设计简介

摘 要

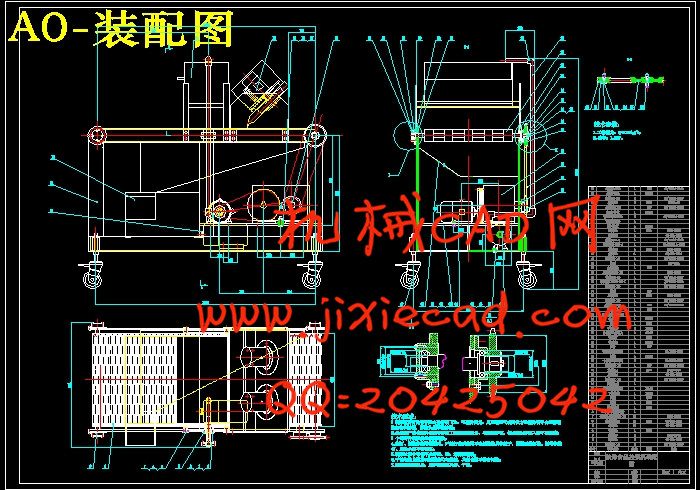

油炸食品挂浆机是一种食品加工机械,可以加工原料以及半成品,此设计完成了油炸食品挂浆机(以下简称挂浆机)的设计工作。介绍了挂浆机应用场合以及发展现状和挂浆机的工作原理。

本次设计的挂浆机主要有三部分组成:传动部分、走浆系统和机架。设计的重点是传动部分和走浆系统。

传动系统的设计过程中通过选择比较选择了以下方案:

电动机 → V带传动 → 减速器 → 链传动 →主动轴 → 网带 → 被动轴

此传动方案简单可行,便于实现。

在传动系统的设计过程中详细的作了如下设计计算:电动机的选择计算,减速器的选择计算,带传动的设计计算以及链传动的设计计算。

走浆系统采用一个浆泵将下储料箱的浆送到上储料箱形成浆瀑布从而实现挂浆。走浆系统设计过程中涉及到了泵的选择计算,以及上、下两个料箱的选材和设计。

本设计过程中还对轴进行了选材、设计计算和危险截面的校核计算,同时对轴承进行了详细的校核计算。最后还对设备的安装调试以及保养做了简单介绍。

观键词:挂浆机;传动;走浆;

Abstract

The thick liquid hanging machine is a kind of food processing machinery .It can process raw materials and semi-manufactured goods, this design has finished the fried food and hung the thick liquid machine (hereafter referred to as the thick liquid hanging machine) Design work. Have recommended hanging the thick liquid machine and using the occasion, current situation of the development and operation principle that hang the thick liquid machine.

The one that designs hangs the thick liquid machine and is made up of three parts mainly this time: Running part, the thick liquid system leaves and the framework. Focal point that design to walk thick liquid system.

Through choosing to relatively choose the following scheme in the design process of the transmission:

Motor→V takes the transmission→Decelerator→Chain transmission→Initiative axle→The network taking →Passive axle

This transmission scheme is simple and feasible, easy to realize.

Have designed and calculated as follows in the course of design of the transmission: Choice of motor calculate, choice of decelerator calculate, with transmission design calculate and design, chain of transmission calculate.

Walk thick liquid system adopt one thick liquid pump is it store thick liquid, material of case store material case form thick liquid waterfall to is it register for thick liquid to realize on sending to lay.

The choice involving the pump is calculated to leave in the systematic design process of thick liquid, and have, put selecting suitable materials and design of two material cases.

Have also designed calculating that calculates with dangerous and sectional check to the axle in this design process, calculate detailed check to the bearing at the same time. Also debug and maintain simple introduction to the installation of the equipment finally.

Keywords: The thick liquid hanging machine;transmission;the thick liquid leaves;

目 录

1 绪论 1

1.1 立题意义 1

1.2 国内外挂浆机的研究动向及发展前景 1

2 总体方案的设计与选择 3

2.1 传动系统方案的设计和选择 3

2.2 走浆系统的设计 4

2.3 挂浆机工作原理 4

3 油炸食品挂浆机的主要参数选择和传动系统的设计计算 6

3.1 设计参数 6

3.2 网带带速和带长的设计计算 6

3.3 网带上的功率和滚筒转数的计算 6

3.4 电动机的选择 7

3.5 带传动的设计计算 8

3.5.1 带传动的设计计算 8

3.5.2 带轮的设计计算 11

3.6 减速器的选择计算 13

3.6.1 如何选择减速器 13

3.6.2 减速器的选用方法 14

3.6.3 减速器的选用 14

3.7 链传动的设计计算(根据GB/T18150-2000) 16

3.7.1 链的设计 16

3.7.2 链齿轮的设计 19

3.7.3 齿形参数 21

4 走浆系统设计计算及机架的设计 22

4.1 走浆系统设计计算及机架的设计 22

4.1.1 泵的选择 22

4.1.2 上储料箱的设计 22

4.1.3 下储料箱的设计 22

4.2 机架的设计 23

4.2.1 选材 23

4.2.2 机架的设计 23

4.2.3 挂浆机的安装和移动装置 24

5 主要零部件的结构设计计算 25

5.1 主动轴的设计计算 25

5.1.1 选择轴的材料 25

5.1.2 轴的结构设计 25

5.1.3 按弯扭合成条件初步计算轴径 26

5.1.4 危险截面的校核 31

5.2 轴承的选用和校核 32

5.2.1 轴承的选用 32

5.2.2 轴承的校核 32

6 安装使用说明 37

6.1 挂浆机的安装 37

6.2 挂浆机的使用及维护 37

7 结论 38

参考文献 39

致谢 40

油炸食品挂浆机是一种食品加工机械,可以加工原料以及半成品,此设计完成了油炸食品挂浆机(以下简称挂浆机)的设计工作。介绍了挂浆机应用场合以及发展现状和挂浆机的工作原理。

本次设计的挂浆机主要有三部分组成:传动部分、走浆系统和机架。设计的重点是传动部分和走浆系统。

传动系统的设计过程中通过选择比较选择了以下方案:

电动机 → V带传动 → 减速器 → 链传动 →主动轴 → 网带 → 被动轴

此传动方案简单可行,便于实现。

在传动系统的设计过程中详细的作了如下设计计算:电动机的选择计算,减速器的选择计算,带传动的设计计算以及链传动的设计计算。

走浆系统采用一个浆泵将下储料箱的浆送到上储料箱形成浆瀑布从而实现挂浆。走浆系统设计过程中涉及到了泵的选择计算,以及上、下两个料箱的选材和设计。

本设计过程中还对轴进行了选材、设计计算和危险截面的校核计算,同时对轴承进行了详细的校核计算。最后还对设备的安装调试以及保养做了简单介绍。

观键词:挂浆机;传动;走浆;

Abstract

The thick liquid hanging machine is a kind of food processing machinery .It can process raw materials and semi-manufactured goods, this design has finished the fried food and hung the thick liquid machine (hereafter referred to as the thick liquid hanging machine) Design work. Have recommended hanging the thick liquid machine and using the occasion, current situation of the development and operation principle that hang the thick liquid machine.

The one that designs hangs the thick liquid machine and is made up of three parts mainly this time: Running part, the thick liquid system leaves and the framework. Focal point that design to walk thick liquid system.

Through choosing to relatively choose the following scheme in the design process of the transmission:

Motor→V takes the transmission→Decelerator→Chain transmission→Initiative axle→The network taking →Passive axle

This transmission scheme is simple and feasible, easy to realize.

Have designed and calculated as follows in the course of design of the transmission: Choice of motor calculate, choice of decelerator calculate, with transmission design calculate and design, chain of transmission calculate.

Walk thick liquid system adopt one thick liquid pump is it store thick liquid, material of case store material case form thick liquid waterfall to is it register for thick liquid to realize on sending to lay.

The choice involving the pump is calculated to leave in the systematic design process of thick liquid, and have, put selecting suitable materials and design of two material cases.

Have also designed calculating that calculates with dangerous and sectional check to the axle in this design process, calculate detailed check to the bearing at the same time. Also debug and maintain simple introduction to the installation of the equipment finally.

Keywords: The thick liquid hanging machine;transmission;the thick liquid leaves;

目 录

1 绪论 1

1.1 立题意义 1

1.2 国内外挂浆机的研究动向及发展前景 1

2 总体方案的设计与选择 3

2.1 传动系统方案的设计和选择 3

2.2 走浆系统的设计 4

2.3 挂浆机工作原理 4

3 油炸食品挂浆机的主要参数选择和传动系统的设计计算 6

3.1 设计参数 6

3.2 网带带速和带长的设计计算 6

3.3 网带上的功率和滚筒转数的计算 6

3.4 电动机的选择 7

3.5 带传动的设计计算 8

3.5.1 带传动的设计计算 8

3.5.2 带轮的设计计算 11

3.6 减速器的选择计算 13

3.6.1 如何选择减速器 13

3.6.2 减速器的选用方法 14

3.6.3 减速器的选用 14

3.7 链传动的设计计算(根据GB/T18150-2000) 16

3.7.1 链的设计 16

3.7.2 链齿轮的设计 19

3.7.3 齿形参数 21

4 走浆系统设计计算及机架的设计 22

4.1 走浆系统设计计算及机架的设计 22

4.1.1 泵的选择 22

4.1.2 上储料箱的设计 22

4.1.3 下储料箱的设计 22

4.2 机架的设计 23

4.2.1 选材 23

4.2.2 机架的设计 23

4.2.3 挂浆机的安装和移动装置 24

5 主要零部件的结构设计计算 25

5.1 主动轴的设计计算 25

5.1.1 选择轴的材料 25

5.1.2 轴的结构设计 25

5.1.3 按弯扭合成条件初步计算轴径 26

5.1.4 危险截面的校核 31

5.2 轴承的选用和校核 32

5.2.1 轴承的选用 32

5.2.2 轴承的校核 32

6 安装使用说明 37

6.1 挂浆机的安装 37

6.2 挂浆机的使用及维护 37

7 结论 38

参考文献 39

致谢 40