设计简介

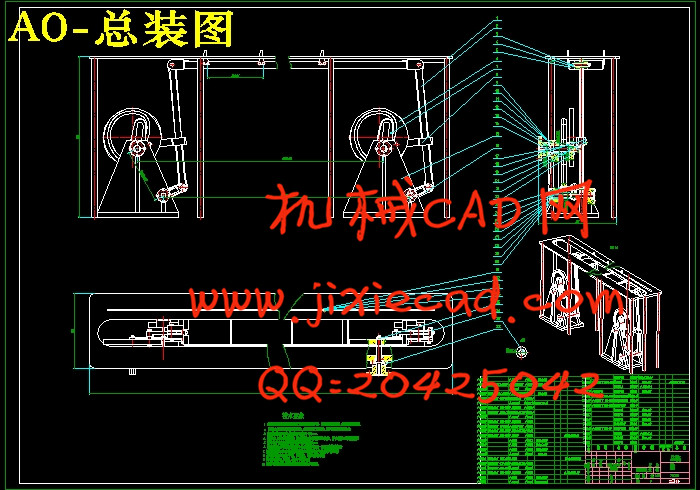

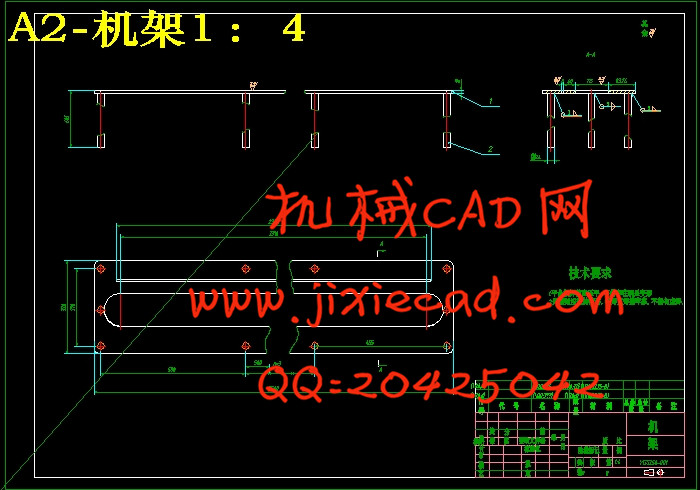

摘 要:自动输送是自动化的核心组成,应用广泛,对于其运动需进行严格分析、设计及优化,自动输送机可以不需复杂的控制系统,而只需设计相应的机构便可满足使用要求。本文设计的自动输送机主要针对特一压盖,对轨迹及相关零件进行了设计计算。该输送装置是由凸轮、曲柄和若干个连杆构成的。输送杆垂直方向的运动是由凸轮驱动的,而水平往复运动则由曲柄驱动,合成运动能快速送进、快速返回。结构上底盘与机架采用焊接结构,销轴采用两端紧定螺母锁紧式.

关键词:自动送料机;连杆设计;凸轮设计优化及加工;运动分析;有限元分析

Abstract:Automatic transmission,the core component of automation, is widely applied and rigorous analysis, design and optimization are necessarily conducted on its motion. To meet its operating requirement, a complicated control system is not necessary but the design of appropriate institutions. The design of auto-feeder in this paper is mainly focus on the type of gland, in which the track and related parts of this machine will be designed and calculated. This conveying device is composed of several parts including a cam, a crank, and a number of connecting rod. The cam makes the feed rod move in a vertical direction while a horizontal reciprocating motion is driven by the crank ,and its resultant motion can realize both swift feed and fast return. Structurally, welded structure will be adopted in chassis and rack while nut locking will be introduced to fix both ends of the pin..

Keywords: Auto-feeder; Connecting rod design; Optimization and processing of the cam design ; Kinematic analysis; Finite element analysis.

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1前言………………………………………………………………………………2

1.1课题的背景与意义…………………………………………………………………2

1.2国内外输送机发展趋势与水平……………………………………………………2

1.3我国输送机的未来之路与展望……………………………………………………3

2机械系统设计……………………………………………………………………4

2.1动作分析及轨迹初定………………………………………………………………4

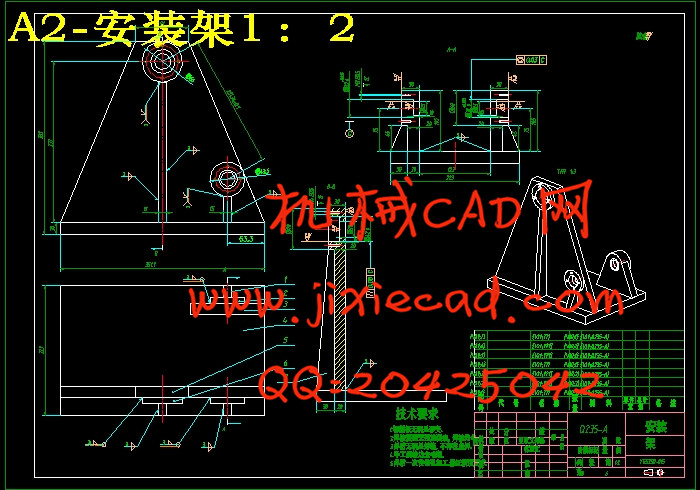

2.2执行机构设计………………………………………………………………………5

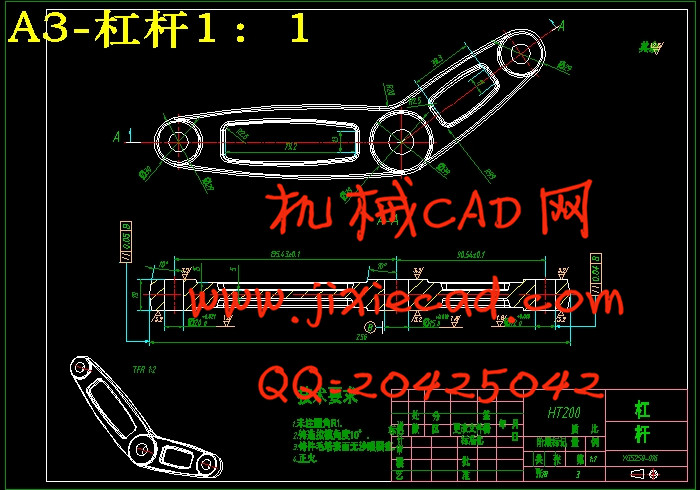

2.3连杆杆长的设计与计算……………………………………………………………6

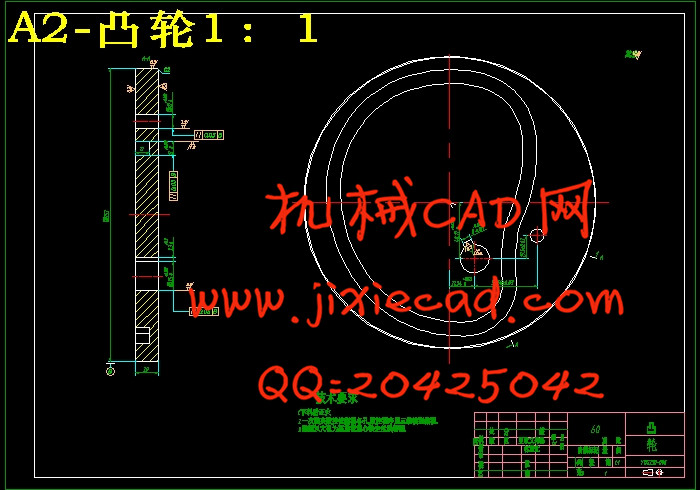

2.4凸轮设计

2.4.1轨迹优化及凸轮廓线……………………………………………………………7

2.4.2凸轮孔 …………………………………………………………………………10

2.4.3凸轮的加工制造 ………………………………………………………………11

2.5电动机选择……………………………………………………………………… 16

3传动零件的设计计算 ……………………………………………………………17

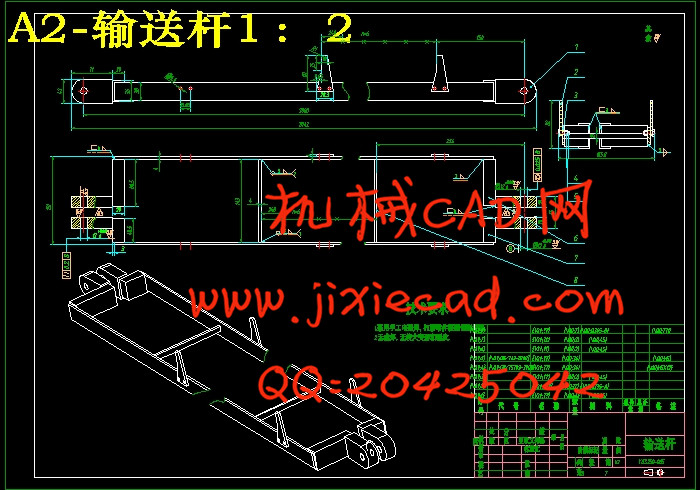

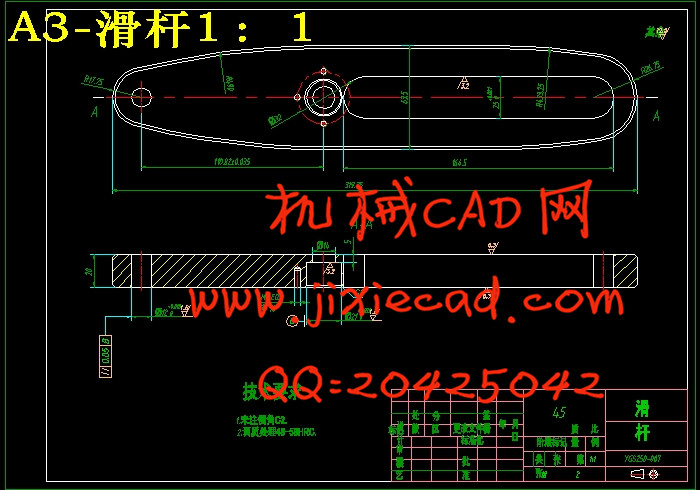

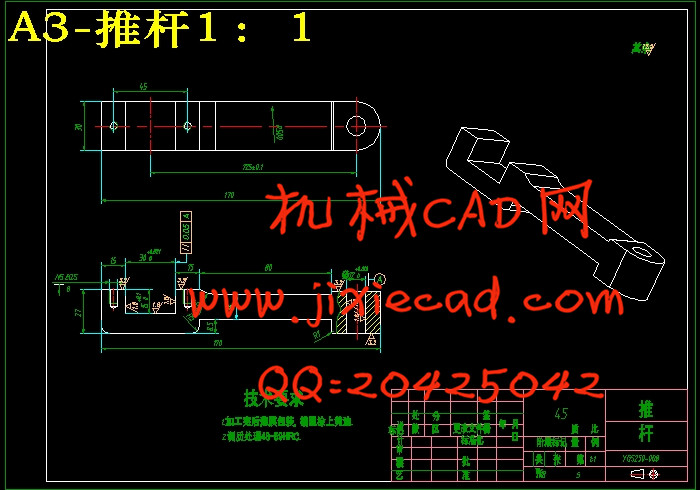

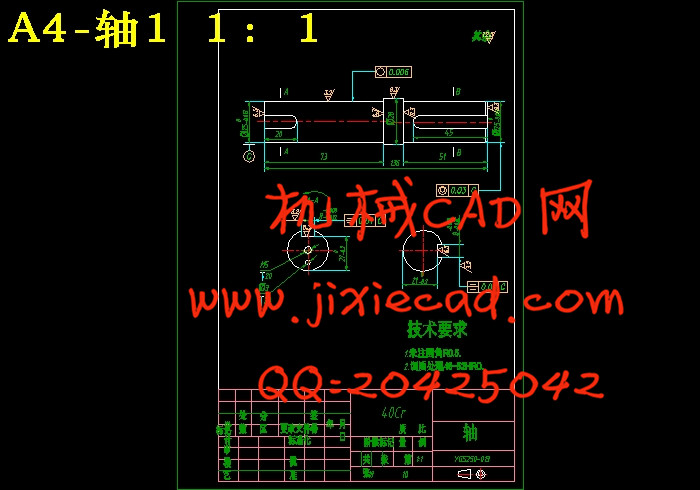

3.1输送杆的设计…………………………………………………………………… 17

3.2键连接强度计算………………………………………………………………… 19

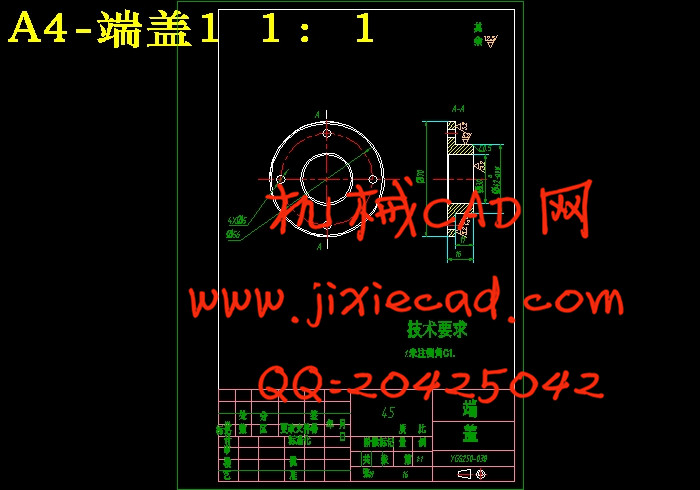

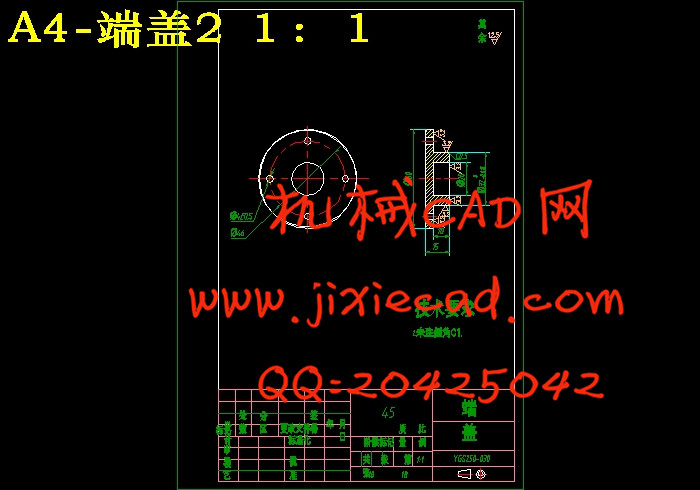

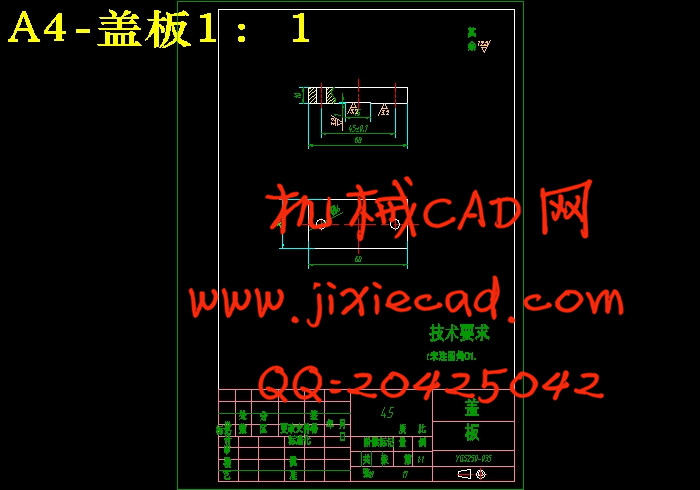

3.3轴的结构设计…………………………………………………………………… 20

4机构的动力学分析…………………………………………………………………20

4.1运动模型的建立………………………………………………………………… 20

4.2运动分析………………………………………………………………………… 21

5有限元分析校核…………………………………………………………………… 24

5.1有限元CAE设计的优势………………………………………………………… 24

5.2输送杆的有限元校核…………………………………………………………… 25

5.3回转轴的有限元校核…………………………………………………………… 26

6结论…………………………………………………………………………27

参考文献 ………………………………………………………………………28

致谢……………………………………………………………………………29

关键词:自动送料机;连杆设计;凸轮设计优化及加工;运动分析;有限元分析

Abstract:Automatic transmission,the core component of automation, is widely applied and rigorous analysis, design and optimization are necessarily conducted on its motion. To meet its operating requirement, a complicated control system is not necessary but the design of appropriate institutions. The design of auto-feeder in this paper is mainly focus on the type of gland, in which the track and related parts of this machine will be designed and calculated. This conveying device is composed of several parts including a cam, a crank, and a number of connecting rod. The cam makes the feed rod move in a vertical direction while a horizontal reciprocating motion is driven by the crank ,and its resultant motion can realize both swift feed and fast return. Structurally, welded structure will be adopted in chassis and rack while nut locking will be introduced to fix both ends of the pin..

Keywords: Auto-feeder; Connecting rod design; Optimization and processing of the cam design ; Kinematic analysis; Finite element analysis.

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1前言………………………………………………………………………………2

1.1课题的背景与意义…………………………………………………………………2

1.2国内外输送机发展趋势与水平……………………………………………………2

1.3我国输送机的未来之路与展望……………………………………………………3

2机械系统设计……………………………………………………………………4

2.1动作分析及轨迹初定………………………………………………………………4

2.2执行机构设计………………………………………………………………………5

2.3连杆杆长的设计与计算……………………………………………………………6

2.4凸轮设计

2.4.1轨迹优化及凸轮廓线……………………………………………………………7

2.4.2凸轮孔 …………………………………………………………………………10

2.4.3凸轮的加工制造 ………………………………………………………………11

2.5电动机选择……………………………………………………………………… 16

3传动零件的设计计算 ……………………………………………………………17

3.1输送杆的设计…………………………………………………………………… 17

3.2键连接强度计算………………………………………………………………… 19

3.3轴的结构设计…………………………………………………………………… 20

4机构的动力学分析…………………………………………………………………20

4.1运动模型的建立………………………………………………………………… 20

4.2运动分析………………………………………………………………………… 21

5有限元分析校核…………………………………………………………………… 24

5.1有限元CAE设计的优势………………………………………………………… 24

5.2输送杆的有限元校核…………………………………………………………… 25

5.3回转轴的有限元校核…………………………………………………………… 26

6结论…………………………………………………………………………27

参考文献 ………………………………………………………………………28

致谢……………………………………………………………………………29