设计简介

摘 要

本设计主要设计了液压教学实验台的执行装置液压油缸,简述了液压教学实验台的结构,原理和发展形势。论文结合当前液压教学实验台的发展趋势,液压传动课程的教学特点和要求,确定了液压缸的工作压力。根据工作压力对液压缸的各部件的尺寸进行计算和结构连接的选取确定了液压缸的结构。同时还考虑了液压缸各元件之间密封的选取和设计。最后还考虑了进出油口的管接头设计和液压缸的排气装置,最终完成了液压缸的整体设计。所设计的液压油缸经济适用,适用于中低压的液压系统,而且拆卸和组装都很方便适合液压教学的使用,满足学生和老师进行液压实验的要求。

关键词:液压实验台 液压缸 液压设计 中低液压系统

Hydraulic teaching test-bed implementation of the structural design of devices

The design of the hydraulic design of the main test-bed implementation of the teaching device hydraulic cylinder, hydraulic outlined the structure of test-bed teaching, principles and developments. Thesis combined with the current test-bed hydraulic teaching the development trend of teaching hydraulic characteristics and requirements, determine the work of the hydraulic cylinder pressure. According to the work pressure on the hydraulic cylinder the size of the various components are calculated and the structure of the selected connection identified the structure of hydraulic cylinders. At the same time, also considered among the components of hydraulic cylinder seal selection and design. Finally, taking into account the oil out of the mouth of the pipe connection of hydraulic cylinder design and the exhaust device, the final completion of the overall design of hydraulic cylinder. Designed hydraulic cylinder affordable, suitable for medium and low pressure hydraulic systems, and facilitate the dismantling and assembly are suitable for the use of hydraulic teaching to meet students and teachers to carry out the requirements of hydraulic experiments.

Keywords: hydraulic cylinder hydraulic test-bed design of low-hydraulic system

目 录

1 绪论 1

1.1 引言 1

1.2 液压教学实验概述 1

1.2.1国内外研究概况及发展趋势 1

1.2.2液压教学实验台功能及组成 1

1.3 课题研究依据及本文所做的工作 3

2 多功能液压教学台执行装置的设计 5

2.1 执行装置功能要求 5

2.2 执行装置设计 5

3 多功能液压教学实验台液压缸的设计 6

3.1 液压缸种类的确定 6

3.2 液压缸主要尺寸的确定 6

3.2.1液压工作压力的确定 6

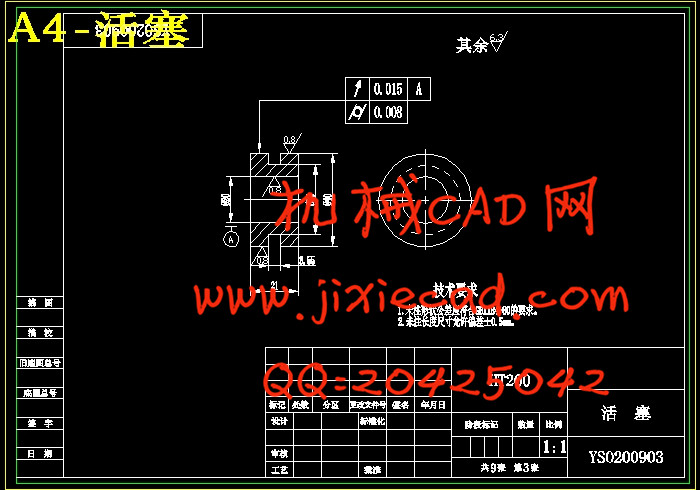

3.2.2液压缸内径D和活塞杆直径d的确定 6

3.2.3液压缸壁厚和外径的计算 8

3.2.4液压缸工作行程的确定 9

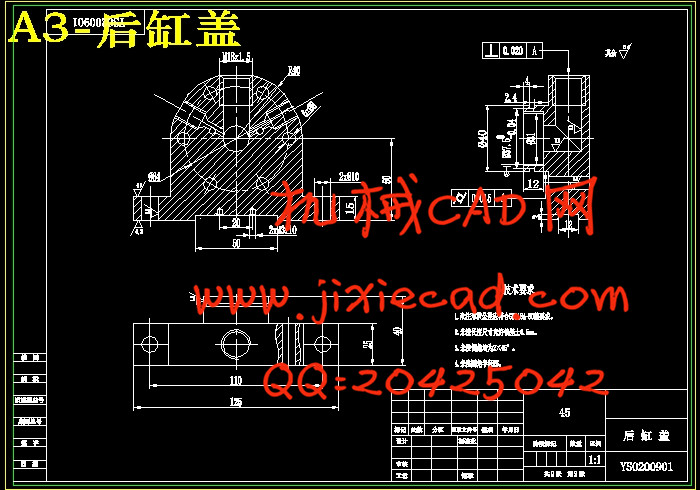

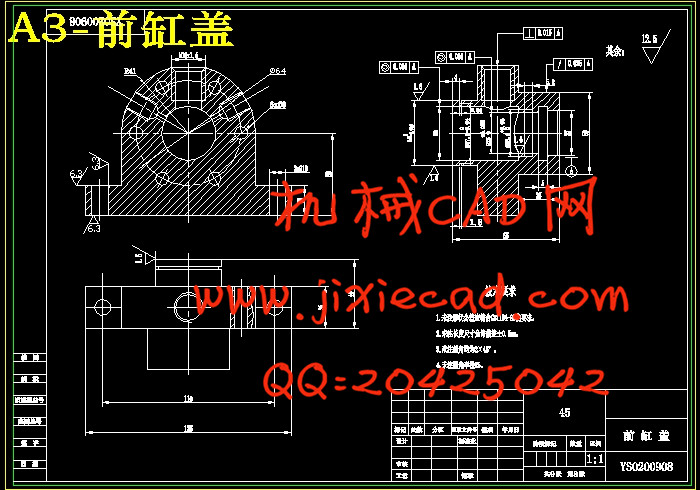

3.2.5液压缸缸盖厚度的确定 9

3.2.6最小导向长度的确定 10

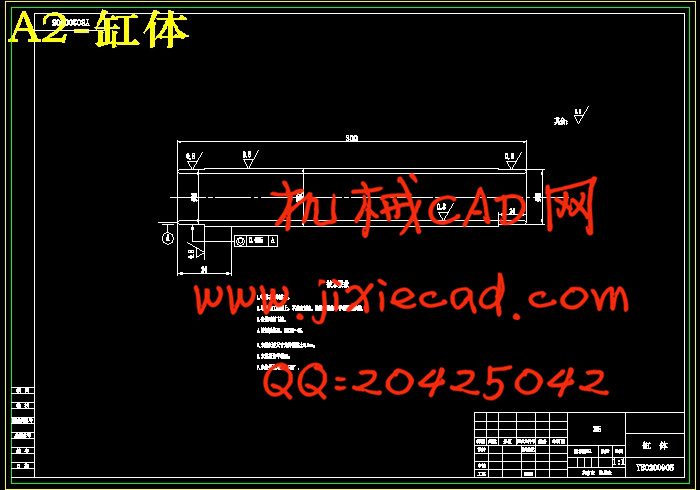

3.2.7缸体长度的确定 11

3.3 液压缸的结构设计 11

3.3.1缸体与缸盖的连接形式 11

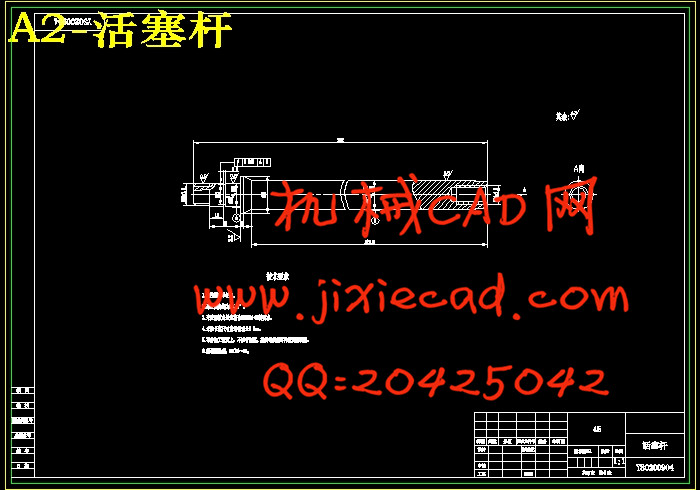

3.3.2活塞杆与活塞的连接结构 11

3.3.3活塞杆导向部分的结构 13

3.3.4活塞、活塞杆及端盖处密封圈的选用 14

3.3.5液压缸的缓冲装置 18

3.3.6液压缸的安装连接结构 20

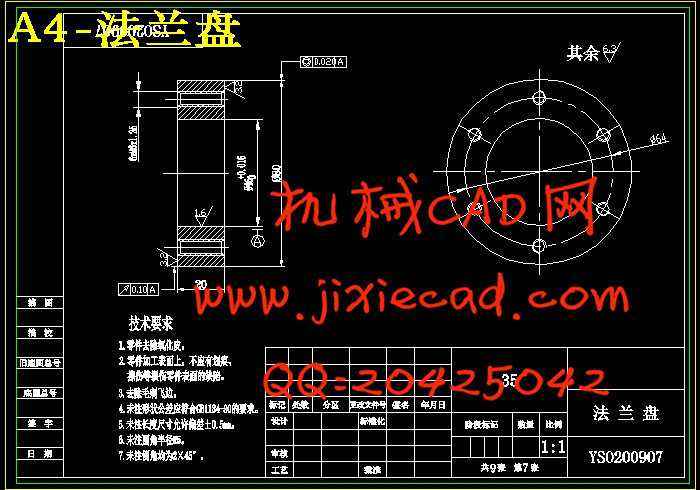

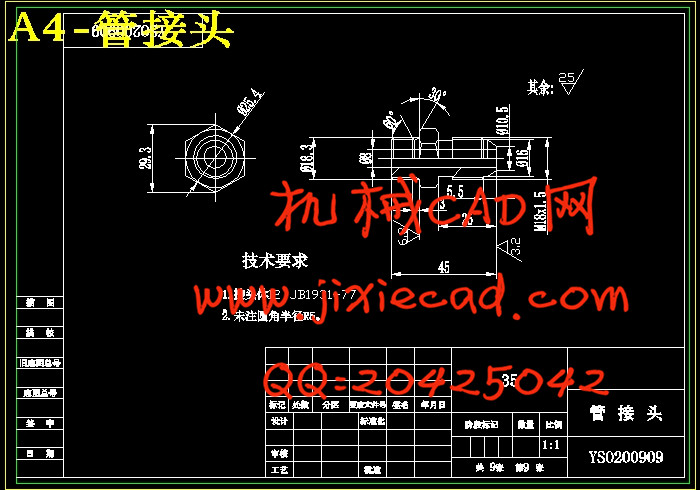

3.3.7液压缸的进出油口的管接头 23

3.3.8液压缸的排气装置 23

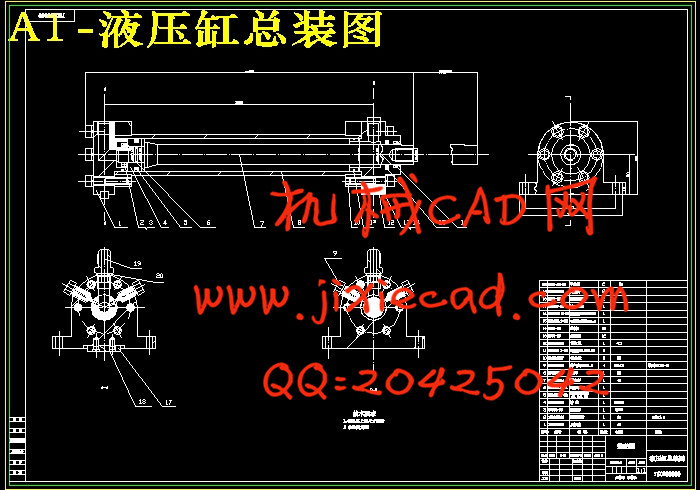

3.3.9液压缸的总体连接 24

4 总结 25

4.1 设计总结 25

参考文献 26

致谢 27

本设计主要设计了液压教学实验台的执行装置液压油缸,简述了液压教学实验台的结构,原理和发展形势。论文结合当前液压教学实验台的发展趋势,液压传动课程的教学特点和要求,确定了液压缸的工作压力。根据工作压力对液压缸的各部件的尺寸进行计算和结构连接的选取确定了液压缸的结构。同时还考虑了液压缸各元件之间密封的选取和设计。最后还考虑了进出油口的管接头设计和液压缸的排气装置,最终完成了液压缸的整体设计。所设计的液压油缸经济适用,适用于中低压的液压系统,而且拆卸和组装都很方便适合液压教学的使用,满足学生和老师进行液压实验的要求。

关键词:液压实验台 液压缸 液压设计 中低液压系统

Hydraulic teaching test-bed implementation of the structural design of devices

The design of the hydraulic design of the main test-bed implementation of the teaching device hydraulic cylinder, hydraulic outlined the structure of test-bed teaching, principles and developments. Thesis combined with the current test-bed hydraulic teaching the development trend of teaching hydraulic characteristics and requirements, determine the work of the hydraulic cylinder pressure. According to the work pressure on the hydraulic cylinder the size of the various components are calculated and the structure of the selected connection identified the structure of hydraulic cylinders. At the same time, also considered among the components of hydraulic cylinder seal selection and design. Finally, taking into account the oil out of the mouth of the pipe connection of hydraulic cylinder design and the exhaust device, the final completion of the overall design of hydraulic cylinder. Designed hydraulic cylinder affordable, suitable for medium and low pressure hydraulic systems, and facilitate the dismantling and assembly are suitable for the use of hydraulic teaching to meet students and teachers to carry out the requirements of hydraulic experiments.

Keywords: hydraulic cylinder hydraulic test-bed design of low-hydraulic system

目 录

1 绪论 1

1.1 引言 1

1.2 液压教学实验概述 1

1.2.1国内外研究概况及发展趋势 1

1.2.2液压教学实验台功能及组成 1

1.3 课题研究依据及本文所做的工作 3

2 多功能液压教学台执行装置的设计 5

2.1 执行装置功能要求 5

2.2 执行装置设计 5

3 多功能液压教学实验台液压缸的设计 6

3.1 液压缸种类的确定 6

3.2 液压缸主要尺寸的确定 6

3.2.1液压工作压力的确定 6

3.2.2液压缸内径D和活塞杆直径d的确定 6

3.2.3液压缸壁厚和外径的计算 8

3.2.4液压缸工作行程的确定 9

3.2.5液压缸缸盖厚度的确定 9

3.2.6最小导向长度的确定 10

3.2.7缸体长度的确定 11

3.3 液压缸的结构设计 11

3.3.1缸体与缸盖的连接形式 11

3.3.2活塞杆与活塞的连接结构 11

3.3.3活塞杆导向部分的结构 13

3.3.4活塞、活塞杆及端盖处密封圈的选用 14

3.3.5液压缸的缓冲装置 18

3.3.6液压缸的安装连接结构 20

3.3.7液压缸的进出油口的管接头 23

3.3.8液压缸的排气装置 23

3.3.9液压缸的总体连接 24

4 总结 25

4.1 设计总结 25

参考文献 26

致谢 27