设计简介

摘 要

天然气汽车减压装置是天然气的汽车的一个重要部件,它的质量好坏车的性能有很大的关系,它在天然气汽车中主要起减压和稳压的作用。因此,通过利用减压装置,可以把2-20MPa的压缩天然气压力降到1-2.5kPa进入混合器,以便与空气混合进入汽缸,由于高压气瓶中的CNG气体压力随着燃料充装和使用不断变化,要保持较稳定的空燃比控制,还要求无论瓶内压力如何变化,减压调节器也应保证进入混合器的燃气压力基本恒定,以此实现比较稳定的燃气与空气混合比控制。从而实现减压和稳压的作用。

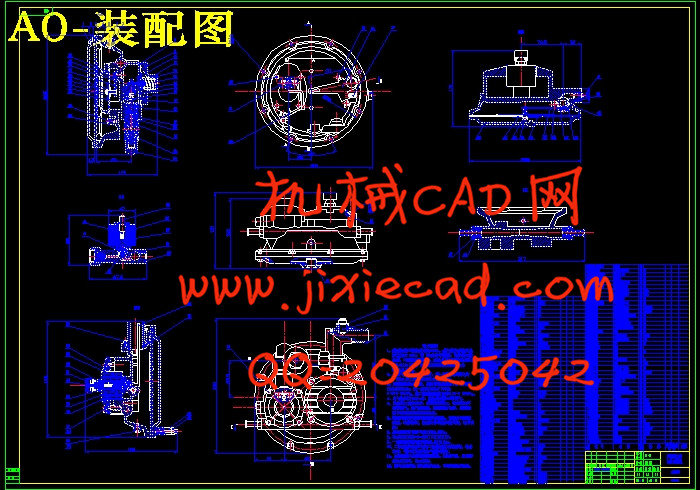

本次毕业设计在原有减压产品的基础上,对其结构布局及形状进行了修改,并对输入发动机过程中的天然气压力的变化值进行了精确的设计,主要是对一级减压阀的缝隙减压和二级减压阀的缝隙减压,以及三级减压阀利用真空度进行减压进行计算,使其能够满足减压至预期的要求。而且对各主要受载荷的零部件进行了强度校核,使选择的材料满足强度要求。预计本次设计出来的减压装置具有结构简单,外行美观,精度高的特点,可提高同类产品的质量,可以满足广大用户的需求。

关键词:天然气汽车;减压装置;减压阀

ABSTRACT

The natural gas automobile decompressor is a natural gas automobile important part, its quality quality vehicle performance has the very big relations, it is main the reduced pressure in the natural gas automobile and the constant voltage function. Therefore, through use decompressor, may 1-20MPa compression natural gas pressure drop to 1-2.5kPa enters the mixer, in order to enters the cylinder with the air mix, because in the high-pressure bottle CNG gas pressure changes, must maintain the stable air-fuel ratio control, also requests regardless of how the bottle internal pressure does change, the reduced pressure regulator also should guarantee enters the mixer basically the fuel gas pressure constant, by this realization quite stable fuel gas and air mixture ratio control. Thus realization reduced pressure and constant voltage function.

This graduation project in original reduced pressure product foundation, have carried on the revision to its structural configuration and the shape, and to input in the engine process the natural gas pressure change value to carry on the precise design, mainly is to the level pressure relief valve slit reduced pressure and two level of pressure relief valve slit reduced pressure, as well as three levels of pressure relief valves carry on the reduced pressure using the vacuum degree to carry on the computation, enables its to satisfy the reduced pressure to the anticipated request. Moreover to each mainly has been carried on the load spare part the intensity examination, causes the choice the material to satisfy the intensity request. Estimated this time designs the decompressor has the structure simply, the layman is artistic, precision high characteristic, may enhance the similar product the quality, May satisfy the user community the demand.

Key words: Natural gas automobile; decompressor; pressure relief valve

天然气汽车减压装置是天然气的汽车的一个重要部件,它的质量好坏车的性能有很大的关系,它在天然气汽车中主要起减压和稳压的作用。因此,通过利用减压装置,可以把2-20MPa的压缩天然气压力降到1-2.5kPa进入混合器,以便与空气混合进入汽缸,由于高压气瓶中的CNG气体压力随着燃料充装和使用不断变化,要保持较稳定的空燃比控制,还要求无论瓶内压力如何变化,减压调节器也应保证进入混合器的燃气压力基本恒定,以此实现比较稳定的燃气与空气混合比控制。从而实现减压和稳压的作用。

本次毕业设计在原有减压产品的基础上,对其结构布局及形状进行了修改,并对输入发动机过程中的天然气压力的变化值进行了精确的设计,主要是对一级减压阀的缝隙减压和二级减压阀的缝隙减压,以及三级减压阀利用真空度进行减压进行计算,使其能够满足减压至预期的要求。而且对各主要受载荷的零部件进行了强度校核,使选择的材料满足强度要求。预计本次设计出来的减压装置具有结构简单,外行美观,精度高的特点,可提高同类产品的质量,可以满足广大用户的需求。

关键词:天然气汽车;减压装置;减压阀

ABSTRACT

The natural gas automobile decompressor is a natural gas automobile important part, its quality quality vehicle performance has the very big relations, it is main the reduced pressure in the natural gas automobile and the constant voltage function. Therefore, through use decompressor, may 1-20MPa compression natural gas pressure drop to 1-2.5kPa enters the mixer, in order to enters the cylinder with the air mix, because in the high-pressure bottle CNG gas pressure changes, must maintain the stable air-fuel ratio control, also requests regardless of how the bottle internal pressure does change, the reduced pressure regulator also should guarantee enters the mixer basically the fuel gas pressure constant, by this realization quite stable fuel gas and air mixture ratio control. Thus realization reduced pressure and constant voltage function.

This graduation project in original reduced pressure product foundation, have carried on the revision to its structural configuration and the shape, and to input in the engine process the natural gas pressure change value to carry on the precise design, mainly is to the level pressure relief valve slit reduced pressure and two level of pressure relief valve slit reduced pressure, as well as three levels of pressure relief valves carry on the reduced pressure using the vacuum degree to carry on the computation, enables its to satisfy the reduced pressure to the anticipated request. Moreover to each mainly has been carried on the load spare part the intensity examination, causes the choice the material to satisfy the intensity request. Estimated this time designs the decompressor has the structure simply, the layman is artistic, precision high characteristic, may enhance the similar product the quality, May satisfy the user community the demand.

Key words: Natural gas automobile; decompressor; pressure relief valve

目 录

摘要 .................................................................І

ABSTRACT..........................................................П

绪论 .................................................................1

0.1天然气汽车减压装置的用途和功能 1

0.2天然气汽车减压装置在我国的发展概况 1

0.3天然气汽车减压装置设计的目的和意义 1

1 设计任务书 .........................................................3

1.1设计题目 3

1.2题目说明 3

1.2.1设计参数规范 3

1.2.2符合标准 3

1.2.3设计思路 3

1.3设计方案 3

1.4资料调研 4

1.4.1减压阀的定义 4

1.4.2减压阀的工作原理 4

1.4.3减压阀的工作过程 7

2 设计方案的研究与选择............................................. 9

2.1减压调节器的分类 9

2.2方案选择 9

2.2.1方案一及其优缺点 9

2.2.2方案二及其优缺点 9

2.2.3 设计方案的选择 10

3 总体方案设计 ......................................................11

3.1一级减压阀的设计 11

3.1.1一级减压阀的工作原理 11

3.1.2一级减压阀阀室的设计 11

3.1.3一级减压阀杠杆、弹簧与阀口的设计 11

3.2二级减压阀的设计 19

3.2.1二级减压阀的工作原理 19

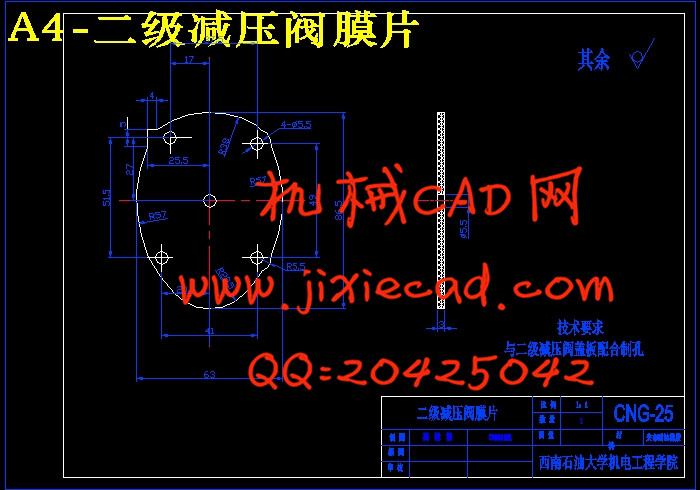

3.2.2二级减压阀阀室及盖板、杠杆、上档板的设计 19

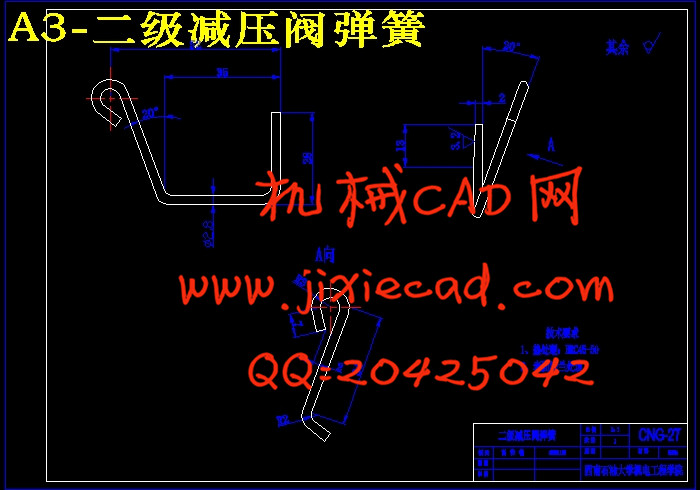

3.2.3二级减压阀弹簧的设计 19

3.3三级减压阀的设计 22

3.3.1三级减压阀的工作原理 22

3.3.2三级减压阀盖板、杠杆、上挡板、阀口的设计 22

3.3.3三级减压阀调节弹簧的设计 22

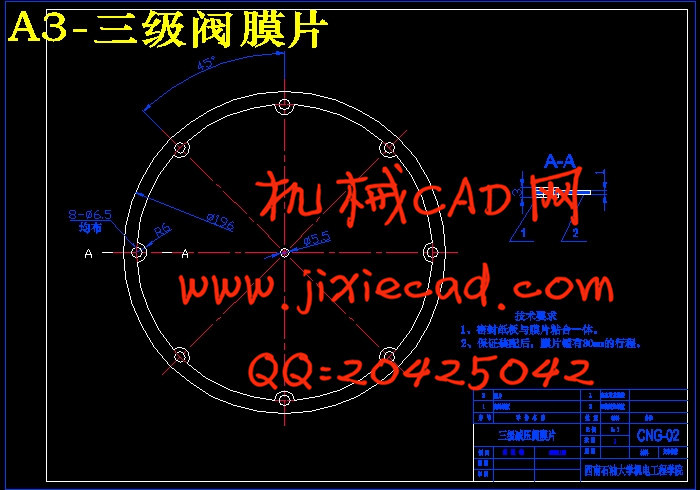

3.3.4 三级减压阀膜片的设计与校核 25

3.4怠速阀的设计 26

3.4.1怠速阀的工作原理 26

3.4.2怠速阀阀室及阀体的设计 26

3.4.3怠速阀芯及怠速阀弹簧的设计 28

3.5其他重要零部件的设计 29

3.5.1高压电磁阀阀芯、先导阀、弹簧的设计 29

3.5.2安全阀及其弹簧的设计 30

3.5.3进气接头的设计 31

3.5.4一级阀盖连结螺柱和三级阀盖连结螺栓的选择 32

4 天然气汽车减压装置的使用说明 ......................................35

4.1天然气汽车减压装置的使用注意事项 35

4.2天然气汽车减压装置的拆装、检查与调整 35

4.2.1拆卸 35

4.2.2清洗、检查、更换 35

4.2.3组装、调整 36

5 总结 ..............................................................38

谢辞 39

参考文献............................................................40

摘要 .................................................................І

ABSTRACT..........................................................П

绪论 .................................................................1

0.1天然气汽车减压装置的用途和功能 1

0.2天然气汽车减压装置在我国的发展概况 1

0.3天然气汽车减压装置设计的目的和意义 1

1 设计任务书 .........................................................3

1.1设计题目 3

1.2题目说明 3

1.2.1设计参数规范 3

1.2.2符合标准 3

1.2.3设计思路 3

1.3设计方案 3

1.4资料调研 4

1.4.1减压阀的定义 4

1.4.2减压阀的工作原理 4

1.4.3减压阀的工作过程 7

2 设计方案的研究与选择............................................. 9

2.1减压调节器的分类 9

2.2方案选择 9

2.2.1方案一及其优缺点 9

2.2.2方案二及其优缺点 9

2.2.3 设计方案的选择 10

3 总体方案设计 ......................................................11

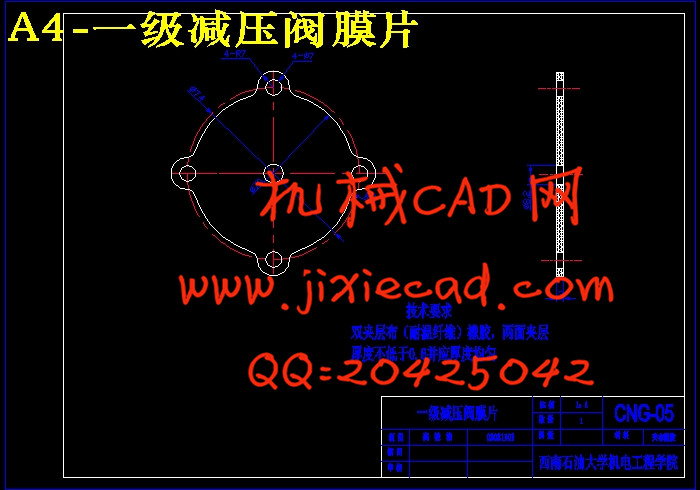

3.1一级减压阀的设计 11

3.1.1一级减压阀的工作原理 11

3.1.2一级减压阀阀室的设计 11

3.1.3一级减压阀杠杆、弹簧与阀口的设计 11

3.2二级减压阀的设计 19

3.2.1二级减压阀的工作原理 19

3.2.2二级减压阀阀室及盖板、杠杆、上档板的设计 19

3.2.3二级减压阀弹簧的设计 19

3.3三级减压阀的设计 22

3.3.1三级减压阀的工作原理 22

3.3.2三级减压阀盖板、杠杆、上挡板、阀口的设计 22

3.3.3三级减压阀调节弹簧的设计 22

3.3.4 三级减压阀膜片的设计与校核 25

3.4怠速阀的设计 26

3.4.1怠速阀的工作原理 26

3.4.2怠速阀阀室及阀体的设计 26

3.4.3怠速阀芯及怠速阀弹簧的设计 28

3.5其他重要零部件的设计 29

3.5.1高压电磁阀阀芯、先导阀、弹簧的设计 29

3.5.2安全阀及其弹簧的设计 30

3.5.3进气接头的设计 31

3.5.4一级阀盖连结螺柱和三级阀盖连结螺栓的选择 32

4 天然气汽车减压装置的使用说明 ......................................35

4.1天然气汽车减压装置的使用注意事项 35

4.2天然气汽车减压装置的拆装、检查与调整 35

4.2.1拆卸 35

4.2.2清洗、检查、更换 35

4.2.3组装、调整 36

5 总结 ..............................................................38

谢辞 39

参考文献............................................................40