设计简介

液压式组合建筑机械机械部分设计

摘 要

液压式钢筋弯曲切断套丝多用机具有节约能源,加工效率高,易于控制,加工性能好等特点,它符合现代社会发展的需求,在建筑行业具有很好的发展前途。本文较为详细的介绍了多用机机械部分的设计过程和产品结构的一些说明。

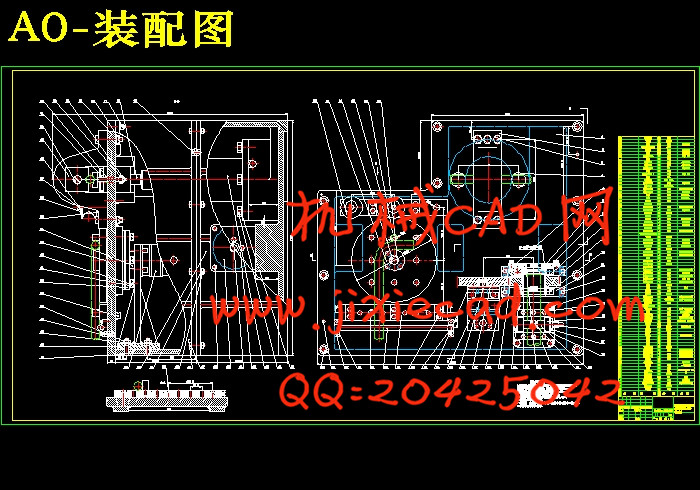

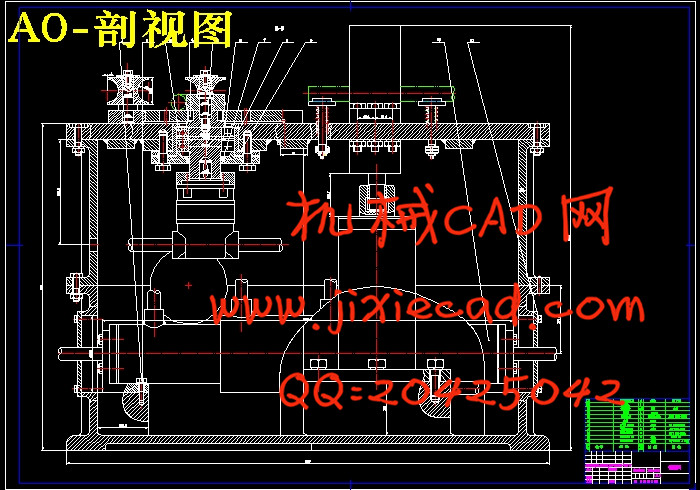

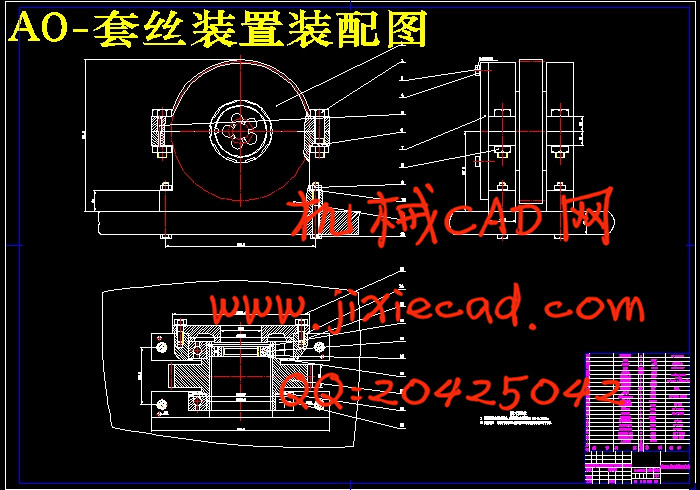

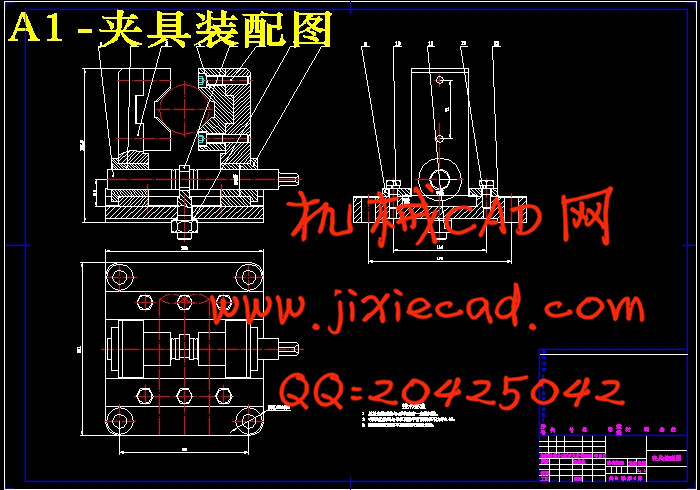

首先根据设计任务书提出的要求作出各种方案,通过分析论证各方案的优劣,选出其中较好的方案,进行设计。本设计部分分六大块:第一,切割部分设计,切割设计包含切断力计算,液压缸的布置,刀具的设计、刀具座的设计,初步估计出刀杆部分的轴径以及与活塞的连接。第二:弯曲设计,弯曲设计包括计算工作盘转速,工作时扭矩及功率的大小,设计主轴,初步确定其最小轴径尺寸,再根据要求设计出工作盘,及附件的结构尺寸。第三:套丝设计,套丝设计包括切削力和切削功率的计算,夹具的设计。第四:液压马达的选择及其应用。第五:液压马达支撑座的设计。第六:箱体的设计。

其次,各部分结构设计完成后,其质量到底如何,其强度刚度能否达到要求,能否满足生产需要,这些要靠校核来检测,齿轮的校核,传动轴的校核,键的校核。对这些部分的校核都通过对其强度和刚度进行验算,用其结果与其许用的强度、刚度进行比较,从而确定各危险部位是否满足要求。

关键词 弯曲成型机/成型轮/切割机/套丝/夹具/液压马达/液压缸/精度。

Hydraulic combination of construction machinery part of the design

The first, Make a various project according to the request of the design mission book, pass analytical good and bad of the argument everyone's case, select to among them compare good of project, carry on the design. This design part divides in to six courses :The first, the design of cutting, this design containment to cut off the dint calculation, to arrange the hydra cylinder, the design of the knife ,the first estimates the stalk path of a knife pole part and with the conjunction of the piston. The second: the design of bending machine, curve the design to include to compute the work dish to turn soon, in the work`s hour twists force and the size of the powers, the design principal axis, the first step makes sure its the minimum stalk the path size, then design a work dish according to the request, and the structure size of the enclosure. The third: A threading machine design, this design includes to slice to pare the dint and slice the calculation of pare the power, the design of the tongs. The fourth: The choice of the hydromotor and it is applied. The fifth: the design of the hydromotor that the hydromotor props up. The sixth: The design of the machine`s body.

After each parts of structure design completed, it`s quantity exactly how, its strength just the degree can attain the request, can satisfy to produce the demand, these pits that want to depend on calculating, the gear`s checking, the check of the driver shaft, the check of the key. All these passing to the pits of these parts as to it's strength and just the degree carries on checking to calculate, the strength that allowed , using these results, comparised with each others, thus making sure whether each dangerous part satisfies the request or not.

KEYWORDS bending machine , the forming round , cutting machine, threading machine , fixture, hydromotor, hydra cylinder, accuracy.

目 录

中文摘要………………………………………………………………………………Ⅰ

英文摘要………………………………………………………………………………Ⅱ

方案论证………………………………………………………………………………IV

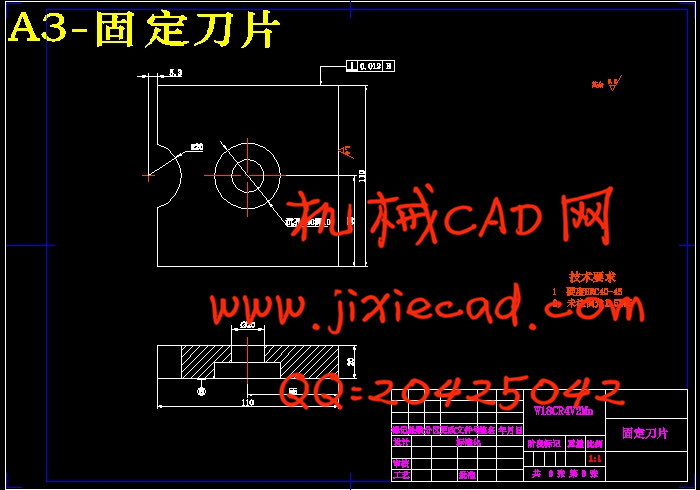

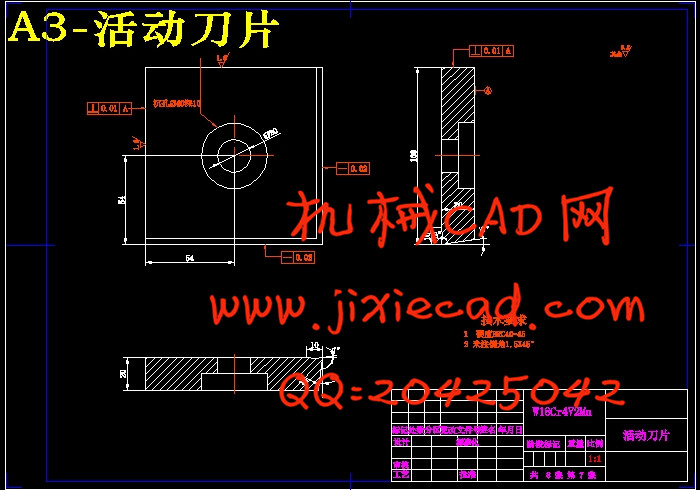

1 钢筋切削机构的设计………………………………………………………………1

1.1 切断力的计算………………………………………………………………… 1

1.2 刀具的设计……………………………………………………………………3

1.3 刀具的固定和连接 …………………………………………………………5

1.4 作用在切断机构上力的计算与螺栓的校核……………………………5

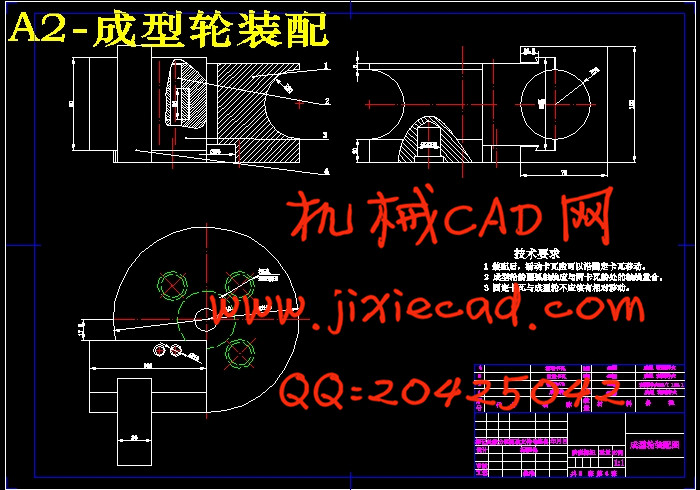

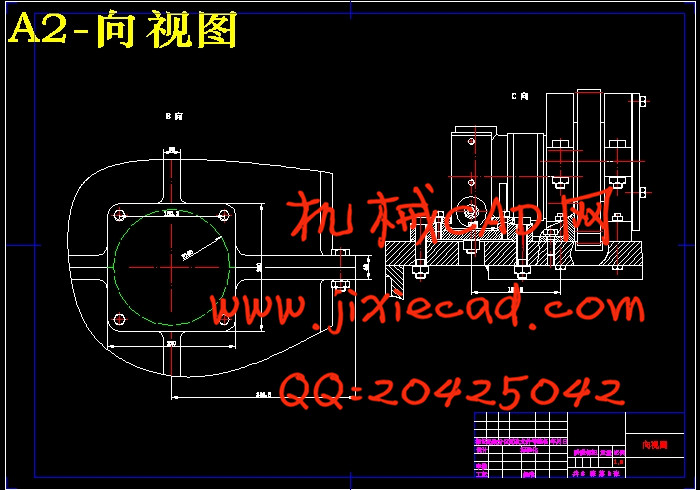

2 弯曲部分设计 ………………………………………………………………………7

2.1 工作盘转速…………………………………………………………………… 8

2.2 作用在工作盘上的扭矩M…………………………………………………… 8

2.3 危险部位轴的直径…………………………………………………………9

2.4 传动轴处的键的设计与校核 ……………………………………………9

2.5 工作盘及附件的选择和使用…………………………………………… 10

2.5.1 工作盘的设计原理…………………………………………………10

2.5.2 心轴的使用…………………………………………………… 10

2.5.3 成型轴的使用………………………………………………… 10

2.5.4 挡板轴的使用…………………… …………………………… 11

2.5.5 送料辊的使用……………………………………………………11

2.5.6 钢筋挡架的使用…………………………………………………11

2.5.7 钢筋的弯曲成型……………………………………………………12

2.5.8 心轴与成型轴R的确定…………………………………………… 12

2.5.9 工作转盘上的心轴的校核…………………………………………13

3 套丝机构的设计……………………………………………………………………14

3.1 套丝时切削力计算……………………………………………………………14

3.1.1 按车削计算…………………………………………………………14

3.1.2 按套丝时的公式计算………………………………………………14

3.2 套丝机构的设计………………………………………………………………15

3.2.1 板牙及其板牙架……………………………………………………15

3.2.2 齿轮轴的设计…………………………………………………… 17

3.2. 3 齿轮轴的抗扭校核 …………………………………………… 17

3.2.4 齿轮轴内花键的校核 ………………………………………… 17

3.2.5 齿轮的设计校核 ……………………………………………… 18

3.2.6 套丝机构中螺栓组的设计校核 ………………………………… 23

3.2.7 夹具的设计…………………………………………………………24

3.2.8 夹具的夹紧力计算…………………………………………………25

4 液压马达的选择及其使用…………………………………………………………26

4.1 液压马达使用注意项…………………………………………………26

4.2 液压马达的选用……………………………………………………… 26

5 液压马达支撑座的设计…………………………………………………………… 27

6 箱体的设计………………………………………………………………………… 28

总结…………………………………………………………………………………29

致谢…………………………………………………………………………………31

参考文献…………………………………………………………………………… 32

摘 要

液压式钢筋弯曲切断套丝多用机具有节约能源,加工效率高,易于控制,加工性能好等特点,它符合现代社会发展的需求,在建筑行业具有很好的发展前途。本文较为详细的介绍了多用机机械部分的设计过程和产品结构的一些说明。

首先根据设计任务书提出的要求作出各种方案,通过分析论证各方案的优劣,选出其中较好的方案,进行设计。本设计部分分六大块:第一,切割部分设计,切割设计包含切断力计算,液压缸的布置,刀具的设计、刀具座的设计,初步估计出刀杆部分的轴径以及与活塞的连接。第二:弯曲设计,弯曲设计包括计算工作盘转速,工作时扭矩及功率的大小,设计主轴,初步确定其最小轴径尺寸,再根据要求设计出工作盘,及附件的结构尺寸。第三:套丝设计,套丝设计包括切削力和切削功率的计算,夹具的设计。第四:液压马达的选择及其应用。第五:液压马达支撑座的设计。第六:箱体的设计。

其次,各部分结构设计完成后,其质量到底如何,其强度刚度能否达到要求,能否满足生产需要,这些要靠校核来检测,齿轮的校核,传动轴的校核,键的校核。对这些部分的校核都通过对其强度和刚度进行验算,用其结果与其许用的强度、刚度进行比较,从而确定各危险部位是否满足要求。

关键词 弯曲成型机/成型轮/切割机/套丝/夹具/液压马达/液压缸/精度。

Hydraulic combination of construction machinery part of the design

ABSTRACT

The hydraulic type of machine using reinforcing bar flection cuts off a set of silk to have the economy energy, processing the efficiency high, be easy to be controlled, processing the good function etc. characteristics, it fits the need of the modern and social development, having the good development prospect at the profession of construction. This text will introduce to you the design process and the structure of this machine more detailedly.The first, Make a various project according to the request of the design mission book, pass analytical good and bad of the argument everyone's case, select to among them compare good of project, carry on the design. This design part divides in to six courses :The first, the design of cutting, this design containment to cut off the dint calculation, to arrange the hydra cylinder, the design of the knife ,the first estimates the stalk path of a knife pole part and with the conjunction of the piston. The second: the design of bending machine, curve the design to include to compute the work dish to turn soon, in the work`s hour twists force and the size of the powers, the design principal axis, the first step makes sure its the minimum stalk the path size, then design a work dish according to the request, and the structure size of the enclosure. The third: A threading machine design, this design includes to slice to pare the dint and slice the calculation of pare the power, the design of the tongs. The fourth: The choice of the hydromotor and it is applied. The fifth: the design of the hydromotor that the hydromotor props up. The sixth: The design of the machine`s body.

After each parts of structure design completed, it`s quantity exactly how, its strength just the degree can attain the request, can satisfy to produce the demand, these pits that want to depend on calculating, the gear`s checking, the check of the driver shaft, the check of the key. All these passing to the pits of these parts as to it's strength and just the degree carries on checking to calculate, the strength that allowed , using these results, comparised with each others, thus making sure whether each dangerous part satisfies the request or not.

KEYWORDS bending machine , the forming round , cutting machine, threading machine , fixture, hydromotor, hydra cylinder, accuracy.

目 录

中文摘要………………………………………………………………………………Ⅰ

英文摘要………………………………………………………………………………Ⅱ

方案论证………………………………………………………………………………IV

1 钢筋切削机构的设计………………………………………………………………1

1.1 切断力的计算………………………………………………………………… 1

1.2 刀具的设计……………………………………………………………………3

1.3 刀具的固定和连接 …………………………………………………………5

1.4 作用在切断机构上力的计算与螺栓的校核……………………………5

2 弯曲部分设计 ………………………………………………………………………7

2.1 工作盘转速…………………………………………………………………… 8

2.2 作用在工作盘上的扭矩M…………………………………………………… 8

2.3 危险部位轴的直径…………………………………………………………9

2.4 传动轴处的键的设计与校核 ……………………………………………9

2.5 工作盘及附件的选择和使用…………………………………………… 10

2.5.1 工作盘的设计原理…………………………………………………10

2.5.2 心轴的使用…………………………………………………… 10

2.5.3 成型轴的使用………………………………………………… 10

2.5.4 挡板轴的使用…………………… …………………………… 11

2.5.5 送料辊的使用……………………………………………………11

2.5.6 钢筋挡架的使用…………………………………………………11

2.5.7 钢筋的弯曲成型……………………………………………………12

2.5.8 心轴与成型轴R的确定…………………………………………… 12

2.5.9 工作转盘上的心轴的校核…………………………………………13

3 套丝机构的设计……………………………………………………………………14

3.1 套丝时切削力计算……………………………………………………………14

3.1.1 按车削计算…………………………………………………………14

3.1.2 按套丝时的公式计算………………………………………………14

3.2 套丝机构的设计………………………………………………………………15

3.2.1 板牙及其板牙架……………………………………………………15

3.2.2 齿轮轴的设计…………………………………………………… 17

3.2. 3 齿轮轴的抗扭校核 …………………………………………… 17

3.2.4 齿轮轴内花键的校核 ………………………………………… 17

3.2.5 齿轮的设计校核 ……………………………………………… 18

3.2.6 套丝机构中螺栓组的设计校核 ………………………………… 23

3.2.7 夹具的设计…………………………………………………………24

3.2.8 夹具的夹紧力计算…………………………………………………25

4 液压马达的选择及其使用…………………………………………………………26

4.1 液压马达使用注意项…………………………………………………26

4.2 液压马达的选用……………………………………………………… 26

5 液压马达支撑座的设计…………………………………………………………… 27

6 箱体的设计………………………………………………………………………… 28

总结…………………………………………………………………………………29

致谢…………………………………………………………………………………31

参考文献…………………………………………………………………………… 32