设计简介

摘 要:移动式龙门吊是一种应用非常广泛的起重机械,它常用于工地、码头和工厂中重型货物的起升和转移。本设计主要任务是对起吊机构、移动机构和自锁机构的设计。采用许用应力法和计算机辅助设计法进行设计。设计过程先用估计的门式起重机各结构尺寸数据对起重机的强度、疲劳强度、稳定性、刚度进行粗略的校核计算,待以上因素都达到材料的许用要求后,画出龙门吊小车结构图,然后计算出移动小车功率和起吊机构功率,再用此功率来选择电动机。以电机功率和额定起重重量作为技术参数来计算和选择联轴器、轴承和其他部件。若未通过,再重复上述步骤,直到通过。同时在设计中参考了各种资料, 文献 来完成此次设计. 本设计方案通过反复斟酌, 认真讨论, 反复校核, 力求设计合理。

关键词:移动龙门起重机; 起吊装置; 吊钩; 移动小车

Abstract: Mobile gantry crane is a kind of widely used hoisting machinery, it is commonly used on site, docks and factories of heavy cargo lift and transfer. The main task of this design is the design of the hoisting mechanism, moving mechanism and a self-locking mechanism. Using a design by stress m- ethod and computer aided design method. Design first with the size of the structure of gantry crane esti- mates of crane strength, fatigue strength, stability, rigidity for rough calculation, these factors have to be allowable to the material requirements, draw the gantry trolley structure diagram, and then calculates the moving trolley power and lifting mechanism of power, and this power to select the motor. The motor p- ower and rated lifting weight as a technical parameter calculation and selection of couplings, bearings a- nd aother components. If not through the, repeat the above steps, until the. Also in reference to the design of all kinds of information, documents to complete the design. This design scheme through repeated,seri- ous discussion, repeatedly check, strive to design reasonable.

Keywords: Longmen mobile cranes; Lifting devices; Lifting hook; Mobile robot

目 录

摘 要………………………………………………………………………………………1

关键词………………………………………………………………………………………1

1 前言………………………………………………………………………………………2

2 国内外研究现状…………………………………………………………………………4

3 起吊机构的设计…………………………………………………………………………5

3.1 起吊机构的原理………………………………………………………………………5

3.2 起吊机方案的确定……………………………………………………………………5

3.3 钢丝绳的选择…………………………………………………………………………6

3.4 滑轮主尺寸的计算……………………………………………………………………7

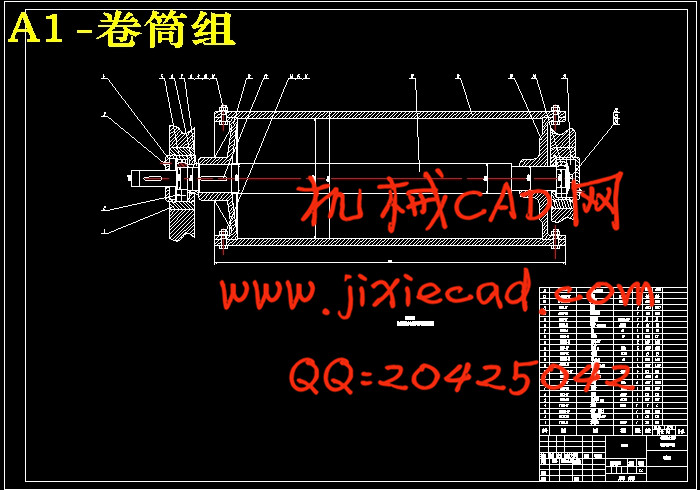

3.5 卷筒部件的设计及校核………………………………………………………………7

3.5.1 卷筒的设计及校核…………………………………………………………………7

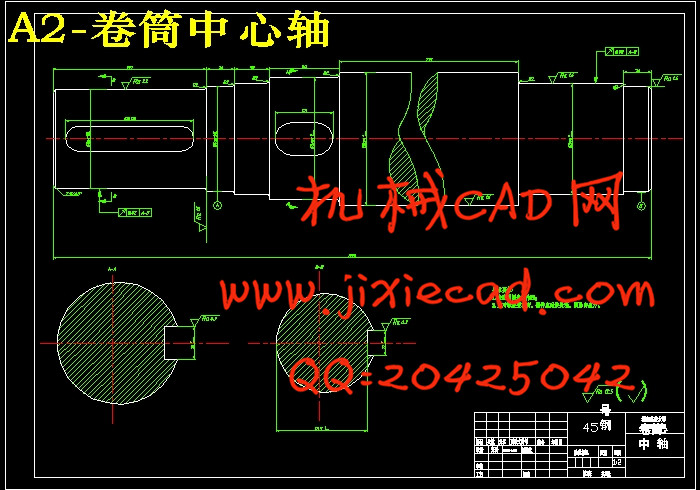

3.5.2 卷筒中心轴的计算及校核…………………………………………………………9

3.5.3 卷筒中心轴键的校核………………………………………………………………10

3.5.4 卷筒中心轴轴承的校核……………………………………………………………11

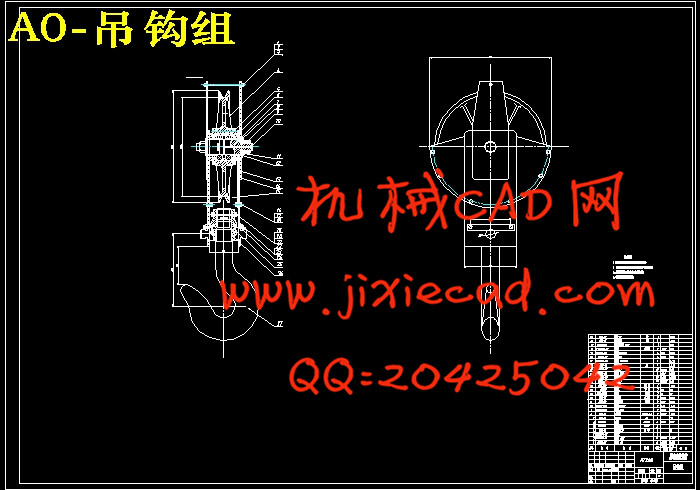

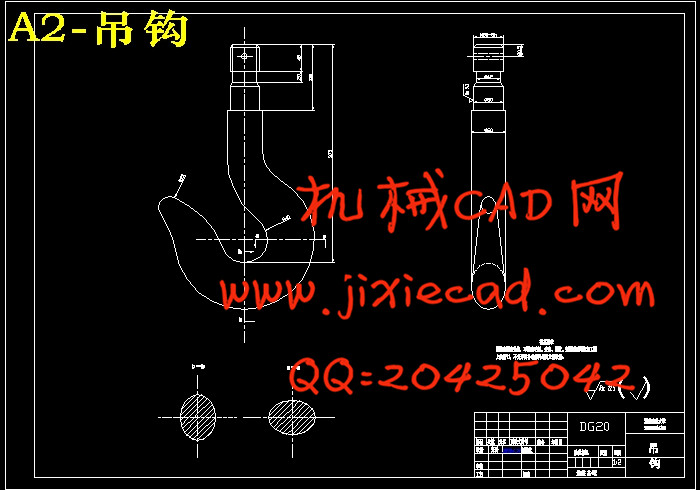

3.6 吊钩的设计与校核……………………………………………………………………11

3.6.1 吊钩主要尺寸………………………………………………………………………11

3.6.2 吊钩的校核…………………………………………………………………………11

3.7 横梁的设计……………………………………………………………………………12

3.8 起吊电动机……………………………………………………………………………13

3.8.1 起吊电动机的工作原理……………………………………………………………13

3.8.2 起吊电动机的选择…………………………………………………………………13

3.8.3 起吊电动机发热条件的校核………………………………………………………14

3.9 起吊减速器的设计……………………………………………………………………14

3.10 起吊制动器的设计…………………………………………………………………14

3.10.1 起吊制动器的工作原理…………………………………………………………14

3.10.2 起吊制动器的选择………………………………………………………………15

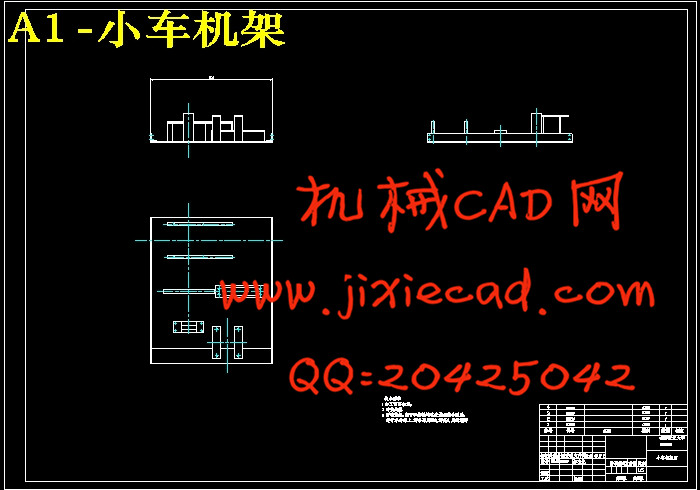

4 移动机构的设计 ………………………………………………………………………15

4.1 移动机构方案的确定 ………………………………………………………………15

4.2 车轮的设计及校核 …………………………………………………………………15

4.3 车轮中心轴校核 ……………………………………………………………………15

5 结论 ……………………………………………………………………………………17

参考文献 …………………………………………………………………………………18

致 谢 …………………………………………………………………………………19

关键词:移动龙门起重机; 起吊装置; 吊钩; 移动小车

Abstract: Mobile gantry crane is a kind of widely used hoisting machinery, it is commonly used on site, docks and factories of heavy cargo lift and transfer. The main task of this design is the design of the hoisting mechanism, moving mechanism and a self-locking mechanism. Using a design by stress m- ethod and computer aided design method. Design first with the size of the structure of gantry crane esti- mates of crane strength, fatigue strength, stability, rigidity for rough calculation, these factors have to be allowable to the material requirements, draw the gantry trolley structure diagram, and then calculates the moving trolley power and lifting mechanism of power, and this power to select the motor. The motor p- ower and rated lifting weight as a technical parameter calculation and selection of couplings, bearings a- nd aother components. If not through the, repeat the above steps, until the. Also in reference to the design of all kinds of information, documents to complete the design. This design scheme through repeated,seri- ous discussion, repeatedly check, strive to design reasonable.

Keywords: Longmen mobile cranes; Lifting devices; Lifting hook; Mobile robot

目 录

摘 要………………………………………………………………………………………1

关键词………………………………………………………………………………………1

1 前言………………………………………………………………………………………2

2 国内外研究现状…………………………………………………………………………4

3 起吊机构的设计…………………………………………………………………………5

3.1 起吊机构的原理………………………………………………………………………5

3.2 起吊机方案的确定……………………………………………………………………5

3.3 钢丝绳的选择…………………………………………………………………………6

3.4 滑轮主尺寸的计算……………………………………………………………………7

3.5 卷筒部件的设计及校核………………………………………………………………7

3.5.1 卷筒的设计及校核…………………………………………………………………7

3.5.2 卷筒中心轴的计算及校核…………………………………………………………9

3.5.3 卷筒中心轴键的校核………………………………………………………………10

3.5.4 卷筒中心轴轴承的校核……………………………………………………………11

3.6 吊钩的设计与校核……………………………………………………………………11

3.6.1 吊钩主要尺寸………………………………………………………………………11

3.6.2 吊钩的校核…………………………………………………………………………11

3.7 横梁的设计……………………………………………………………………………12

3.8 起吊电动机……………………………………………………………………………13

3.8.1 起吊电动机的工作原理……………………………………………………………13

3.8.2 起吊电动机的选择…………………………………………………………………13

3.8.3 起吊电动机发热条件的校核………………………………………………………14

3.9 起吊减速器的设计……………………………………………………………………14

3.10 起吊制动器的设计…………………………………………………………………14

3.10.1 起吊制动器的工作原理…………………………………………………………14

3.10.2 起吊制动器的选择………………………………………………………………15

4 移动机构的设计 ………………………………………………………………………15

4.1 移动机构方案的确定 ………………………………………………………………15

4.2 车轮的设计及校核 …………………………………………………………………15

4.3 车轮中心轴校核 ……………………………………………………………………15

5 结论 ……………………………………………………………………………………17

参考文献 …………………………………………………………………………………18

致 谢 …………………………………………………………………………………19