设计简介

摘要

本论文设计是一种适合谷物(例如:水稻、大豆、麦子)干燥的干燥机的结构、干燥原理、干燥过程、结构参数的确定方法、干燥性能,但主要是针对水稻的干燥。干燥是指去掉水稻中的水分。按方式分,干燥有烘干和晒干两种,所谓烘干,就是利用燃料烘烤方式蒸发谷中的水分。本论文设计的太阳能水循环谷物干燥机(搅拌机式)在国内有重要的意义。晒干,就是利用自然风来去掉水稻中的水分。按方法分,干燥有分为自然干燥和人工干燥两种。自然干燥,就是利用自然风和太阳能去掉水稻中的水分。人工干燥就是利用干燥机去掉水稻中的水分,人工干燥必须要有热量和风。干燥的目的主要是防止水稻在贮藏中由于水分过多而腐烂和发芽的问题,太阳能干燥就不但节约资源还而且对环境无污染。此外,干燥还可以减少重量便于运输、贮藏和改善水稻的性质和性能,以便下一步作业等。

关键词: 干燥 ;人工干燥; 谷物; 搅拌机

Abstract

The design is suitable for grain ( such as: rice, soybean, wheat) drying dryer structure, principle of drying, drying process, a determining method of structural parameters, drying properties, but mainly for paddy drying. Dry refers to remove moisture content in rice. According to the method, drying drying and drying to two, so-called drying, baking is the use of fuel evaporation of moisture in the valley. In this paper the design of solar energy water circulation grain drier ( mixer type ) in the country has important significance. Dried, is the use of natural wind to remove moisture content in rice. According to the method, drying is divided into natural drying and artificial drying two. Natural drying, is the use of natural wind and solar energy to remove the moisture content in rice. Artificial drying is the use of dryer to remove the rice in water, artificial drying must have heat and wind. Drying is the main purpose of preventing rice during storage due to excessive moisture and decay and germination problems, solar drying will not only save resources and no pollution to the environment. In addition, drying can also reduce weight is convenient for transportation, storage and improve rice properties and performance, so that the next operation

Key word: Drying; drying; grain; mixer

目录

摘要

Abstract

1 绪论1

1.1 水稻干燥的意义1

1.2 水稻干燥机理1

1.3.1 太阳能的介绍.2

1.3.2 太阳能热水器原理及优势.2

1.3.3 水介质的优势.2

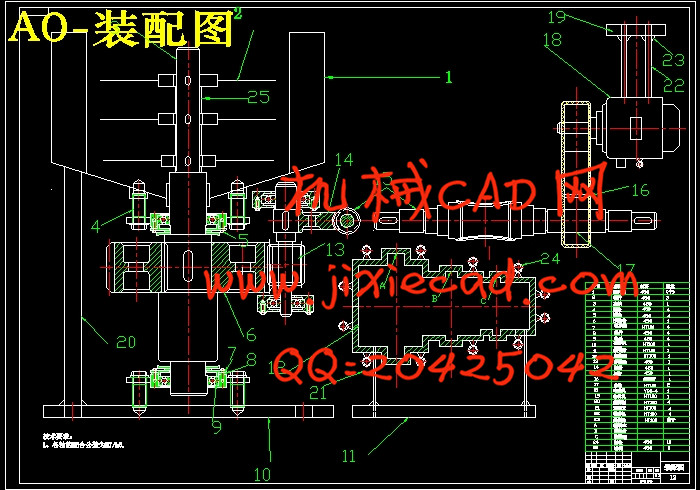

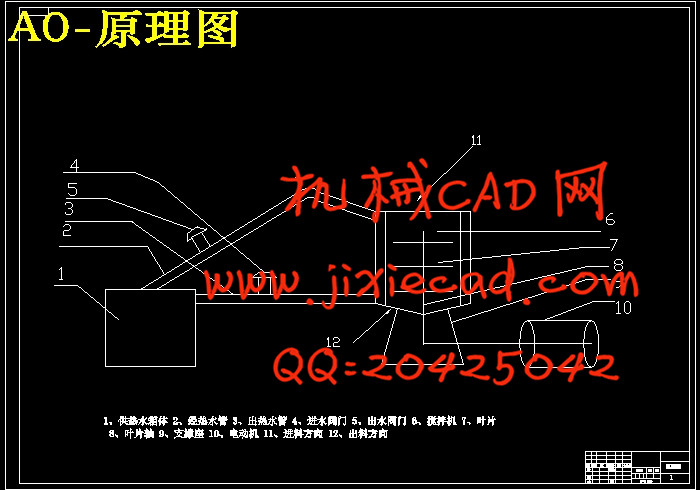

2 太阳能水循环水稻干燥机工作过程设计4

2.1 干燥机基本工作简述4

2.2 水稻干燥机的基本设计要求4

2.2.1 水稻有关参数5

2.3. 水稻干燥耗能计算5

3 干燥机设计.6

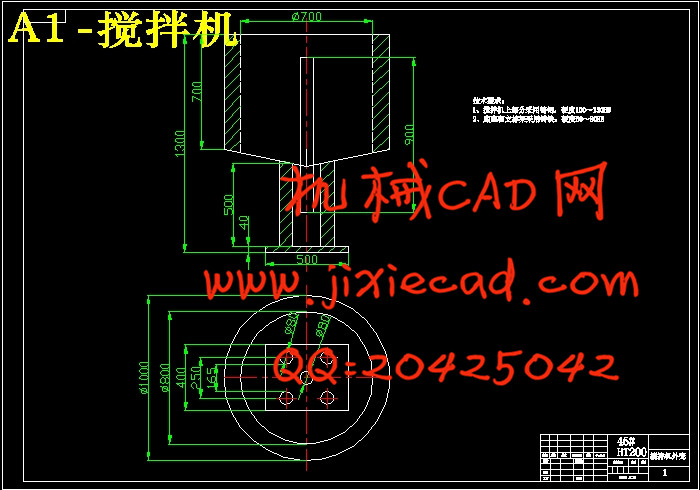

3.1 搅拌机的容积设计6

3.1.1 尺寸设计6

3.1.2 热量计算6

4 动力装置选用7

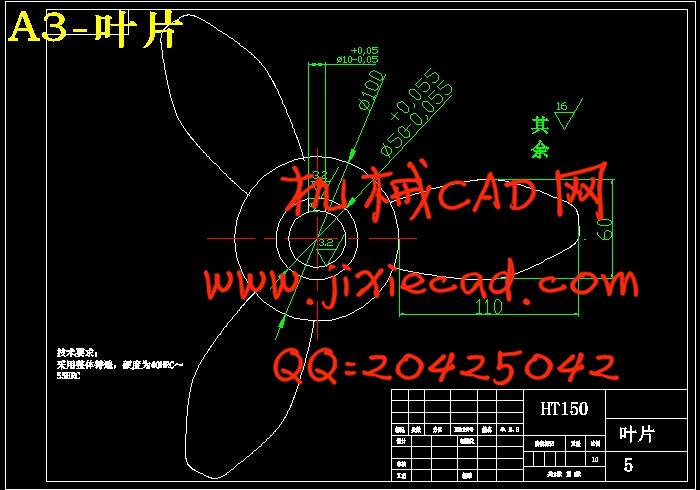

4.1.1 叶片选用7

4.1.2 主轴转速的确定7

4.2 传动装置设计7

4.2.1传动链设计7

4.2.2 电动机选择8

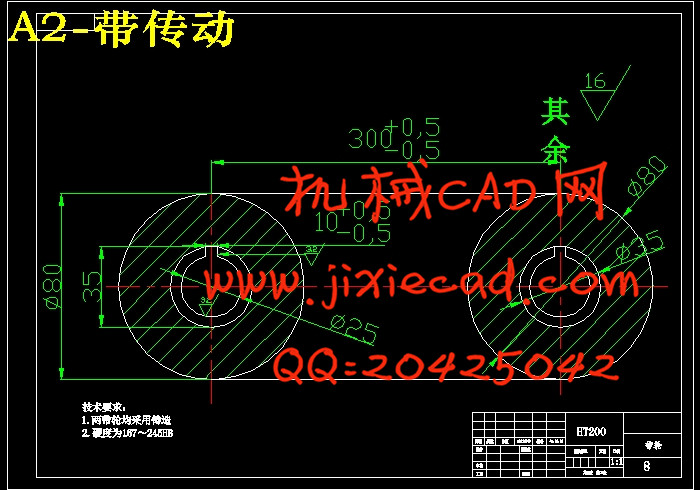

4.2.3 带轮设计8

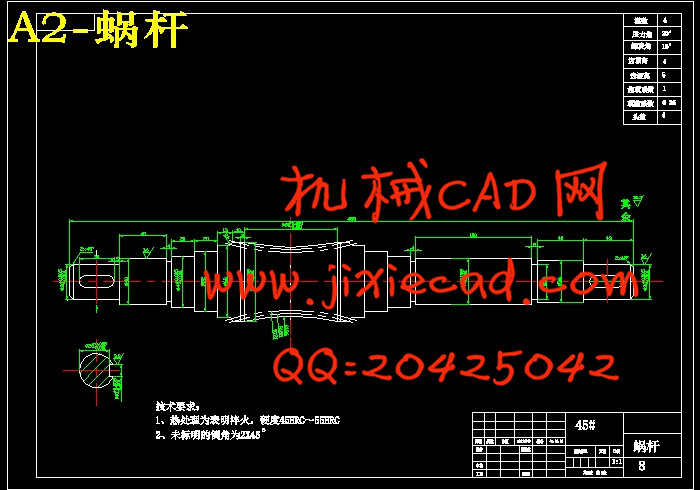

4.2.4 蜗杆涡轮设计9

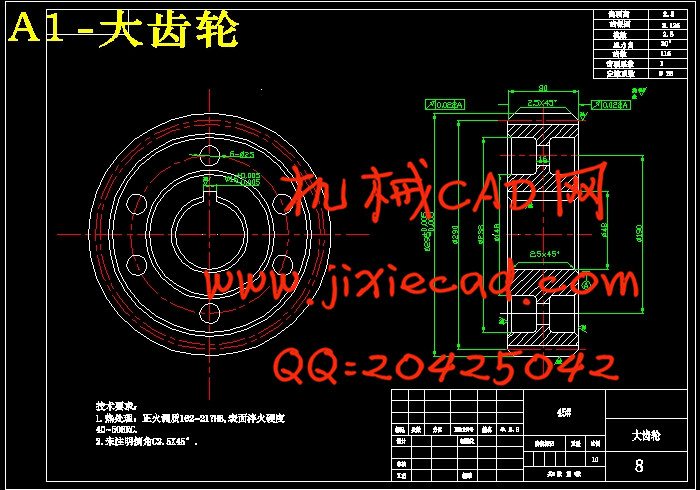

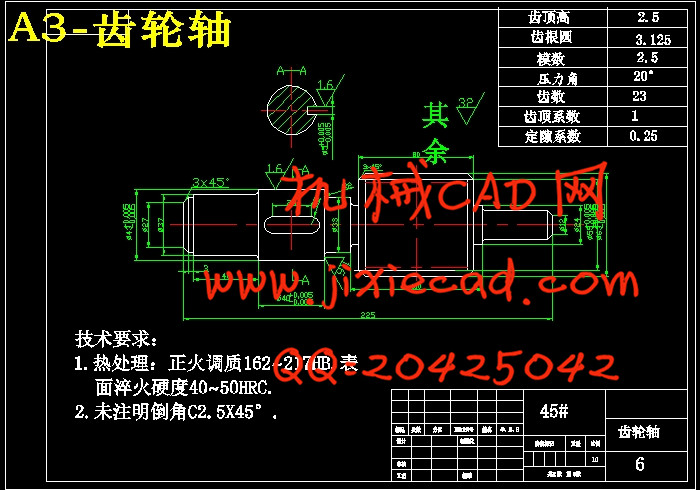

4.2.5 齿轮传动设计9

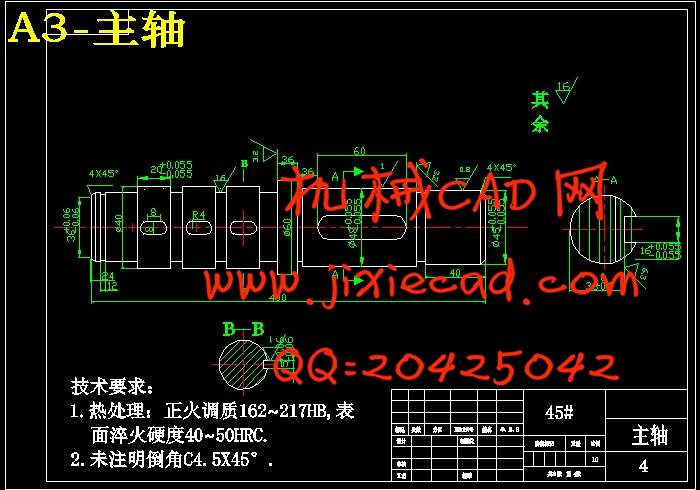

4.3 叶片轴的设计12

4.3.1 轴的材料12

4.3.2 轴上圆角与倒角确定13

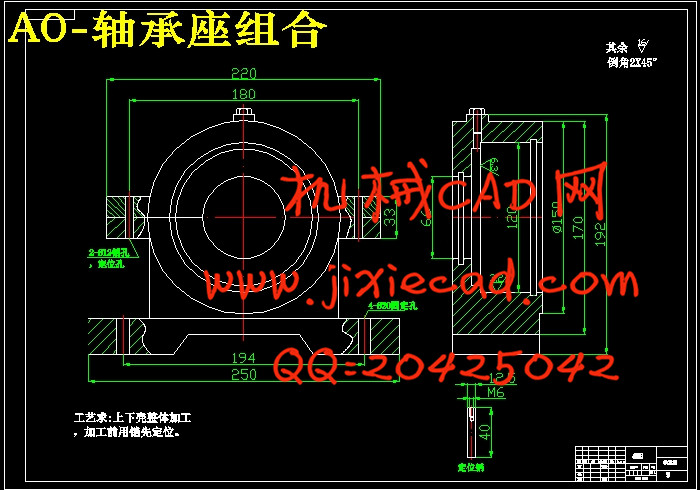

4.3.3 轴承13

4.4 太阳能电池板选择.13

5 其它部件的选用14

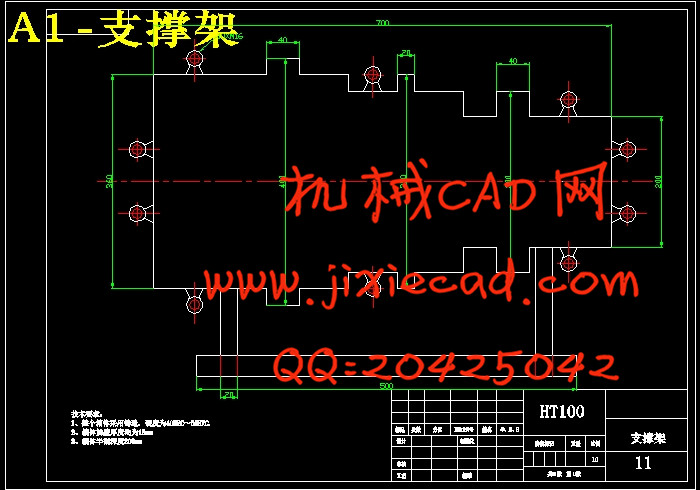

5.1 搅拌机底座支架14

5.2 水管16

5.3 水泵和阀门16

5.4 搅拌机材料16

小结17

参考文献19

致谢.20

本论文设计是一种适合谷物(例如:水稻、大豆、麦子)干燥的干燥机的结构、干燥原理、干燥过程、结构参数的确定方法、干燥性能,但主要是针对水稻的干燥。干燥是指去掉水稻中的水分。按方式分,干燥有烘干和晒干两种,所谓烘干,就是利用燃料烘烤方式蒸发谷中的水分。本论文设计的太阳能水循环谷物干燥机(搅拌机式)在国内有重要的意义。晒干,就是利用自然风来去掉水稻中的水分。按方法分,干燥有分为自然干燥和人工干燥两种。自然干燥,就是利用自然风和太阳能去掉水稻中的水分。人工干燥就是利用干燥机去掉水稻中的水分,人工干燥必须要有热量和风。干燥的目的主要是防止水稻在贮藏中由于水分过多而腐烂和发芽的问题,太阳能干燥就不但节约资源还而且对环境无污染。此外,干燥还可以减少重量便于运输、贮藏和改善水稻的性质和性能,以便下一步作业等。

关键词: 干燥 ;人工干燥; 谷物; 搅拌机

Abstract

The design is suitable for grain ( such as: rice, soybean, wheat) drying dryer structure, principle of drying, drying process, a determining method of structural parameters, drying properties, but mainly for paddy drying. Dry refers to remove moisture content in rice. According to the method, drying drying and drying to two, so-called drying, baking is the use of fuel evaporation of moisture in the valley. In this paper the design of solar energy water circulation grain drier ( mixer type ) in the country has important significance. Dried, is the use of natural wind to remove moisture content in rice. According to the method, drying is divided into natural drying and artificial drying two. Natural drying, is the use of natural wind and solar energy to remove the moisture content in rice. Artificial drying is the use of dryer to remove the rice in water, artificial drying must have heat and wind. Drying is the main purpose of preventing rice during storage due to excessive moisture and decay and germination problems, solar drying will not only save resources and no pollution to the environment. In addition, drying can also reduce weight is convenient for transportation, storage and improve rice properties and performance, so that the next operation

Key word: Drying; drying; grain; mixer

目录

摘要

Abstract

1 绪论1

1.1 水稻干燥的意义1

1.2 水稻干燥机理1

1.3.1 太阳能的介绍.2

1.3.2 太阳能热水器原理及优势.2

1.3.3 水介质的优势.2

2 太阳能水循环水稻干燥机工作过程设计4

2.1 干燥机基本工作简述4

2.2 水稻干燥机的基本设计要求4

2.2.1 水稻有关参数5

2.3. 水稻干燥耗能计算5

3 干燥机设计.6

3.1 搅拌机的容积设计6

3.1.1 尺寸设计6

3.1.2 热量计算6

4 动力装置选用7

4.1.1 叶片选用7

4.1.2 主轴转速的确定7

4.2 传动装置设计7

4.2.1传动链设计7

4.2.2 电动机选择8

4.2.3 带轮设计8

4.2.4 蜗杆涡轮设计9

4.2.5 齿轮传动设计9

4.3 叶片轴的设计12

4.3.1 轴的材料12

4.3.2 轴上圆角与倒角确定13

4.3.3 轴承13

4.4 太阳能电池板选择.13

5 其它部件的选用14

5.1 搅拌机底座支架14

5.2 水管16

5.3 水泵和阀门16

5.4 搅拌机材料16

小结17

参考文献19

致谢.20