设计简介

摘 要: 喂粕机用于粘胶生产中定时定量连续喂送浆粕至浸渍桶。常见的喂粕机由两条无端平面输送胶带和前后两撑辊组成。前撑辊由无级变速马达带动,使输送带前进,同时也使分页刀匀速拨动,均匀地把置于输送带上的浆粕在极慢的前进速度中被一页页定量地送入浸渍桶内,完成投料。本文主要对喂粕机分页器部件进行设计,主要内容包括:方案的总体设计,齿轮的设计与校核,凸轮的设计,轴的设计与校核,联轴器和滚动轴承的选择,箱体附件的设计,拨杆的设计。

关键词:喂粕机;分页器;

Abstract: Feed pulp machine used in viscose production timing quantitative continuous feeding pulp to impregnation barrel. Common meal feeding machine is made up of both before and after the two gratuitous flat belt and support roller. Support roller driven by stepless variable speed motor, before make the conveyor belt to go forward, but also make the paging knife moving at a constant speed, evenly placed on the conveyor belt of the pulp in extremely slow speed page into dipping ladle, quantitatively feeding. This paper pager parts to carry on the design of feed pulp machine, main contents include: overall design scheme, the design of the gear and checking, the design of the CAM, the design of the shaft and checking, coupling and the choice of rolling bearing, cabinet accessories design, the design of the shifter lever

Key words: Hello pulp machine; The pager;

目 录

摘要 .........................................................1

关键词.......................................................1

1.前言.........................................................1

2.喂粕机分页器部件传动方案的总体设计............................2

2.1 机械传动方案设计原则 ....................................2

2.2 喂粕机分页器部件传动方案设计...............................3

2.3 电动机的选择 ..........................................4

2.4 传动装置的运动和动力参数...................................5

2.4.1 传动比....................................................5

2.4.2 机械效率...................................................5

2.4.2 机械效率...................................................5

2.4.3 工作机功率.................................................5

2.4.4 转矩T.....................................................5

2.4.5 验算.......................................................6

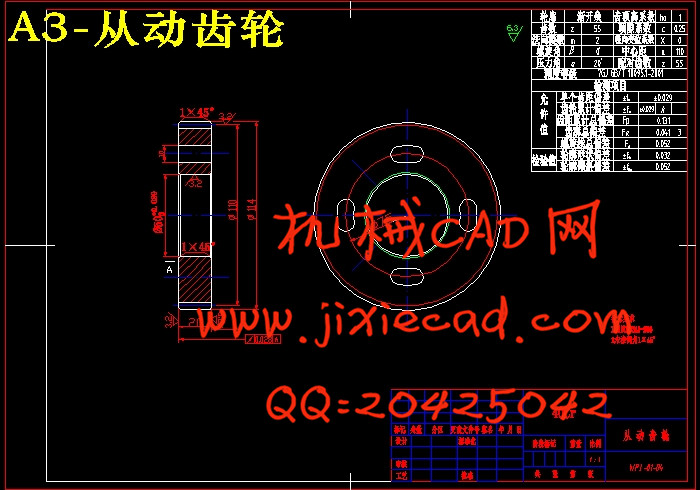

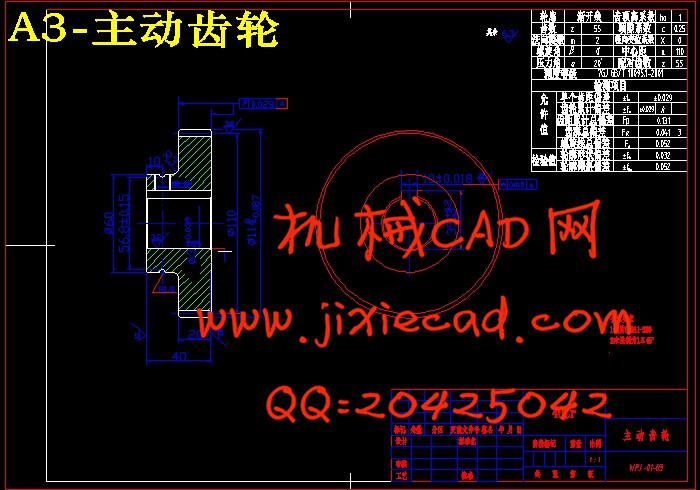

3 齿轮设计.......................................................6

3.1 齿轮选择.......................................................6

3.1.1 选择齿轮类型................................................7

3.1.2 选择材料,热处理,齿轮精度等级和齿数........................8

3.2 齿轮1的相关计算..............................................8

3.2.1 名义载荷....................................................9

3.2.2 计算载荷....................................................9

3.2.3 按齿根弯曲疲劳强度效核........................................10

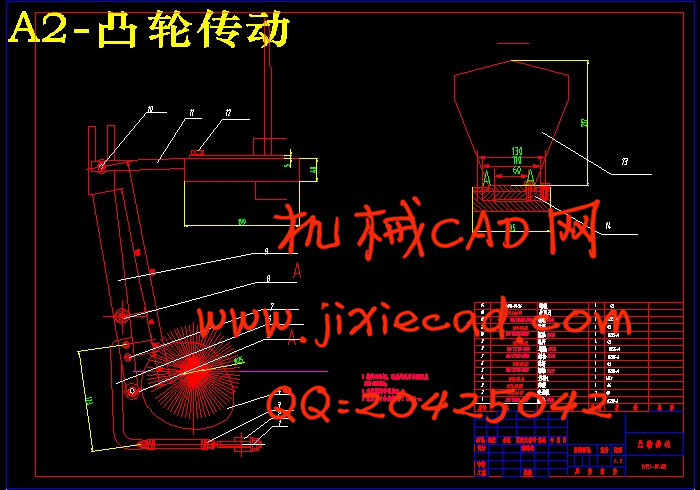

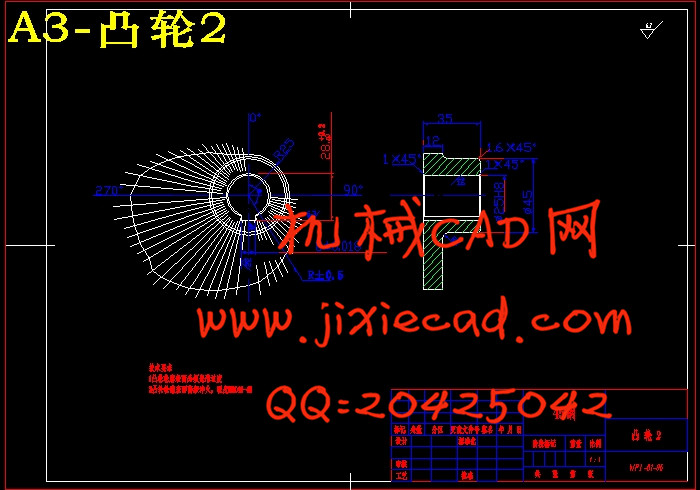

4 凸轮机构的设计..................................................11

4.1凸轮机构的选择...................................................12

4.1.1凸轮的选择................................................12

4.2凸轮1机构的设计...........................................13

4.2.1凸轮基本尺寸确定...........................................13

4.2.2凸轮轮廓曲线的设计.......................................14

4.3凸轮2机构的设计.........................................14

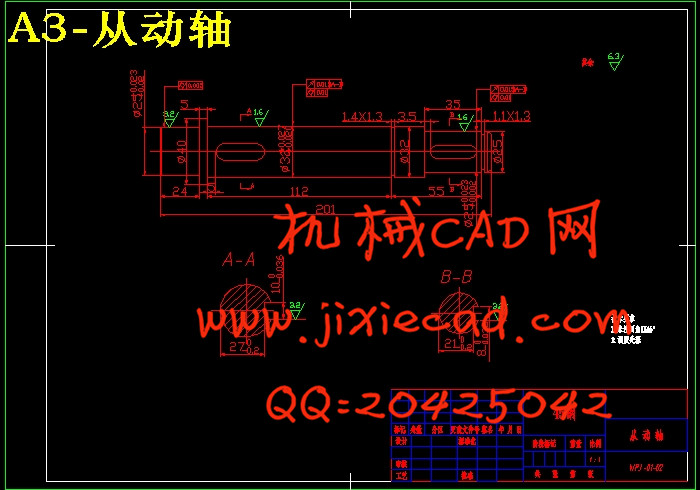

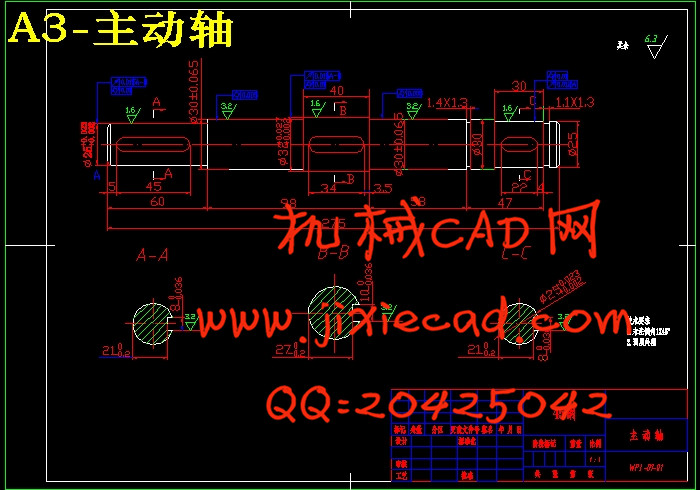

5轴的设计计算..............................................15

5.1轴的设计概述...........................................16

5.1.1主轴的设计计算.....................................17

5.2.选择轴的材料........................................18

5.3.按扭转强度初估轴的最小直径..........................19

5.4.轴系初步设计........................................19

5.5轴的结构设计.........................................19

5.6按弯曲许用应力计算...................................20

5.7副轴的设计计算.......................................20

5.8.选择轴的材料.........................................20

5.9 按扭转强度初估轴的最小直径...........................21

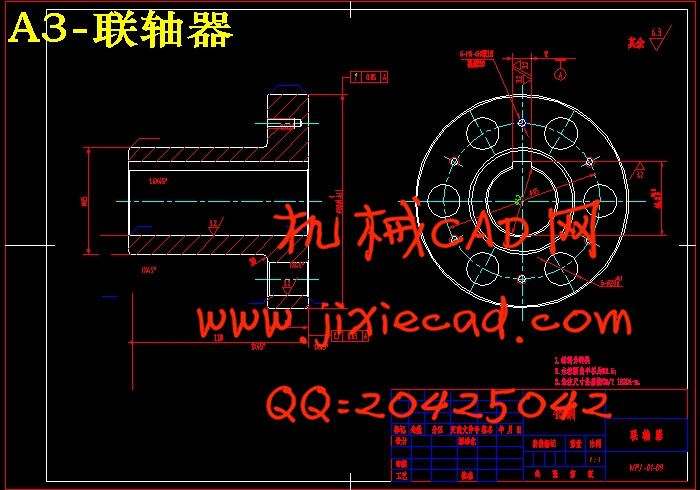

6 联轴器和滚动轴承的选择................................21

6.1 联轴器介绍和分类.....................................21

6.1.1 联轴器的相关介.....................................22

6.2 联轴器的选择..........................................22

6.2.1联轴器的类型选择.......................................22

6.2.2联轴器转矩计算.........................................22

6.2.3 选择联轴器的型号...................................23

6.3 轴承的选择............................................23

6.3.1 轴承的选择..........................................23

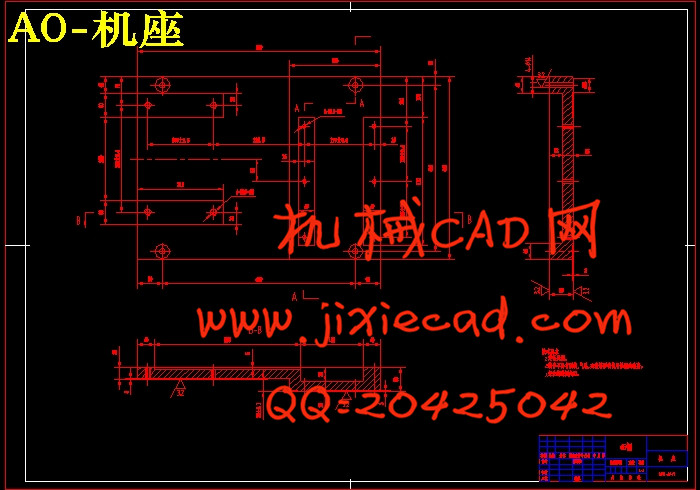

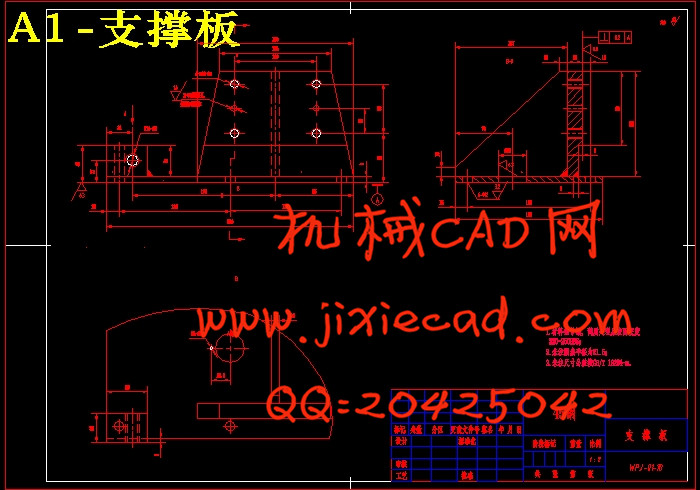

7 箱体及附件的设计.......................................23

7.1 箱体的基本结构设计....................................24

7.1.1 设计的主要问题和设计要求............................24

7.1.2 箱体的主要功能 .....................................24

7.1.3 箱体材料的选则......................................25

7.1.4 箱体的热处理 ......................................25

7.1.5 分页机箱体的结构.....................................25

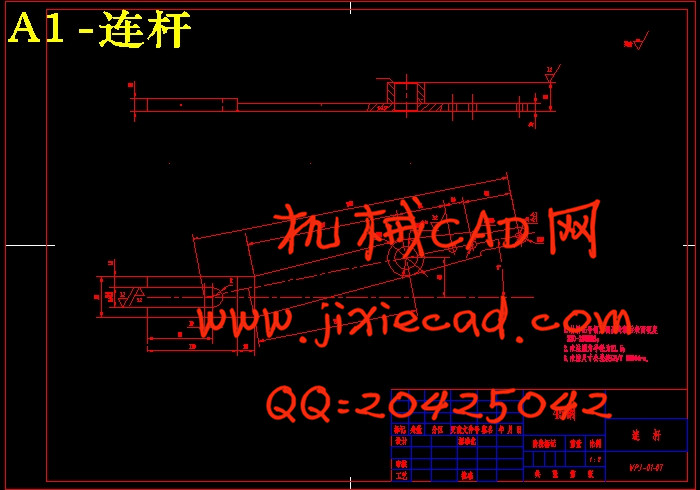

8.拨杆的相关设计............................................25

9.润滑和密封的设计.........................................26

9.1润滑方式 ..............................................26

9.1.1 滚动轴承润滑.............................................26

9.1.齿轮传动润滑...............................................26

9.2 密封装置..................................................26

9.2.1 接触式旋转密封装置.......................................26

10 总结..........................................................27

参考资料 .....................................................28

致谢 .......................................................28

关键词:喂粕机;分页器;

Abstract: Feed pulp machine used in viscose production timing quantitative continuous feeding pulp to impregnation barrel. Common meal feeding machine is made up of both before and after the two gratuitous flat belt and support roller. Support roller driven by stepless variable speed motor, before make the conveyor belt to go forward, but also make the paging knife moving at a constant speed, evenly placed on the conveyor belt of the pulp in extremely slow speed page into dipping ladle, quantitatively feeding. This paper pager parts to carry on the design of feed pulp machine, main contents include: overall design scheme, the design of the gear and checking, the design of the CAM, the design of the shaft and checking, coupling and the choice of rolling bearing, cabinet accessories design, the design of the shifter lever

Key words: Hello pulp machine; The pager;

目 录

摘要 .........................................................1

关键词.......................................................1

1.前言.........................................................1

2.喂粕机分页器部件传动方案的总体设计............................2

2.1 机械传动方案设计原则 ....................................2

2.2 喂粕机分页器部件传动方案设计...............................3

2.3 电动机的选择 ..........................................4

2.4 传动装置的运动和动力参数...................................5

2.4.1 传动比....................................................5

2.4.2 机械效率...................................................5

2.4.2 机械效率...................................................5

2.4.3 工作机功率.................................................5

2.4.4 转矩T.....................................................5

2.4.5 验算.......................................................6

3 齿轮设计.......................................................6

3.1 齿轮选择.......................................................6

3.1.1 选择齿轮类型................................................7

3.1.2 选择材料,热处理,齿轮精度等级和齿数........................8

3.2 齿轮1的相关计算..............................................8

3.2.1 名义载荷....................................................9

3.2.2 计算载荷....................................................9

3.2.3 按齿根弯曲疲劳强度效核........................................10

4 凸轮机构的设计..................................................11

4.1凸轮机构的选择...................................................12

4.1.1凸轮的选择................................................12

4.2凸轮1机构的设计...........................................13

4.2.1凸轮基本尺寸确定...........................................13

4.2.2凸轮轮廓曲线的设计.......................................14

4.3凸轮2机构的设计.........................................14

5轴的设计计算..............................................15

5.1轴的设计概述...........................................16

5.1.1主轴的设计计算.....................................17

5.2.选择轴的材料........................................18

5.3.按扭转强度初估轴的最小直径..........................19

5.4.轴系初步设计........................................19

5.5轴的结构设计.........................................19

5.6按弯曲许用应力计算...................................20

5.7副轴的设计计算.......................................20

5.8.选择轴的材料.........................................20

5.9 按扭转强度初估轴的最小直径...........................21

6 联轴器和滚动轴承的选择................................21

6.1 联轴器介绍和分类.....................................21

6.1.1 联轴器的相关介.....................................22

6.2 联轴器的选择..........................................22

6.2.1联轴器的类型选择.......................................22

6.2.2联轴器转矩计算.........................................22

6.2.3 选择联轴器的型号...................................23

6.3 轴承的选择............................................23

6.3.1 轴承的选择..........................................23

7 箱体及附件的设计.......................................23

7.1 箱体的基本结构设计....................................24

7.1.1 设计的主要问题和设计要求............................24

7.1.2 箱体的主要功能 .....................................24

7.1.3 箱体材料的选则......................................25

7.1.4 箱体的热处理 ......................................25

7.1.5 分页机箱体的结构.....................................25

8.拨杆的相关设计............................................25

9.润滑和密封的设计.........................................26

9.1润滑方式 ..............................................26

9.1.1 滚动轴承润滑.............................................26

9.1.齿轮传动润滑...............................................26

9.2 密封装置..................................................26

9.2.1 接触式旋转密封装置.......................................26

10 总结..........................................................27

参考资料 .....................................................28

致谢 .......................................................28