设计简介

筒仓成型机设计

摘 要

近些年,随着国民经济的发展和人民生活水平的不断提高,食用粮食费持续增长。粮食作为主要的物质原料,储存安全的重要性不言而喻。那么,储仓建设能否满足需要,储仓的适用性、经济性、储存的安全性、生产的自动化程度等能否适应新的要求?这些都成为我国粮食主管部门和相关建设单位需要仔细考虑并加以解决的问题。为此,我们需要对粮食储仓工艺及设备的选型进行梳理、探讨。本文重点从粮食储藏的角度探讨了粮食钢板筒仓的发展历程、应用现状、类型特点和工艺设备配备情况。简述了我国钢板筒仓的应用发展概况,分析了钢板筒仓的类型、制造过程和各自的优缺点。介绍了筒仓的储粮特性,并对钢板筒仓的工艺设计及配套设备进行了探讨。

关键词:钢板;筒仓;类型;结构;储粮特性

Abstract

In recent years, with the development of national economy and people's living standards continue to improve, the consumption of food costs continue to grow. Food as the main raw materials of substance, the importance of safe storage. Storage building can meet the need, store the suitability of economic security, production, storage, degree of automation, whether to meet the new requirements? These have become China's grain departments and construction units need to carefully consider and solve the problem. To this end, we need to sort out the food storage warehouse process and the selection of equipment to explore. This article focuses explored from the perspective of grain storage, grain steel silos course of development, application status, types, characteristics, and process equipment with the situation. Overview of China's steel silos of application development, analysis of the type of steel silos, manufacturing processes and their advantages and disadvantages. The silo grain storage characteristics, and process design of steel silos and ancillary equipment were discussed.

Keywords: steel plate; silo; type; structure; grain storage features

目 录

1 绪论....................................................................1

1.1我国粮食钢板筒仓的应用发展状况......................................1

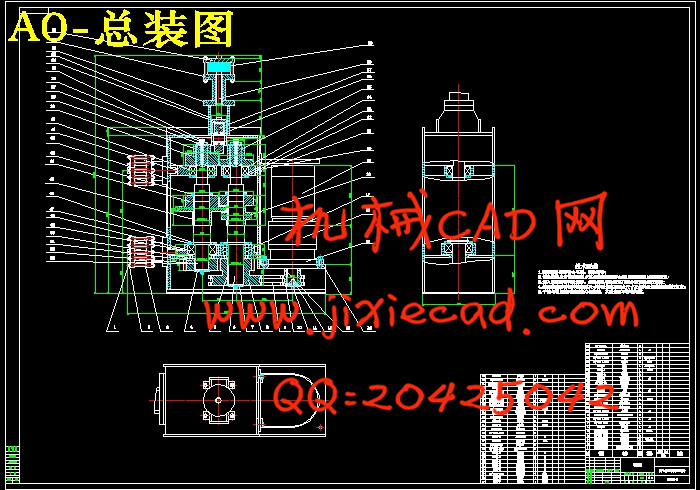

1.2钢板筒仓的类型......................................................2

1.2.1粮食螺旋钢板筒仓..............................................2

1.2.2螺栓装配式镀锌波纹板钢板筒仓..................................2

1.2.3焊接仓........................................................2

1.3钢板筒仓的结构组成和储粮特性........................................3

1.3.1结构组成 .....................................................3

1.3.1储量特性......................................................3

1.4钢板筒仓的使用寿命..................................................3

1.5钢板筒仓所用的材料..................................................4

1.6钢板筒仓完善的技术..................................................4

1.7钢板筒仓工艺布置及配套工艺设备......................................4

1.8钢板筒仓的优点......................................................5

2 筒仓成型机的工艺设计....................................................5

2.1几何尺寸............................................................6

2.2工艺过程............................................................6

3 弯曲力计算..............................................................8

4 电动机的选择与计算......................................................9

4.1电动机的类型选择....................................................9

4.2电动机功率的选择....................................................9

4.2.1工作机所需要功率的计算.........................................9

4.2.2确定电动机的额定功率..........................................9

4.2.3确定电动机的转速.............................................10

5 传动装置的功率参数计算.................................................10

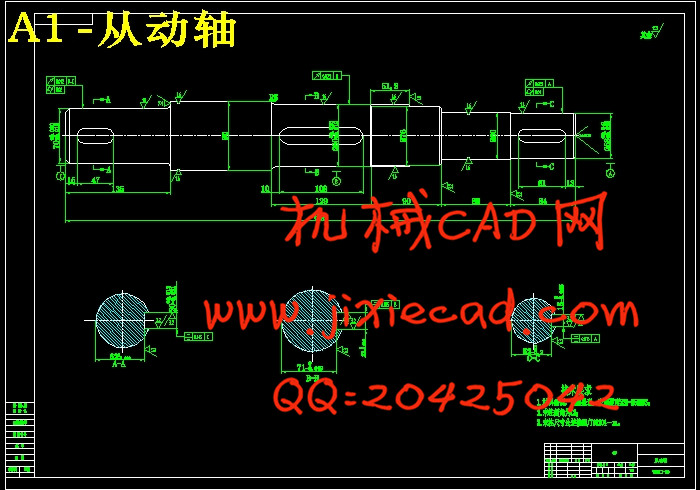

6 轴的设计和计算.........................................................11

6.1轴的结构设计.......................................................11

6.2确定各轴段的尺寸...................................................12

6.2.1轴的直径的计算...............................................12

6.2.2各轴端直径. .................................................12

6.2.3各轴段的长度.................................................13

6.3轴的强度校核..................................................... .13

7 齿轮的设计.............................................................17

7.1齿轮转动比的选择...................................................17

7.2齿面强度计算.......................................................17

7.3齿轮的参数.........................................................18

7.4齿轮的校核.........................................................19

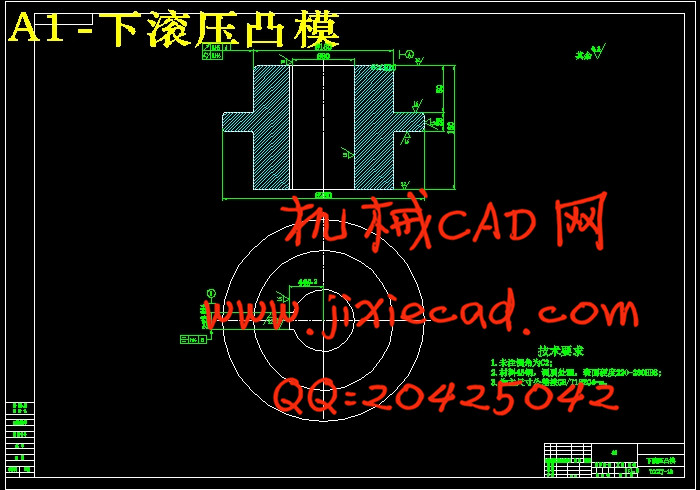

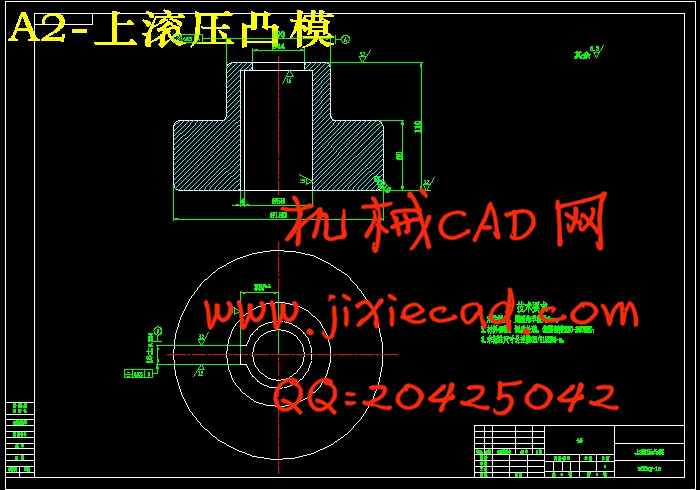

8 上滚压凸模设计.........................................................19

9 键的选择及校核.........................................................20

9.1键的选择...........................................................20

9.2校核键选择的强度...................................................20

10 轴承的设计............................................................21

11 结构设计..............................................................21

结论.....................................................................23

致谢.....................................................................24

参考文献.................................................................25

摘 要

近些年,随着国民经济的发展和人民生活水平的不断提高,食用粮食费持续增长。粮食作为主要的物质原料,储存安全的重要性不言而喻。那么,储仓建设能否满足需要,储仓的适用性、经济性、储存的安全性、生产的自动化程度等能否适应新的要求?这些都成为我国粮食主管部门和相关建设单位需要仔细考虑并加以解决的问题。为此,我们需要对粮食储仓工艺及设备的选型进行梳理、探讨。本文重点从粮食储藏的角度探讨了粮食钢板筒仓的发展历程、应用现状、类型特点和工艺设备配备情况。简述了我国钢板筒仓的应用发展概况,分析了钢板筒仓的类型、制造过程和各自的优缺点。介绍了筒仓的储粮特性,并对钢板筒仓的工艺设计及配套设备进行了探讨。

关键词:钢板;筒仓;类型;结构;储粮特性

Abstract

In recent years, with the development of national economy and people's living standards continue to improve, the consumption of food costs continue to grow. Food as the main raw materials of substance, the importance of safe storage. Storage building can meet the need, store the suitability of economic security, production, storage, degree of automation, whether to meet the new requirements? These have become China's grain departments and construction units need to carefully consider and solve the problem. To this end, we need to sort out the food storage warehouse process and the selection of equipment to explore. This article focuses explored from the perspective of grain storage, grain steel silos course of development, application status, types, characteristics, and process equipment with the situation. Overview of China's steel silos of application development, analysis of the type of steel silos, manufacturing processes and their advantages and disadvantages. The silo grain storage characteristics, and process design of steel silos and ancillary equipment were discussed.

Keywords: steel plate; silo; type; structure; grain storage features

目 录

1 绪论....................................................................1

1.1我国粮食钢板筒仓的应用发展状况......................................1

1.2钢板筒仓的类型......................................................2

1.2.1粮食螺旋钢板筒仓..............................................2

1.2.2螺栓装配式镀锌波纹板钢板筒仓..................................2

1.2.3焊接仓........................................................2

1.3钢板筒仓的结构组成和储粮特性........................................3

1.3.1结构组成 .....................................................3

1.3.1储量特性......................................................3

1.4钢板筒仓的使用寿命..................................................3

1.5钢板筒仓所用的材料..................................................4

1.6钢板筒仓完善的技术..................................................4

1.7钢板筒仓工艺布置及配套工艺设备......................................4

1.8钢板筒仓的优点......................................................5

2 筒仓成型机的工艺设计....................................................5

2.1几何尺寸............................................................6

2.2工艺过程............................................................6

3 弯曲力计算..............................................................8

4 电动机的选择与计算......................................................9

4.1电动机的类型选择....................................................9

4.2电动机功率的选择....................................................9

4.2.1工作机所需要功率的计算.........................................9

4.2.2确定电动机的额定功率..........................................9

4.2.3确定电动机的转速.............................................10

5 传动装置的功率参数计算.................................................10

6 轴的设计和计算.........................................................11

6.1轴的结构设计.......................................................11

6.2确定各轴段的尺寸...................................................12

6.2.1轴的直径的计算...............................................12

6.2.2各轴端直径. .................................................12

6.2.3各轴段的长度.................................................13

6.3轴的强度校核..................................................... .13

7 齿轮的设计.............................................................17

7.1齿轮转动比的选择...................................................17

7.2齿面强度计算.......................................................17

7.3齿轮的参数.........................................................18

7.4齿轮的校核.........................................................19

8 上滚压凸模设计.........................................................19

9 键的选择及校核.........................................................20

9.1键的选择...........................................................20

9.2校核键选择的强度...................................................20

10 轴承的设计............................................................21

11 结构设计..............................................................21

结论.....................................................................23

致谢.....................................................................24

参考文献.................................................................25