设计简介

摘要

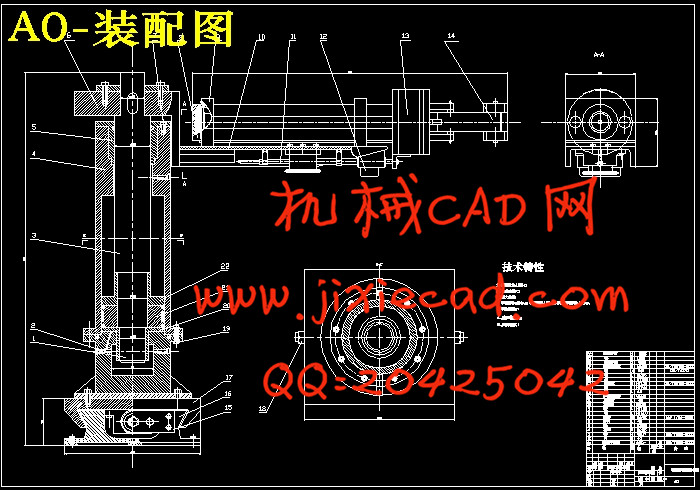

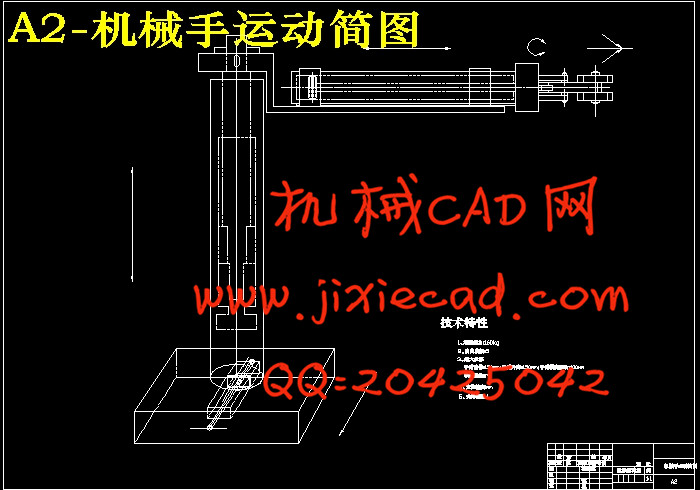

本次设计的液压传动机械手根据规定的动作顺序,综合运用所学的基本理论、基本知识和相关的机械设计专业知识,完成对机械手的设计,并绘制必要装配图、液压系统图。机械手的机械结构采用油缸、螺杆、导向筒等机械器件组成;在液压传动机构中,机械手的手臂伸缩采用伸缩油缸,手腕回转采用回转油缸,机械手的升降采用升降油缸,立柱的横移采用横向移动油缸。

本设计拟开发的上料机械手可在空间抓放物体,动作灵活多样,可代替人工在高温和危险的作业区进行作业,可抓取重量较大的工件。

关键词 机械手、液压

Abstract

The design of hydraulic drive manipulator movements under the provisions of the order ,use the basic theory , basic knowledge and related mechanical design expertise comprehensively to complete the design,and drawing the necessary assembly, hydraulic system map . Manipulator mechanical structure using tanks, screw , guide tubes and other mechanical device component ;In the hydraulic drive bodies ,manipulator arm stretching using telescopic tank ,manipulator movements using tank movements ,the column takes the horizontal movement of tanks .

The design of the proposed development of the information on the manipulator can grasp up in space objects ,flexible and varied movements ,can replace the artificial heat and dangerous operation conducted operations,and can grasp the larger workpieces .

Keywords Manipulator 、Hydraulic

目 录

1 前言

1.1概述-------------------------------------------------------------(1)

1.2世界机器人的发展-------------------------------------------------(1)

1.3我国工业机器人的发展---------------------------------------------(2)

1.4 我要设计的机械手-------------------------------------------------(3)

2 手部结构及其计算-------------------------------------------------------(6)

2.1概述-------------------------------------------------------------(6)

2.2设计时的参考要求-------------------------------------------------(7)

2.3驱动力的计算 ----------------------------------------------------(7)

2.4两支点回转式钳爪的定位误差的分析---------------------------------(9)

3 腕部的结构及其计算----------------------------------------------------(11)

3.1概述------------------------------------------------------------(11)

3.2 腕部的结构形式--------------------------------------------------(11)

3.3手腕驱动力矩的计算-----------------------------------------------(12)

4 臂部的结构及其计算----------------------------------------------------(15)

4.1概述------------------------------------------------------------(15)

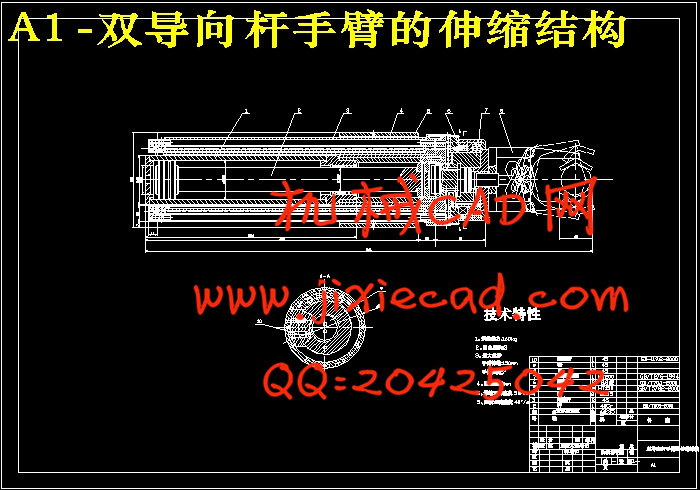

4.2手臂直线运动机构------------------------------------------------(15)

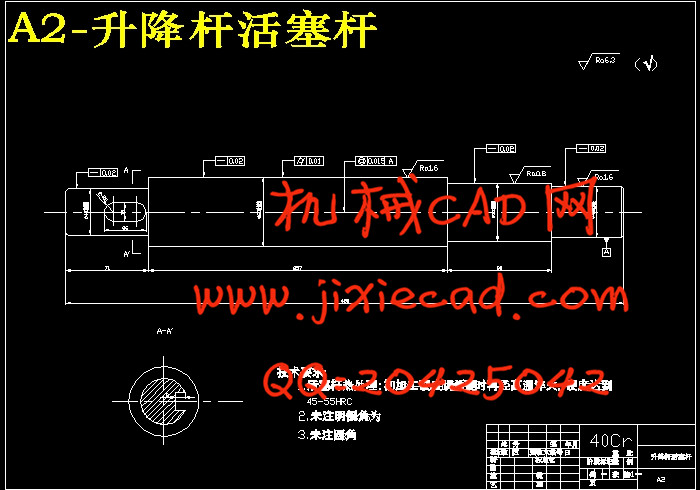

4.3手臂升降运动----------------------------------------------------(18)

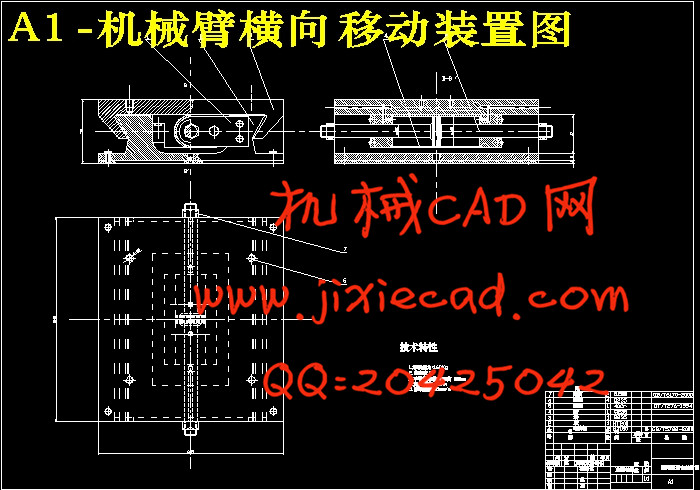

4.4手臂的横向移动--------------------------------------------------(19)

4.5 臂部运动驱动力计算----------------------------------------------(21)

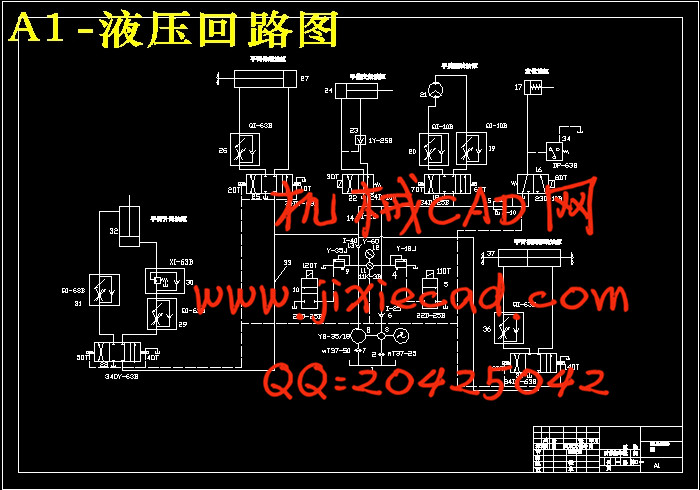

5 液压系统的设计--------------------------------------------------------(22)

5.1液压系统简介-----------------------------------------------------(22)

5.2液压系统的组成--------------------------------------------------(23)

5.3机械手液压系统的控制回路-----------------------------------------(23)

5.4械手的液压传动系统-----------------------------------------------(25)

5.5机械手液压系统的简单计算-----------------------------------------(29)

6 机械手的定位与平稳性—————————————————————————(36)

6.1影响平稳性和定位精度的因素---------------------------------------(36)

6.2机械手运动的缓冲装置---------------------------------------------(36)

6.3机械手运动的缓冲装置——————————————————————(37)

7 设计心得 -------------------------------------------------------------(38)

8 参考文献 -------------------------------------------------------------(40)

本次设计的液压传动机械手根据规定的动作顺序,综合运用所学的基本理论、基本知识和相关的机械设计专业知识,完成对机械手的设计,并绘制必要装配图、液压系统图。机械手的机械结构采用油缸、螺杆、导向筒等机械器件组成;在液压传动机构中,机械手的手臂伸缩采用伸缩油缸,手腕回转采用回转油缸,机械手的升降采用升降油缸,立柱的横移采用横向移动油缸。

本设计拟开发的上料机械手可在空间抓放物体,动作灵活多样,可代替人工在高温和危险的作业区进行作业,可抓取重量较大的工件。

关键词 机械手、液压

Abstract

The design of hydraulic drive manipulator movements under the provisions of the order ,use the basic theory , basic knowledge and related mechanical design expertise comprehensively to complete the design,and drawing the necessary assembly, hydraulic system map . Manipulator mechanical structure using tanks, screw , guide tubes and other mechanical device component ;In the hydraulic drive bodies ,manipulator arm stretching using telescopic tank ,manipulator movements using tank movements ,the column takes the horizontal movement of tanks .

The design of the proposed development of the information on the manipulator can grasp up in space objects ,flexible and varied movements ,can replace the artificial heat and dangerous operation conducted operations,and can grasp the larger workpieces .

Keywords Manipulator 、Hydraulic

目 录

1 前言

1.1概述-------------------------------------------------------------(1)

1.2世界机器人的发展-------------------------------------------------(1)

1.3我国工业机器人的发展---------------------------------------------(2)

1.4 我要设计的机械手-------------------------------------------------(3)

2 手部结构及其计算-------------------------------------------------------(6)

2.1概述-------------------------------------------------------------(6)

2.2设计时的参考要求-------------------------------------------------(7)

2.3驱动力的计算 ----------------------------------------------------(7)

2.4两支点回转式钳爪的定位误差的分析---------------------------------(9)

3 腕部的结构及其计算----------------------------------------------------(11)

3.1概述------------------------------------------------------------(11)

3.2 腕部的结构形式--------------------------------------------------(11)

3.3手腕驱动力矩的计算-----------------------------------------------(12)

4 臂部的结构及其计算----------------------------------------------------(15)

4.1概述------------------------------------------------------------(15)

4.2手臂直线运动机构------------------------------------------------(15)

4.3手臂升降运动----------------------------------------------------(18)

4.4手臂的横向移动--------------------------------------------------(19)

4.5 臂部运动驱动力计算----------------------------------------------(21)

5 液压系统的设计--------------------------------------------------------(22)

5.1液压系统简介-----------------------------------------------------(22)

5.2液压系统的组成--------------------------------------------------(23)

5.3机械手液压系统的控制回路-----------------------------------------(23)

5.4械手的液压传动系统-----------------------------------------------(25)

5.5机械手液压系统的简单计算-----------------------------------------(29)

6 机械手的定位与平稳性—————————————————————————(36)

6.1影响平稳性和定位精度的因素---------------------------------------(36)

6.2机械手运动的缓冲装置---------------------------------------------(36)

6.3机械手运动的缓冲装置——————————————————————(37)

7 设计心得 -------------------------------------------------------------(38)

8 参考文献 -------------------------------------------------------------(40)