设计简介

摘要

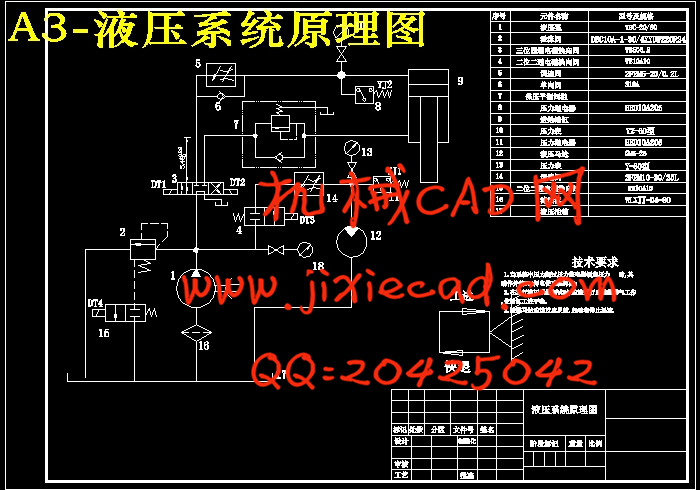

本文主要介绍了台式钻床的改造和设计,通过导入液压进给系统和PLC控制系统将台式钻床改造为自动钻床,并可通过PLC实现自动控制。该钻床在钻削过程中可以用液压油缸来实现自动进给和快速退回;主运动可以由液压马达来实现。本设计采用设计方法有:传统的设计方法与现代研究方法相结合;计算机辅助设计;模块化设计等。液压台钻设计的主要特点:

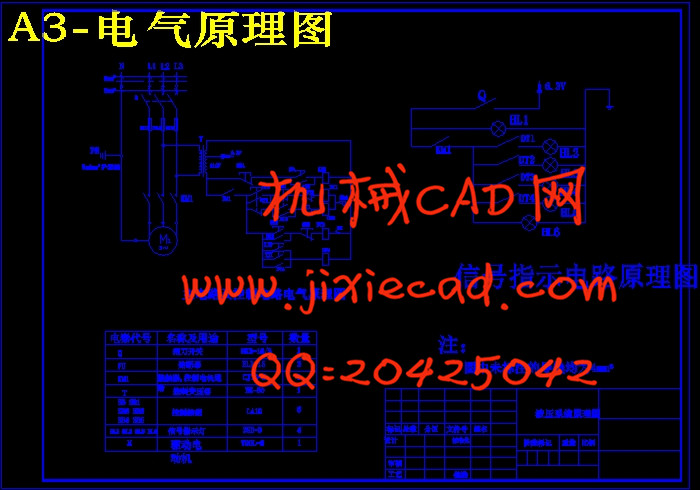

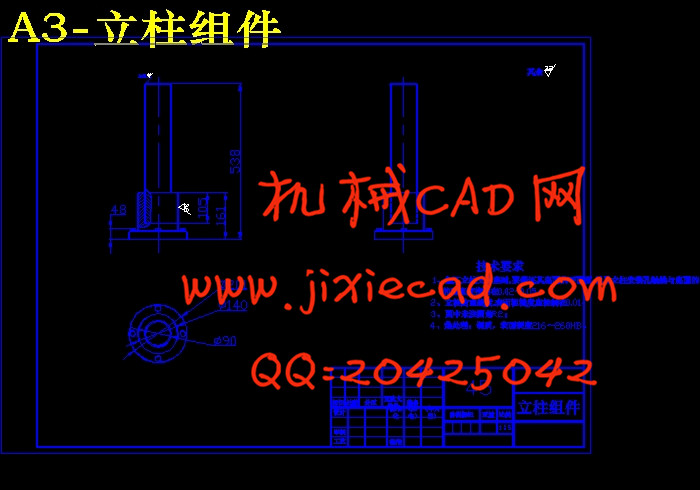

1、考虑到液压台式钻床的使用环境及工况特点,从结构紧凑、加工及制造简单、使用和维护安全方便、经济性好等方面着手,将总设计分为液压系统、电气控制系统和机械传动系统三大模块来进行;在整体布局上分为上装和下装两大部分。

2、为了减少布局空间,将台钻下装部分设计成箱体控制柜的形式,底座油箱置于下层,上层为液压及电气集成控制区,将驱动电机用联接法兰联成一体,将所有的液压控制阀集成安装在一个大的阀块体上,大大减小了台钻的整体布局。

3、本设计在可以实现在钻孔加工时的自动进给和快退;钻孔深度半自动控制及速度显示装置,在很大程度上减轻了劳动强度,提高生产效率。

4、由于液压传动技术和电气控制技术的诸多特点,在元件的选择、设计上突显其优越性,大大降低了生产成本。

关键词: 模块化设计;联接法兰;集成控制

1.Considering the working characteristic of the hydraulic pressure drill press, I take measures at the aspects of the compact configuration ,making simple, using conveniently、 maintenance safely and economic. I divide it into three module .They are hydraulic pressure system, electrical control system and machine drive system. Seeing form the whole layout, I divide it into upside chest and base chest.

2. For reducing the room, I design the base chest into the form of the control tank. The pedestal oil box located the under layer, the super stratum is the integration control area of the hydraulic pressure and electrical control. Join the drive electromotor with the hydraulic pressure pump by the link flange .All the hydraulic pressure control clique install on the assemble piece. It will reduce the collectivity area.

3. The design can realize downwards and forward movement automatically and fleetly. Bore deepness semiautomatic control equipment, velocity display device reduce the worker’s laboring intensity, increase productivity consumedly.

4. Because of the characteristics of the hydraulic pressure system and electrical control system, they display the advantage of the selection of the element and whole design, and reduce the produce cost consumedly.

Key words: the design of module; link flange; integration control

本文主要介绍了台式钻床的改造和设计,通过导入液压进给系统和PLC控制系统将台式钻床改造为自动钻床,并可通过PLC实现自动控制。该钻床在钻削过程中可以用液压油缸来实现自动进给和快速退回;主运动可以由液压马达来实现。本设计采用设计方法有:传统的设计方法与现代研究方法相结合;计算机辅助设计;模块化设计等。液压台钻设计的主要特点:

1、考虑到液压台式钻床的使用环境及工况特点,从结构紧凑、加工及制造简单、使用和维护安全方便、经济性好等方面着手,将总设计分为液压系统、电气控制系统和机械传动系统三大模块来进行;在整体布局上分为上装和下装两大部分。

2、为了减少布局空间,将台钻下装部分设计成箱体控制柜的形式,底座油箱置于下层,上层为液压及电气集成控制区,将驱动电机用联接法兰联成一体,将所有的液压控制阀集成安装在一个大的阀块体上,大大减小了台钻的整体布局。

3、本设计在可以实现在钻孔加工时的自动进给和快退;钻孔深度半自动控制及速度显示装置,在很大程度上减轻了劳动强度,提高生产效率。

4、由于液压传动技术和电气控制技术的诸多特点,在元件的选择、设计上突显其优越性,大大降低了生产成本。

关键词: 模块化设计;联接法兰;集成控制

Abstract

This thesis mainly illustrates the improving and design of Bench-type drilling machine. The drill press can be move forward automatically and downward fleetly by the hydraulic oil jar. Hydraulic motor can achieve the central locomotion. The first mean of my graduation design integrate the traditional design and modern design commutatively, the second is CAD, and the third is the design of modularity, and so on. The characteristic of the design of the hydraulic pressure drill shows as follows:1.Considering the working characteristic of the hydraulic pressure drill press, I take measures at the aspects of the compact configuration ,making simple, using conveniently、 maintenance safely and economic. I divide it into three module .They are hydraulic pressure system, electrical control system and machine drive system. Seeing form the whole layout, I divide it into upside chest and base chest.

2. For reducing the room, I design the base chest into the form of the control tank. The pedestal oil box located the under layer, the super stratum is the integration control area of the hydraulic pressure and electrical control. Join the drive electromotor with the hydraulic pressure pump by the link flange .All the hydraulic pressure control clique install on the assemble piece. It will reduce the collectivity area.

3. The design can realize downwards and forward movement automatically and fleetly. Bore deepness semiautomatic control equipment, velocity display device reduce the worker’s laboring intensity, increase productivity consumedly.

4. Because of the characteristics of the hydraulic pressure system and electrical control system, they display the advantage of the selection of the element and whole design, and reduce the produce cost consumedly.

Key words: the design of module; link flange; integration control