设计简介

摘 要

高效率、高精度加工是今后时代发展的趋向,利用自动化设备加工的产品质量一致性较好,加工精度和效率均比普通设备高出很多。自动上料系统是PC陶瓷磨床提高效率的必要改进项目,随着科技的发展,我们的生产效率满足不了生产效益的要求,所以在今后的发展中往半自动化和全自动化发展。本文在查阅大量资料的基础上,对现有的自动化设备做了深入分析,结合其他自动化上料项目改造的经验,设计了一套PC陶瓷磨床的自动上料结构,设计内容如下:

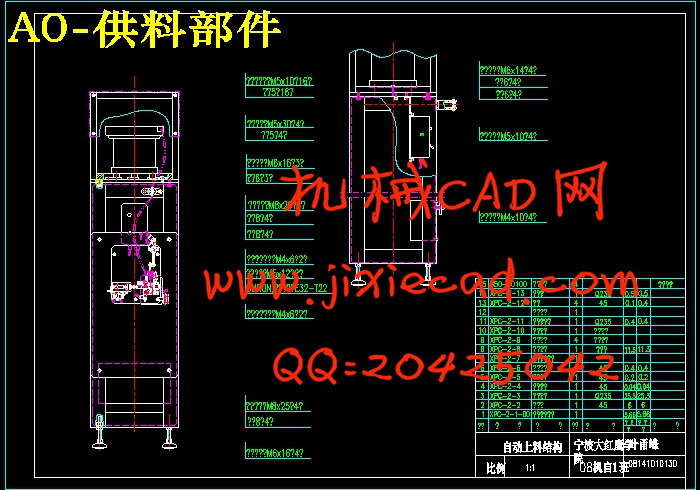

(1)::总体设计,对自动上料的组成,有关数据的计算,主要技术以及总体设计的分析。

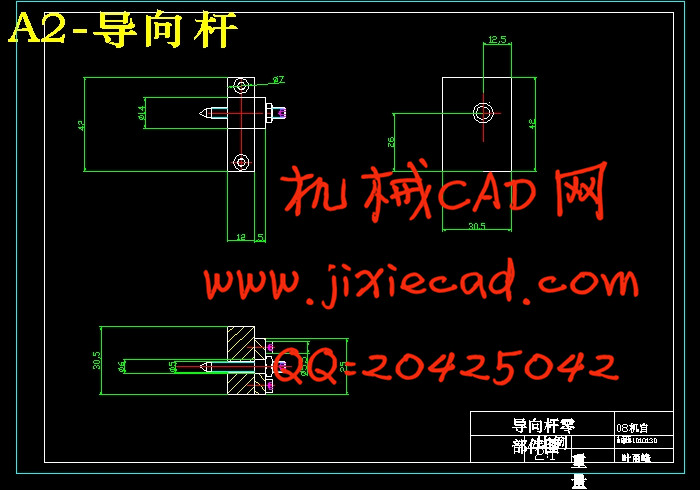

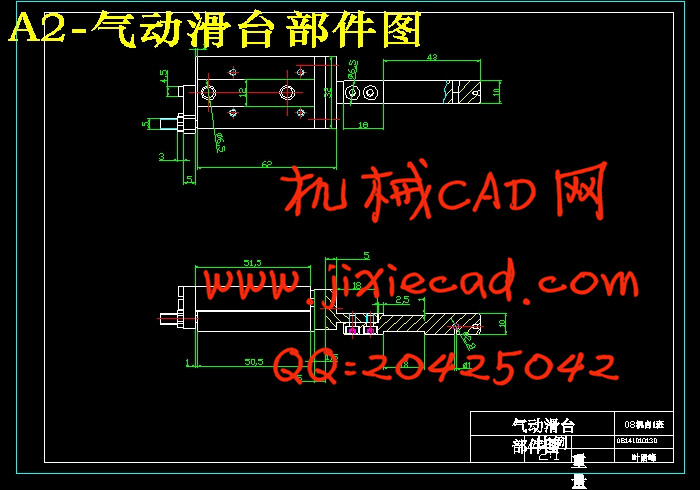

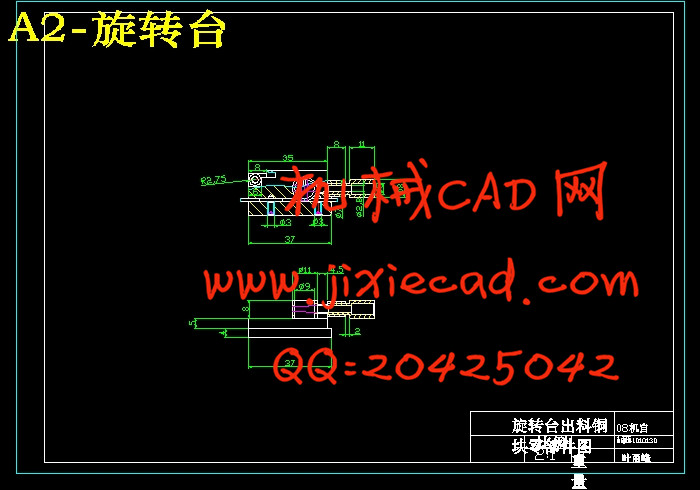

(2):传送系统的设计,以及振动料斗,气缸的选择和位移传感器的选择。

(3):完成机械结构的装配。

在振动料斗选择和传感器选择上,查阅了相当多的资料和数据,选择了一款高效高精度的。

通过本文的研究,基本解决了PC磨床自动上料结构设计过程中的主要问题,为后续的开发和生产提供了了理论基础,也为自动化上料的发展提供了一个方向。

关键词:自动化设计,上料结构,传送系统,传感器设计

Abstract

The High efficiency, high precision machining is the trend of the development of times, use automation equipment processing products quality consistency is better, the processing precision and efficiency are much higher than normal equipment。Automatic feeding system is one of the PC ceramic grinding machine efficiency necessary improvement project, with the development of science and technology, our production efficiency can't satisfy the production benefit demand, so in the future development to half the automation of automation and development..Based on consulting a large number of data, on the basis of the existing automation equipment to do the thorough analysis, combined with other automatic feeding project reform experience, designed a set of ceramic grinding machine of PC automatic feeding structure, design content as follows::

(1) :General design of automatic feeding the composition of the relevant data are calculated, the main technology and the analysis of the overall design.

(2) Teleport in the design of the system, and vibration hopper, the choice of the cylinder and displacement sensor selection.

(3) :Complete mechanical structure of the assembly.

The research in this paper to solve the basic PC grinder automatic feeding the main problems in the process of structural design, development and production of for the follow-up provide theory basis of it, but also for automation feeding development provides a direction

Automation design feeding structures to transmit system sensor design

Key Words: Automation design ,feeding,structures to transmit system,sensor design

目 录

摘 要 IAbstract II

目 录 III

第1章 绪论 4

第2章.方案的确定 6

2.1零件图分析 6

2.2根据零件图设计对应的机械尺寸 7

2.3对陶瓷插芯PC磨床进行了解 8

2.4对设计图的分析 9

第3章.振动料斗 10

3.1振动料斗的解析 11

3.2振动料斗的原理 12

第4章.气压缸 13

4.1气压缸的传递 13

4.2气压缸链接之间的设计 14

第5章.传感器 15

5.1传感器的应用. 15

总结及展望 17

参考文献 18

致 谢 19