设计简介

摘 要

随着科学技术的不断发展,工业水平的不断进步,粉尘污染问题变得日趋严重,人们对空气质量的要求越来越高了,大气环境越来越受到重视,空气质量也被列入了每天的天气预报中。

木材加工业作为一项基础工业,在社会的发展中扮演了不可或缺的角色,然而,由于木材工艺的要求,木材加工过程中对大气产生了一定程度的粉尘污染。粉尘的污染首先危害的是人民的健康,严重时对工业,农业,林业生产等都能造成危害。消除粉尘污染,改善环境是关系到保护人民健康、多快好省地发展工农业生产的大事。在木材加工过程中产生的粉尘急需很好地被解决。

木材在加工过程中产生的废料有相对粉尘较大的小木块,一些非颗粒型的刨花,还有大量细小的木屑粉尘等。根据粉尘的特性,旋风除尘器等除尘设备在处理小颗粒时效果不好,而布袋除尘器在这方面具有很大的优势。

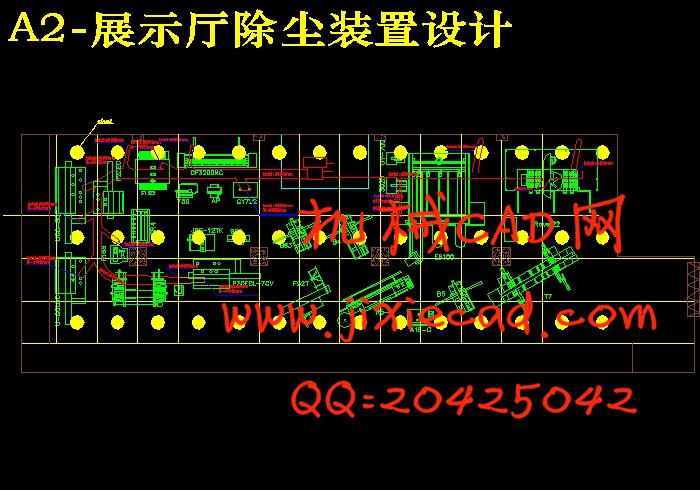

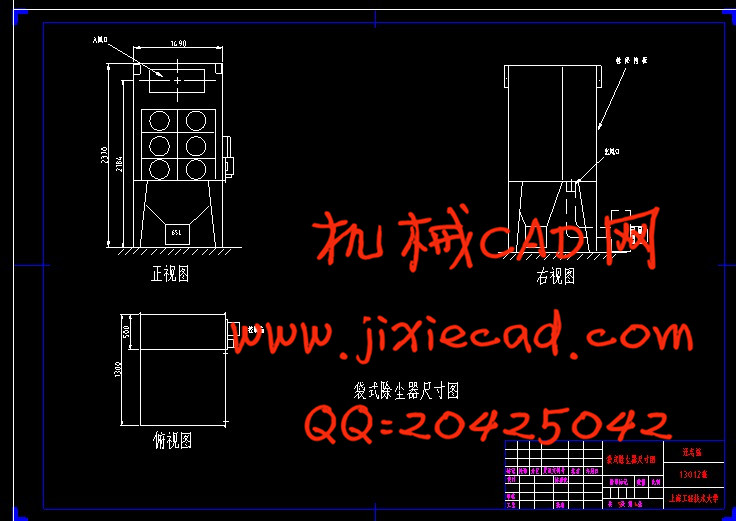

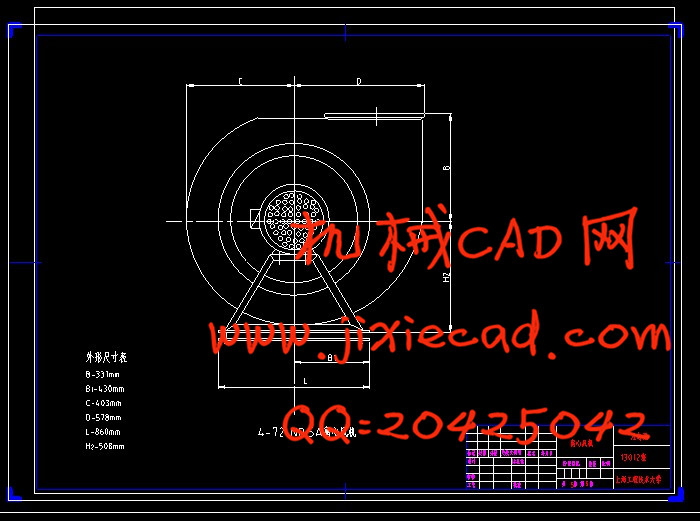

木工展示厅是个特殊的场所,展示厅内要求保持清洁,不能有粉尘飞扬,以保证操作工人和参观人员的身体健康。由于除尘器位置要求安装在展厅内(一般安装在室外较多),故本设计选用高效布袋除尘器。其体积小,过滤面积大,外形美观,附合展示厅内除尘系统的技术和整体美观要求。除尘系统采用低噪声环保型风机,在管道的设计上考虑美观性和实用性相结合,另外附合企业规定的噪声标准指标达到要求。

关键词:除尘装置, 木材加工, 粉尘, 袋式除尘器

Design for Exhibition Hall’s dust-catcher

ABSTRACT

With the all along development of science technology and all along advancement of industry, pollution problem become heavier and heavier. Air quality is required more and more, and atmosphere is attached more and more importance to. Air quality is also taken into the weather forecast everyday.

As a basic wage, wood-machining is playing as an untouchable role. However, because of the requirement of the wood-technics, soot come out when the wood is being dried. First, soot is bad for people’s health. Industry, agriculture, wood production will be impacted badly when the air is polluted heavily. Clean up the air pollution, protect and reform the environment is the great thing leading to people’s health and developing the economy quickly and effectively. The soot, coming from the wood-machining, must be taken order with immediately.

The waste material that they produce in the course of processing has relative dust than big small billet, some is not the wood shaving of the particle type, there are a large amount of tiny saw-dust . According to characteristic of dust, whirlwind dust remover etc. cleaner bad result while dealing with the tiny particle, and the sack cleaner has very great advantages in this respect.

Woodwork Exhibition room is a special place that keeping atmosphere clean and no fly upward, guaranteeing operating worker and visitors health. Selecting high-efficiency sack cleaner in this design because demand for dust remover position is in the exhibition room (install generally in the getting more outdoors). Its character is small, large filter area, beautiful, conform to technology demand and the whole dust removal system are required beautiful The dust removal system adopts the low in noise environmental protection type air blower, paying attention to combining practicability with beauty in the design of the pipeline, conforming to the standard of the noise that enterprises stipulate in addition.

Key words: dust-catcher,wood-machining,soot,sack cleaner

摘要………………………………………………………………………… 1

ABSTRACT…………………………………………………………………… 3

0 引言 …………………………………………………………………… 5

1 粉尘 ………………………………………………………………… 6

1.1 粉尘的种类 ………………………………………………………… 6

1.2 粉尘特性 …………………………………………………………… 6

1.2.1 密度……………………………………………………………… 7

1.2.2 粘附性…………………………………………………………… 7

1.2.3 爆炸性……………………………………………………………… 7

1.2.4 荷电性和比电阻…………………………………………………… 7

1.2.5 润湿性……………………………………………………………… 7

1.2.6 粉尘粒径及粒径分布……………………………………………… 7

1.3 粉尘的危害…………………………………………………………… 8

2 除尘……………………………………………………………………… 8

2.1 木工除尘的特点…………………………………………………………9

2.2 除尘机理 ……………………………………………………………… 9

2.3 除尘的三个阶段……………………………………………………… 10

2.4 除尘器分类 ………………………………………………………… 12

2.5 除尘器的介绍………………………………………………………… 13

2.5.1 重力除尘器………………………………………………………… 13

2.5.2 惯性除尘器………………………………………………………… 14

2.5.3 离心除尘器………………………………………………………… 15

2.5.4 袋式除尘器………………………………………………………… 15

2.5.5 洗涤除尘器………………………………………………………… 16

2.5.6 电除尘器…………………………………………………………… 16

2.6 除尘器的选择………………………………………………………… 17

2.7 脉冲袋式除尘器……………………………………………………… 17

2.7.1 脉冲袋式除尘器的除尘原理……………………………………… 18

2.7.2 脉冲袋式除尘器的优点……………………………………………19

2.7.3 影响脉冲袋式除尘器性能的因素…………………………………19

3 管路设计计算及风机选择………………………………………………20

3.1 管路设计……………………………………………………………… 20

3.1.1 管路形式和操作要点……………………………………………… 20

3.1.2 管路材质…………………………………………………………… 21

3.2 管路阻力计算………………………………………………………… 21

3.3计算系统的总阻力…………………………………………………… 37

3.4 风机的选择 ……………………………………………………………38

3.5 管路阻力二次计算…………………………………………………… 40

3.6 计算系统的二次总阻力……………………………………………… 48

3.7 风机的二次选择……………………………………………………… 48

4 噪声控制………………………………………………………………… 49

4.1 噪声控制的方法……………………………………………………… 49

4.2 降低噪声措施………………………………………………………… 49

5 结论……………………………………………………………………… 50

参考文献…………………………………………………………………… 51

随着科学技术的不断发展,工业水平的不断进步,粉尘污染问题变得日趋严重,人们对空气质量的要求越来越高了,大气环境越来越受到重视,空气质量也被列入了每天的天气预报中。

木材加工业作为一项基础工业,在社会的发展中扮演了不可或缺的角色,然而,由于木材工艺的要求,木材加工过程中对大气产生了一定程度的粉尘污染。粉尘的污染首先危害的是人民的健康,严重时对工业,农业,林业生产等都能造成危害。消除粉尘污染,改善环境是关系到保护人民健康、多快好省地发展工农业生产的大事。在木材加工过程中产生的粉尘急需很好地被解决。

木材在加工过程中产生的废料有相对粉尘较大的小木块,一些非颗粒型的刨花,还有大量细小的木屑粉尘等。根据粉尘的特性,旋风除尘器等除尘设备在处理小颗粒时效果不好,而布袋除尘器在这方面具有很大的优势。

木工展示厅是个特殊的场所,展示厅内要求保持清洁,不能有粉尘飞扬,以保证操作工人和参观人员的身体健康。由于除尘器位置要求安装在展厅内(一般安装在室外较多),故本设计选用高效布袋除尘器。其体积小,过滤面积大,外形美观,附合展示厅内除尘系统的技术和整体美观要求。除尘系统采用低噪声环保型风机,在管道的设计上考虑美观性和实用性相结合,另外附合企业规定的噪声标准指标达到要求。

关键词:除尘装置, 木材加工, 粉尘, 袋式除尘器

Design for Exhibition Hall’s dust-catcher

ABSTRACT

With the all along development of science technology and all along advancement of industry, pollution problem become heavier and heavier. Air quality is required more and more, and atmosphere is attached more and more importance to. Air quality is also taken into the weather forecast everyday.

As a basic wage, wood-machining is playing as an untouchable role. However, because of the requirement of the wood-technics, soot come out when the wood is being dried. First, soot is bad for people’s health. Industry, agriculture, wood production will be impacted badly when the air is polluted heavily. Clean up the air pollution, protect and reform the environment is the great thing leading to people’s health and developing the economy quickly and effectively. The soot, coming from the wood-machining, must be taken order with immediately.

The waste material that they produce in the course of processing has relative dust than big small billet, some is not the wood shaving of the particle type, there are a large amount of tiny saw-dust . According to characteristic of dust, whirlwind dust remover etc. cleaner bad result while dealing with the tiny particle, and the sack cleaner has very great advantages in this respect.

Woodwork Exhibition room is a special place that keeping atmosphere clean and no fly upward, guaranteeing operating worker and visitors health. Selecting high-efficiency sack cleaner in this design because demand for dust remover position is in the exhibition room (install generally in the getting more outdoors). Its character is small, large filter area, beautiful, conform to technology demand and the whole dust removal system are required beautiful The dust removal system adopts the low in noise environmental protection type air blower, paying attention to combining practicability with beauty in the design of the pipeline, conforming to the standard of the noise that enterprises stipulate in addition.

Key words: dust-catcher,wood-machining,soot,sack cleaner

摘要………………………………………………………………………… 1

ABSTRACT…………………………………………………………………… 3

0 引言 …………………………………………………………………… 5

1 粉尘 ………………………………………………………………… 6

1.1 粉尘的种类 ………………………………………………………… 6

1.2 粉尘特性 …………………………………………………………… 6

1.2.1 密度……………………………………………………………… 7

1.2.2 粘附性…………………………………………………………… 7

1.2.3 爆炸性……………………………………………………………… 7

1.2.4 荷电性和比电阻…………………………………………………… 7

1.2.5 润湿性……………………………………………………………… 7

1.2.6 粉尘粒径及粒径分布……………………………………………… 7

1.3 粉尘的危害…………………………………………………………… 8

2 除尘……………………………………………………………………… 8

2.1 木工除尘的特点…………………………………………………………9

2.2 除尘机理 ……………………………………………………………… 9

2.3 除尘的三个阶段……………………………………………………… 10

2.4 除尘器分类 ………………………………………………………… 12

2.5 除尘器的介绍………………………………………………………… 13

2.5.1 重力除尘器………………………………………………………… 13

2.5.2 惯性除尘器………………………………………………………… 14

2.5.3 离心除尘器………………………………………………………… 15

2.5.4 袋式除尘器………………………………………………………… 15

2.5.5 洗涤除尘器………………………………………………………… 16

2.5.6 电除尘器…………………………………………………………… 16

2.6 除尘器的选择………………………………………………………… 17

2.7 脉冲袋式除尘器……………………………………………………… 17

2.7.1 脉冲袋式除尘器的除尘原理……………………………………… 18

2.7.2 脉冲袋式除尘器的优点……………………………………………19

2.7.3 影响脉冲袋式除尘器性能的因素…………………………………19

3 管路设计计算及风机选择………………………………………………20

3.1 管路设计……………………………………………………………… 20

3.1.1 管路形式和操作要点……………………………………………… 20

3.1.2 管路材质…………………………………………………………… 21

3.2 管路阻力计算………………………………………………………… 21

3.3计算系统的总阻力…………………………………………………… 37

3.4 风机的选择 ……………………………………………………………38

3.5 管路阻力二次计算…………………………………………………… 40

3.6 计算系统的二次总阻力……………………………………………… 48

3.7 风机的二次选择……………………………………………………… 48

4 噪声控制………………………………………………………………… 49

4.1 噪声控制的方法……………………………………………………… 49

4.2 降低噪声措施………………………………………………………… 49

5 结论……………………………………………………………………… 50

参考文献…………………………………………………………………… 51