设计简介

硬脆材料双面研磨/抛光机的设计

摘要:双面平面研磨是在传统研磨机构的基础上,通过改变研磨平面的数目从而来提高研磨精度和效率的一种研磨方式。其加工原理就是利用涂敷或压嵌在研具上的磨料颗粒,通过研具与工件在一定压力下的相对运动对加工表面进行精整加工,从而来实现加工精度的要求。

本文通过对平面研磨机构多种运动方式的分析,以及研磨精度要求,并结合现有研磨机,从而设计出一种新型的行星式双面平面研磨机构,并对其运动轨迹做了具体研究。这种研磨方式不仅解决了传统研磨存在加工效率低、加工成本高、加工精度和加工质量不稳定等缺点,提高了研磨技术水平,保证研磨加工精度和加工质量,而且还可以实现在一定范围内不同直径圆柱工件的研磨,提高了加工效率,降低了加工成本,使研磨技术进一步实用化。

关键词:双面研磨;结构设计;轨迹曲线

Double-sided Grinding Of The Hard-brittle Materials/Polishing Machine Design

Abstract:

Double-sided plane grinding is the traditional grinding institutions, and on the basis of the number of by changing the grinding plane to improve the grinding efficiency and precision of a kind of grinding way. Its processing principle is to use the coating or pressure with embedded in the research on the abrasive particles with and workpiece, through research in the relative movement under certain pressure of machining surface finish machining, thus to realize the machining accuracy of requirements.

This thesis through to plane grinding institutions of various sports mode analysis, and grinding accuracy requirement, and combine existing grinding machine, thus designed a new double plane grinding mechanism, and to its trajectory made specific research. This kind of grinding way not only solves existing traditional grinding machining efficiency is low, the processing cost, high machining accuracy and processing quality unstable shortcomings, improves grinding technology level and guarantee of grinding accuracy and processing quality, but also can realize within the scope of certain and different cylinder workpiece, improves the grinding machining efficiency and reduce the processing cost, make grinding technology further practional utilization.

Key words:Double-sided Grinding ;Structure Design ;Path Curves

目录

摘要…………………………………………………………….…………………………………..……………….….….2

第一章 绪论……………………..………………………………………………………………………….....4

1.1脆硬材料的一些简介…………………………………………………………………….……4

1.2国内外研磨和抛光的历史及其发展现状……………………………………….….4

第二章 工作原理及基本要求……………..………………………………………….………....6

2.1抛光机理……………………………………………………………………………………………..6

2.2双面研磨机的工作原理………………………………………………………………………6

2.3双面研磨机的主要特点………………………………………………………………………7

2.4本次设计的主要方向………………………………………………………………………….8

第三章 研磨与抛光的主要工艺因素…………………………………………….…9

3.1工艺因素及其选择原则……………………………………………………………………...9

3.2研磨盘和抛光盘…………………………………………………………………………………10

3.3平面研磨使用的研具…………………………………………………………………………13

3.4磨粒…………………………………………………………………………………………………….13

3.5加工液………………………………………………………………………………………………..13

3.6工艺参数………………………………………………………………………………………….…13

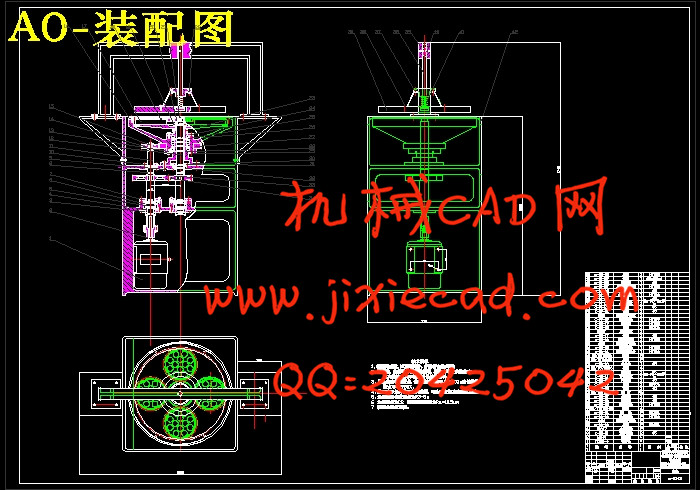

第四章 结构设计及相关强度校核………………………………..…………………..…….14

4.1工件保持架的选择..……………………………………………………………………………14

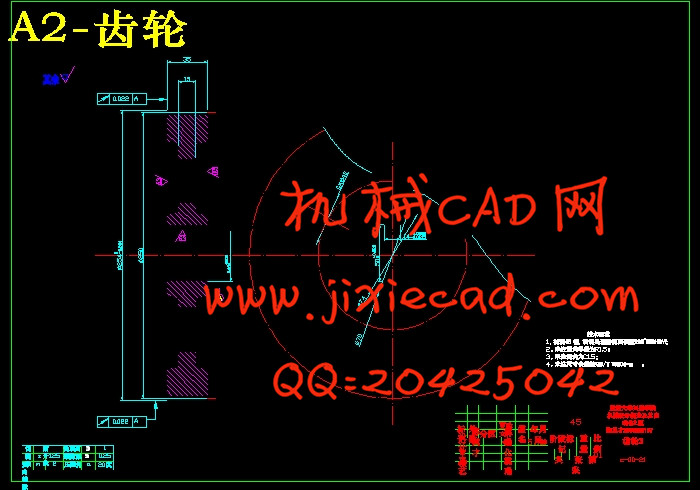

4.2小齿轮的选择……………………………………………………………………………………..15

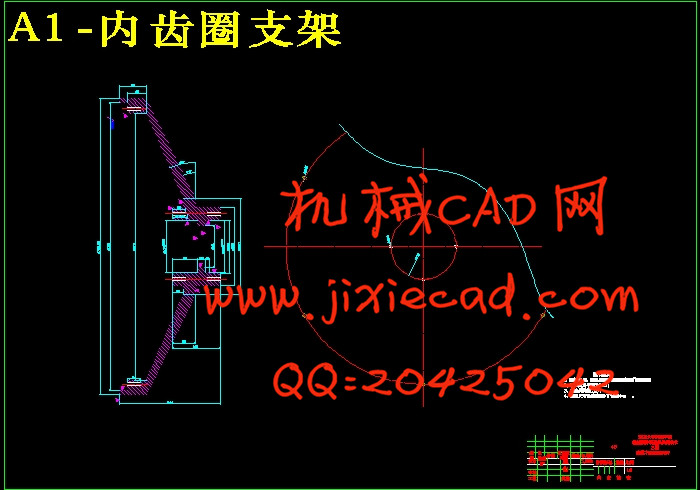

4.3内齿圈的选择……………………………………………………………………………………..15

4.4保持架、内齿圈、小齿轮组成的轮系中各齿轮运动速度的确定….…16

4.5其他齿轮的选择………………………………………………………………………………....17

4.5.1齿轮1的选择….……………………………………………………………………….…17

4.5.2齿轮2的选择………………………………………………………………………….….17

4.5.3齿轮3和齿轮4的确定……………………………………………………………..18

4.6轴承的选择及其参数……..………………………….…………………………………….…19

4.7电动机的选择………..……………………..………………………………………………….…20

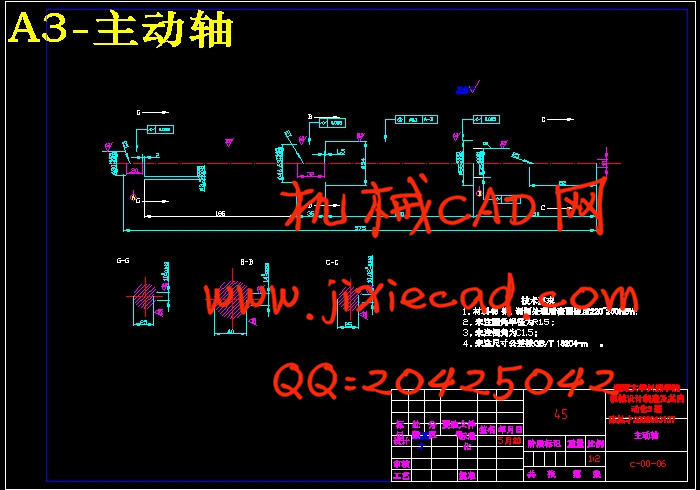

4.8轴的设计及强度校核计算.…………………………………………..…………………….21

总结………………………………………………………………………..……….…………………...23

参考文献………………………………………….………….……………….……………………....24

摘要:双面平面研磨是在传统研磨机构的基础上,通过改变研磨平面的数目从而来提高研磨精度和效率的一种研磨方式。其加工原理就是利用涂敷或压嵌在研具上的磨料颗粒,通过研具与工件在一定压力下的相对运动对加工表面进行精整加工,从而来实现加工精度的要求。

本文通过对平面研磨机构多种运动方式的分析,以及研磨精度要求,并结合现有研磨机,从而设计出一种新型的行星式双面平面研磨机构,并对其运动轨迹做了具体研究。这种研磨方式不仅解决了传统研磨存在加工效率低、加工成本高、加工精度和加工质量不稳定等缺点,提高了研磨技术水平,保证研磨加工精度和加工质量,而且还可以实现在一定范围内不同直径圆柱工件的研磨,提高了加工效率,降低了加工成本,使研磨技术进一步实用化。

关键词:双面研磨;结构设计;轨迹曲线

Double-sided Grinding Of The Hard-brittle Materials/Polishing Machine Design

Abstract:

Double-sided plane grinding is the traditional grinding institutions, and on the basis of the number of by changing the grinding plane to improve the grinding efficiency and precision of a kind of grinding way. Its processing principle is to use the coating or pressure with embedded in the research on the abrasive particles with and workpiece, through research in the relative movement under certain pressure of machining surface finish machining, thus to realize the machining accuracy of requirements.

This thesis through to plane grinding institutions of various sports mode analysis, and grinding accuracy requirement, and combine existing grinding machine, thus designed a new double plane grinding mechanism, and to its trajectory made specific research. This kind of grinding way not only solves existing traditional grinding machining efficiency is low, the processing cost, high machining accuracy and processing quality unstable shortcomings, improves grinding technology level and guarantee of grinding accuracy and processing quality, but also can realize within the scope of certain and different cylinder workpiece, improves the grinding machining efficiency and reduce the processing cost, make grinding technology further practional utilization.

Key words:Double-sided Grinding ;Structure Design ;Path Curves

目录

摘要…………………………………………………………….…………………………………..……………….….….2

第一章 绪论……………………..………………………………………………………………………….....4

1.1脆硬材料的一些简介…………………………………………………………………….……4

1.2国内外研磨和抛光的历史及其发展现状……………………………………….….4

第二章 工作原理及基本要求……………..………………………………………….………....6

2.1抛光机理……………………………………………………………………………………………..6

2.2双面研磨机的工作原理………………………………………………………………………6

2.3双面研磨机的主要特点………………………………………………………………………7

2.4本次设计的主要方向………………………………………………………………………….8

第三章 研磨与抛光的主要工艺因素…………………………………………….…9

3.1工艺因素及其选择原则……………………………………………………………………...9

3.2研磨盘和抛光盘…………………………………………………………………………………10

3.3平面研磨使用的研具…………………………………………………………………………13

3.4磨粒…………………………………………………………………………………………………….13

3.5加工液………………………………………………………………………………………………..13

3.6工艺参数………………………………………………………………………………………….…13

第四章 结构设计及相关强度校核………………………………..…………………..…….14

4.1工件保持架的选择..……………………………………………………………………………14

4.2小齿轮的选择……………………………………………………………………………………..15

4.3内齿圈的选择……………………………………………………………………………………..15

4.4保持架、内齿圈、小齿轮组成的轮系中各齿轮运动速度的确定….…16

4.5其他齿轮的选择………………………………………………………………………………....17

4.5.1齿轮1的选择….……………………………………………………………………….…17

4.5.2齿轮2的选择………………………………………………………………………….….17

4.5.3齿轮3和齿轮4的确定……………………………………………………………..18

4.6轴承的选择及其参数……..………………………….…………………………………….…19

4.7电动机的选择………..……………………..………………………………………………….…20

4.8轴的设计及强度校核计算.…………………………………………..…………………….21

总结………………………………………………………………………..……….…………………...23

参考文献………………………………………….………….……………….……………………....24