设计简介

带位移电反馈的二级电液比例节流阀设计

摘要:电液比例技术发展迅猛,以其控制精度较高、结构简单、成本合理等优点在工业生产中获得了越来越来广泛的应用,它的发展程度也可从一个侧面反映一个国家液压工业技术水平,因而日益受到各国工业界的重视。

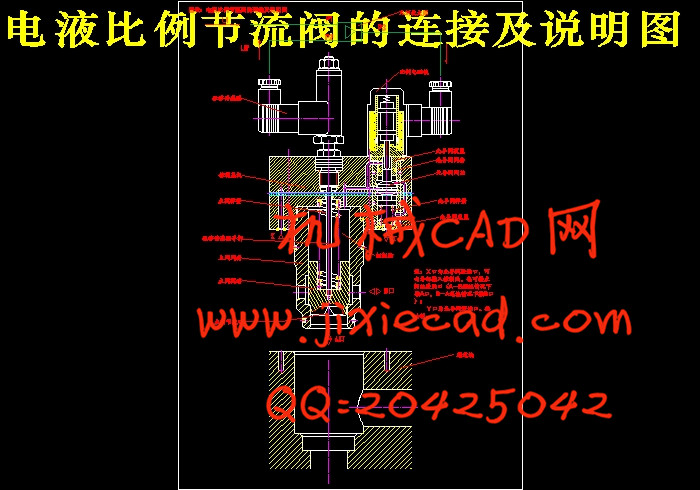

本设计的课题是电液比例阀中的一类——二级电液比例节流阀。在对该阀各部分的结构、原理及性能参数进行详细分析的基础上,完成了功率级为二通插装阀,先导级为电液比例三通减压溢流阀,通径为32mm,最大流量为480L/min,进油口额定工作压力为31.5MPa,出油口额定工作压力为30.5MPa的电液比例节流阀的结构设计与参数设计。

关键词:电液比例节流阀; 插装阀; 比例电磁铁

The design of two stage electro-hydraulic proportional throttle valve with displacement electricity feedback

Majority:Machine Design & Manufacturing and Automation

Abstract: The technology of electro-hydraulic proportional develops swiftly and violently, it has more and more come the widespread application in the industrial production by its precision control, the simply structure, the reasonable cost and so on, its degree of development also might reflect a national hydraulic pressure industrial technology level from a side, so this technology received more and more value by the various countries' industrial field.

The topic of this graduation project is precisely one kind of electro-hydraulic proportional valve----two stage electro-hydraulic proportional throttle valve. This design will first carry on detailed analysis to the structure, principle and function parameter of various part of this kind of valve, then complete the structural design and the parameter design of the two stage electro-hydraulic proportional throttle valve ,this valve's main stage is cartridge valve ,its forerunner stage is three contacts reduced pressure overflow valve .This valve's rectum is 32mm,and its max regulated flow is 480L/min,the oil input port fixed working pressure is 31.5MPa, the output port fixed working pressure is 30.5MPa.

Keyword: Electro-hydraulic proportional throttle valve; Cartridge valves; Proportion electro-magnet ratio electromagnet

目录

前言…………………………………………………………………………………………………………1

正文…………………………………………………………………………………………………………2

1 绪论…………………………………………………………………………………………………………2

1.1 电液比例阀概述……………………………………………………………………………………2

1.2 电液比例阀的特点与分类…………………………………………………………………………2

1.3 电液比例阀的发展阶段……………………………………………………………………………3

1.4 电液比例技术在我国的发展………………………………………………………………………5

1.5 比例流量阀………………………………………………………………………………………5

2 流量阀控制流量的一般原理………………………………………………………………………………7

2.1 流量控制的基本原理………………………………………………………………………………8

2.4 主阀阀芯节流口形式的确定………………………………………………………………………8

3 比例节流阀结构设计……………………………………………………………………………………9

3.1 插装阀介绍………………………………………………………………………………………9

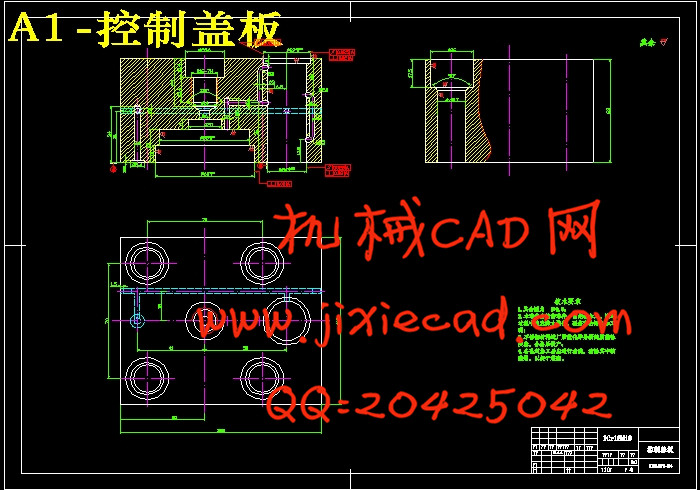

3.2 控制盖板的设计…………………………………………………………………………………9

3.3 插装式主阀设计…………………………………………………………………………………11

3.4 先导阀设计………………………………………………………………………………………21

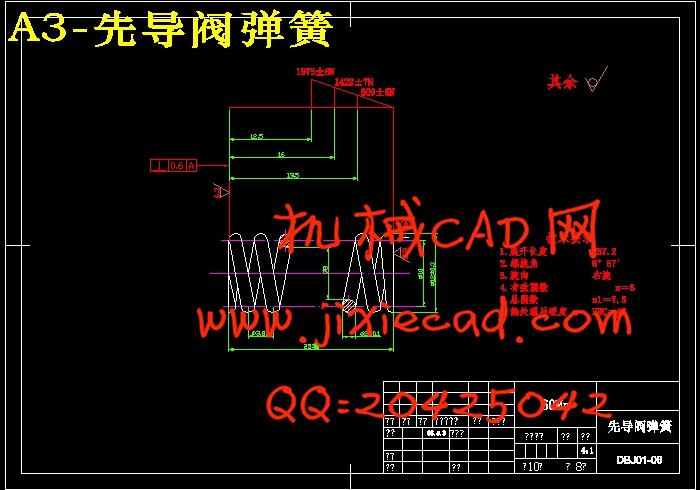

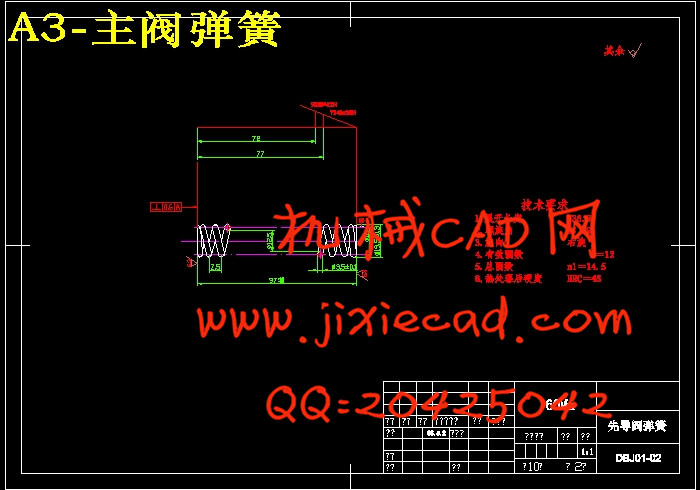

3.5 弹簧的选用………………………………………………………………………………………30

3.6 公差与配合的确定………………………………………………………………………………31

3.7 比例放大器………………………………………………………………………………………33

3.8 比例电磁铁………………………………………………………………………………………36

3.9 结构设计小结……………………………………………………………………………………37

4 节流阀工作总原理分析及其性能参数指标……………………………………………………………38

4.1 原理分析…………………………………………………………………………………………38

4.2 静态性能指标……………………………………………………………………………………39

4.3 动态性能指标……………………………………………………………………………………40

5 比例控制系统……………………………………………………………………………………………41

5.1 反馈的概念………………………………………………………………………………………41

5.2 闭环控制与开环控制……………………………………………………………………………41

5.3 电液比例控制系统的组成……………………………………………………………………42

5.4 电液比例控制系统的特点………………………………………………………………………43

5.5 比例控制系统的分类……………………………………………………………………………43

5.6 比例控制系统的发展趋势………………………………………………………………………44

5.7 小结……………………………………………………………………………………………44

结论…………………………………………………………………………………………………………45

参考文献……………………………………………………………………………………………………46

致谢…………………………………………………………………………………………………………47

摘要:电液比例技术发展迅猛,以其控制精度较高、结构简单、成本合理等优点在工业生产中获得了越来越来广泛的应用,它的发展程度也可从一个侧面反映一个国家液压工业技术水平,因而日益受到各国工业界的重视。

本设计的课题是电液比例阀中的一类——二级电液比例节流阀。在对该阀各部分的结构、原理及性能参数进行详细分析的基础上,完成了功率级为二通插装阀,先导级为电液比例三通减压溢流阀,通径为32mm,最大流量为480L/min,进油口额定工作压力为31.5MPa,出油口额定工作压力为30.5MPa的电液比例节流阀的结构设计与参数设计。

关键词:电液比例节流阀; 插装阀; 比例电磁铁

The design of two stage electro-hydraulic proportional throttle valve with displacement electricity feedback

Majority:Machine Design & Manufacturing and Automation

Abstract: The technology of electro-hydraulic proportional develops swiftly and violently, it has more and more come the widespread application in the industrial production by its precision control, the simply structure, the reasonable cost and so on, its degree of development also might reflect a national hydraulic pressure industrial technology level from a side, so this technology received more and more value by the various countries' industrial field.

The topic of this graduation project is precisely one kind of electro-hydraulic proportional valve----two stage electro-hydraulic proportional throttle valve. This design will first carry on detailed analysis to the structure, principle and function parameter of various part of this kind of valve, then complete the structural design and the parameter design of the two stage electro-hydraulic proportional throttle valve ,this valve's main stage is cartridge valve ,its forerunner stage is three contacts reduced pressure overflow valve .This valve's rectum is 32mm,and its max regulated flow is 480L/min,the oil input port fixed working pressure is 31.5MPa, the output port fixed working pressure is 30.5MPa.

Keyword: Electro-hydraulic proportional throttle valve; Cartridge valves; Proportion electro-magnet ratio electromagnet

目录

前言…………………………………………………………………………………………………………1

正文…………………………………………………………………………………………………………2

1 绪论…………………………………………………………………………………………………………2

1.1 电液比例阀概述……………………………………………………………………………………2

1.2 电液比例阀的特点与分类…………………………………………………………………………2

1.3 电液比例阀的发展阶段……………………………………………………………………………3

1.4 电液比例技术在我国的发展………………………………………………………………………5

1.5 比例流量阀………………………………………………………………………………………5

2 流量阀控制流量的一般原理………………………………………………………………………………7

2.1 流量控制的基本原理………………………………………………………………………………8

2.4 主阀阀芯节流口形式的确定………………………………………………………………………8

3 比例节流阀结构设计……………………………………………………………………………………9

3.1 插装阀介绍………………………………………………………………………………………9

3.2 控制盖板的设计…………………………………………………………………………………9

3.3 插装式主阀设计…………………………………………………………………………………11

3.4 先导阀设计………………………………………………………………………………………21

3.5 弹簧的选用………………………………………………………………………………………30

3.6 公差与配合的确定………………………………………………………………………………31

3.7 比例放大器………………………………………………………………………………………33

3.8 比例电磁铁………………………………………………………………………………………36

3.9 结构设计小结……………………………………………………………………………………37

4 节流阀工作总原理分析及其性能参数指标……………………………………………………………38

4.1 原理分析…………………………………………………………………………………………38

4.2 静态性能指标……………………………………………………………………………………39

4.3 动态性能指标……………………………………………………………………………………40

5 比例控制系统……………………………………………………………………………………………41

5.1 反馈的概念………………………………………………………………………………………41

5.2 闭环控制与开环控制……………………………………………………………………………41

5.3 电液比例控制系统的组成……………………………………………………………………42

5.4 电液比例控制系统的特点………………………………………………………………………43

5.5 比例控制系统的分类……………………………………………………………………………43

5.6 比例控制系统的发展趋势………………………………………………………………………44

5.7 小结……………………………………………………………………………………………44

结论…………………………………………………………………………………………………………45

参考文献……………………………………………………………………………………………………46

致谢…………………………………………………………………………………………………………47