设计简介

摘要

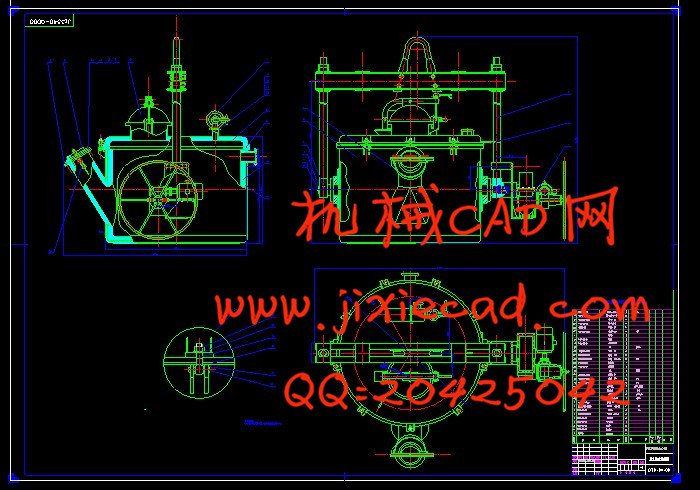

真空抬包是电解铝冶炼过程中的一个重要设备,其主要功能是将电解槽中的电解铝液吸出并倒运至混合炉,是转运铝水的重要设备。真空抬包能够将电解槽中的电解铝液吸出并倒运到混合炉后浇铸成铝锭。该设备维护费用低、安全性高、工人劳动强度低等特点,一次可吸取几个电解槽内的铝液并直接送至混合炉,无需中途转浇包倒运,铝液热量损失小。该抬包采用正压喷射吸铝,改变了传统的负压直接吸铝,消除了负压吸铝对真空系统的危害,由于其可与电解槽共用一个气源,可省去整套真空系统,减少岗位配置,降低设备维护、检修费用,节约运行中的电费开支。

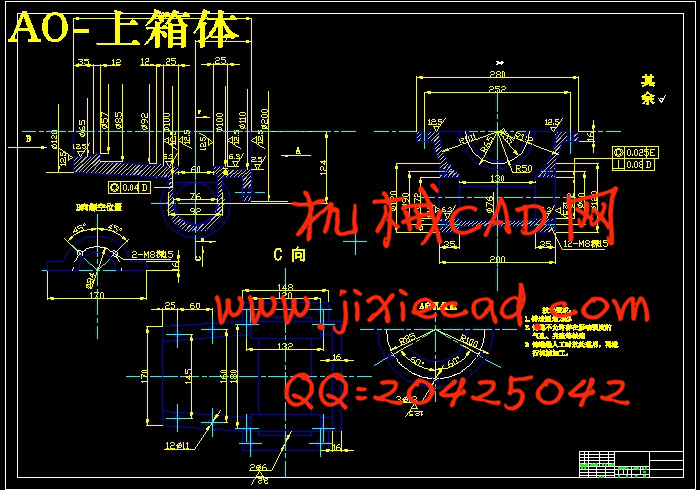

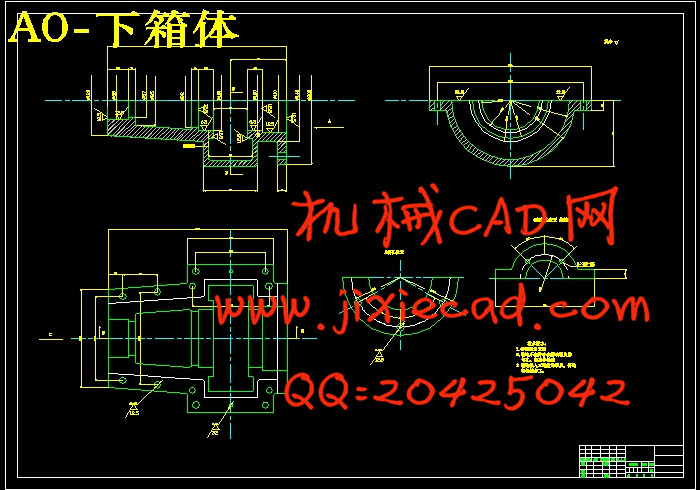

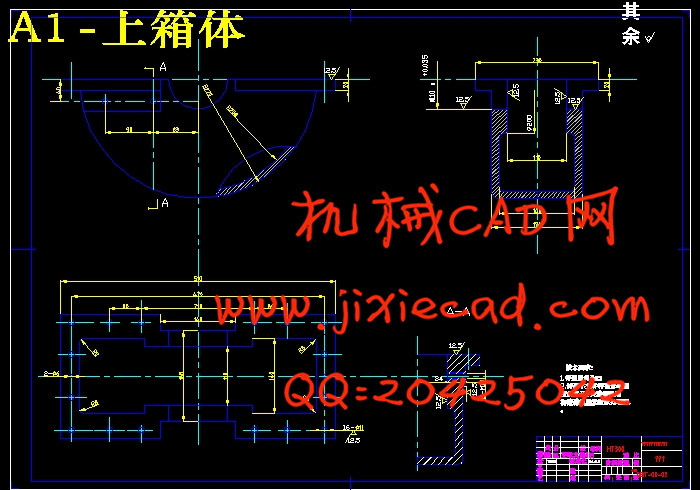

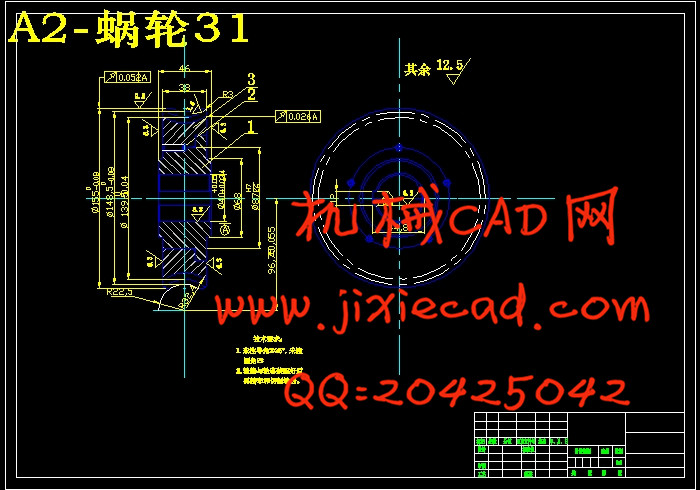

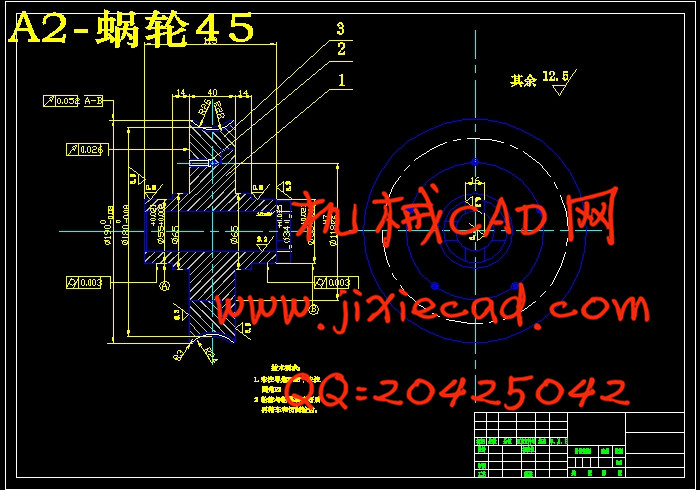

真空抬包采用茶壶式浇包的结构形式,铝液从包底浇出,熔渣被挡在包内,撇渣效果好。减速机是抬包的倾转机构,采用3级蜗轮蜗杆减速机。由于抬包容积的增大,自重及盛铝量均增大,抬包的倾转力矩增大,手动倾转费力、效率低而且不安全,该减速机在结构形式设计为手动与电动均可,正常操作为电动,手动为检修和突发事故时用,手动与电动的切换采用爪式离合器,切换迅速方便,安全可靠。该减速机电动为三级蜗轮蜗杆减速,手动为两级蜗轮蜗杆减速,减速比大。

关键词:真空抬包、减速机、蜗轮、蜗杆

Abstract

Vacuum Ladle electrolytic aluminum smelting process is important for the equipment, Its main function is to the electrolytic aluminum electrolytic cell fluid aspirated and unlucky to mixed stoves, aluminum water transit is important equipment. Ladle vacuum can be electrolyzer the smelter was sucked out of the mix and unlucky after casting furnace into ingots. The equipment maintenance costs low, safe, low labor intensity characteristics, Several lessons can be a cell of molten aluminum and directly sent mixed furnace without the halfway turn Ladle unlucky. Al small liquid heat loss. Ladle the use of suction pressure spray of aluminum, changed the traditional vacuum suction direct aluminum, Elimination of aluminum suction vacuum system for the harm, because of their shared cell with a gas source. package can be saved vacuum system to reduce the allocation of posts, reducing equipment maintenance, repair costs, saving operation of the electricity bill.

Ladle using vacuum-pouring teapot packet structure, aluminum liquid poured from the underwrite that was blocking the slag ladle, skims good effect. Reducer is Ladle dip turn, used three worm-drive. Ladle volume due to the increase of self-respect and all aluminum volume increased, ladle the tilting torque increases, manual dumping switch effort, inefficient and unsafe, the slowdown in aircraft structure design of the manual and electric may, the normal operation of electric, Manual for Maintenance and use of emergency, manual and electrical switch using a claw-type clutch, switching speedy and convenient, safe and reliable. The electric drive for three worm-slow manual for the two worm-deceleration than decelerating.

Keywords : vacuum ladle, reduction gears, worm gears, Worm

目 录

前言……………………………………………………………………………………1

1 项目分析……………………………………………………………………………3

1.1 真空抬包系统现有情况………………………………………………………3

1.2 本次设计改进所要解决的问题………………………………………………3

2 真空抬包总体设计方案……………………………………………………………5

3 大速比倾包系统设计………………………………………………………………6

3.1 倾转力矩的分析………………………………………………………………6

3.1.1 空包包体的倾转力矩 …………………………………………………6

3.1.2 余留铝液的倾转力矩 …………………………………………………7

3.1.3 摩擦力矩 ………………………………………………………………9

3.1.4 结论分析 ………………………………………………………………9

3.2 减速机构的分析………………………………………………………………9

3.2.1 蜗轮蜗杆减速机介绍 …………………………………………………9

3.2.2 传动比的分配…………………………………………………………11

3.2.3 电动机的选择…………………………………………………………11

3.2.4 蜗轮蜗杆设计…………………………………………………………11

4 真空抬包工艺参数 ………………………………………………………………21

5 主要部分的设计计算与校核 ……………………………………………………22

5.1 吊钩处………………………………………………………………………22

5.2 吊臂处………………………………………………………………………22

5.3 吊臂与包体连接处…………………………………………………………23

6 经济性分析 ………………………………………………………………………24

总结 …………………………………………………………………………………25

致谢 …………………………………………………………………………………27

参考文献 ……………………………………………………………………………28

真空抬包是电解铝冶炼过程中的一个重要设备,其主要功能是将电解槽中的电解铝液吸出并倒运至混合炉,是转运铝水的重要设备。真空抬包能够将电解槽中的电解铝液吸出并倒运到混合炉后浇铸成铝锭。该设备维护费用低、安全性高、工人劳动强度低等特点,一次可吸取几个电解槽内的铝液并直接送至混合炉,无需中途转浇包倒运,铝液热量损失小。该抬包采用正压喷射吸铝,改变了传统的负压直接吸铝,消除了负压吸铝对真空系统的危害,由于其可与电解槽共用一个气源,可省去整套真空系统,减少岗位配置,降低设备维护、检修费用,节约运行中的电费开支。

真空抬包采用茶壶式浇包的结构形式,铝液从包底浇出,熔渣被挡在包内,撇渣效果好。减速机是抬包的倾转机构,采用3级蜗轮蜗杆减速机。由于抬包容积的增大,自重及盛铝量均增大,抬包的倾转力矩增大,手动倾转费力、效率低而且不安全,该减速机在结构形式设计为手动与电动均可,正常操作为电动,手动为检修和突发事故时用,手动与电动的切换采用爪式离合器,切换迅速方便,安全可靠。该减速机电动为三级蜗轮蜗杆减速,手动为两级蜗轮蜗杆减速,减速比大。

关键词:真空抬包、减速机、蜗轮、蜗杆

Abstract

Vacuum Ladle electrolytic aluminum smelting process is important for the equipment, Its main function is to the electrolytic aluminum electrolytic cell fluid aspirated and unlucky to mixed stoves, aluminum water transit is important equipment. Ladle vacuum can be electrolyzer the smelter was sucked out of the mix and unlucky after casting furnace into ingots. The equipment maintenance costs low, safe, low labor intensity characteristics, Several lessons can be a cell of molten aluminum and directly sent mixed furnace without the halfway turn Ladle unlucky. Al small liquid heat loss. Ladle the use of suction pressure spray of aluminum, changed the traditional vacuum suction direct aluminum, Elimination of aluminum suction vacuum system for the harm, because of their shared cell with a gas source. package can be saved vacuum system to reduce the allocation of posts, reducing equipment maintenance, repair costs, saving operation of the electricity bill.

Ladle using vacuum-pouring teapot packet structure, aluminum liquid poured from the underwrite that was blocking the slag ladle, skims good effect. Reducer is Ladle dip turn, used three worm-drive. Ladle volume due to the increase of self-respect and all aluminum volume increased, ladle the tilting torque increases, manual dumping switch effort, inefficient and unsafe, the slowdown in aircraft structure design of the manual and electric may, the normal operation of electric, Manual for Maintenance and use of emergency, manual and electrical switch using a claw-type clutch, switching speedy and convenient, safe and reliable. The electric drive for three worm-slow manual for the two worm-deceleration than decelerating.

Keywords : vacuum ladle, reduction gears, worm gears, Worm

目 录

前言……………………………………………………………………………………1

1 项目分析……………………………………………………………………………3

1.1 真空抬包系统现有情况………………………………………………………3

1.2 本次设计改进所要解决的问题………………………………………………3

2 真空抬包总体设计方案……………………………………………………………5

3 大速比倾包系统设计………………………………………………………………6

3.1 倾转力矩的分析………………………………………………………………6

3.1.1 空包包体的倾转力矩 …………………………………………………6

3.1.2 余留铝液的倾转力矩 …………………………………………………7

3.1.3 摩擦力矩 ………………………………………………………………9

3.1.4 结论分析 ………………………………………………………………9

3.2 减速机构的分析………………………………………………………………9

3.2.1 蜗轮蜗杆减速机介绍 …………………………………………………9

3.2.2 传动比的分配…………………………………………………………11

3.2.3 电动机的选择…………………………………………………………11

3.2.4 蜗轮蜗杆设计…………………………………………………………11

4 真空抬包工艺参数 ………………………………………………………………21

5 主要部分的设计计算与校核 ……………………………………………………22

5.1 吊钩处………………………………………………………………………22

5.2 吊臂处………………………………………………………………………22

5.3 吊臂与包体连接处…………………………………………………………23

6 经济性分析 ………………………………………………………………………24

总结 …………………………………………………………………………………25

致谢 …………………………………………………………………………………27

参考文献 ……………………………………………………………………………28