设计简介

摘要

根据型钢的种类设计型钢垛型,有利于型钢的堆放和运输,提高工人的劳动强度。

堆垛机属于堆垛物件之设备,堆垛机特别用于轧钢生产线上型钢的堆垛。它是一种用来堆垛型钢装置,是由传递、拨钢、链条输送、定位、平移、翻转、垛台升降,钢垛压紧等机构组成,其特征是定位机构上的定位板可更换,在控制摆动油缸的转动,从而改变型钢在垛型中堆垛的位置,使之达到最加堆垛方式。本实用新型结构简单,易于维修,操作方便,大大降低了工人的劳动强度。

关键字 型钢堆垛 堆垛机 型钢

ABSTRACT

The pack of sections designs to propitious to pile up and transport sections, and improve to lab of intension to worker.

Stacker is a equipment that can stow thing. Stacker is particularly stacked sections with producted in line of steel rolling .It is assort of equipment that is use to stow pack of sections, it makes up of transfer dial to sections. With changing transportation, with orientationing, with moving flat, over turn, battlements of desk rising and capitulate, steel buttress of impactation ,and character of it is that orientation of board on orientation machine can be changed. On account of controlling to stowing of oil jar to turning, that can change position sections are pile up in pack of sections, that can win pack of sections very good. The practicality new type configuration is briefness, prone to service, and operate conveniencly, and that can greatly play down laboring intension of worker.

KEYWORDS Pack of sections Stacker Sections

目录

中文摘要------------------------------------------------1

外文摘要------------------------------------------------2

1、绪论------------------------------------------------5

1.1型钢生产概况 -------------------------------------5

1.2型钢生产方法--------------------------------------5

1.3型钢的分类----------------------------------------5

1.4型钢生产工艺对堆垛的要求--------------------------6

2、型钢垛型设计计算 ------------------------------------7

2.1型钢堆垛和垛型尺寸--------------------------------7

2.2垛型设计计算--------------------------------------7

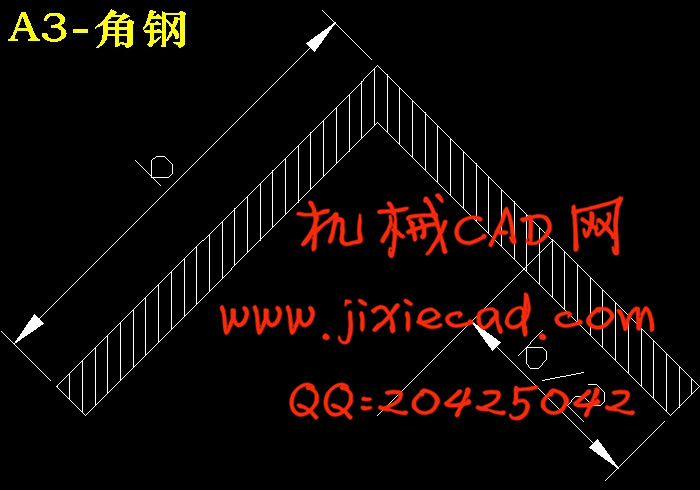

2.3角钢绕度的计算 -----------------------------------8

3、总体方案设计 ---------------------------------------10

3.1意义---------------------------------------------10

3.2型钢自动堆垛主要设备组成--------------------------10

3.3设计方案-----------------------------------------11

3.3设计要点-----------------------------------------12

4、机构运动分析与参数计算------------------------------13

4.1堆垛动作时序表-----------------------------------13

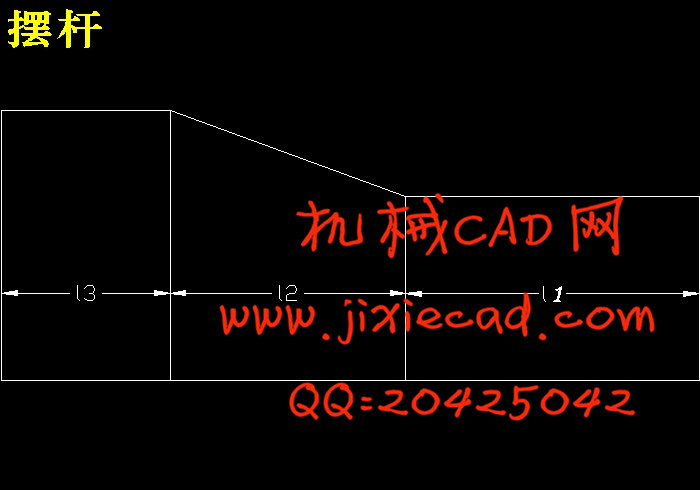

4.2摆杆和电磁铁转动的运动分析计算--------------------13

4.2.1摆杆第一次转动加速度与角速度的计算-----------13

4.2.2电磁铁自转加速度与角速度的计算---------------14

4.2.3摆杆第二次转动加速度与角速度的计算-----------14

4.2.4摆杆第三次转动加速度与角速度的计算-----------14

4.2.5摆杆的第四次转动加速度与角速度的计算---------15

4.3摆杆设计与计算-----------------------------------15

4.3.1摆杆的参数确定------------------------------16

4.3.2摆杆质量的计算------------------------------16

4.4电磁铁的设计与计算-------------------------------16

5、机构的动力分析--------------------------------------18

5.1转动惯量的计算-----------------------------------18

5.1.1摆杆转动惯量--------------------------------18

5.1.2电磁铁转动惯量------------------------------18

5.1.3型钢转动惯量--------------------------------18

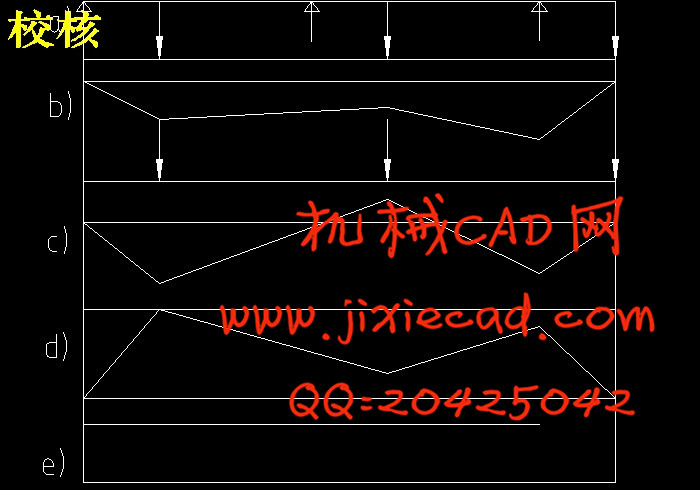

5.2主传动轴受力与动静扭矩计算 ---------------------19

6、主要零件的设计计算-------------------------------26

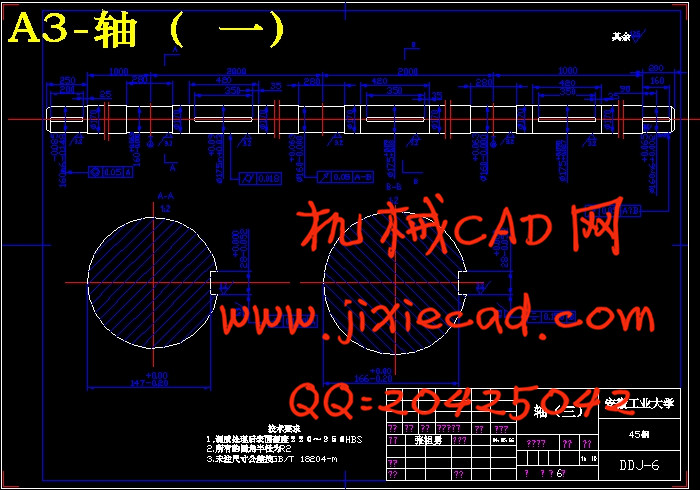

6.1轴的设计计算与校核------------------------------26

6.1.1初步确定轴的最小直径------------------------26

6.1.2联轴器的选择-------------------------------27

6.1.3轴的结构设计-------------------------------27

6.1.4按弯扭合成应力校核轴的强度------------------28

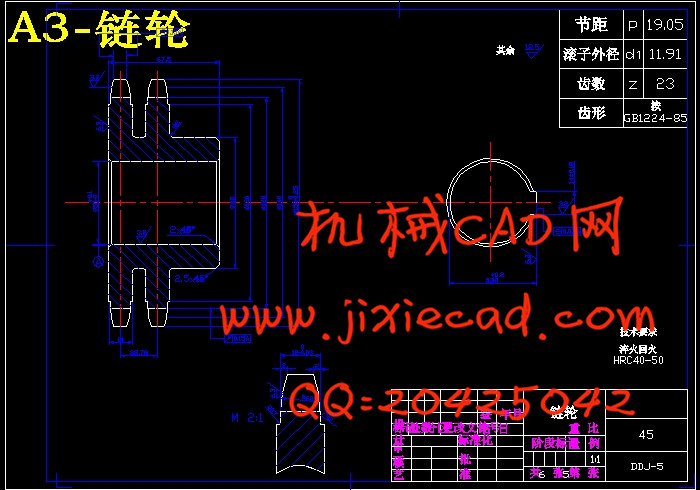

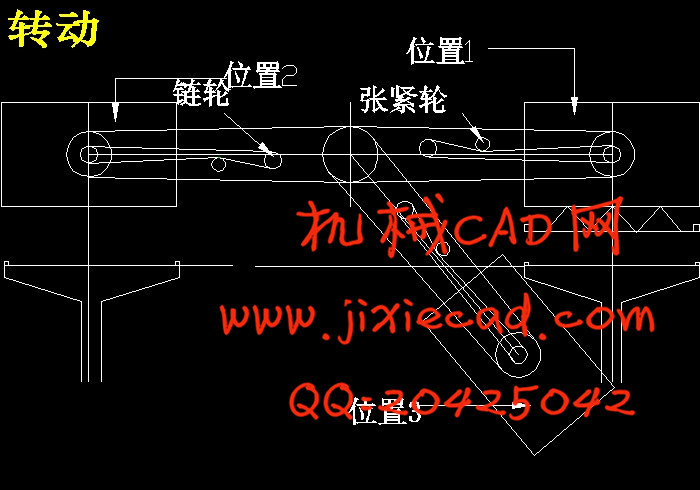

6.2链轮设计计算-----------------------------------29

6.2.1链轮型号选择-------------------------------29

6.2.2从动链轮轴径的计算-------------------------30

6.2.3滚子链的静强度计算-------------------------31

6.2.4主动轮轴径的计算---------------------------32

6.2.5链轮主要参数计算---------------------------32

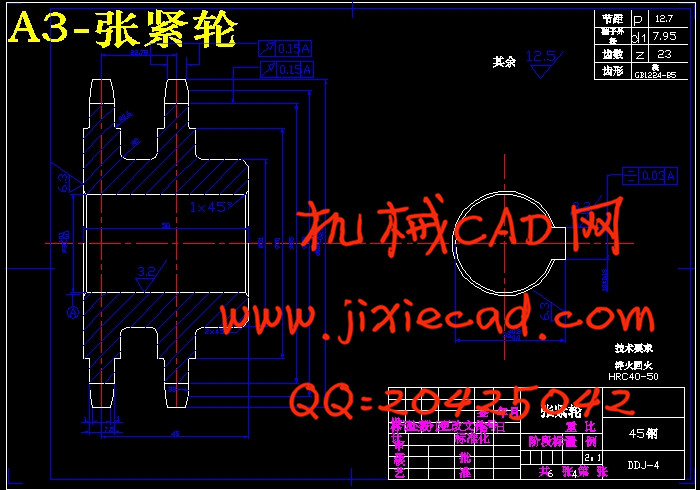

6.3张紧轮的设计计算--------------------------------34

6.3.1张紧轮型号选择-----------------------------34

6.3.2张紧轮主要参数计算-------------------------34

7、传动装置选择--------------------------------------36

设计体会----------------------------------------------37

致谢--------------------------------------------------38

参考文献----------------------------------------------39

根据型钢的种类设计型钢垛型,有利于型钢的堆放和运输,提高工人的劳动强度。

堆垛机属于堆垛物件之设备,堆垛机特别用于轧钢生产线上型钢的堆垛。它是一种用来堆垛型钢装置,是由传递、拨钢、链条输送、定位、平移、翻转、垛台升降,钢垛压紧等机构组成,其特征是定位机构上的定位板可更换,在控制摆动油缸的转动,从而改变型钢在垛型中堆垛的位置,使之达到最加堆垛方式。本实用新型结构简单,易于维修,操作方便,大大降低了工人的劳动强度。

关键字 型钢堆垛 堆垛机 型钢

ABSTRACT

The pack of sections designs to propitious to pile up and transport sections, and improve to lab of intension to worker.

Stacker is a equipment that can stow thing. Stacker is particularly stacked sections with producted in line of steel rolling .It is assort of equipment that is use to stow pack of sections, it makes up of transfer dial to sections. With changing transportation, with orientationing, with moving flat, over turn, battlements of desk rising and capitulate, steel buttress of impactation ,and character of it is that orientation of board on orientation machine can be changed. On account of controlling to stowing of oil jar to turning, that can change position sections are pile up in pack of sections, that can win pack of sections very good. The practicality new type configuration is briefness, prone to service, and operate conveniencly, and that can greatly play down laboring intension of worker.

KEYWORDS Pack of sections Stacker Sections

目录

中文摘要------------------------------------------------1

外文摘要------------------------------------------------2

1、绪论------------------------------------------------5

1.1型钢生产概况 -------------------------------------5

1.2型钢生产方法--------------------------------------5

1.3型钢的分类----------------------------------------5

1.4型钢生产工艺对堆垛的要求--------------------------6

2、型钢垛型设计计算 ------------------------------------7

2.1型钢堆垛和垛型尺寸--------------------------------7

2.2垛型设计计算--------------------------------------7

2.3角钢绕度的计算 -----------------------------------8

3、总体方案设计 ---------------------------------------10

3.1意义---------------------------------------------10

3.2型钢自动堆垛主要设备组成--------------------------10

3.3设计方案-----------------------------------------11

3.3设计要点-----------------------------------------12

4、机构运动分析与参数计算------------------------------13

4.1堆垛动作时序表-----------------------------------13

4.2摆杆和电磁铁转动的运动分析计算--------------------13

4.2.1摆杆第一次转动加速度与角速度的计算-----------13

4.2.2电磁铁自转加速度与角速度的计算---------------14

4.2.3摆杆第二次转动加速度与角速度的计算-----------14

4.2.4摆杆第三次转动加速度与角速度的计算-----------14

4.2.5摆杆的第四次转动加速度与角速度的计算---------15

4.3摆杆设计与计算-----------------------------------15

4.3.1摆杆的参数确定------------------------------16

4.3.2摆杆质量的计算------------------------------16

4.4电磁铁的设计与计算-------------------------------16

5、机构的动力分析--------------------------------------18

5.1转动惯量的计算-----------------------------------18

5.1.1摆杆转动惯量--------------------------------18

5.1.2电磁铁转动惯量------------------------------18

5.1.3型钢转动惯量--------------------------------18

5.2主传动轴受力与动静扭矩计算 ---------------------19

6、主要零件的设计计算-------------------------------26

6.1轴的设计计算与校核------------------------------26

6.1.1初步确定轴的最小直径------------------------26

6.1.2联轴器的选择-------------------------------27

6.1.3轴的结构设计-------------------------------27

6.1.4按弯扭合成应力校核轴的强度------------------28

6.2链轮设计计算-----------------------------------29

6.2.1链轮型号选择-------------------------------29

6.2.2从动链轮轴径的计算-------------------------30

6.2.3滚子链的静强度计算-------------------------31

6.2.4主动轮轴径的计算---------------------------32

6.2.5链轮主要参数计算---------------------------32

6.3张紧轮的设计计算--------------------------------34

6.3.1张紧轮型号选择-----------------------------34

6.3.2张紧轮主要参数计算-------------------------34

7、传动装置选择--------------------------------------36

设计体会----------------------------------------------37

致谢--------------------------------------------------38

参考文献----------------------------------------------39