设计简介

摘 要:啤酒作为一种口味独特的风味饮料.深受广大老百姓的喜欢。灌装机是啤酒包装生产线的核心设备,因此,灌装机灌装效果的好坏直接影响到企业的经济效益。液体的灌装方式分为常压式、等压式、真空式、机械压力式四种。一般而言酒类灌装多采用常压式灌装方式,常压式灌装机使用方便,具有速度可调、计量准确、运行平稳、无噪音和液体不外溢等优点,使用广泛。

关键词:灌装机;常压式灌装方式;

Abstract: The beer takes one kind of taste unique flavor drink. Deeply generalcommon people's liking. Fills installing equipment is the beer packing production line coreequipment, therefore, fills installing equipment to fill installs theeffect the quality directly to affect enterprise's economicefficiency. The liquid fills installs the way to divide into the atmosphericpressure type, the equi-pressure type, the vacuum type, the mechanicalpressure type four kinds. Generally speaking the wines fill install use the atmospheric pressuretype to fill install the way, the atmospheric pressure type fill theinstalling equipment easy to operate, has the speed to be possible toadjust, the measurement accurate, the movement steady, does not havemerit and so on noise and liquid overflow, the use is not widespread.

Key words: Fills installing equipment; The atmospheric pressure type fills installs the way

目 录

摘要……………………………………………………………………………4

关键词…………………………………………………………………………4

1 前言…………………………………………………………………………5

1.1 研究意义…………………………………………………………………5

1.2 国内外研究现状…………………………………………………………5

1.3 发展趋势…………………………………………………………………6

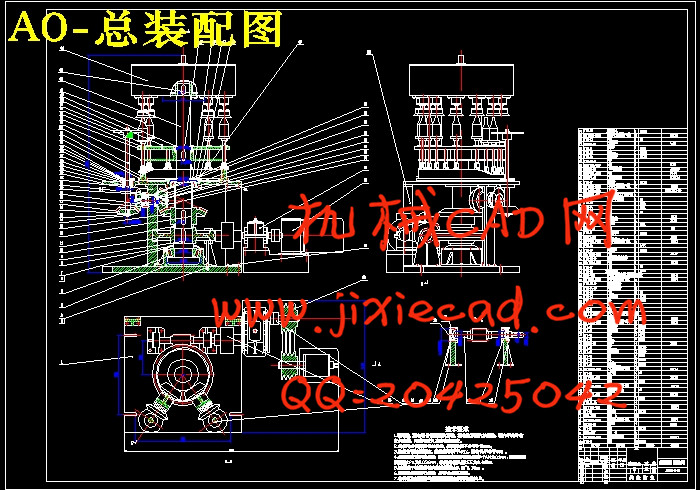

2 总体方案的确定……………………………………………………………7

2.1 确定用途与灌装方式……………………………………………………8

2.2 工艺分析…………………………………………………………………8

2.2.1 确定机械类型…………………………………………………………8

2.2.2 分析执行机构的运动要求……………………………………………9

2.3 拟定主要技术参数………………………………………………………9

3 旋转式灌装机的设计计算…………………………………………………10

3.1 电动机的选择……………………………………………………………10

3.2 灌装机输送管路计算……………………………………………………12

3.2.1 圆管直径………………………………………………………………13

3.2.2 圆管壁厚………………………………………………………………14

3.3 灌装时间的确定…………………………………………………………14

3.4 旋转式灌装机的工艺计算………………………………………………17

3.4.1 旋转式灌装机的生产率分析…………………………………………17

3.4.2 旋转式灌装机的最小旋转角懂得确定………………………………18

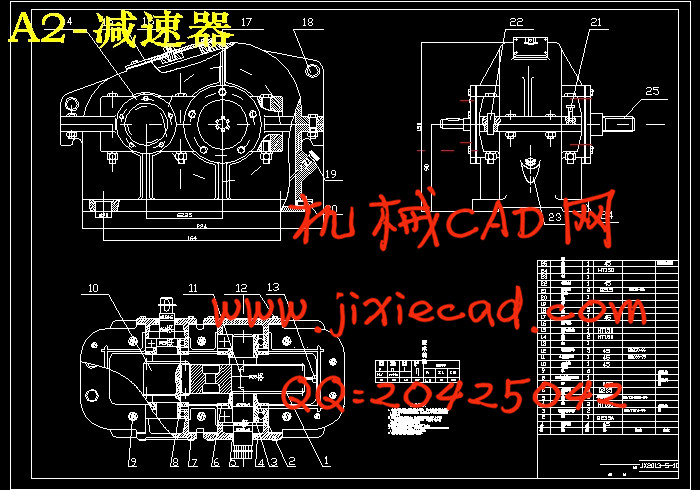

3.5 旋转式灌装机的传动系统设计…………………………………………21

3.5.1 传动比分析……………………………………………………………22

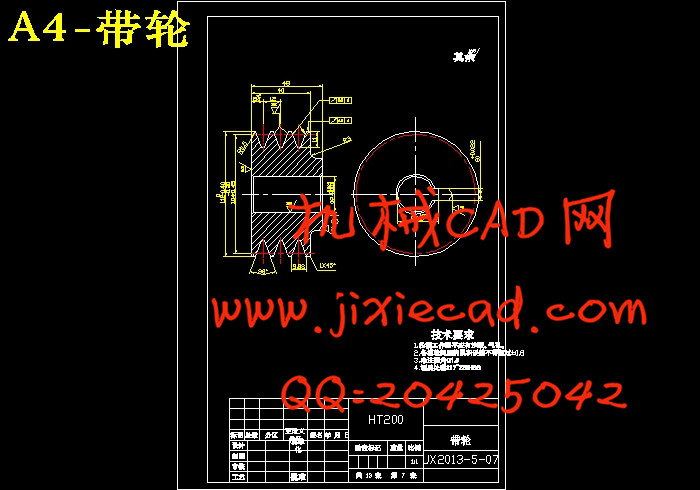

3.5.2 旋转式灌装机带传动设计………………………………………………22

3.5.3 蜗杆涡轮的传动设计……………………………………………………24

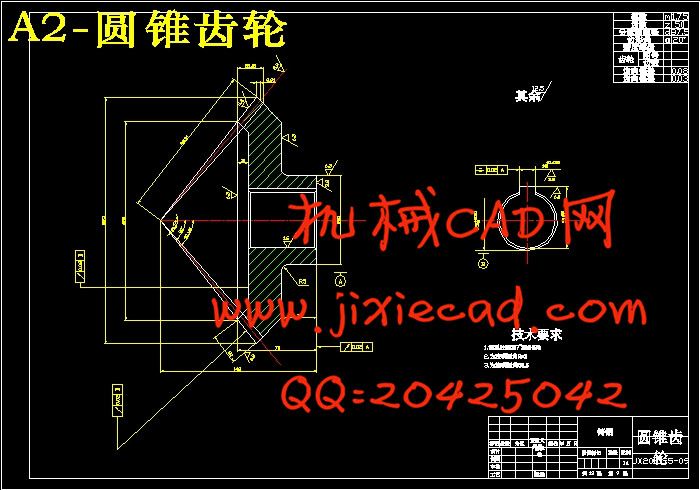

3.5.4 齿轮传动设计……………………………………………………………28

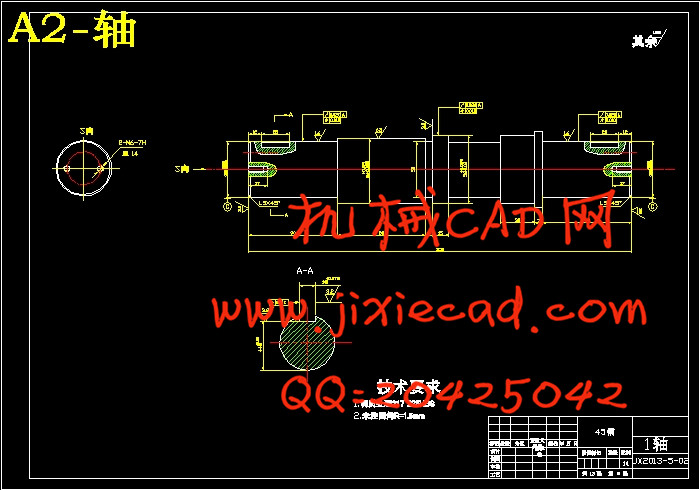

3.6 旋转主轴的设计……………………………………………………………30

3.6.1 轴的强度计算……………………………………………………………30

3.6.2 轴的刚度计算……………………………………………………………30

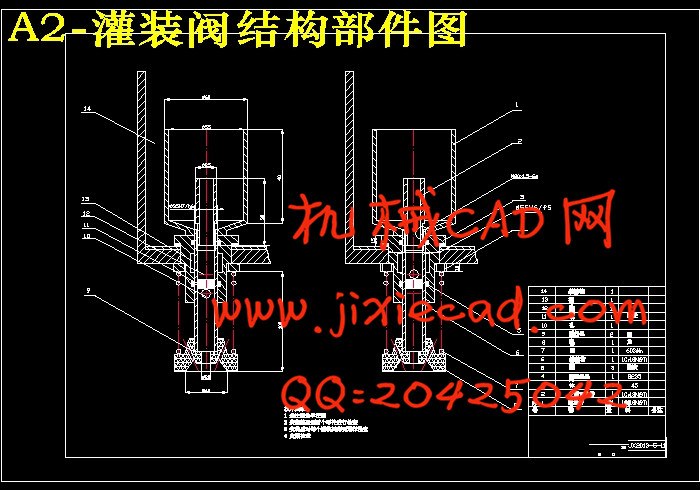

3.7 灌装阀的设计………………………………………………………………32

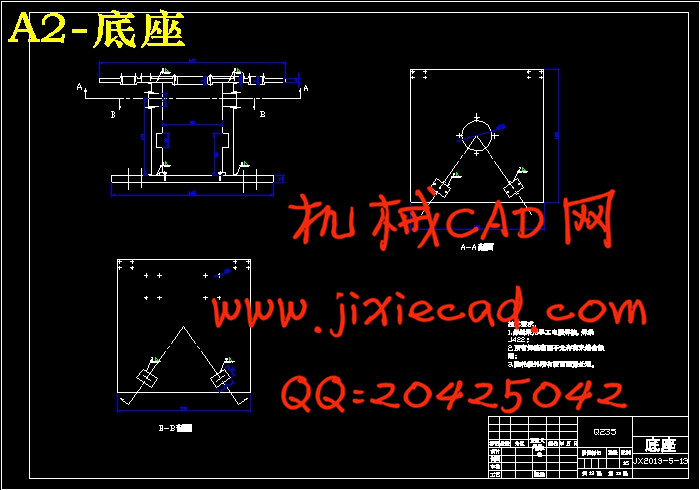

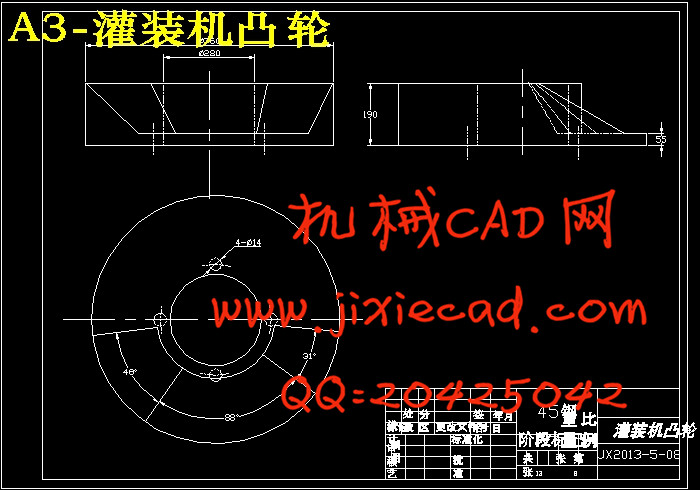

3.8 升降瓶机构的设计…………………………………………………………32

4 结论……………………………………………………………………………33

参考文献…………………………………………………………………………33

致谢………………………………………………………………………………34

关键词:灌装机;常压式灌装方式;

Abstract: The beer takes one kind of taste unique flavor drink. Deeply generalcommon people's liking. Fills installing equipment is the beer packing production line coreequipment, therefore, fills installing equipment to fill installs theeffect the quality directly to affect enterprise's economicefficiency. The liquid fills installs the way to divide into the atmosphericpressure type, the equi-pressure type, the vacuum type, the mechanicalpressure type four kinds. Generally speaking the wines fill install use the atmospheric pressuretype to fill install the way, the atmospheric pressure type fill theinstalling equipment easy to operate, has the speed to be possible toadjust, the measurement accurate, the movement steady, does not havemerit and so on noise and liquid overflow, the use is not widespread.

Key words: Fills installing equipment; The atmospheric pressure type fills installs the way

目 录

摘要……………………………………………………………………………4

关键词…………………………………………………………………………4

1 前言…………………………………………………………………………5

1.1 研究意义…………………………………………………………………5

1.2 国内外研究现状…………………………………………………………5

1.3 发展趋势…………………………………………………………………6

2 总体方案的确定……………………………………………………………7

2.1 确定用途与灌装方式……………………………………………………8

2.2 工艺分析…………………………………………………………………8

2.2.1 确定机械类型…………………………………………………………8

2.2.2 分析执行机构的运动要求……………………………………………9

2.3 拟定主要技术参数………………………………………………………9

3 旋转式灌装机的设计计算…………………………………………………10

3.1 电动机的选择……………………………………………………………10

3.2 灌装机输送管路计算……………………………………………………12

3.2.1 圆管直径………………………………………………………………13

3.2.2 圆管壁厚………………………………………………………………14

3.3 灌装时间的确定…………………………………………………………14

3.4 旋转式灌装机的工艺计算………………………………………………17

3.4.1 旋转式灌装机的生产率分析…………………………………………17

3.4.2 旋转式灌装机的最小旋转角懂得确定………………………………18

3.5 旋转式灌装机的传动系统设计…………………………………………21

3.5.1 传动比分析……………………………………………………………22

3.5.2 旋转式灌装机带传动设计………………………………………………22

3.5.3 蜗杆涡轮的传动设计……………………………………………………24

3.5.4 齿轮传动设计……………………………………………………………28

3.6 旋转主轴的设计……………………………………………………………30

3.6.1 轴的强度计算……………………………………………………………30

3.6.2 轴的刚度计算……………………………………………………………30

3.7 灌装阀的设计………………………………………………………………32

3.8 升降瓶机构的设计…………………………………………………………32

4 结论……………………………………………………………………………33

参考文献…………………………………………………………………………33

致谢………………………………………………………………………………34