设计简介

摘 要

具有一定规则截面形状的阵列微凹坑结构,可以有效改善润滑和抗磨效果,目前成熟的微凹坑加工方法极少。本文介绍了摩擦副表面微凹坑结构的研究及其应用现状,提出了采用微细超声复合加工新技术加工微凹坑的构想,进而提出本文研究工作内容。分析微细超声加工、微细电解加工原理、特点以及工艺特性,探讨超声振动对脉冲放电及微细电解过程的改善作用机理,分析在加工微凹坑时微细电解复合超声振动的必要性和技术优势,构建、完善超声电解复合加工试验系统。

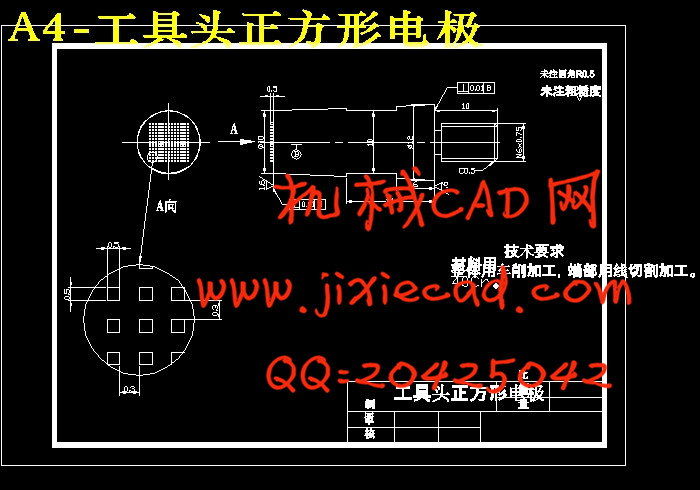

根据微凹坑超声复合加工的特点,选择工作液、工具电极振动频率及振幅、进给压力等加工参数,制定微凹坑超声复合加工试验方案。使用不同形状工具电极,对硬质合金YT15和YG8、不锈钢、单晶硅、压电陶瓷、玻璃钢等材料进行了微凹坑单一超声加工试验及分析;对硬质合金YT15和YG8、不锈钢等材料进行微凹坑单一超声加工与超声复合加工的对比试验;重点研究了超声电解复合加工中电解电压参数对微凹坑加工效率、精度、表面质量及微凸起工具电极损耗的影响规律。试验验证了在金属材料表面进行微凹坑超声复合加工的必要性及可行性。

关键词:微凹坑,超声复合加工,微凸起工具电极

Abstract

The array micro-pits with regular profiles can modify surface tribology character, improve lubrication and wear-resisting. As the manufacturing methods are few, the research and current application situation of micro-pits on working surface between friction pairs are introduced in this paper. Ultrasonic combined micro-machining is proposed as a new technology, and then content and research significance of this paper are confirmed.

Besides,the principle, working characteristic, realization condition and technologic property of USM, EDM and ECM are analyzed. The processing of impulsive discharge and micro-electrochemical can be improved by ultrasonic vibration. Then the mechanism and technical superiority of ultrasonic combined electrical discharge micro-machining are studied, as well as ultrasonic combined electrochemical micro-machining.At last, systems ofultrasonic combined electrical discharge micro-machining and ultrasonic combined electrochemical micro-machining are completed.

Working parameters like working fluid, oscillation frequency of tool electrodes, contact pressure are chosen according to analysing of processing systems, experiment scheme are presented. Single process experiments of ultrasonic machining of micro-pits are carried on cemented carbide(YT15, YG8), stainless steel, monocrystal line silicon, PZT, glass steel with different tool electrodes; contrast tests between single ultrasonic machining and ultrasonic combined machining are carried on kentaniums and stainless steel. Machining efficiency and precision of micro-pits on working surface between friction pairs as well as waster of tool electrodes influenced by electrolysis voltage amplitude and impulse frequency are mainly discussed. The feasibility of the ultrasonic combined micro-machining of micro-pits used in machining kentaniums and stainless steel is confirmed.

Key words: micro-pit, ultrasonic combined machining, micro-protrude

目 录

摘 要 I

Abstract II

第一章 绪论 1

1.1 微凹坑结构的研究及应用背景 1

1.2 本文研究主要内容 1

1.3 本章小结 2

第二章 微细超声复合加工 3

2.1 微细超声加工 3

2.1.1 微细超声加工原理 3

2.1.2 加工特点 5

2.2 微细电解加工 6

2.2.1 微细电解加工原理 6

2.2.2 加工特点 7

2.3 本章小结 8

第三章 微凹坑加工工具——微凸起电极的设计制作 9

3.1 微凹坑设计 9

3.1.1 微凹坑设计原则 9

3.2 微凸起工具电极设计 9

3.3 微凸起工具电极材料选择 12

3.4 微凸起工具电极制作 12

3.5 变幅杆设计与制作 13

3.6 本章小结 15

第四章 微凹坑超声复合加工试验 17

4.1 试验参数选择 17

4.1.1 试验件材料 17

4.1.2 工作液 18

4.1.3 工具电极超声振动频率及振幅 19

4.2 微细超声加工试验 20

4.2.1 阵列圆形微凹坑单一超声加工试验 21

4.2.2 阵列正方形微凹坑单一超声加工试验 21

4.2.3 阵列菱形微凹坑单一超声加工试验 22

4.2.4 试验结果分析 23

4.3 微细超声电解复合加工 24

4.3.1 阵列圆形微凹坑超声电解复合加工试验 25

4.4 本章小结 26

第五章 总结与展望 27

5.1 总结 27

5.2 研究展望 27

参考文献 28

致谢 29