设计简介

摘要:近年来,随着钢铁业、煤炭业、电力业的持续迅猛发展,挖掘机等工程机械的需求日益增加,并广泛地运用于房屋建筑、筑路工程、水利建设、农林开发、港口建设、国防工事的土石方施工和矿山采掘工业中。由于其作业工况复杂多变,挖掘方式往往是凭借操作者的经验,根据实际作业工况决定,为了减小操作者的挖掘经验对挖掘效果的影响,就迫切需要建立起铲斗挖掘轨迹与各液压缸的直接对应关系,实现挖掘机操作的自动化。同时由于挖掘机的工作环境的复杂性及工况的多变性,就要求液压挖掘机本身结构要根据环境的不同作相应的调整,这就决定了挖掘机设计的平凡性、重复性。然而液压挖掘机的工作装置又是一个多自由度的多杆系统,各铰点的确定非常复杂,这些因素就造成了液压挖掘机的投资大、设计周期长,严重地影响了厂商的经济效益及国民经济的发展。

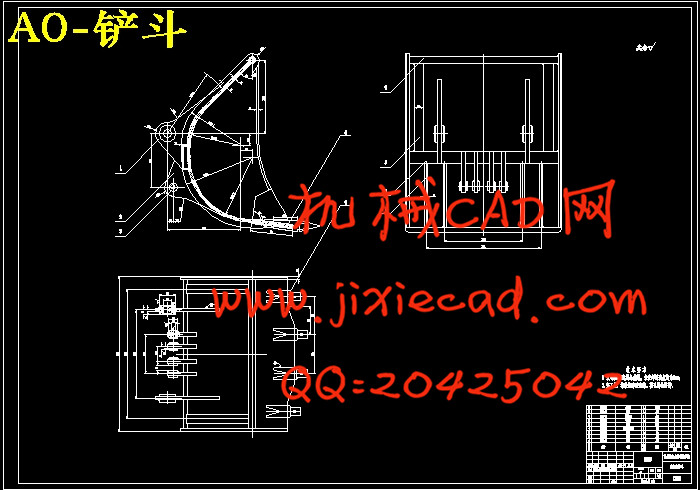

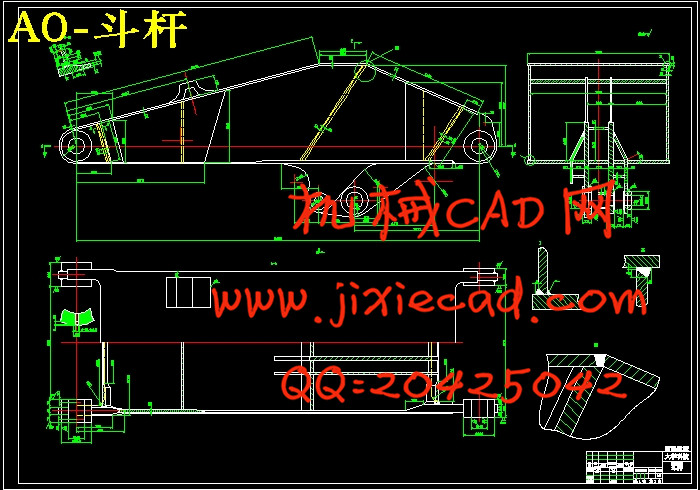

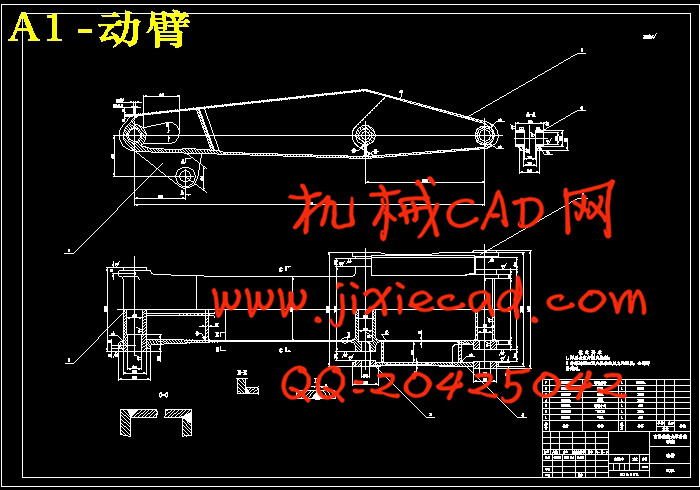

本文主要的设计工作主要有以下几个方面:在现场测绘及参考有关资料的基础上了解液压挖掘机的工作方式及工作环境。确定液压挖掘机各个工作装置的结构,查找相关资料并结合经验公式对挖掘机工作装置的总体进行设计,用比例法和经验公式计算出工作装置各部分的基本尺寸并对其进行应力分析,然后绘制出其二维CAD图纸,继而用PRO/E画出各装置的三维模型。将各装置装配后对其进行运动模拟仿真。

关键词:挖掘机;工作装置;CAD;PRO/E;运动仿真

Abstract: In recent years, as steel, coal industry and quarrying continued rapid development, excavators engineering machinery requirement increasingly, and is widely used in housing construction, road engineering, water conservancy construction, forestry development, port construction, national defense construction and conditions of fortifications mining extraction industryDue to the complex and changeable, mining operation condition is often with operator way according to the actual working experience, decision, in order to reduce homework to excavate the mining experience operator, the effects will is in urgent need to build up the bucket with various hydraulic cylinder dig trajectory direct corresponding relation, realize the automation. Excavator operationAt the same time because of the complexity of an excavator working environment and conditions, requires the fluidity of hydraulic excavator itself according to the different structural environment makes the corresponding adjustment, this determines the excavator design of ordinary sex, repeatability. However hydraulic excavator working device is a much more freedom, the hinge point bar system to determine the very complex, these factors will cause the hydraulic excavator big investment, design cycle is long, the serious influence on the economic benefits of the manufacturers and national economic development.

This paper mainly design work mainly in the following aspects: in the field surveying and mapping and reference on the basis of relevant information about the hydraulic excavator way of working and working environment Determine the hydraulic excavator, each working device search relevant material and structure of practical experience formula of the overall work device for excavators designed, use proportion method and experience calculation work device each part of basic size and carries on the stress analysis, and then plot its two-dimensional CAD drawings, and then painted with PRO/E 3d model of each device. After each device assembly of its motion simulation

Keywords: Hydraulic Excavator; Working device; Boom;Stick;Face-shovel

目录

1 前言 (1)

1.1课题研究的背景和意义 (1)

1.2 液压挖掘机研究现状及发展动态 (1)

1.2.1 国外的研究现状及发展动态 (2)

1.2.2 国内的研究现状及发展动态 (3)

1.3 本文研究的主要内容 (5)

2液压正铲挖掘机工作装置的运动分析 (6)

2.1 液压正铲挖掘机的基本组成和工作原理 (6)

2.2 工作装置结构方案的确定 (7)

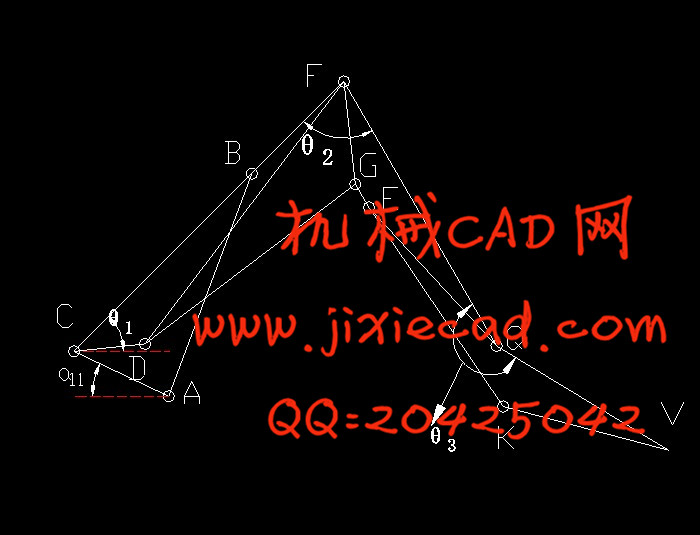

2.3 工作装置运动分析 (10)

2.3.1动臂运动分析 (10)

2.3.2斗杆运动分析 (12)

2.3.3斗齿尖的几种特殊工作位置的计算 (13)

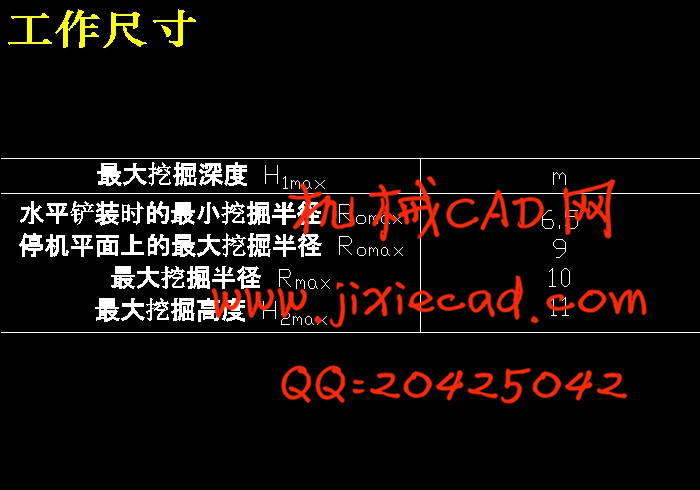

3 工作装置尺寸的设计确定 (17)

3.1应用举例 (17)

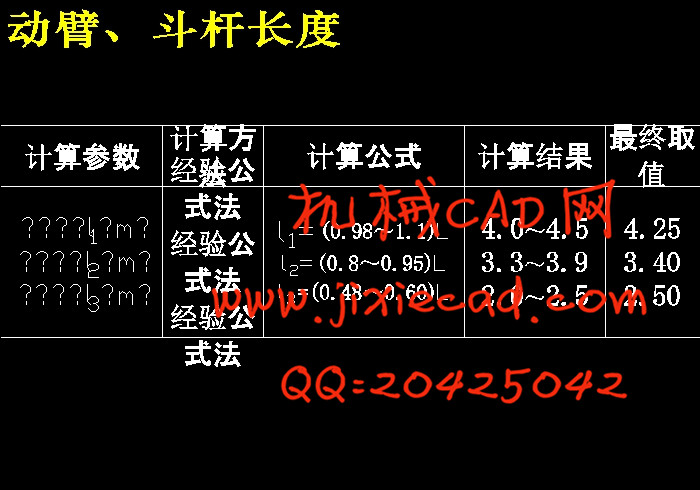

3.1.2动臂及斗杆长度确定 …………………………………………………(17)

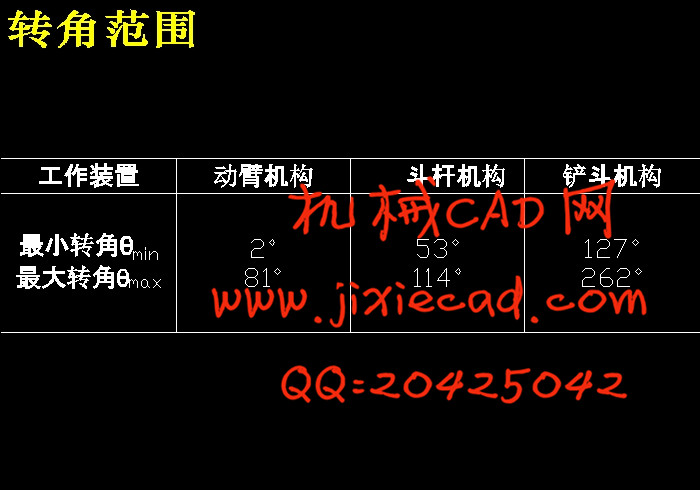

3.1.2机构转角范围确定 (18)

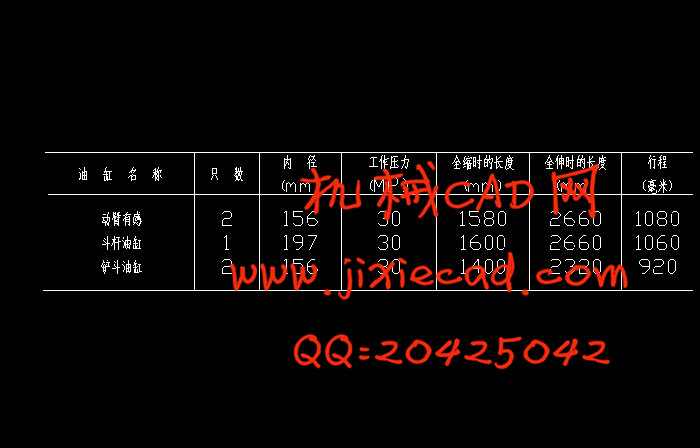

3.2 油缸铰点及行程确定 (19)

3.2.1动臂油缸的铰点及行程确定 (19)

3.2.2 斗杆油缸铰点及行程确定 (19)

3.2.3 铲斗油缸铰点及行程确定 (19)

3.3工作装置的位置模型建立 (19)

3.3.1 动臂与平台铰点位置C的确定 (20)

3.3.2 动臂及斗杆长度的确定 (20)

3.3.3 机构转角范围确定 (20)

3.4工作装置油缸铰点及行程确定 (25)

3.4.1动臂油缸的铰点及行程确定 (25)

3.4.2斗杆油缸铰点及行程确定 (28)

3.4.3铲斗油缸铰点及行程确定 (31)

3.5液压正铲挖掘机三维模型 (32)

4 结论 (34)

参考文献 (35)

致谢 (36)

本文主要的设计工作主要有以下几个方面:在现场测绘及参考有关资料的基础上了解液压挖掘机的工作方式及工作环境。确定液压挖掘机各个工作装置的结构,查找相关资料并结合经验公式对挖掘机工作装置的总体进行设计,用比例法和经验公式计算出工作装置各部分的基本尺寸并对其进行应力分析,然后绘制出其二维CAD图纸,继而用PRO/E画出各装置的三维模型。将各装置装配后对其进行运动模拟仿真。

关键词:挖掘机;工作装置;CAD;PRO/E;运动仿真

Abstract: In recent years, as steel, coal industry and quarrying continued rapid development, excavators engineering machinery requirement increasingly, and is widely used in housing construction, road engineering, water conservancy construction, forestry development, port construction, national defense construction and conditions of fortifications mining extraction industryDue to the complex and changeable, mining operation condition is often with operator way according to the actual working experience, decision, in order to reduce homework to excavate the mining experience operator, the effects will is in urgent need to build up the bucket with various hydraulic cylinder dig trajectory direct corresponding relation, realize the automation. Excavator operationAt the same time because of the complexity of an excavator working environment and conditions, requires the fluidity of hydraulic excavator itself according to the different structural environment makes the corresponding adjustment, this determines the excavator design of ordinary sex, repeatability. However hydraulic excavator working device is a much more freedom, the hinge point bar system to determine the very complex, these factors will cause the hydraulic excavator big investment, design cycle is long, the serious influence on the economic benefits of the manufacturers and national economic development.

This paper mainly design work mainly in the following aspects: in the field surveying and mapping and reference on the basis of relevant information about the hydraulic excavator way of working and working environment Determine the hydraulic excavator, each working device search relevant material and structure of practical experience formula of the overall work device for excavators designed, use proportion method and experience calculation work device each part of basic size and carries on the stress analysis, and then plot its two-dimensional CAD drawings, and then painted with PRO/E 3d model of each device. After each device assembly of its motion simulation

Keywords: Hydraulic Excavator; Working device; Boom;Stick;Face-shovel

目录

1 前言 (1)

1.1课题研究的背景和意义 (1)

1.2 液压挖掘机研究现状及发展动态 (1)

1.2.1 国外的研究现状及发展动态 (2)

1.2.2 国内的研究现状及发展动态 (3)

1.3 本文研究的主要内容 (5)

2液压正铲挖掘机工作装置的运动分析 (6)

2.1 液压正铲挖掘机的基本组成和工作原理 (6)

2.2 工作装置结构方案的确定 (7)

2.3 工作装置运动分析 (10)

2.3.1动臂运动分析 (10)

2.3.2斗杆运动分析 (12)

2.3.3斗齿尖的几种特殊工作位置的计算 (13)

3 工作装置尺寸的设计确定 (17)

3.1应用举例 (17)

3.1.2动臂及斗杆长度确定 …………………………………………………(17)

3.1.2机构转角范围确定 (18)

3.2 油缸铰点及行程确定 (19)

3.2.1动臂油缸的铰点及行程确定 (19)

3.2.2 斗杆油缸铰点及行程确定 (19)

3.2.3 铲斗油缸铰点及行程确定 (19)

3.3工作装置的位置模型建立 (19)

3.3.1 动臂与平台铰点位置C的确定 (20)

3.3.2 动臂及斗杆长度的确定 (20)

3.3.3 机构转角范围确定 (20)

3.4工作装置油缸铰点及行程确定 (25)

3.4.1动臂油缸的铰点及行程确定 (25)

3.4.2斗杆油缸铰点及行程确定 (28)

3.4.3铲斗油缸铰点及行程确定 (31)

3.5液压正铲挖掘机三维模型 (32)

4 结论 (34)

参考文献 (35)

致谢 (36)