设计简介

摘 要

在激烈的市场竞争与客户需求越来越个性化趋势下,纺织企业在生产技术方面不断地面临新的挑战,目前国内中小型企业主要还停留在手动裁剪和冲裁的落后状态,布料剪裁技术改造将直接影响企业生产能力和产品质量。而作为刚兴起的超声波裁剪,这在纺织工业的织造、整理、服装缝制等方面都已获得日益广泛的认可。但国内超声波裁剪技术还尚未成熟,因此对于超声波裁剪技术的研究具有重要的意义。

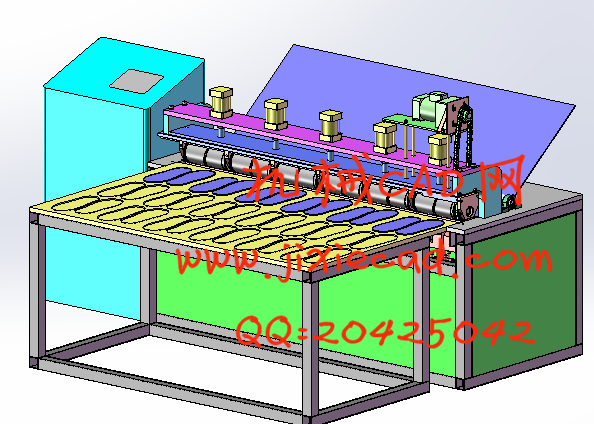

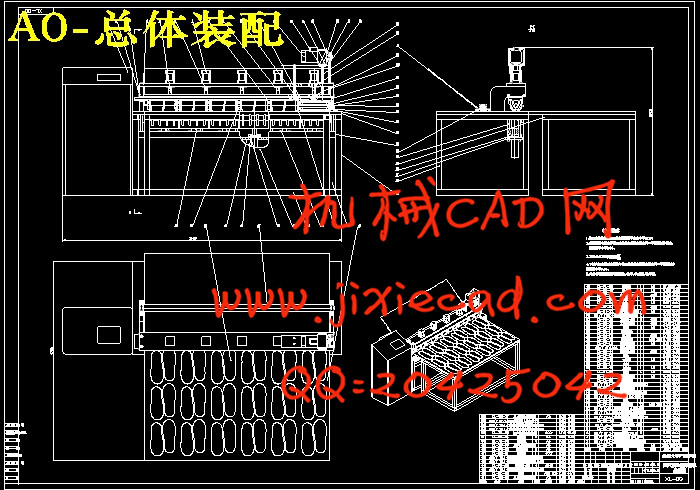

本文对企业一次性拖鞋裁剪下料的研究,,配合布料复合机以24m/min输送的宽1.6m的染整布料进行切割加工是此次设计的要点,使下料与布料复合生产流程之间联系起来,实现半自动加工,提高机械化程度,提高生产效率。

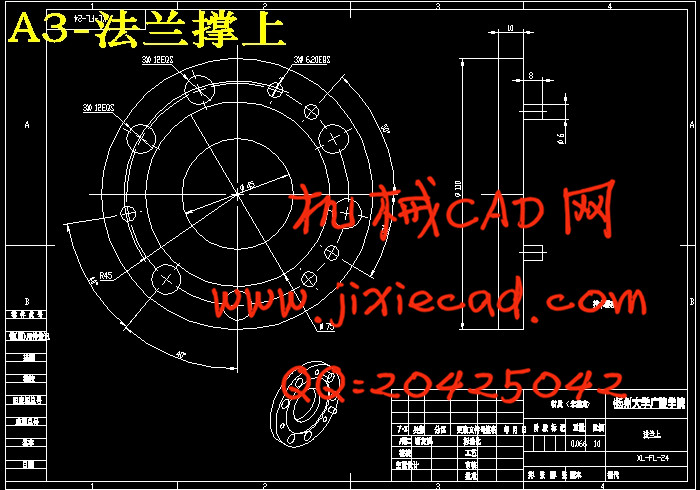

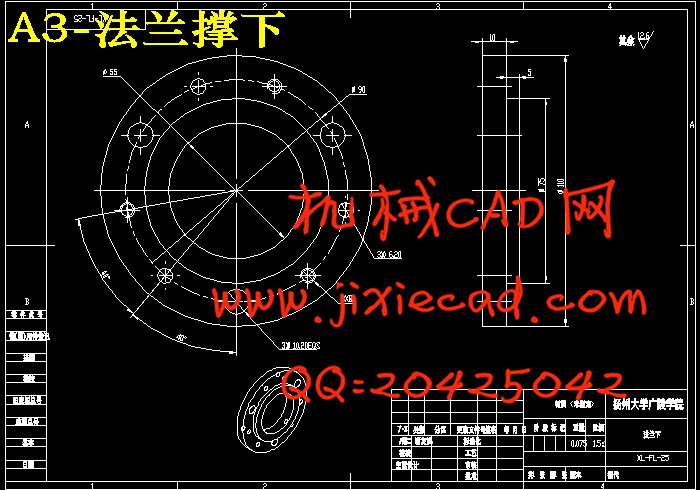

设计中通过类似机械进行改造,利用CAD、Solidworks等工程制图软件进行绘图三维仿真,然后结合理论计算。对一些设计部件进行必要的计算和校核,使设计系统初步满足实际应用的要求,可以为后期整机的研制提供很好的参考,使其具有一定的理论意义和实用价值。

关键词:纺织品、超声波裁剪、结构设计

ABSTRACT

In the market competition and customer demand intense increasinglypersonalized trend, textile enterprises continue to face new challenges in the production technology, the current domestic small and medium enterprises is stillin manual cutting and punching the backward state, cloth cutting technology will directly affect the production capacity of enterprises and the quality of the products. As the ultrasonic cutting emerging in the textile industry, weaving,finishing, garment and other aspects have been widely recognized. But the domestic ultrasonic cutting technology is not mature, so it is very important for the study of ultrasonic cutting technology.

In this paper, the study on enterprise disposable slippers, cutting, dyeing clothwidth of 1.6m with cloth composite machine with 24m/min transport by cutting ispoint of this design, the connection between the material and fabric compositeproduction processes, and semi - automatic processing, improve the degree of mechanization, improve production efficiency.

The design through the transformation of similar machine, drawing three dimensional simulation using CAD, Solidworks and other engineering drawing software, and then according to the theory of computation. By calculating and checking the necessary for some design part, the design system to meet the requirements of practical applications, provide a good reference for thedevelopment of late, it has certain theoretical significance and practical value.

Keywords: textiles, ultrasonic cutting, structure design

目 录在激烈的市场竞争与客户需求越来越个性化趋势下,纺织企业在生产技术方面不断地面临新的挑战,目前国内中小型企业主要还停留在手动裁剪和冲裁的落后状态,布料剪裁技术改造将直接影响企业生产能力和产品质量。而作为刚兴起的超声波裁剪,这在纺织工业的织造、整理、服装缝制等方面都已获得日益广泛的认可。但国内超声波裁剪技术还尚未成熟,因此对于超声波裁剪技术的研究具有重要的意义。

本文对企业一次性拖鞋裁剪下料的研究,,配合布料复合机以24m/min输送的宽1.6m的染整布料进行切割加工是此次设计的要点,使下料与布料复合生产流程之间联系起来,实现半自动加工,提高机械化程度,提高生产效率。

设计中通过类似机械进行改造,利用CAD、Solidworks等工程制图软件进行绘图三维仿真,然后结合理论计算。对一些设计部件进行必要的计算和校核,使设计系统初步满足实际应用的要求,可以为后期整机的研制提供很好的参考,使其具有一定的理论意义和实用价值。

关键词:纺织品、超声波裁剪、结构设计

ABSTRACT

In the market competition and customer demand intense increasinglypersonalized trend, textile enterprises continue to face new challenges in the production technology, the current domestic small and medium enterprises is stillin manual cutting and punching the backward state, cloth cutting technology will directly affect the production capacity of enterprises and the quality of the products. As the ultrasonic cutting emerging in the textile industry, weaving,finishing, garment and other aspects have been widely recognized. But the domestic ultrasonic cutting technology is not mature, so it is very important for the study of ultrasonic cutting technology.

In this paper, the study on enterprise disposable slippers, cutting, dyeing clothwidth of 1.6m with cloth composite machine with 24m/min transport by cutting ispoint of this design, the connection between the material and fabric compositeproduction processes, and semi - automatic processing, improve the degree of mechanization, improve production efficiency.

The design through the transformation of similar machine, drawing three dimensional simulation using CAD, Solidworks and other engineering drawing software, and then according to the theory of computation. By calculating and checking the necessary for some design part, the design system to meet the requirements of practical applications, provide a good reference for thedevelopment of late, it has certain theoretical significance and practical value.

Keywords: textiles, ultrasonic cutting, structure design

摘 要 I

ABSTRACT II

第一章 绪 论 1

1.1 课题的研究背景及意义 1

1.2拖鞋(一次性拖鞋)发展 2

1.3 纺织自动裁剪国内外研究现状 3

1.4 本课题研究的主要内容 4

第二章 超声波切割和熔合技术概述 5

2.1 超声波切割原理 5

2.2 比于传统剪裁,超声波切割优点 6

2.3 超声波切割适用范围 7

2.4 本章小结 8

第三章 超声波裁剪机总体方案 9

3.1 方案的列举 9

3.2 方案的比较 11

3.3 方案的选择 11

3.4 本章小结 12

第四章 超声波裁剪机的结构设计和系统分析 13

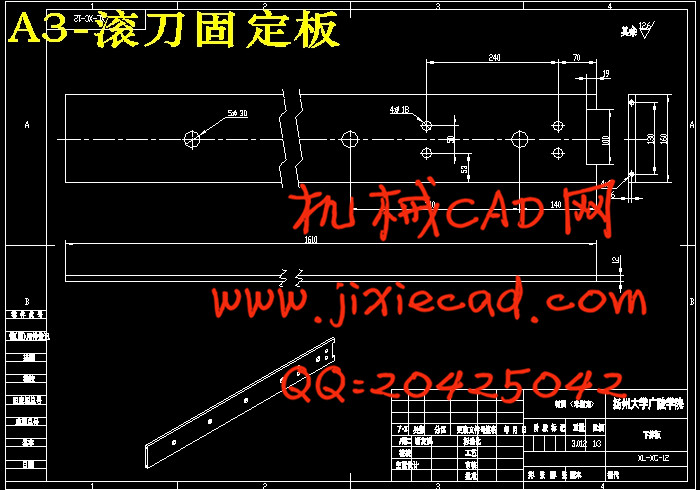

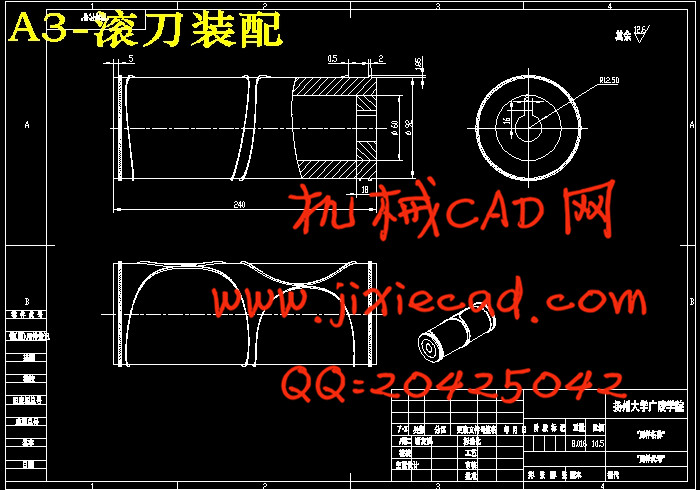

4.1滚刀尺寸确定 14

4.2 电机链轮的选定及相关参数的确定 16

4.2.1电机类型的选择 17

4.2.2链轮的选择及链条确定 18

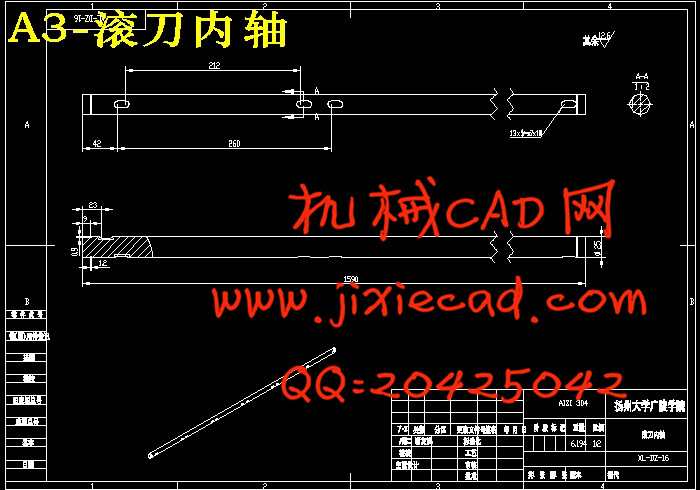

4.3 滚刀内轴的设计和校核 19

4.4 气缸支撑板的静态分析 24

4.4.1应力图显示 25

4.4.2 应力分析 26

4.4.3 变形分析 26

4.5 本章小结 26

第五章 超声波系统研究 27

5.1超声波发生器 27

5.2 声学部件 27

5.3 阶梯形变幅杆的理论公式与计算 29

5.3.1 位移节点

5.3.2 放大系数

5.3.3 计算 31

5.5 本章小结 32

第六章 总结 33

致 谢 34

参考文献 35