设计简介

摘 要

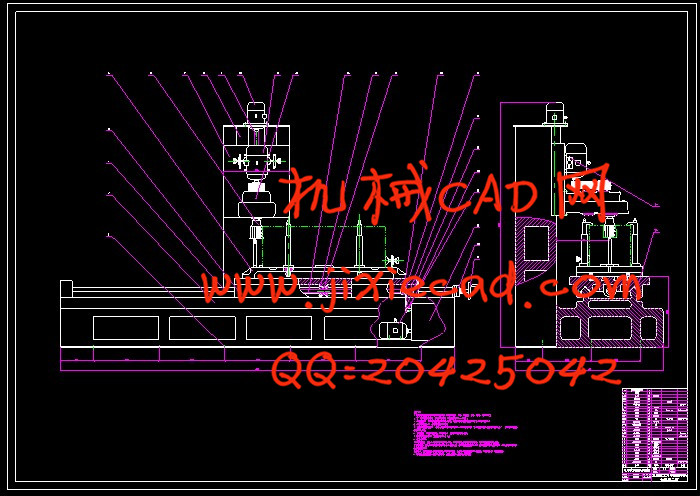

金属切削机床是机械制造装备中最具代表性的产品,在国民生产中占据十分重要的位置。本次设计说明书主要设计了铣床的结构,其中减速器设计从电动机的功率确定到最大,最小转速参数的设计,到标准公比的选用和转速的确定,齿数,齿轮的确定等都严格按照要求设计。通过查阅了多种设计资料确定了主传动系统结构,各轴直径的计算和它们的刚度,强度的校核,齿轮的齿数,模数和带轮的设计,从而确定了主轴箱的大体结构,从而绘制出各视图和零件图。最后结合各部分的设计设计出铣床的总体图形,完成碳块专用铣床的全部设计。

通过本次毕业设计,不仅使我在大学四年里所学的知识有了更进一步的巩固与提高,同时也增强了自己查阅资料和独立分析问题与解决问题的能力,为今后更好地工作与学习打下了坚实的基础。

关键词: 减速器; 定位 ; 工装夹具; 铣床;

Carbon block special purpose milling machine design

Abstract

The metals slices machine bed is a machine manufacturing material inside to have most the representative product, copying the very important position in citizen produce, this Reducer design from biggest, the least turns soon the parameter designs the standard compares of choose to use to turn to really settle soon, wheel number, the wheel gear really settles etc, all strict design according to the request, Checking various designs data made sure the lord spreads to move the system construction and turn soon diagram, diametric calculation in each stalk with they just the school of a strength, the wheel of the wheel gear number, the mold counts to spread the design that move the chain with the lord, from but made sure the big construction of the principal axis box, rom but draw the assemble diagram to see the diagram with each direction. Finally, all parts of the design of the overall design of a milling machine graphics, carbon block for milling machine to complete the full design.

Through the graduated design that my four years of university knowledge has been made to further consolidate and enhance the same time, it also reinforced its own analysis and problem-solving ability, thus better for the future work and study to lay a solid foundation.

Keywords : Reducer; Positioning; Fixture;Milling machine;

目 录

第一篇 产品分析及方案确定 1

第一章 绪论 1

第二章 动力箱设计 3

第一节 分析产品 3

第二节 加工方法 3

第三节 参数确定 4

(一)铣削要素 4

(二)选用电机 5

(三)减速器设计 6

(四)齿轮的设计与校核 7

(五)主传动系统图 22

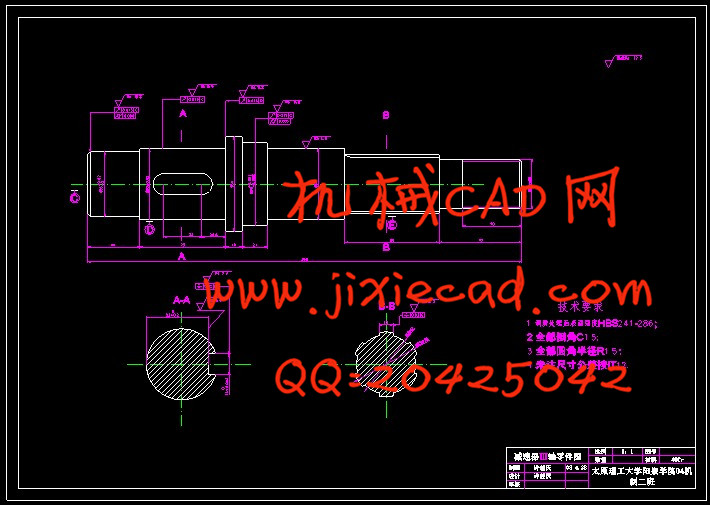

(六)轴的设计与校核 22

(七)带轮参数的设计 31

(八)箱体的总体设计 33

第二篇 铣床附件的设计 34

第一章 铣床夹具的设计 34

第一节 铣床夹具的功能 34

第二节 专用夹具的设计 35

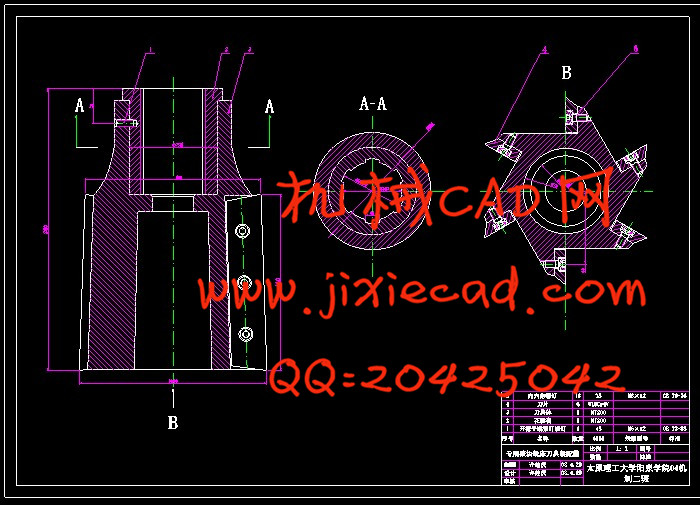

第二章 刀具的设计 36

第三章 机床附件 37

第一节 导轨的选用 37

第二节 滑台的选用 37

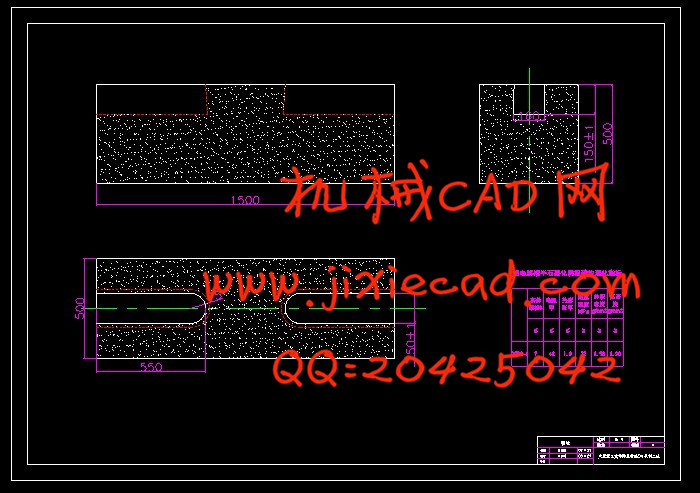

第三节 床身立柱的设计 38

第四节 排屑 38

第五节 油漆 38

结 论 38

参考文献 40

中英文翻译 41

金属切削机床是机械制造装备中最具代表性的产品,在国民生产中占据十分重要的位置。本次设计说明书主要设计了铣床的结构,其中减速器设计从电动机的功率确定到最大,最小转速参数的设计,到标准公比的选用和转速的确定,齿数,齿轮的确定等都严格按照要求设计。通过查阅了多种设计资料确定了主传动系统结构,各轴直径的计算和它们的刚度,强度的校核,齿轮的齿数,模数和带轮的设计,从而确定了主轴箱的大体结构,从而绘制出各视图和零件图。最后结合各部分的设计设计出铣床的总体图形,完成碳块专用铣床的全部设计。

通过本次毕业设计,不仅使我在大学四年里所学的知识有了更进一步的巩固与提高,同时也增强了自己查阅资料和独立分析问题与解决问题的能力,为今后更好地工作与学习打下了坚实的基础。

关键词: 减速器; 定位 ; 工装夹具; 铣床;

Carbon block special purpose milling machine design

Abstract

The metals slices machine bed is a machine manufacturing material inside to have most the representative product, copying the very important position in citizen produce, this Reducer design from biggest, the least turns soon the parameter designs the standard compares of choose to use to turn to really settle soon, wheel number, the wheel gear really settles etc, all strict design according to the request, Checking various designs data made sure the lord spreads to move the system construction and turn soon diagram, diametric calculation in each stalk with they just the school of a strength, the wheel of the wheel gear number, the mold counts to spread the design that move the chain with the lord, from but made sure the big construction of the principal axis box, rom but draw the assemble diagram to see the diagram with each direction. Finally, all parts of the design of the overall design of a milling machine graphics, carbon block for milling machine to complete the full design.

Through the graduated design that my four years of university knowledge has been made to further consolidate and enhance the same time, it also reinforced its own analysis and problem-solving ability, thus better for the future work and study to lay a solid foundation.

Keywords : Reducer; Positioning; Fixture;Milling machine;

目 录

第一篇 产品分析及方案确定 1

第一章 绪论 1

第二章 动力箱设计 3

第一节 分析产品 3

第二节 加工方法 3

第三节 参数确定 4

(一)铣削要素 4

(二)选用电机 5

(三)减速器设计 6

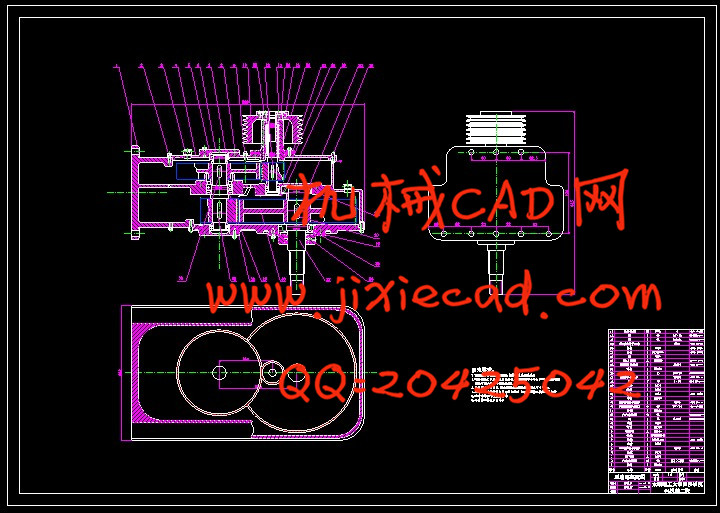

(四)齿轮的设计与校核 7

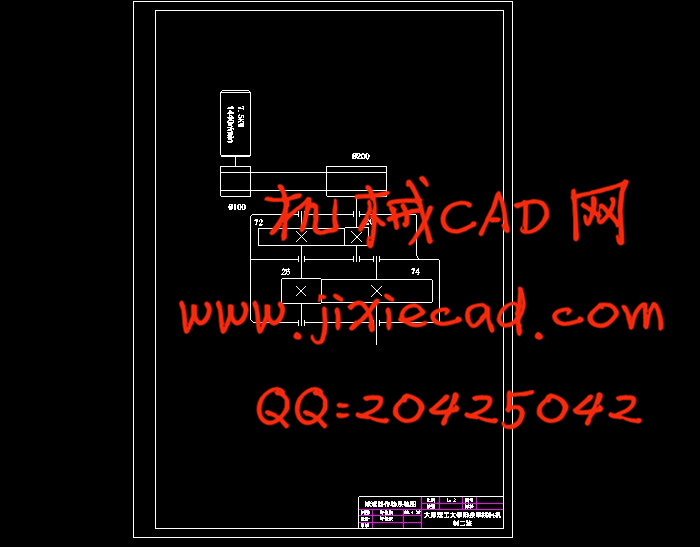

(五)主传动系统图 22

(六)轴的设计与校核 22

(七)带轮参数的设计 31

(八)箱体的总体设计 33

第二篇 铣床附件的设计 34

第一章 铣床夹具的设计 34

第一节 铣床夹具的功能 34

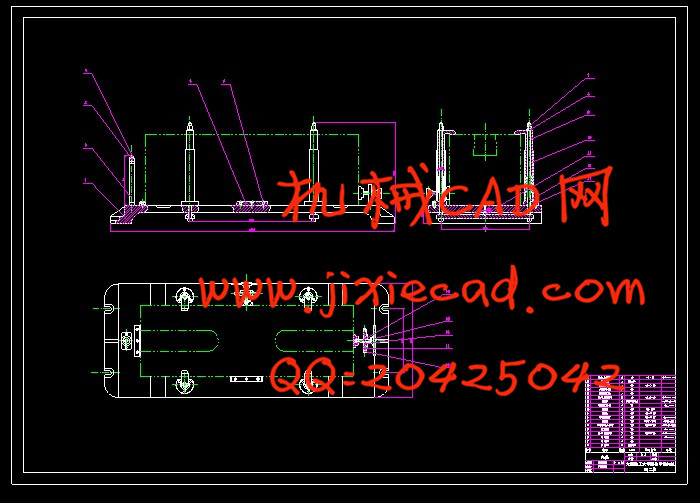

第二节 专用夹具的设计 35

第二章 刀具的设计 36

第三章 机床附件 37

第一节 导轨的选用 37

第二节 滑台的选用 37

第三节 床身立柱的设计 38

第四节 排屑 38

第五节 油漆 38

结 论 38

参考文献 40

中英文翻译 41