设计简介

摘要

近些年由于生活水平的提高,人们对家居装饰提出了更高的要求,竹材因其强度高,耐磨性好,纹理清晰美观,而且为天然绿色环保产品大大迎合人们回归自然的心理,深受人们的喜爱,市场前景非常广阔。为了组织大规模生产,必须使用合理高效的专用加工机械,但以竹子为原料生产板材是八十年代才开始研究的课题,到目前为止,最具有代表性的展开法为半竹平板加压展开法、旋切展开法2种,对于最有经济附加值的整竹无裂纹展开因其难度较大而在国内外基木属于空白。

要想获得整竹无裂纹展开竹平板,竹筒去青是关键工艺,去青后的竹筒表面质量的好坏将直接影响竹平板的展开质量。本文所涉及就是力求在遵循竹子特点的前提下,开发出一套成本低,操作方便,生产效率高,适用于大规模生产加工的整竹无裂纹展开的竹筒技术及装备,从而获得幅面宽度为250-300mm、厚度为5-6.5mm、长度为2500mm的整竹展开竹平板、竹平板刨切薄片及薄片贴面装饰板。

本文采用通过理论与实践相结合的研究方法,首先大量查阅有关毛竹特性的资料,再直接对采自毛竹原产地的原材料进行实际的数据测量和分析。同时在考虑毛竹竹筒几何外形不规则以及材料的特殊性的基础上对目前的多种去青加工方法进行比对分析,最终选择了表现最优的砂辊磨削方法,为使所设计的加工设备与市场现有设备相比较具有更好的通用性和操作性,适用各地组织大规模竹材加工,本文依据毛竹的特点对所设计的设备的各部件进行优化,特别是对关键的竹筒的装夹设备,小型简易砂辊的特殊结构进行了详细的设计优化。

在去青磨削中,磨削力的大小是由磨头拉紧弹簧的拉力大小决定的。由于毛竹“三度”的影响,砂辊随竹筒外形的变化而浮动时,必然会引起磨削力的变化。为保证竹筒表面的磨削质量,应使在磨削过程中磨削力的变化尽量小,即拉紧弹簧的拉力变化尽量小。我们根据上述原则对拉紧弹簧的设计和安装位置的选择进行了详细分析设计。还是由于毛竹的“三度”的影响,特别是弯曲度的影响,在磨削时,竹筒自身旋转会引起砂辊的上下、左右浮动。弯曲度越大,浮动量越大,引起弹簧的拉力变化就越大,因而磨削力的变化越大,表面加工质量就越差。为了适应外形既弯曲又椭圆的竹筒去青要求,本课题设计出了一种专用的装夹装置。其结构简单、造价低廉、可靠性好。同时我们还根据磨削力的变化尽量小等原则刘‘夹具的装夹位置进行了优化设计。。一般木材磨削用的砂辊尺寸较大,结构比较复杂。而在竹材加工中,需要设计一种较小的包裹式砂辊,其磨削直径为150mm,轴向砂布宽度为100mm。我们所设计的简易砂辊是针对整竹去青设计的一种特殊砂辊,它不仅工作可靠、性能优,而且结构紧凑、重量轻,更换砂布方便、快捷。论文详细阐述了它的结构特点,并重点对砂辊中的关键零件弹性环的强度和刚度进行了理论分析和计算。

本课题研究设计出了一种全新的整竹去青加工工艺及设备,加工获得整竹表面的加工质量理想,适合于无裂纹展开,具有较高的推广意义。

关键词:整竹无裂纹展开,去青,磨削,砂辊,设计

Abstract

Due to the improvement of living standards in recent years, people have decorated home a higher demand, bamboo its high strength, good abrasion resistance, texture clear appearance, but also for the natural green products to meet the people back to nature much of the psychological, deep by the people's favorite, the market prospects are very broad. To organize a large-scale production, to be rational and efficient use of dedicated processing machinery, but as raw materials to produce bamboo plate is only the beginning of the eighties study, so far, the most representative of the expansion method for the pressure plate to start a half bamboo law, two kinds of expansion method peeling, for most of the entire economic value-added bamboo and crack-free and more difficult to start because of their base at home and abroad belong to the blank wood.

To obtain crack-free to start the whole bamboo bamboo plate, bamboo is the key to green technology, to the post-green bamboo surface quality will directly affect the quality of the plate to start the quality of bamboo. In this paper, is involved in trying to follow the premise of the characteristics of bamboo, the development of a set of low-cost, convenient operation, high productivity for large-scale bamboo production and processing of the whole crack-free start of the bamboo tube technology and equipment so as to attain the size width of 250-300mm, a thickness of 5-6.5mm, length 2500mm started the whole bamboo bamboo plate, bamboo plate Sliced thin veneer sheets and decorative boards.

In this paper, the theory and practice through a combination of research methods, first of all characteristics of a large number of Bamboo have access to the information, and then directly taken from the bamboo of origin of raw materials for the actual measurement and analysis of data. At the same time, consider bamboo bamboo irregular geometry and the material basis of the specificity of the current processing of a variety of methods to Green than on analysis, the final choice of the optimal performance of the sand roller grinding methods, designed to make processing equipment and existing equipment compared to the market with better versatility and interoperability for large-scale bamboo processing throughout the organization, this article on the basis of the characteristics of bamboo equipment designed to optimize the various components, especially for the critical loading of bamboo folder equipment, a small summary of the special structure of sand roller carried out a detailed design optimization.

Grinding in to the Green, the grinding force is stretched by the Head of the tension spring the size of the decision. As the bamboo "three times" the impact of sand-roll with the changes in tube shape when floating, is bound to cause changes in grinding force. In order to ensure the quality of bamboo surface grinding, grinding should be made in the course of the changes in grinding force as small as possible, that is, the spring tension of the tension changes as small as possible. In line with these principles, we spring to tighten the design and installation of the choice of the location of a detailed analysis of the design. Or as a result of bamboo's "three times", especially the effects of curvature in the grinding, the bamboo tube itself will cause rotation of the upper and lower sand roller, floating around. The greater the curvature, the greater the amount of floating, spring tension changes caused by the greater, and therefore the greater the changes in grinding force, the worse the quality of surface processing. In order to adapt to both curved and elliptical shape of the tube to Green requested that the subject of a special design of the clamping device. Its simple structure, low cost and reliability. At the same time we also in accordance with changes in grinding force as small as possible the principles of Liu 'fixture clamping position was optimized. . General wood grinding roller with a larger size of the sand, the structure is rather complicated. In bamboo processing, it is necessary to design a smaller package-type sand roll, the grinding diameter 150mm, emery cloth axial width of 100mm. We designed a simple sand roller bamboo for the whole design to the Green Sand of a special roller, it is not only reliable, excellent performance and compact structure, light weight, the replacement of emery cloth convenient, fast. Paper described in detail the characteristics of its structure and focus on the key roll sand flexible parts of the strength and stiffness of ring theoretical analysis and calculation.

This research designed a brand-new to the whole green bamboo processing technology and equipment, processing, access to the entire surface of the processing quality bamboo ideal, suitable for crack-free to start the promotion of high significance.

Key words: crack-free to start the whole Penny to Qing, grinding, sand roll, design

目录

第1章 绪论 5

1.1课题研究的目的和意义5

1.2 国内外研究的现状 6

1.3 论文主要研究内容 7

1.4 研究方法及具体步骤 7

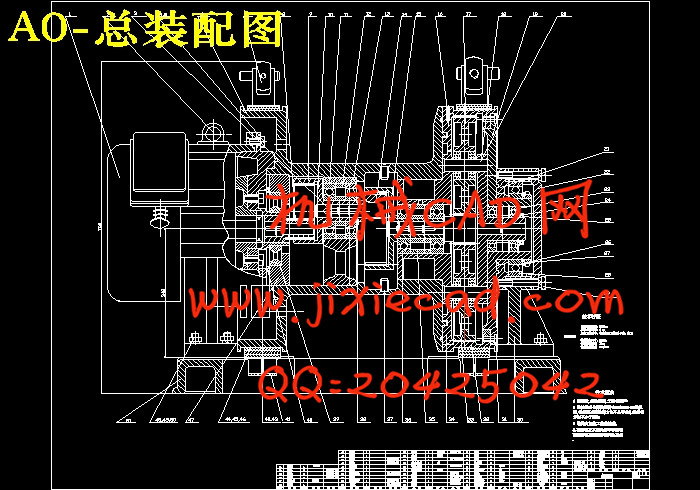

第2章 去青机驱动系统设计 10

2.1 设计方案的确定 10

2.1.1 设计参数 10

2.1.2 设计方案的确定 10

2.2 电机的选择 11

2.2.1 电动机的容量 11

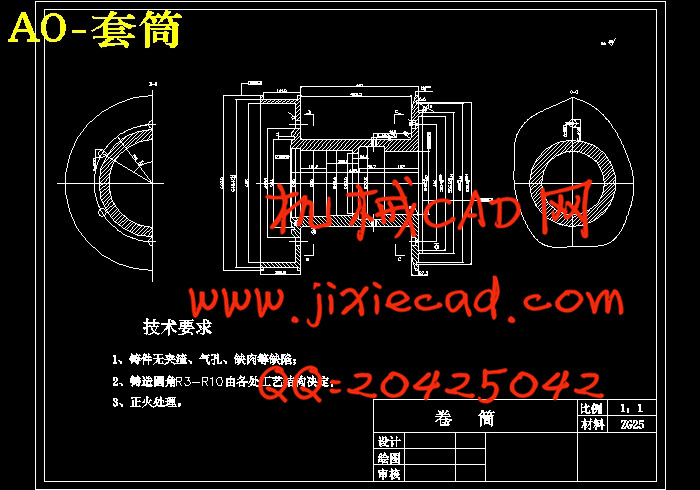

2.2.2 卷筒的转速 12

2.2.3 计算总传动比 分配各级传动比 12

第3章 去青机传动系统的设计 14

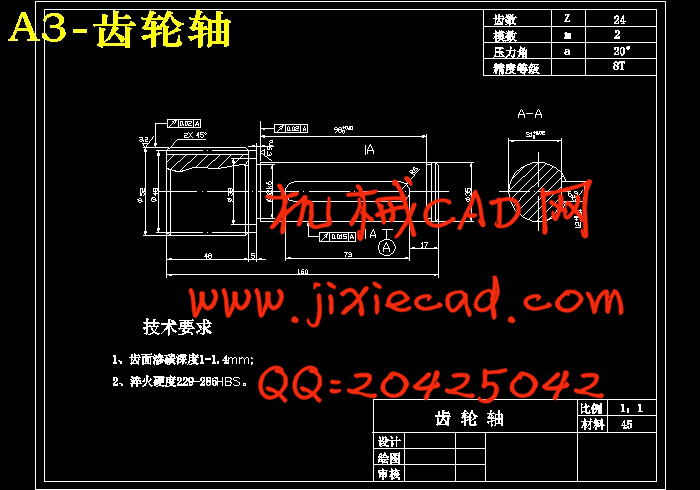

3.1电动机轴齿的设计 14

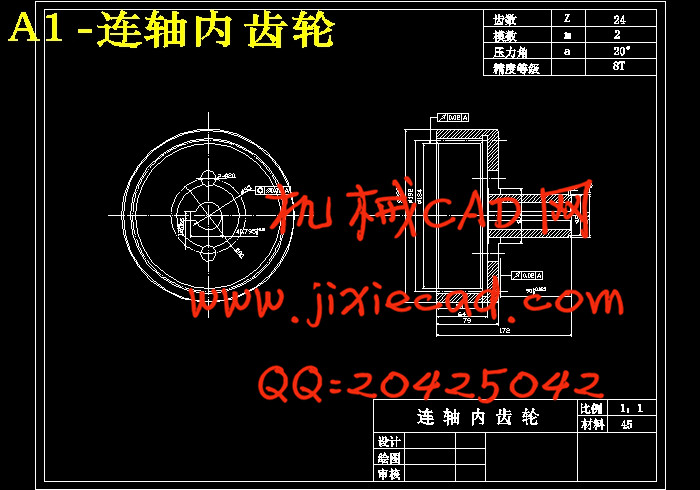

3.2 内齿轮的设计 16

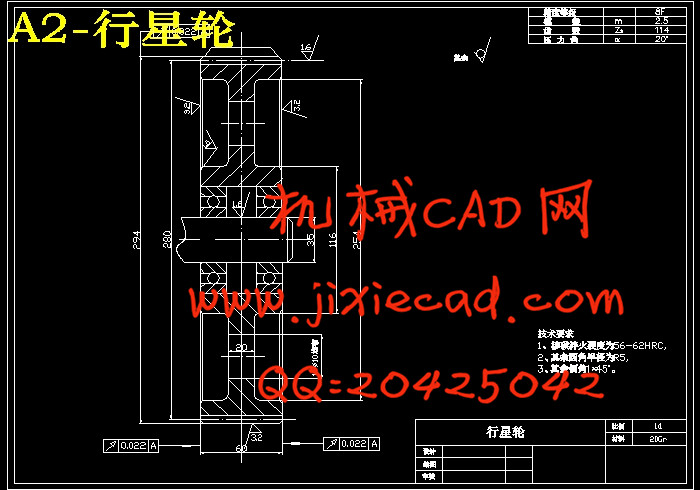

3.3行星齿轮的设计 18

3.4轴的设计及轴承的校核 19

3.4.1 轴的结构设计原则 19

3.4.2 轴承的选择 20

3.4.3 轴材料的选择 20

3.4.4 轴2的设计,计算及轴承的确定 20

3.4.2轴3的设计,计算及轴承的确定 23

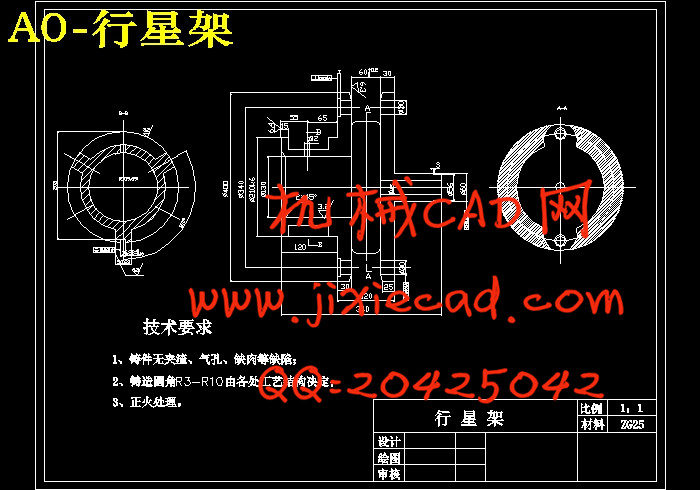

3.5行星架的选择 23

第4章 去青机执行机构设计 25

第5章 制动器的设计 30

结论 36

致谢 37

参考文献 38

近些年由于生活水平的提高,人们对家居装饰提出了更高的要求,竹材因其强度高,耐磨性好,纹理清晰美观,而且为天然绿色环保产品大大迎合人们回归自然的心理,深受人们的喜爱,市场前景非常广阔。为了组织大规模生产,必须使用合理高效的专用加工机械,但以竹子为原料生产板材是八十年代才开始研究的课题,到目前为止,最具有代表性的展开法为半竹平板加压展开法、旋切展开法2种,对于最有经济附加值的整竹无裂纹展开因其难度较大而在国内外基木属于空白。

要想获得整竹无裂纹展开竹平板,竹筒去青是关键工艺,去青后的竹筒表面质量的好坏将直接影响竹平板的展开质量。本文所涉及就是力求在遵循竹子特点的前提下,开发出一套成本低,操作方便,生产效率高,适用于大规模生产加工的整竹无裂纹展开的竹筒技术及装备,从而获得幅面宽度为250-300mm、厚度为5-6.5mm、长度为2500mm的整竹展开竹平板、竹平板刨切薄片及薄片贴面装饰板。

本文采用通过理论与实践相结合的研究方法,首先大量查阅有关毛竹特性的资料,再直接对采自毛竹原产地的原材料进行实际的数据测量和分析。同时在考虑毛竹竹筒几何外形不规则以及材料的特殊性的基础上对目前的多种去青加工方法进行比对分析,最终选择了表现最优的砂辊磨削方法,为使所设计的加工设备与市场现有设备相比较具有更好的通用性和操作性,适用各地组织大规模竹材加工,本文依据毛竹的特点对所设计的设备的各部件进行优化,特别是对关键的竹筒的装夹设备,小型简易砂辊的特殊结构进行了详细的设计优化。

在去青磨削中,磨削力的大小是由磨头拉紧弹簧的拉力大小决定的。由于毛竹“三度”的影响,砂辊随竹筒外形的变化而浮动时,必然会引起磨削力的变化。为保证竹筒表面的磨削质量,应使在磨削过程中磨削力的变化尽量小,即拉紧弹簧的拉力变化尽量小。我们根据上述原则对拉紧弹簧的设计和安装位置的选择进行了详细分析设计。还是由于毛竹的“三度”的影响,特别是弯曲度的影响,在磨削时,竹筒自身旋转会引起砂辊的上下、左右浮动。弯曲度越大,浮动量越大,引起弹簧的拉力变化就越大,因而磨削力的变化越大,表面加工质量就越差。为了适应外形既弯曲又椭圆的竹筒去青要求,本课题设计出了一种专用的装夹装置。其结构简单、造价低廉、可靠性好。同时我们还根据磨削力的变化尽量小等原则刘‘夹具的装夹位置进行了优化设计。。一般木材磨削用的砂辊尺寸较大,结构比较复杂。而在竹材加工中,需要设计一种较小的包裹式砂辊,其磨削直径为150mm,轴向砂布宽度为100mm。我们所设计的简易砂辊是针对整竹去青设计的一种特殊砂辊,它不仅工作可靠、性能优,而且结构紧凑、重量轻,更换砂布方便、快捷。论文详细阐述了它的结构特点,并重点对砂辊中的关键零件弹性环的强度和刚度进行了理论分析和计算。

本课题研究设计出了一种全新的整竹去青加工工艺及设备,加工获得整竹表面的加工质量理想,适合于无裂纹展开,具有较高的推广意义。

关键词:整竹无裂纹展开,去青,磨削,砂辊,设计

Abstract

Due to the improvement of living standards in recent years, people have decorated home a higher demand, bamboo its high strength, good abrasion resistance, texture clear appearance, but also for the natural green products to meet the people back to nature much of the psychological, deep by the people's favorite, the market prospects are very broad. To organize a large-scale production, to be rational and efficient use of dedicated processing machinery, but as raw materials to produce bamboo plate is only the beginning of the eighties study, so far, the most representative of the expansion method for the pressure plate to start a half bamboo law, two kinds of expansion method peeling, for most of the entire economic value-added bamboo and crack-free and more difficult to start because of their base at home and abroad belong to the blank wood.

To obtain crack-free to start the whole bamboo bamboo plate, bamboo is the key to green technology, to the post-green bamboo surface quality will directly affect the quality of the plate to start the quality of bamboo. In this paper, is involved in trying to follow the premise of the characteristics of bamboo, the development of a set of low-cost, convenient operation, high productivity for large-scale bamboo production and processing of the whole crack-free start of the bamboo tube technology and equipment so as to attain the size width of 250-300mm, a thickness of 5-6.5mm, length 2500mm started the whole bamboo bamboo plate, bamboo plate Sliced thin veneer sheets and decorative boards.

In this paper, the theory and practice through a combination of research methods, first of all characteristics of a large number of Bamboo have access to the information, and then directly taken from the bamboo of origin of raw materials for the actual measurement and analysis of data. At the same time, consider bamboo bamboo irregular geometry and the material basis of the specificity of the current processing of a variety of methods to Green than on analysis, the final choice of the optimal performance of the sand roller grinding methods, designed to make processing equipment and existing equipment compared to the market with better versatility and interoperability for large-scale bamboo processing throughout the organization, this article on the basis of the characteristics of bamboo equipment designed to optimize the various components, especially for the critical loading of bamboo folder equipment, a small summary of the special structure of sand roller carried out a detailed design optimization.

Grinding in to the Green, the grinding force is stretched by the Head of the tension spring the size of the decision. As the bamboo "three times" the impact of sand-roll with the changes in tube shape when floating, is bound to cause changes in grinding force. In order to ensure the quality of bamboo surface grinding, grinding should be made in the course of the changes in grinding force as small as possible, that is, the spring tension of the tension changes as small as possible. In line with these principles, we spring to tighten the design and installation of the choice of the location of a detailed analysis of the design. Or as a result of bamboo's "three times", especially the effects of curvature in the grinding, the bamboo tube itself will cause rotation of the upper and lower sand roller, floating around. The greater the curvature, the greater the amount of floating, spring tension changes caused by the greater, and therefore the greater the changes in grinding force, the worse the quality of surface processing. In order to adapt to both curved and elliptical shape of the tube to Green requested that the subject of a special design of the clamping device. Its simple structure, low cost and reliability. At the same time we also in accordance with changes in grinding force as small as possible the principles of Liu 'fixture clamping position was optimized. . General wood grinding roller with a larger size of the sand, the structure is rather complicated. In bamboo processing, it is necessary to design a smaller package-type sand roll, the grinding diameter 150mm, emery cloth axial width of 100mm. We designed a simple sand roller bamboo for the whole design to the Green Sand of a special roller, it is not only reliable, excellent performance and compact structure, light weight, the replacement of emery cloth convenient, fast. Paper described in detail the characteristics of its structure and focus on the key roll sand flexible parts of the strength and stiffness of ring theoretical analysis and calculation.

This research designed a brand-new to the whole green bamboo processing technology and equipment, processing, access to the entire surface of the processing quality bamboo ideal, suitable for crack-free to start the promotion of high significance.

Key words: crack-free to start the whole Penny to Qing, grinding, sand roll, design

目录

第1章 绪论 5

1.1课题研究的目的和意义5

1.2 国内外研究的现状 6

1.3 论文主要研究内容 7

1.4 研究方法及具体步骤 7

第2章 去青机驱动系统设计 10

2.1 设计方案的确定 10

2.1.1 设计参数 10

2.1.2 设计方案的确定 10

2.2 电机的选择 11

2.2.1 电动机的容量 11

2.2.2 卷筒的转速 12

2.2.3 计算总传动比 分配各级传动比 12

第3章 去青机传动系统的设计 14

3.1电动机轴齿的设计 14

3.2 内齿轮的设计 16

3.3行星齿轮的设计 18

3.4轴的设计及轴承的校核 19

3.4.1 轴的结构设计原则 19

3.4.2 轴承的选择 20

3.4.3 轴材料的选择 20

3.4.4 轴2的设计,计算及轴承的确定 20

3.4.2轴3的设计,计算及轴承的确定 23

3.5行星架的选择 23

第4章 去青机执行机构设计 25

第5章 制动器的设计 30

结论 36

致谢 37

参考文献 38