设计简介

万能材料试验机

摘 要:试验机是在各种条件、环境下测定金属材料、非金属材料、机械零件、工程结构等的机械性能、工艺性能、内部缺陷和校验旋转零部件动态不平衡量的精密测试仪器,可以对材料进行拉伸、压缩、弯曲、剪切、扭转、冲击、疲劳、蠕变、持久、松弛、磨损、硬度等试验。近年来,试验机行业技术突飞猛进。试验机向着两个方向即超微外力检测与超大外力检测发展。高检测精度、高灵敏度、运动平稳、易于操纵是目前试验机的主要发展方向。

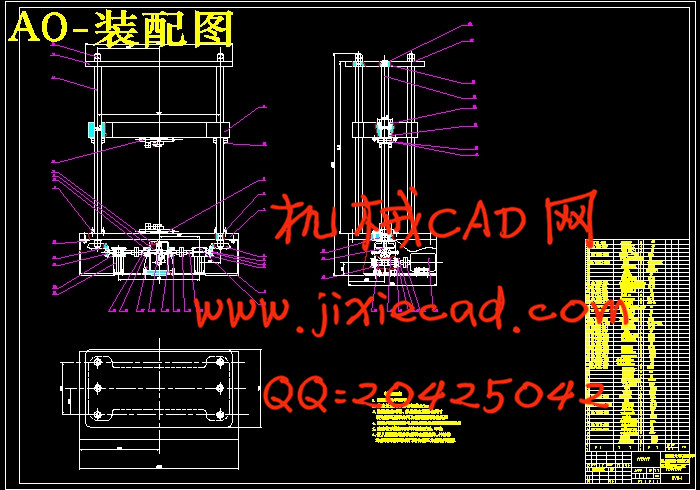

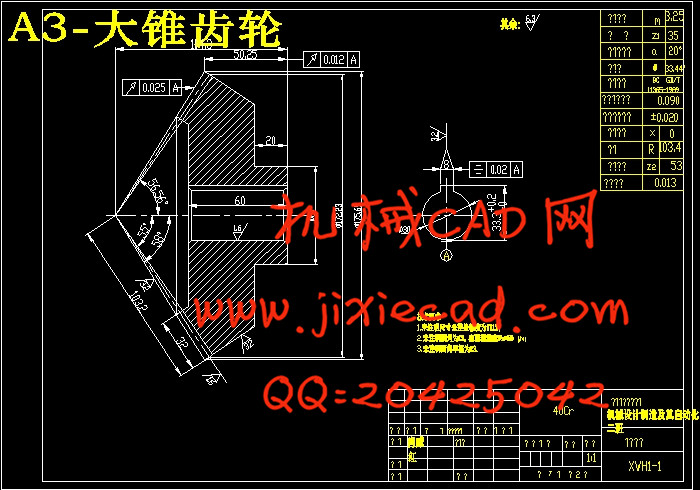

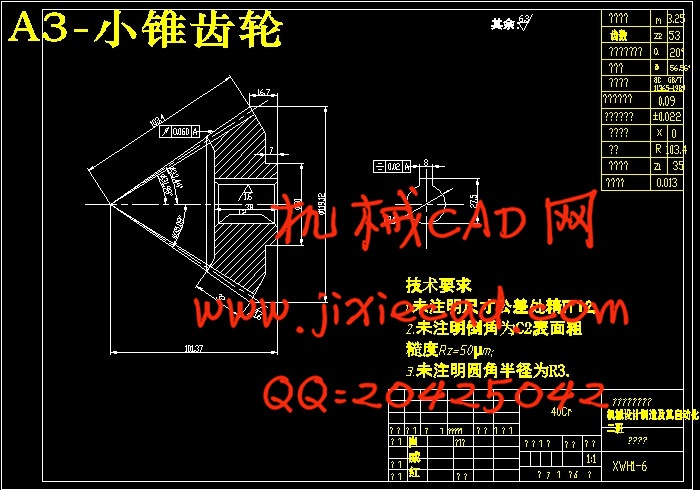

本文首先概述了试验机的基本定义、分类与国内外一些重要生产商的成果。第二部分论述了所想到的四种方案并对这些方案优缺点作了分析和对比。前三种方案均为利用滚珠丝杠,最后一种则利用液压。在彼此比较后决定选第一种方案。第三部分则是说明了试验机的主要机械传动部分的设计以及对它们的校核过程。试验机的传动部分主要由蜗轮蜗杆、锥齿轮、滚珠丝杠三部分组成。经过校核后所有设计均符合要求。用ProE软件完成试验机的三维总装图,然后得到了整个试验机的二维装配图和蜗轮蜗杆、锥齿轮、轴等二维零件图。在文章的最后简明的介绍了做本次毕业设计的一些心得体会。

关键词: 试验机;蜗轮蜗杆;锥齿轮;滚珠丝杆;ProE

Universal testing machine

ABSTRACT:Test machine in various conditions and environment in metal materials, non-metallic materials, machinery accessory, engineering structures such as mechanical properties, technics performance, Internal defects and checking dynamic imbalance rotating parts of sophisticated testing equipment, such as materials tension, compression, bending, shear, reversing, impact, fatigue, creep, lasting and relaxation, wear, hardness tests. In recent years,the technic of the test machine industry advances rapidly. Test machine is the direction toward the development of the super-tiny force detection and the development of super-large external force testing. Detection of high-precision, high sensitivity, smooth motion, easily operated test machine is the main development direction presently.

This paper first summarizes the test machine's basic definition, classification, and some important domestic and foreign manufacturers results. The second part, discussing about the experiences of the four projects as well as advantages and disadvantages of these projects are analyzed and compared . The foregoing three programs are the use of ball screw, the last one is using the hydraulic pressure. In comparison with each other decide the first option. The third part is the experiment, the major part of the mechanical drive design and the process of checking them. The main drive system of the test machine includes the worm,taper gear, ball screw three components. After checking all the design had complied with the request. The three-dimensional assembly drawings of the test machine are finished by the soft called PROE.Then,export the planar drawings,such as worm gear&worm,taper gear,shaft and so on. In the end concisely introduce the meeting and what had learned in the graduate design experiences.

Keywords:Test Machine, Worm Gear & Worm,Taper Gear,Ball Screws ,Proe

目录

摘 要1

第一章 概述 3

1.1材料试验机概述 3

第二章 设计方案 10

2.1方案简述 10

2.1.1方案一 10

2.1.2方案二 10

2.1.3方案三 11

2.1.4方案四 12

2.2各种方案比较 12

第三章 设计中有关计算 14

3.1电动机的选择 14

3.2传动装置总传动比的计算及其分配 14

3.3蜗轮蜗杆传动系统的设计与校核 15

3.4锥齿轮的传动设计 19

3.5传动轴的设计与校核 26

3.5.1计算蜗轮传动轴 26

3.5.2 锥齿轮传动轴 28

3.6滚珠丝杠传动的设计与校核 29

3.6.1工作压强计算 30

3.6.2静载荷计算 31

3.6.3螺杆强度 31

3.6.4寿命计算 31

结论 35

致谢 36

参考文献 37

摘 要:试验机是在各种条件、环境下测定金属材料、非金属材料、机械零件、工程结构等的机械性能、工艺性能、内部缺陷和校验旋转零部件动态不平衡量的精密测试仪器,可以对材料进行拉伸、压缩、弯曲、剪切、扭转、冲击、疲劳、蠕变、持久、松弛、磨损、硬度等试验。近年来,试验机行业技术突飞猛进。试验机向着两个方向即超微外力检测与超大外力检测发展。高检测精度、高灵敏度、运动平稳、易于操纵是目前试验机的主要发展方向。

本文首先概述了试验机的基本定义、分类与国内外一些重要生产商的成果。第二部分论述了所想到的四种方案并对这些方案优缺点作了分析和对比。前三种方案均为利用滚珠丝杠,最后一种则利用液压。在彼此比较后决定选第一种方案。第三部分则是说明了试验机的主要机械传动部分的设计以及对它们的校核过程。试验机的传动部分主要由蜗轮蜗杆、锥齿轮、滚珠丝杠三部分组成。经过校核后所有设计均符合要求。用ProE软件完成试验机的三维总装图,然后得到了整个试验机的二维装配图和蜗轮蜗杆、锥齿轮、轴等二维零件图。在文章的最后简明的介绍了做本次毕业设计的一些心得体会。

关键词: 试验机;蜗轮蜗杆;锥齿轮;滚珠丝杆;ProE

Universal testing machine

ABSTRACT:Test machine in various conditions and environment in metal materials, non-metallic materials, machinery accessory, engineering structures such as mechanical properties, technics performance, Internal defects and checking dynamic imbalance rotating parts of sophisticated testing equipment, such as materials tension, compression, bending, shear, reversing, impact, fatigue, creep, lasting and relaxation, wear, hardness tests. In recent years,the technic of the test machine industry advances rapidly. Test machine is the direction toward the development of the super-tiny force detection and the development of super-large external force testing. Detection of high-precision, high sensitivity, smooth motion, easily operated test machine is the main development direction presently.

This paper first summarizes the test machine's basic definition, classification, and some important domestic and foreign manufacturers results. The second part, discussing about the experiences of the four projects as well as advantages and disadvantages of these projects are analyzed and compared . The foregoing three programs are the use of ball screw, the last one is using the hydraulic pressure. In comparison with each other decide the first option. The third part is the experiment, the major part of the mechanical drive design and the process of checking them. The main drive system of the test machine includes the worm,taper gear, ball screw three components. After checking all the design had complied with the request. The three-dimensional assembly drawings of the test machine are finished by the soft called PROE.Then,export the planar drawings,such as worm gear&worm,taper gear,shaft and so on. In the end concisely introduce the meeting and what had learned in the graduate design experiences.

Keywords:Test Machine, Worm Gear & Worm,Taper Gear,Ball Screws ,Proe

目录

摘 要1

第一章 概述 3

1.1材料试验机概述 3

第二章 设计方案 10

2.1方案简述 10

2.1.1方案一 10

2.1.2方案二 10

2.1.3方案三 11

2.1.4方案四 12

2.2各种方案比较 12

第三章 设计中有关计算 14

3.1电动机的选择 14

3.2传动装置总传动比的计算及其分配 14

3.3蜗轮蜗杆传动系统的设计与校核 15

3.4锥齿轮的传动设计 19

3.5传动轴的设计与校核 26

3.5.1计算蜗轮传动轴 26

3.5.2 锥齿轮传动轴 28

3.6滚珠丝杠传动的设计与校核 29

3.6.1工作压强计算 30

3.6.2静载荷计算 31

3.6.3螺杆强度 31

3.6.4寿命计算 31

结论 35

致谢 36

参考文献 37