设计简介

智能材料在汽车冷却系统中的应用与设计

——圆筒式磁流变离合器的设计

摘要

由于冷却水温与发动机的许多工作性能有着直接或间接的关系,如果冷却水温保持最佳的温度范围内,不仅可以提高发动机的动力性、减少废气的产生、还可以减少燃料消耗量、增强发动机工作平稳性。

磁流变液 (MRF)是一种在外加磁场作用下流变特性发生急剧变化的材料,它在无外加磁场作用时呈现牛顿流体的流动特性,然而在强磁场作用下,其表观粘度可在毫秒级的短时间内增加几个数量级以上,并呈现类似固体的力学性质,而且粘度的变化是连续、可逆的,即一旦去掉磁场后,又变成可以流动的液体。

圆筒式磁流变离合器是一种利用磁流变液剪切应力来进行离合的一种装置,它传递的力矩随外加磁场的变化迅速变化。在没有磁场作用的情况下,磁流变液处于液体状态,离合器的离合力矩仅为粘性阻力。当有一个外加磁场作用时,磁流变液中的极性粒子马上被极化并沿着磁力线方程成链状分布。这种链状结构就使磁流变液的剪切应力增大,表现出塑性体的特性,因此离合器就可以传递一定的力矩。力矩的大小可以通过调节磁场强度的大小来控制。磁流变离合器具有传动平稳、均衡、结构简单、紧凑、操作简便、能耗低、寿命长等优良性能。

本文首先对磁流变液的材料及流变特性进行了介绍,对磁流变液本构模型进行了分析。对磁流变液的传力方式进行了讨论,并根据剪切模式建立了磁流变液的传力模型,完成了圆筒式磁流变离合器的设计,得出了基本设计公式。

关键词:冷却系统;磁流变液;离合器;传力模型;几何设计方法

The Intelligent Material Is Used For Car Cooling System

Of Application And Design

ABSTRACT

It's well known that cooling water temperature is very important to diesel engine.If cooling water temperature can keep in the optimal ange of cooling water temperature, diesel engine's power can be improved,and less exhaust gas produced, reduce fuel wastage and engine work more calmly.

Magnetorheological(MR) fluids consist of stable suspensions of particles in a carrying fluid such as silicone oils, responding to an applied magnetic field in their rheological behavior. In the absence of applied magnetic field, MR fluids exhibit Newtonian-like behavior. Upon application of a magnetic field, the suspended particles in the MR fluids become polarized and aligned in the direction of the magnetic field. The fluids behave as a semi-solid having a controllable yield stress .

An MR fluid clutch device achieves braking by shear force of the MR fluid.An MR fluid clutch has the property that its torque changes quickly in response to an extenral magnetic field.In the absence of an applied magnetic field,the torque is the viscous force of MR fluids in liquid state.When the external magnetic field is applied,the suspended particles in the MR fluids become polarized and gathered to form chain-like structure. These chain-like structures restrict the movement of the MR fluids,thereby increasing the yield stress of the fluids.The clutch can be achieved by utilizing the shear stress of the MR fluids.The torque can be adjusted continuously by changing the magnetic field strength.

In this paper,the rheological behavior of MR fluids are introduced and the constitutive equation is analyzed, then, the design method of the MR fluids clutch is investigated theoretically.The equation of the torque transmitted by the MR fluids in the clutch is derived to provide the theoretical foundation in the design of the clutch.

Keywords: Cooling System;Magnetorheological fluids(MRF);clutch;mechanical mode;geometric design method

目 录

一、绪论 1

1.1发动机冷却系统 1

1.1.1发动机冷却系统的组成部分 1

1.1.2发动机冷却系统的作用 2

1.1.3冷却系统调节的工作原理 3

1.2目前风扇离合器及存在的问题 4

1.3磁流变液离合器 4

1.4本课题的主要工作 5

二、磁流变液 6

2.1磁流变液的组成 6

2.1.1磁性颗粒 6

2.1.2载 液 7

2.1.3添加剂 7

2.2磁流变液的性能 8

2.2.1磁流变液应满足的指标 8

2.2.2 磁流变液必须具有的性能 8

2.2.3磁流变液的流变机理 9

2.3磁流变效应 10

2.3.1 磁流变效应的特征 10

2.3.2磁流变液的磁畴理论 10

2.3.3磁流变液的链化模型 11

2.3.4影响磁流变效应的因素 13

2.4磁流变液应用于离合器 17

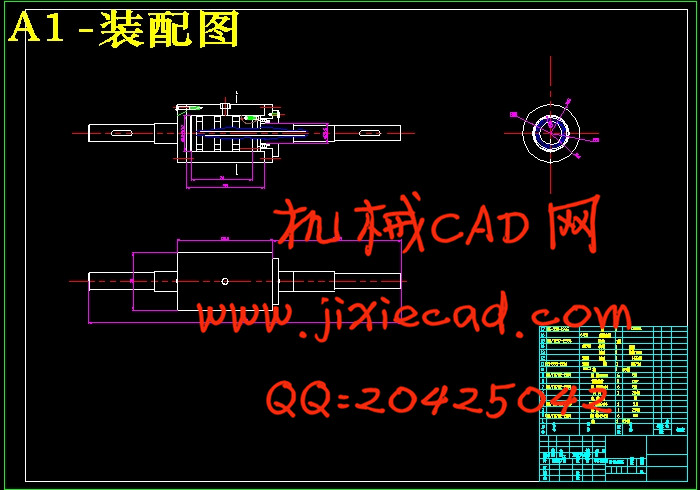

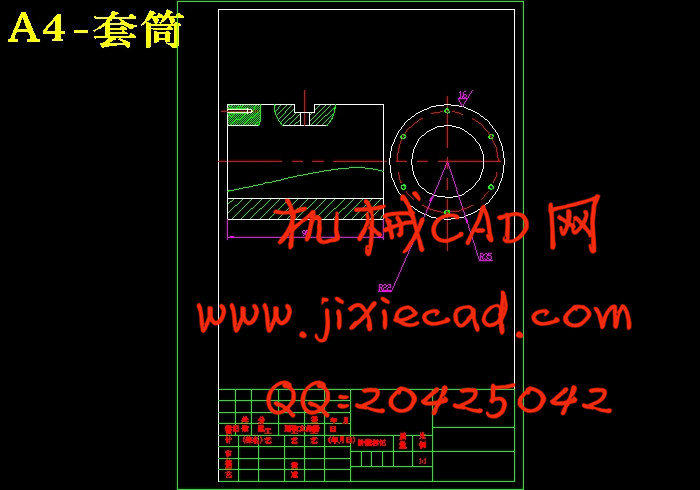

三、圆筒式磁流变离合器 17

3.1圆筒式磁流变离合器工作原理 17

3.2圆筒式磁流变离合器理论分析 18

3.2.1 数学模型 18

3.2.2 流动分析 20

四、磁流变离合器设计 23

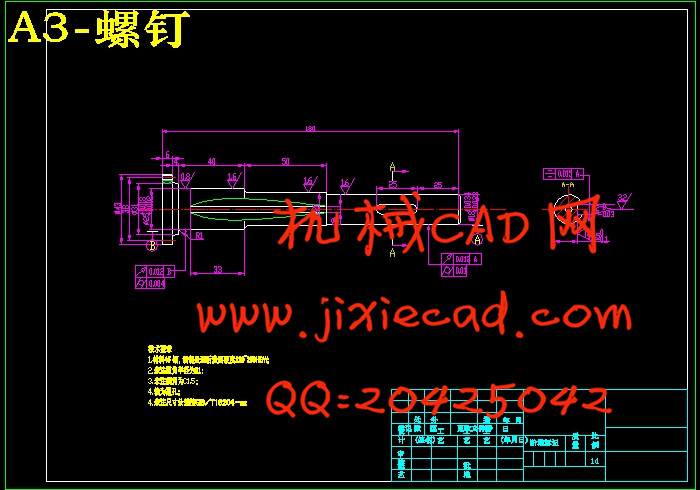

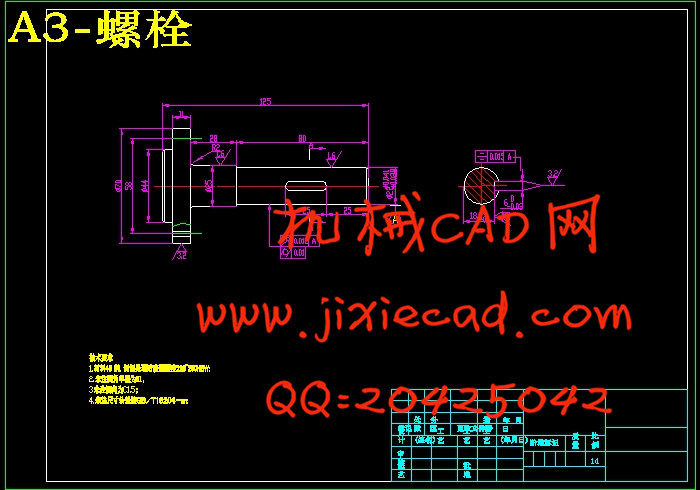

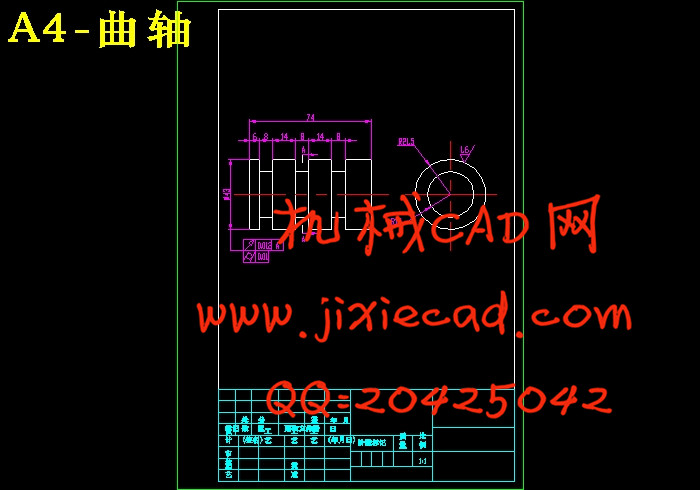

4.1磁流变离合器的失效形式和设计准则 24

4.1.1最大有效转矩 24

4.1.2粘塑性滑动和打滑 24

4.1.3失效形式 25

4.1.4 设计准则 25

4.1.5圆筒式磁流变离合器的关键尺寸 25

4.2圆筒式磁流变离合器的设计方法 27

4.2.1原始数据及设计内容 27

4.2.2设计方法 27

4.3圆筒式磁流变离合器设计 28

4.3.1圆筒式磁流变离合器结构 28

4.3.2圆筒式磁流变离合器设计计算 30

结束语 38

参考文献 38

——圆筒式磁流变离合器的设计

摘要

由于冷却水温与发动机的许多工作性能有着直接或间接的关系,如果冷却水温保持最佳的温度范围内,不仅可以提高发动机的动力性、减少废气的产生、还可以减少燃料消耗量、增强发动机工作平稳性。

磁流变液 (MRF)是一种在外加磁场作用下流变特性发生急剧变化的材料,它在无外加磁场作用时呈现牛顿流体的流动特性,然而在强磁场作用下,其表观粘度可在毫秒级的短时间内增加几个数量级以上,并呈现类似固体的力学性质,而且粘度的变化是连续、可逆的,即一旦去掉磁场后,又变成可以流动的液体。

圆筒式磁流变离合器是一种利用磁流变液剪切应力来进行离合的一种装置,它传递的力矩随外加磁场的变化迅速变化。在没有磁场作用的情况下,磁流变液处于液体状态,离合器的离合力矩仅为粘性阻力。当有一个外加磁场作用时,磁流变液中的极性粒子马上被极化并沿着磁力线方程成链状分布。这种链状结构就使磁流变液的剪切应力增大,表现出塑性体的特性,因此离合器就可以传递一定的力矩。力矩的大小可以通过调节磁场强度的大小来控制。磁流变离合器具有传动平稳、均衡、结构简单、紧凑、操作简便、能耗低、寿命长等优良性能。

本文首先对磁流变液的材料及流变特性进行了介绍,对磁流变液本构模型进行了分析。对磁流变液的传力方式进行了讨论,并根据剪切模式建立了磁流变液的传力模型,完成了圆筒式磁流变离合器的设计,得出了基本设计公式。

关键词:冷却系统;磁流变液;离合器;传力模型;几何设计方法

The Intelligent Material Is Used For Car Cooling System

Of Application And Design

ABSTRACT

It's well known that cooling water temperature is very important to diesel engine.If cooling water temperature can keep in the optimal ange of cooling water temperature, diesel engine's power can be improved,and less exhaust gas produced, reduce fuel wastage and engine work more calmly.

Magnetorheological(MR) fluids consist of stable suspensions of particles in a carrying fluid such as silicone oils, responding to an applied magnetic field in their rheological behavior. In the absence of applied magnetic field, MR fluids exhibit Newtonian-like behavior. Upon application of a magnetic field, the suspended particles in the MR fluids become polarized and aligned in the direction of the magnetic field. The fluids behave as a semi-solid having a controllable yield stress .

An MR fluid clutch device achieves braking by shear force of the MR fluid.An MR fluid clutch has the property that its torque changes quickly in response to an extenral magnetic field.In the absence of an applied magnetic field,the torque is the viscous force of MR fluids in liquid state.When the external magnetic field is applied,the suspended particles in the MR fluids become polarized and gathered to form chain-like structure. These chain-like structures restrict the movement of the MR fluids,thereby increasing the yield stress of the fluids.The clutch can be achieved by utilizing the shear stress of the MR fluids.The torque can be adjusted continuously by changing the magnetic field strength.

In this paper,the rheological behavior of MR fluids are introduced and the constitutive equation is analyzed, then, the design method of the MR fluids clutch is investigated theoretically.The equation of the torque transmitted by the MR fluids in the clutch is derived to provide the theoretical foundation in the design of the clutch.

Keywords: Cooling System;Magnetorheological fluids(MRF);clutch;mechanical mode;geometric design method

目 录

一、绪论 1

1.1发动机冷却系统 1

1.1.1发动机冷却系统的组成部分 1

1.1.2发动机冷却系统的作用 2

1.1.3冷却系统调节的工作原理 3

1.2目前风扇离合器及存在的问题 4

1.3磁流变液离合器 4

1.4本课题的主要工作 5

二、磁流变液 6

2.1磁流变液的组成 6

2.1.1磁性颗粒 6

2.1.2载 液 7

2.1.3添加剂 7

2.2磁流变液的性能 8

2.2.1磁流变液应满足的指标 8

2.2.2 磁流变液必须具有的性能 8

2.2.3磁流变液的流变机理 9

2.3磁流变效应 10

2.3.1 磁流变效应的特征 10

2.3.2磁流变液的磁畴理论 10

2.3.3磁流变液的链化模型 11

2.3.4影响磁流变效应的因素 13

2.4磁流变液应用于离合器 17

三、圆筒式磁流变离合器 17

3.1圆筒式磁流变离合器工作原理 17

3.2圆筒式磁流变离合器理论分析 18

3.2.1 数学模型 18

3.2.2 流动分析 20

四、磁流变离合器设计 23

4.1磁流变离合器的失效形式和设计准则 24

4.1.1最大有效转矩 24

4.1.2粘塑性滑动和打滑 24

4.1.3失效形式 25

4.1.4 设计准则 25

4.1.5圆筒式磁流变离合器的关键尺寸 25

4.2圆筒式磁流变离合器的设计方法 27

4.2.1原始数据及设计内容 27

4.2.2设计方法 27

4.3圆筒式磁流变离合器设计 28

4.3.1圆筒式磁流变离合器结构 28

4.3.2圆筒式磁流变离合器设计计算 30

结束语 38

参考文献 38