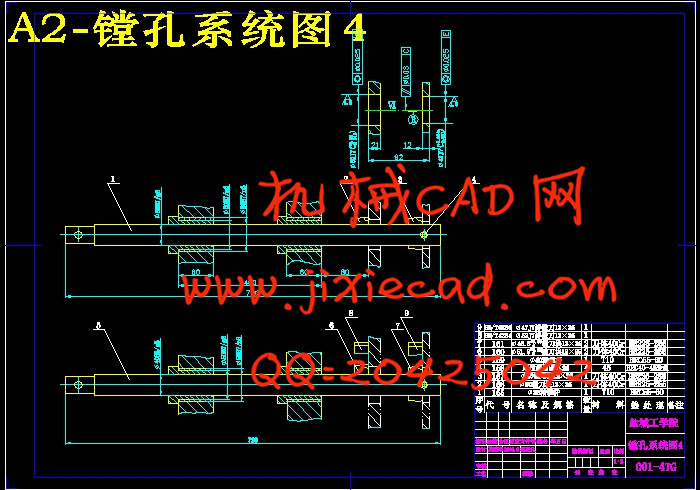

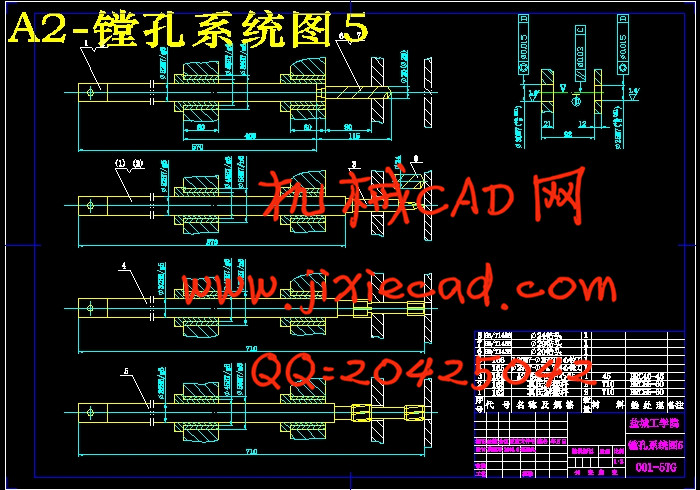

4 镗模的设计 ………………………………………………………………………………… 8

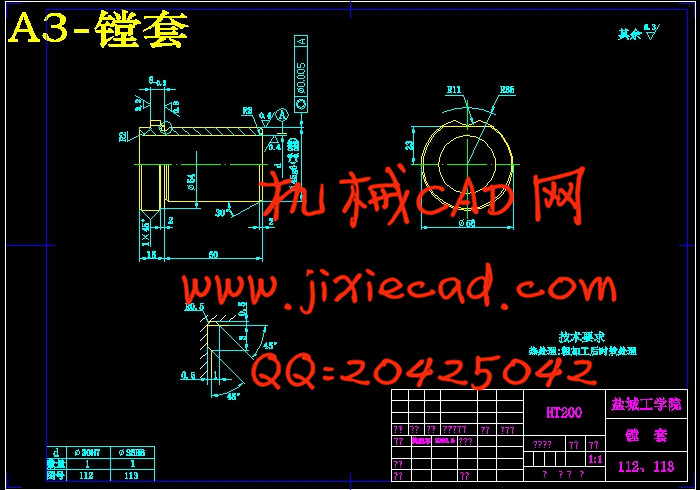

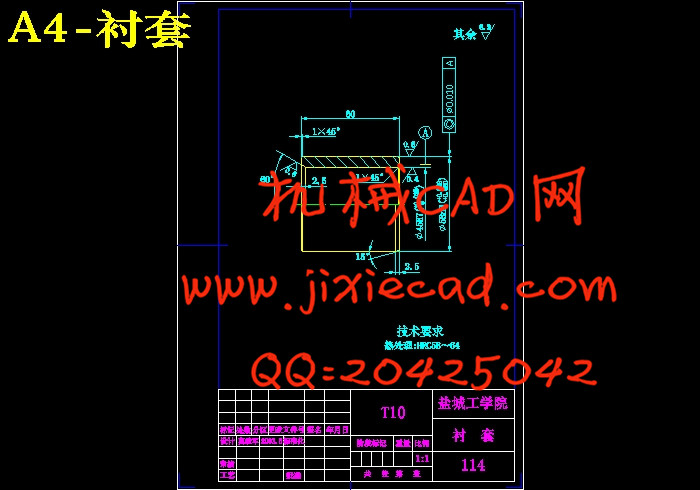

4.1 镗套的选择和设计 ……………………………………………………………………… 8

4.1.1 镗套的结构型式 ……………………………………………………………………… 8

4.1.2 镗套的材料及主要技术要求 ……………………………………………………… 9

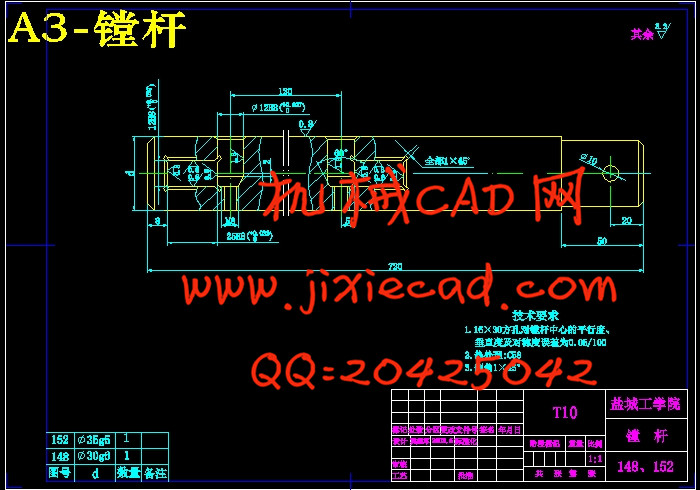

4.2 镗杆的设计 ……………………………………………………………………………… 10

4.2.1 镗杆导向部分结构 …………………………………………………………………… 10

4.2.2 镗杆直径和轴向尺寸 ………………………………………………………………… 10

4.2.3 镗杆的材料 …………………………………………………………………………… 11

4.2.4 镗杆的技术条件 ……………………………………………………………………… 11

4.3 浮动接头 …………………………………………………………………………………… 11

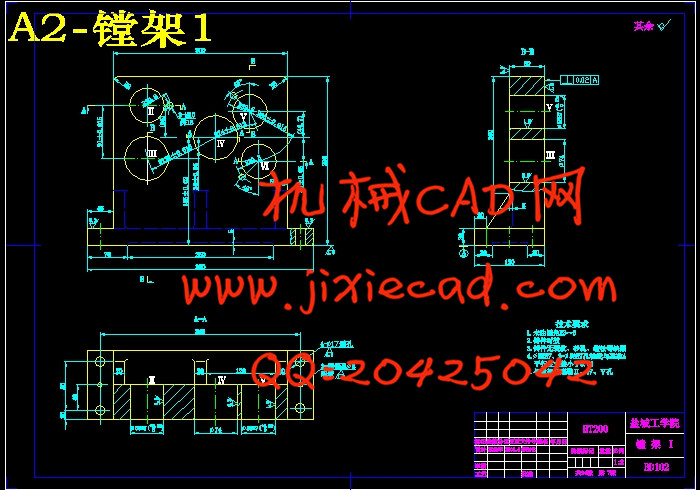

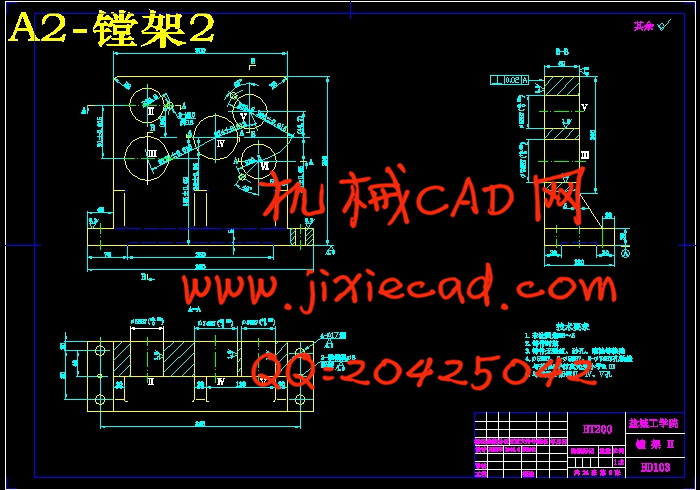

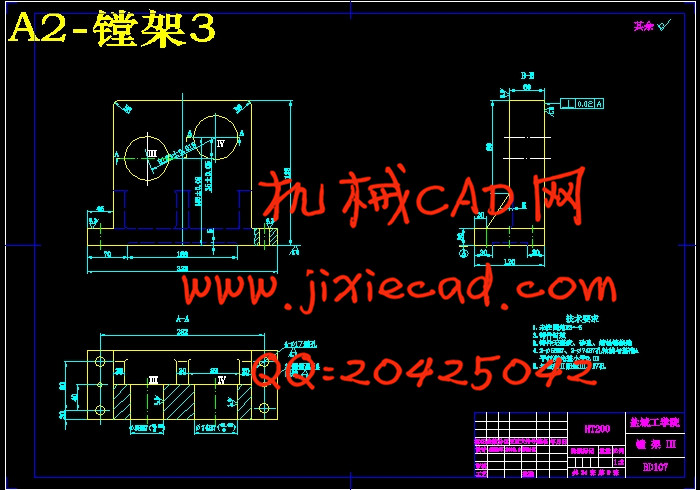

4.4 镗模支架的设计 ………………………………………………………………………… 12

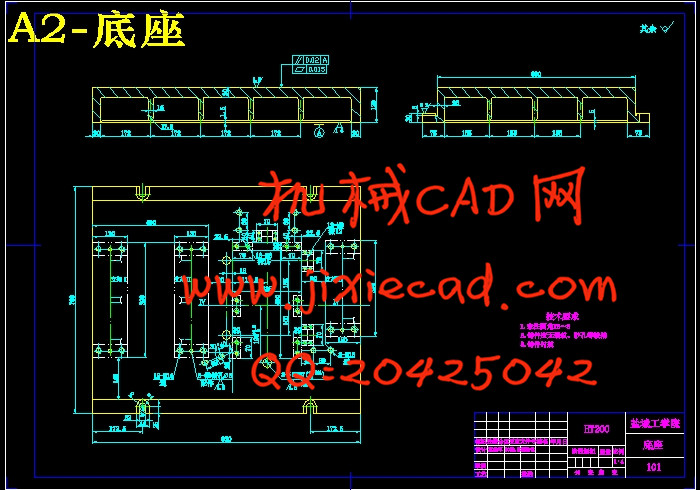

4.5 镗模底座的设计 ………………………………………………………………………… 12

4.6 镗模支架的布置型式 …………………………………………………………………… 13

4.7 原始孔的选择 …………………………………………………………………………… 14

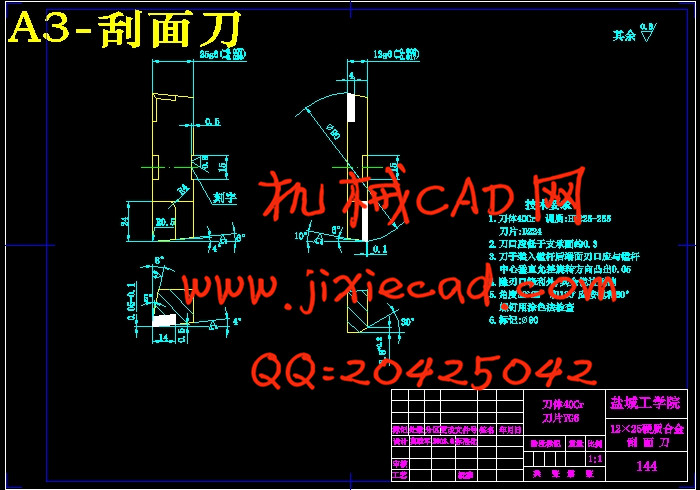

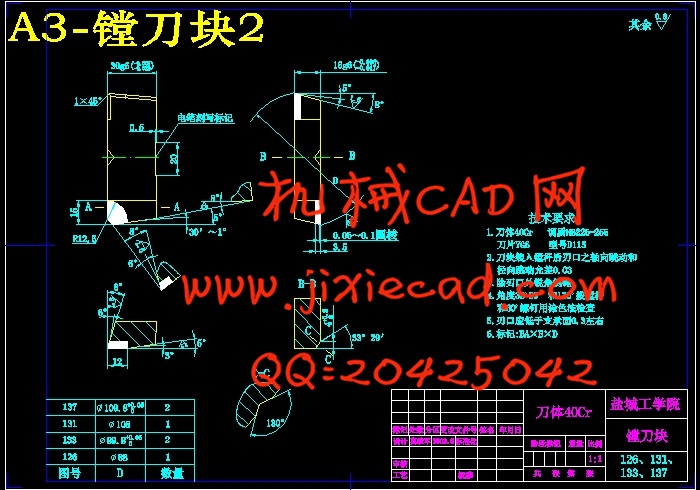

5 孔加工刀具的设计和选用 ………………………………………………………………… 15

5.1 孔加工刀具的类型 ……………………………………………………………………… 15

5.2 孔加工刀具的设计和选用 …………………………………………………………… 15

6 镗孔工艺方案 ……………………………………………………………………………… 18

7 结论 …………………………………………………………………………………………… 20

工作小结与致谢 ……………………………………………………………………………… 21

参考文献 ………………………………………………………………………………………… 22

附件清单 ………………………………………………………………………………………… 23

镗模是一种机械零件加工设备,在箱体类零件加工特别是孔系加工中有着相当广泛的应用。本设计是在一些现有镗模设计的基础上设计而成的。在设计中结合了生产实践中的宝贵经验和先进技术的有关信息,并从生产实际及经济性等角度出发,进行了研究和论证。其设计原理是在保证箱体在加工过程中定位和夹紧安全、可靠、操作方便的基础上,通过对镗孔工艺方案的分析,进行镗模和孔加工刀具的设计和选用。由本设计制造而成的镗模主要用于台式车床车头箱孔系加工。本设计能够做到结构稳定、工作可靠、使用维修方便,当产品更新的时候,通用部件、标准件还可以重新利用,不需要重新制造,具有广阔的市场前景。

关键词:镗模 箱体 孔系加工 镗孔工艺 车床车头箱

Abstract

Bore mould is a machine components process equipment, there is quite extensive application when processed in the body part processing of case especially hole department. It designs to be existing to bore foundation that the mould is designed design and succeed in some originally. In the design,it has combined the relevant information of valuable experience and advanced technology in the production practices in the design, and set out from producing the angles, such as real and economy,etc. study and prove. Its design principle is guaranteeing that the case body makes a reservation and clamps safe, reliably in the course of processing, on the foundation easy to operate, through an analysis of craft scheme of bore hole, bore the design and exertion that the model and hole processed the cutter, used in the desk-top lathe locomotive case the hole department to process mainly. Originally design and can accomplish the structure steadily, the work is reliable, convenient to use and maintain.When the products are upgraded, part in common use, the standard component can also be utilized again, do not need to make again,so it has wide market prospects.

Keywords: bore mould case body hole department processing

bore hole craft locomotive case of the lathe

目 录

0 引言 …………………………………………………………………………………………… 1

1 箱体孔系加工工艺 ………………………………………………………………………… 3

1.1 平行孔系的加工 ………………………………………………………………………… 3

1.2 同轴孔系的加工 ………………………………………………………………………… 3

2 箱体的定位方案 …………………………………………………………………………… 5

3 箱体的夹紧方案 …………………………………………………………………………… 7

4 镗模的设计 ………………………………………………………………………………… 8

4.1 镗套的选择和设计 ……………………………………………………………………… 8

4.1.1 镗套的结构型式 ……………………………………………………………………… 8

4.1.2 镗套的材料及主要技术要求 ……………………………………………………… 9

4.2 镗杆的设计 ……………………………………………………………………………… 10

4.2.1 镗杆导向部分结构 …………………………………………………………………… 10

4.2.2 镗杆直径和轴向尺寸 ………………………………………………………………… 10

4.2.3 镗杆的材料 …………………………………………………………………………… 11

4.2.4 镗杆的技术条件 ……………………………………………………………………… 11

4.3 浮动接头 …………………………………………………………………………………… 11

4.4 镗模支架的设计 ………………………………………………………………………… 12

4.5 镗模底座的设计 ………………………………………………………………………… 12

4.6 镗模支架的布置型式 …………………………………………………………………… 13

4.7 原始孔的选择 …………………………………………………………………………… 14

5 孔加工刀具的设计和选用 ………………………………………………………………… 15

5.1 孔加工刀具的类型 ……………………………………………………………………… 15

5.2 孔加工刀具的设计和选用 …………………………………………………………… 15

6 镗孔工艺方案 ……………………………………………………………………………… 18

7 结论 …………………………………………………………………………………………… 20

工作小结与致谢 ……………………………………………………………………………… 21

参考文献 ………………………………………………………………………………………… 22

附件清单 ………………………………………………………………………………………… 23