设计简介

摘要:。在本次设计中,由于轮式行走机构结构紧凑且工作效率高,通过比较采用了轮胎式行走装置来满足设计要求。 根据设计要求,机重为11吨;轮胎规格为9.00-20;轮胎动力半径r =0.491米。挖掘机最大牵引力P

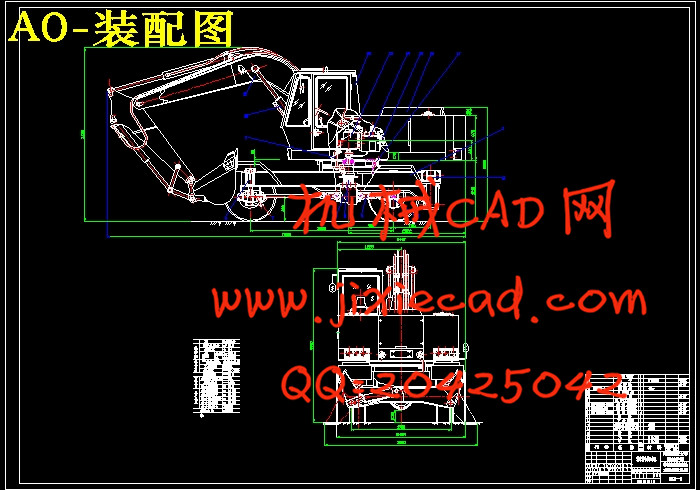

=0.491米。挖掘机最大牵引力P =0.6机重;发动机功率N=58.8KW,转速2000r/min;油泵最大流量2×100l/min;最大工作压力21MPa。最高行驶速度31Km/h,设计取全桥驱动。上部转台是全回转式,因此它可在一个更大的范围内工作。又因采用液压机械传动控制而使整机性能得以改善。与传统机械式挖掘机相比,其行走能力提高到了很多。本次设计的主要内容为:液压挖掘机行走装置方案设计;绘制装配草图和总装配图;动力源选择及有关参数的确定;行走装置牵引力的计算;传动方式比较与选择、传动方案的确定及传动系统的技术设计;行星减速器及零、部件的设计计算,主要零件强度校核;绘制零、部件图和总装配图,进行仿真设计,编写设计计算说明书。

=0.6机重;发动机功率N=58.8KW,转速2000r/min;油泵最大流量2×100l/min;最大工作压力21MPa。最高行驶速度31Km/h,设计取全桥驱动。上部转台是全回转式,因此它可在一个更大的范围内工作。又因采用液压机械传动控制而使整机性能得以改善。与传统机械式挖掘机相比,其行走能力提高到了很多。本次设计的主要内容为:液压挖掘机行走装置方案设计;绘制装配草图和总装配图;动力源选择及有关参数的确定;行走装置牵引力的计算;传动方式比较与选择、传动方案的确定及传动系统的技术设计;行星减速器及零、部件的设计计算,主要零件强度校核;绘制零、部件图和总装配图,进行仿真设计,编写设计计算说明书。

本设计的主要特点是:方案设计中提出多种方案,从可靠性、可实现性、综合性能等进行方案比较,选择方案。其构造特点是行走部件之间的传动采用齿轮传动和液压传动,通过油缸的伸缩来实现挖掘行走过程中的动力传递。差速器与回转平台铰接技术设计中应考虑总体配置合理、安全;选材、加工方法和技术条件参阅相关技术资料;图纸按照所设计的参数进行绘制。充分注意整机各子系统之间的相关性,力求整机性能的一致性和最优化性。从中可以看出整机作业能力有了很大的改进,不仅行走速度快,且整体挖掘机器重量轻,传动平稳,作业效率高,结构紧凑。

关键词:液压挖掘机 行走装置 减速器

Abstract:In this design, because the compact wheel running gear is high efficiency, by comparing the use of a tire to meet the design requirements of walking devices.According to design requirements, machine weight 11 tons; tire sizes 9.00-20; tire dynamic radius r = 0.491 meters. Excavator maximum traction P = 0.6 Weight; engine power N = 58.8KW, speed 2000r/min; pump maximum flow rate 2 × 100l/min; maximum working pressure of 21MPa. Maximum speed 31Km / h, designed to take full bridge driver.Upper turntable is the entire rotation, so it can be in a larger range.Because of the use of hydraulic mechanical transmission the entire machine performance can be improved.Compared with the traditional mechanical excavators, and its capacity to a lot of walking.The design of the main contents are: hydraulic excavator equipment design; assembly drawing general assembly drawings and sketches; power source selection and the determination of the parameters; running gear traction calculation; Transmission comparison and selection, determination and drive schemeTransmission of the technical design; planetary gear and parts and components of the design calculations, the main part strength check; drawn components and parts drawings, and assembly drawings, design calculations prepared statement.

The design of the main features are: program design presented in a variety of programs, from the reliability, can be realized, for programs such as comprehensive performance comparison options.Its structure is characterized by walking between the drive components and hydraulic transmission with gear drive, stretching through the cylinder to achieve the excavation of the power during walking.Differential with the rotary platform articulated the overall technical design should be considered a reasonable allocation, security; selection, processing methods and criteria refer to the relevant technical information; drawings in accordance with the design parameters to draw.Full attention to machine the correlation between the various subsystems, and strive to overall performance of the consistency and optimization.Machine operation capability can be seen from a considerable improvement, not only walking speed, and overall mining machinery, light weight, smooth drive, high efficiency, compact structure.

Keywords: Hydraulic walking device reducer

目 录

1 绪 论 1

1.1 选题意义 1

1.2 国内外研究现状 2

1.3 研究内容及方法 3

2 行走装置设计总体基本方案 4

2.1行走装置设计原则 4

2.2轮式液压挖掘机行走装置的结构形式 4

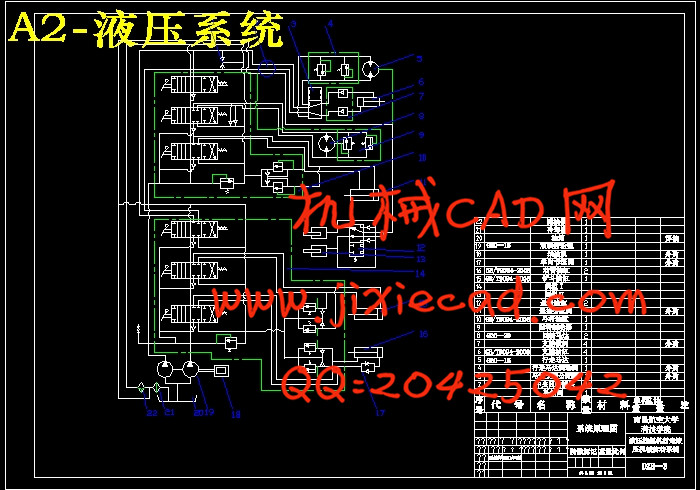

2.3液压系统的设计 6

2.4轮式行走装置的传动设计(液压机械传动) 10

2.5轮式行走装置的构造 11

2.5.1悬挂装置选择 11

2.5.2 转向机构 12

2.5.3 转向方式 13

3 整机传动系的设计 15

3.1选择液压马达类型、行走速度及传动比 15

3.2实际速度及牵引力 17

3.3挖掘机行走装置参数 17

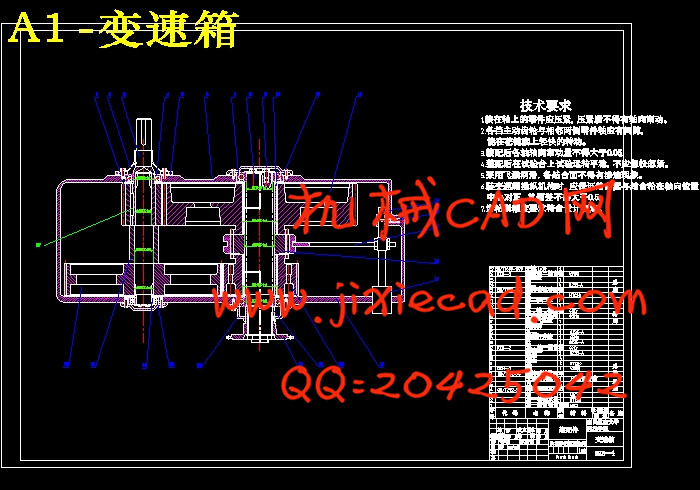

3.4 变速箱设计 18

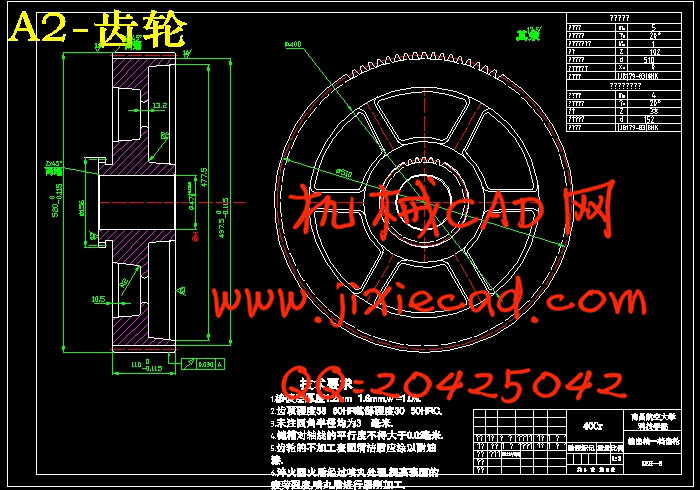

3.4.1低速档齿轮设计 18

1 材料选择 18

2 齿数确定 18

3 按齿面接触强度设计 18

4 按齿根弯曲强度设计 21

5 齿轮几何尺寸计算 23

3.4.2高速档齿轮设计 23

3.4.3齿轮变位 24

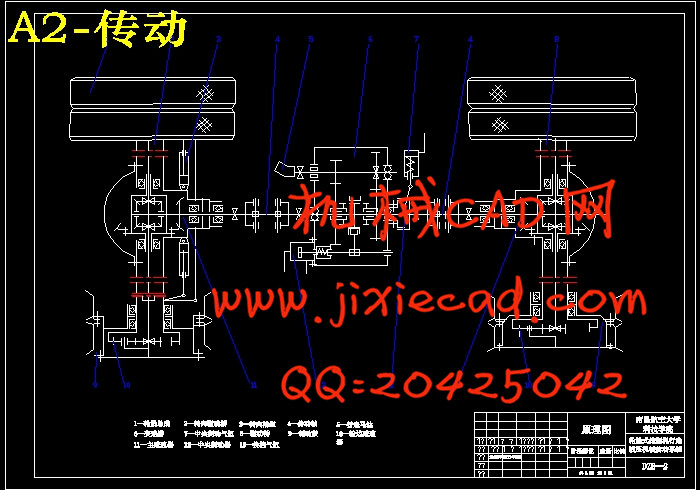

3.5 轮边减速器 26

3.5.1传动方案的选择 26

3.5.2配齿选择 26

3.5.3行星传动系设计 27

主要参数确定. 27

4 其他部件设计 28

4.1轴和轴承设计 28

4.2轴承、键和连轴器的选择 28

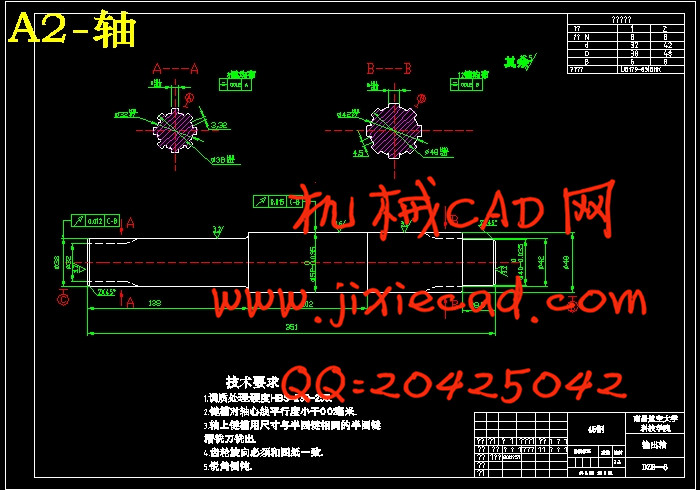

4.2.1输入轴 28

4.2.2 输出轴 29

5液压挖掘机行走装置运动仿真设计 31

5.1模型的建立 31

5.2构件运动配装 31

5.2.1相似点 31

5.2.2 不同点 31

结 论 35

参考文献 36

致 谢 37

本设计的主要特点是:方案设计中提出多种方案,从可靠性、可实现性、综合性能等进行方案比较,选择方案。其构造特点是行走部件之间的传动采用齿轮传动和液压传动,通过油缸的伸缩来实现挖掘行走过程中的动力传递。差速器与回转平台铰接技术设计中应考虑总体配置合理、安全;选材、加工方法和技术条件参阅相关技术资料;图纸按照所设计的参数进行绘制。充分注意整机各子系统之间的相关性,力求整机性能的一致性和最优化性。从中可以看出整机作业能力有了很大的改进,不仅行走速度快,且整体挖掘机器重量轻,传动平稳,作业效率高,结构紧凑。

关键词:液压挖掘机 行走装置 减速器

Abstract:In this design, because the compact wheel running gear is high efficiency, by comparing the use of a tire to meet the design requirements of walking devices.According to design requirements, machine weight 11 tons; tire sizes 9.00-20; tire dynamic radius r = 0.491 meters. Excavator maximum traction P = 0.6 Weight; engine power N = 58.8KW, speed 2000r/min; pump maximum flow rate 2 × 100l/min; maximum working pressure of 21MPa. Maximum speed 31Km / h, designed to take full bridge driver.Upper turntable is the entire rotation, so it can be in a larger range.Because of the use of hydraulic mechanical transmission the entire machine performance can be improved.Compared with the traditional mechanical excavators, and its capacity to a lot of walking.The design of the main contents are: hydraulic excavator equipment design; assembly drawing general assembly drawings and sketches; power source selection and the determination of the parameters; running gear traction calculation; Transmission comparison and selection, determination and drive schemeTransmission of the technical design; planetary gear and parts and components of the design calculations, the main part strength check; drawn components and parts drawings, and assembly drawings, design calculations prepared statement.

The design of the main features are: program design presented in a variety of programs, from the reliability, can be realized, for programs such as comprehensive performance comparison options.Its structure is characterized by walking between the drive components and hydraulic transmission with gear drive, stretching through the cylinder to achieve the excavation of the power during walking.Differential with the rotary platform articulated the overall technical design should be considered a reasonable allocation, security; selection, processing methods and criteria refer to the relevant technical information; drawings in accordance with the design parameters to draw.Full attention to machine the correlation between the various subsystems, and strive to overall performance of the consistency and optimization.Machine operation capability can be seen from a considerable improvement, not only walking speed, and overall mining machinery, light weight, smooth drive, high efficiency, compact structure.

Keywords: Hydraulic walking device reducer

目 录

1 绪 论 1

1.1 选题意义 1

1.2 国内外研究现状 2

1.3 研究内容及方法 3

2 行走装置设计总体基本方案 4

2.1行走装置设计原则 4

2.2轮式液压挖掘机行走装置的结构形式 4

2.3液压系统的设计 6

2.4轮式行走装置的传动设计(液压机械传动) 10

2.5轮式行走装置的构造 11

2.5.1悬挂装置选择 11

2.5.2 转向机构 12

2.5.3 转向方式 13

3 整机传动系的设计 15

3.1选择液压马达类型、行走速度及传动比 15

3.2实际速度及牵引力 17

3.3挖掘机行走装置参数 17

3.4 变速箱设计 18

3.4.1低速档齿轮设计 18

1 材料选择 18

2 齿数确定 18

3 按齿面接触强度设计 18

4 按齿根弯曲强度设计 21

5 齿轮几何尺寸计算 23

3.4.2高速档齿轮设计 23

3.4.3齿轮变位 24

3.5 轮边减速器 26

3.5.1传动方案的选择 26

3.5.2配齿选择 26

3.5.3行星传动系设计 27

主要参数确定. 27

4 其他部件设计 28

4.1轴和轴承设计 28

4.2轴承、键和连轴器的选择 28

4.2.1输入轴 28

4.2.2 输出轴 29

5液压挖掘机行走装置运动仿真设计 31

5.1模型的建立 31

5.2构件运动配装 31

5.2.1相似点 31

5.2.2 不同点 31

结 论 35

参考文献 36

致 谢 37