设计简介

摘 要

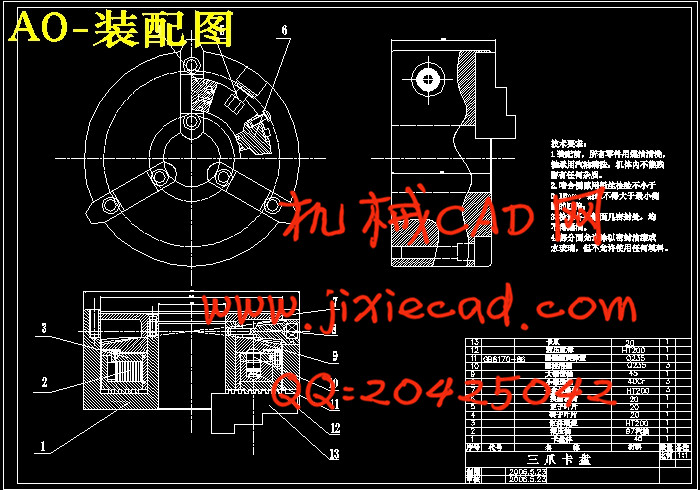

本设计一种在三爪卡盘上加装摆动式液压缸和平面螺旋机构的螺旋摆动式液压缸增力机构的结构。传统的机床如车床、铣床上三爪卡盘的工作一般依靠工人用手工进行夹紧,这不但增加了工人的劳动强度,而且所需夹紧力非常大,还常常有夹不紧的情况,阻碍了生产率的提高。通过在三爪卡盘加装摆动式液压缸和平面螺旋机构构成螺旋摆动式液压缸增力机构,可实现与原有卡盘体的较好结合,并使外加压力能转换成圆周运动,且其结构简单,工作可靠,能达到较高的增力比,具有良好的经济性和可行性。

关键词: 三爪卡盘,液压缸,夹具,增力

Key words: Three-jaw chuck, hydraulic cylinders clamps force

目 录

前言·······················································································································1

第1章 夹具介绍···································································································2

1.1 夹具的特点································································································2

1.2 研究夹具的目的和意义················································································5

1.3 夹具的国内外现状和发展趋势·······································································5

1.4 夹具的基本结构和原理················································································6

第2章 三爪卡盘螺旋摆动式液压缸增力机构的结构和原理······························7

第3章 主要参数确定与结构计算······································································8

3.1 液压腔的结构设计·······················································································8

3.2 转子叶片数的设计······················································································8

3.3 摆动角的设计·····························································································8

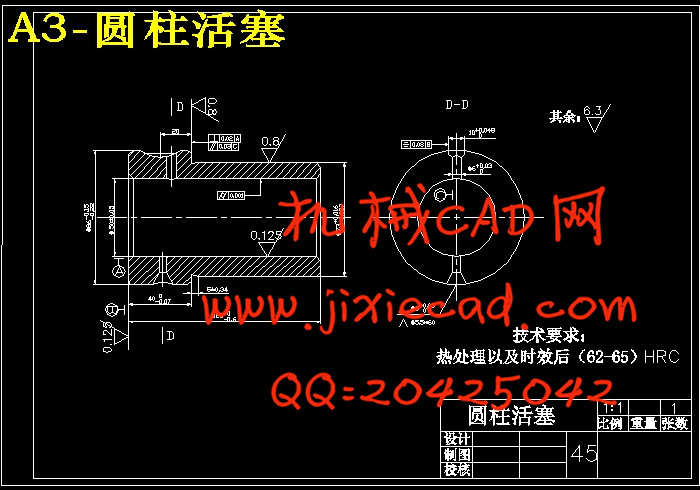

3.4 定子圆柱活塞杠面积的设计·········································································8

第4章 凹槽轮廓线的设计··················································································10

4.1 轮廓面段数的确定····················································································10

4.2 活塞杠升程的确定····················································································10

4.3 参数θ1的设计·························································································11

4.4 参数β的设计··························································································13

第5章 夹具在安装和操作时应注意的事项························································14

5.1 夹具的安装······························································································14

5.2 夹具在操作时应注意的事项·······································································14

第6章 夹具的经济效益分析··············································································16

第7章 单工位夹具与成组夹具的分析································································18

7.1定位基准与定位元件的选择·········································································18

7.2夹紧元件与夹紧力的选择·············································································18

7.3夹具基体的设计夹具基体·············································································18

7.4机壳成组夹具结构······················································································19

第8章 误差分析··································································································22

8.1定位误差分析···························································································22

8.2 装备误差分析··························································································22

参考文献··············································································································24

致谢·····················································································································25

本设计一种在三爪卡盘上加装摆动式液压缸和平面螺旋机构的螺旋摆动式液压缸增力机构的结构。传统的机床如车床、铣床上三爪卡盘的工作一般依靠工人用手工进行夹紧,这不但增加了工人的劳动强度,而且所需夹紧力非常大,还常常有夹不紧的情况,阻碍了生产率的提高。通过在三爪卡盘加装摆动式液压缸和平面螺旋机构构成螺旋摆动式液压缸增力机构,可实现与原有卡盘体的较好结合,并使外加压力能转换成圆周运动,且其结构简单,工作可靠,能达到较高的增力比,具有良好的经济性和可行性。

关键词: 三爪卡盘,液压缸,夹具,增力

Abstract

This paper design a 3 Java Card the installation of the swing hydraulic pressure tank peace side spiral the spiral swing hydraulic pressure tank increased power structure. Traditional machine tools such as lathes, Miller, Chuck 3 Claws of workers in general rely on a manual for gripping, this will not only increase the intensity of the work of the workers, and the required gripping power is very great, but also a folder is not immediately are often the case, hinder the increase in productivity. The 3 Claws chuck the installation of the swing hydraulic pressure tank peace side spiral institutions constitute a spiral swing hydraulic pressure tank increased authority to achieve the original chuck the better, and the additional pressure can be converted into a circular movement and the simple, reliable, can achieve a higher increase to more than a sound economic and practical.Key words: Three-jaw chuck, hydraulic cylinders clamps force

目 录

前言·······················································································································1

第1章 夹具介绍···································································································2

1.1 夹具的特点································································································2

1.2 研究夹具的目的和意义················································································5

1.3 夹具的国内外现状和发展趋势·······································································5

1.4 夹具的基本结构和原理················································································6

第2章 三爪卡盘螺旋摆动式液压缸增力机构的结构和原理······························7

第3章 主要参数确定与结构计算······································································8

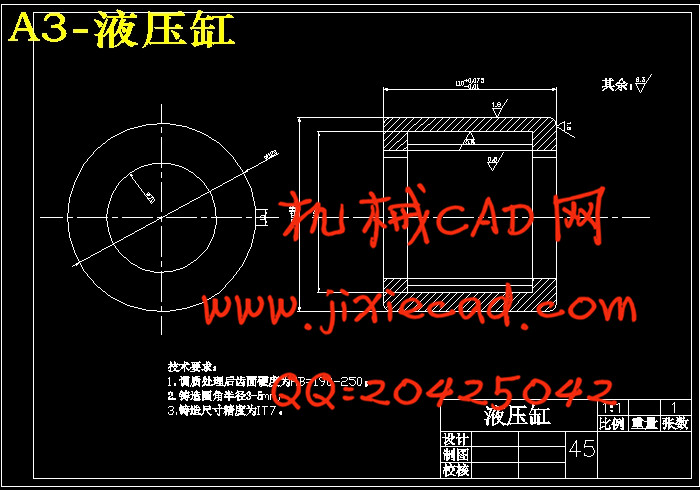

3.1 液压腔的结构设计·······················································································8

3.2 转子叶片数的设计······················································································8

3.3 摆动角的设计·····························································································8

3.4 定子圆柱活塞杠面积的设计·········································································8

第4章 凹槽轮廓线的设计··················································································10

4.1 轮廓面段数的确定····················································································10

4.2 活塞杠升程的确定····················································································10

4.3 参数θ1的设计·························································································11

4.4 参数β的设计··························································································13

第5章 夹具在安装和操作时应注意的事项························································14

5.1 夹具的安装······························································································14

5.2 夹具在操作时应注意的事项·······································································14

第6章 夹具的经济效益分析··············································································16

第7章 单工位夹具与成组夹具的分析································································18

7.1定位基准与定位元件的选择·········································································18

7.2夹紧元件与夹紧力的选择·············································································18

7.3夹具基体的设计夹具基体·············································································18

7.4机壳成组夹具结构······················································································19

第8章 误差分析··································································································22

8.1定位误差分析···························································································22

8.2 装备误差分析··························································································22

参考文献··············································································································24

致谢·····················································································································25