设计简介

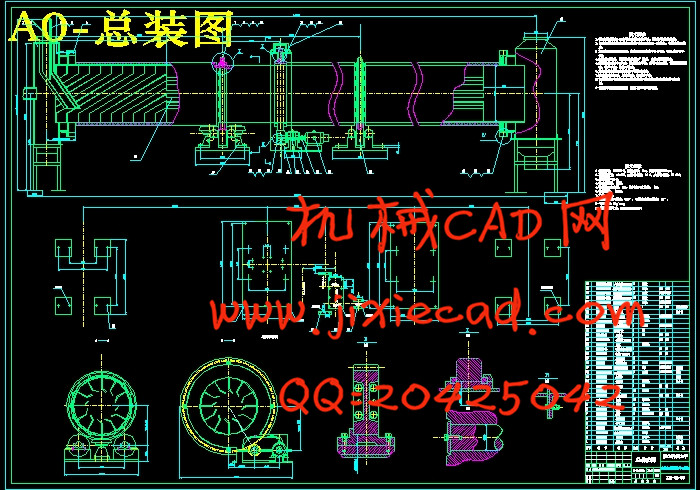

直接加热转筒式干燥机

摘 要

时代在发展,人类在进步。环境保护已经越来越多的被人们所重视。解决煤燃烧产生的大气污染问题是目前一个很重要也很紧迫的问题,随着人类对煤的研究,发现原煤和生物量的混合物燃烧后几乎不含有污染性气体。本设计的目的是为无污染生物煤的生产提供低成本的原煤干燥设备,为生物煤的推广打下坚实的基础,同时也为环保事业做出贡献。本设计采用如下方案:采用转筒式,直接传热方式,主要靠对流传热,采取并流操作,使用高温烟道气作为载体。由一般异步电动机,圆柱齿轮减速器和齿轮齿圈传动组成动力传动装置。由重油燃烧产生烟道气,石棉做保温层,尾气除尘设备选择旋风分离器。物料进、出传送均采用皮带传输机。密封方式颈向迷宫式密封。

在设计任务给定后,确定了设计所需的基本参数。进行了物料衡算和热量衡算,解决了需要消耗多少干燥介质和热量的问题。依据物料衡算和热量衡算的结果计算并确定了设备的规格参数。对干燥设备作了结构设计的详细计算和必要的强度校核。并选择配套的附属装置,如物料的传输方式选择、热风系统加热方式选择、引风机选型等,更加完善了设计的完整性。

关 键 词:直接传热,转筒式,干燥,原煤

Direct heating transfers the cylinder drying machine

Abstract

As the time going ,the environmental protection is getting more and more important in the new century. The output of coal burns is one kind of the things that course the environments pollution. However, scientists find that the output of the mixture burns ,which is the raw coal and creature

This design adopted the tube type dehydrator ,and transmitting heat directly by the main way of convection .and in this design adopted the parallel flow operation ,used the heat flue gas to carry the heat .the general asynchronous motor, cylinder gear speed reducer and tooth ring transmission composite the power transmission apparatus .the bure of the heavy oil create the flue gas and the heat preservation lamella is made by asbestos .the same time tornado separator can remove the dust tail gases. The strap delivers, machine carries out the in and out transmissions of the material. The seal method is diameter faces the maze type seal.

After the design mission given ,I made out all the data that must be compute out. To resole the problem how much medium for dry and the calorific value would be consumed, I have done the material calculates and the sum calorific value calculates. And according them I work out the specification parameter of the equipment. And more I have made some additional deal design, such as hot blast system and the breeze machine etc ,which made the design more perfect the complete.

Key Words:Transmit heat directly , cylinder ,Dry , Raw coal

目 录

1 绪论……………………………………………………………………………………1

1.1干燥技术的概况………………………………………………………………1

1.2干燥技术发展的总趋势………………………………………………………2

1.3干燥器的分类和选型…………………………………………………………3

1.3.1干燥器的分类…………………………………………………………3

1.3.2干燥器的选型…………………………………………………………3

1.4回转圆筒干燥器的特性………………………………………………………4

1.5回转圆筒干燥器在工业上的应用……………………………………………5

1.6回转圆筒干燥器的设计概论…………………………………………………5

2 设计初始参数的确定…………………………………………………………………7

2.1已知参数………………………………………………………………………7

2.2其他所需参数的确定…………………………………………………………7

2.2.1并流适用于下列物料的干燥…………………………………………7

2.2.2逆流方式适用于下列物料……………………………………………7

2.3混合气的参数计算……………………………………………………………12

3 物料衡算和热量衡算…………………………………………………………………14

3.1水分蒸发量……………………………………………………………………14

3.2空气消耗量……………………………………………………………………14

4 设备规格参数的设计和确定…………………………………………………………16

4.1筒体直径………………………………………………………………………16

4.2容积散热系数…………………………………………………………………16

4.3筒体长度………………………………………………………………………16

4.3.1预热段长度……………………………………………………………16

4.3.2蒸发段长度……………………………………………………………18

4.3.3加热段长度……………………………………………………………18

4.4转筒得转速喝倾斜度得选择…………………………………………………19

4.4.1转速……………………………………………………………………19

4.4.2筒体地斜度……………………………………………………………19

4.5停留时间………………………………………………………………………19

4.6填充系数………………………………………………………………………20

4.7热风系统加热形式的选择……………………………………………………21

4.8鼓风机或引风机的选型………………………………………………………21

4.9旋风分离器和进、出料装置…………………………………………………22

5 回转圆筒干燥器的结构设计与计算…………………………………………………24

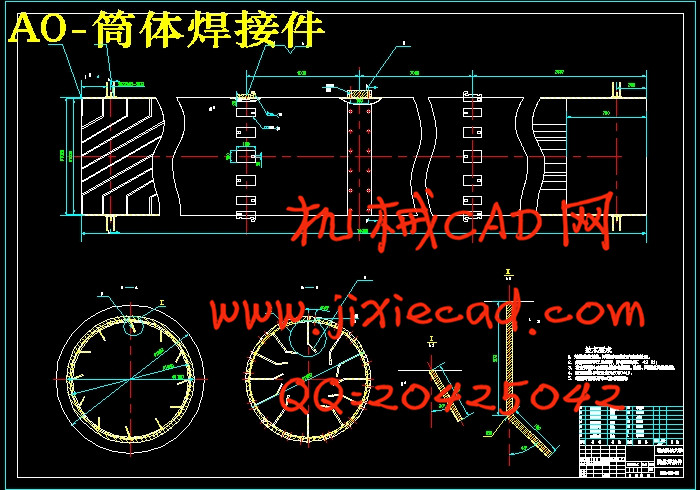

5.1筒体设计………………………………………………………………………24

5.1.1筒体结构组成…………………………………………………………24

5.1.2筒体载荷计算…………………………………………………………29

5.1.3筒体弯矩与应力计算…………………………………………………32

5.1.4筒体变形计算…………………………………………………………35

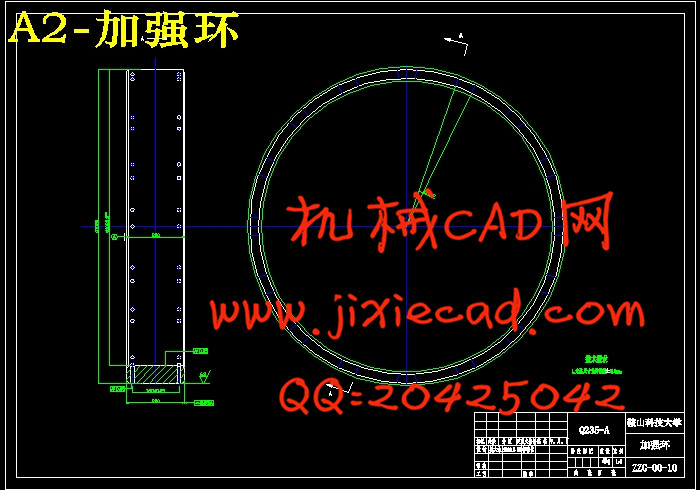

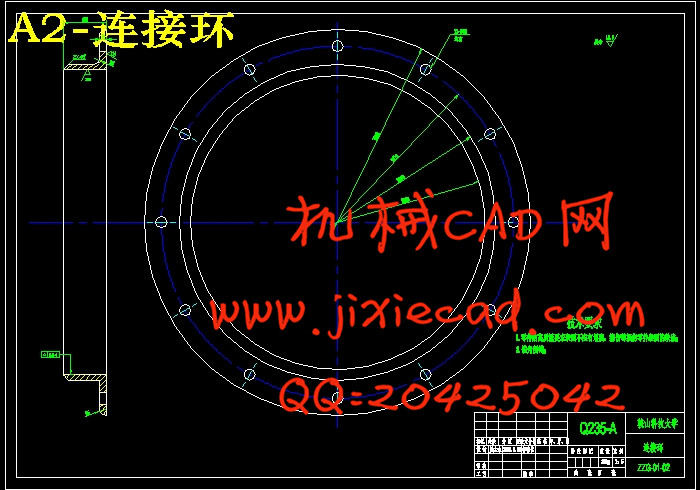

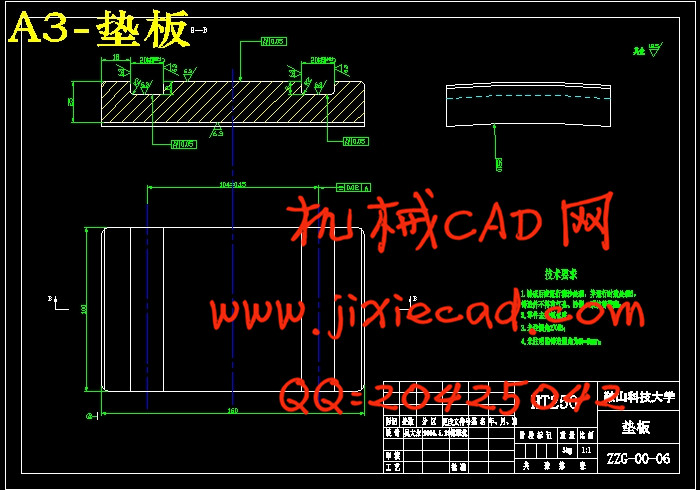

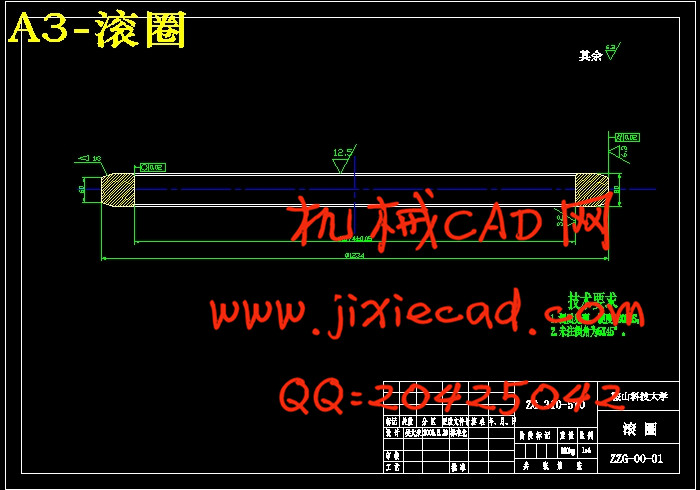

5.2滚圈设计………………………………………………………………………38

5.2.1滚圈的结构型式………………………………………………………38

5.2.2滚圈的设计与计算……………………………………………………39

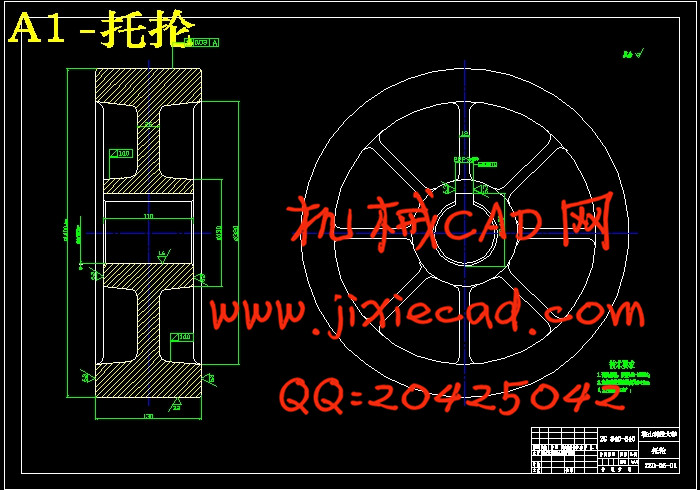

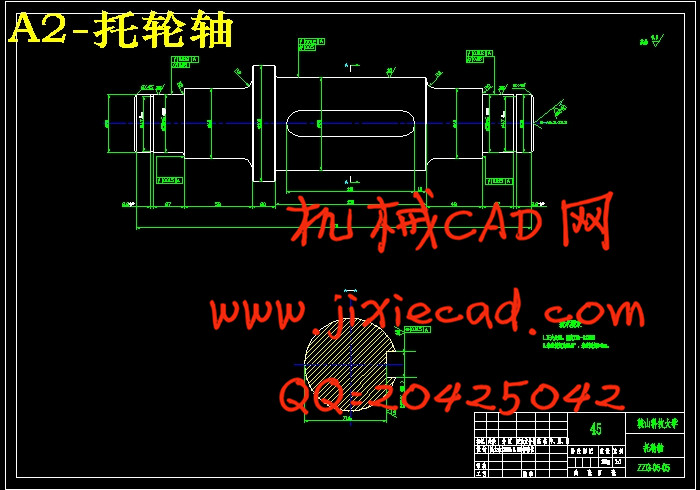

5.3托轮及轴承设计………………………………………………………………41

5.3.1结构设计………………………………………………………………41

5.3.2托轮及轴承的计算……………………………………………………42

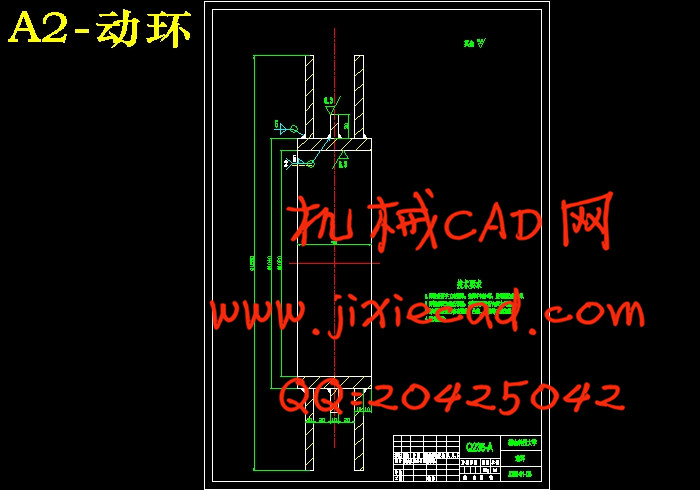

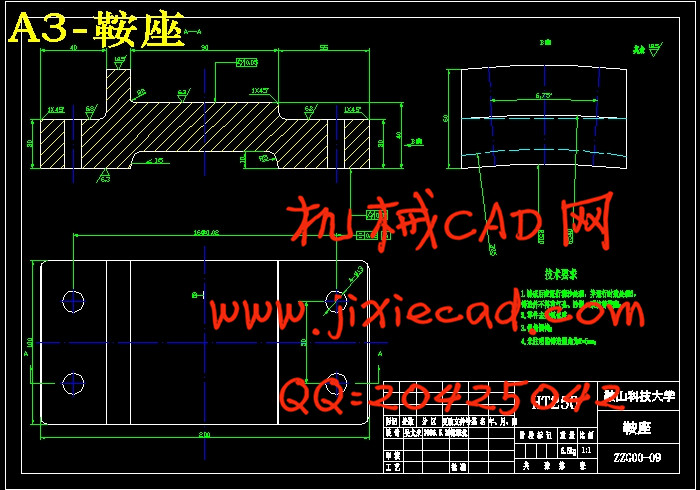

5.4挡轮及轴的设计………………………………………………………………46

5.4.1挡轮……………………………………………………………………46

5.4.2挡轮受力………………………………………………………………46

5.4.3挡轮参数的确定………………………………………………………47

5.4.4挡轮轴及轴承的选择…………………………………………………48

5.5传动装置的确定设计依据……………………………………………………49

5.5.1电动机选型……………………………………………………………49

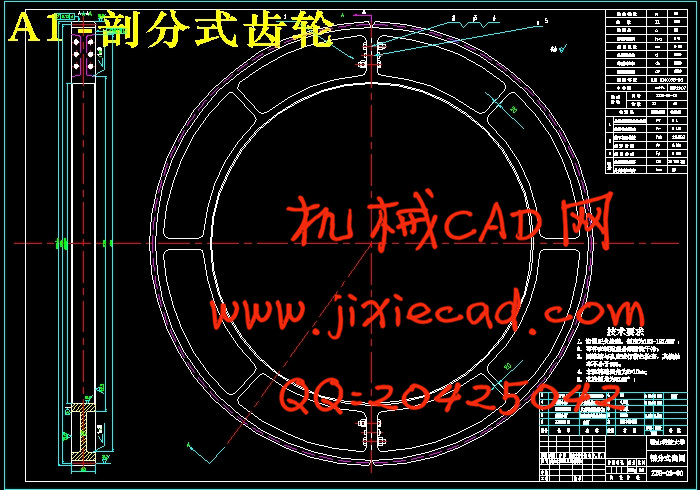

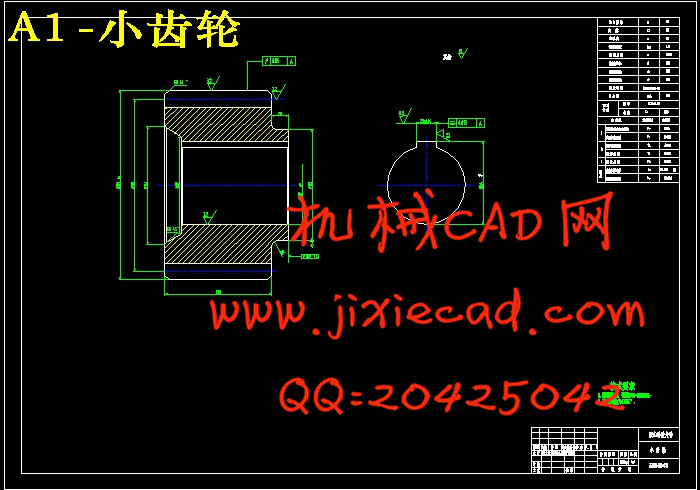

5.5.2齿轮配置………………………………………………………………49

5.5.3传动装置计算…………………………………………………………50

5.6减速器的选型…………………………………………………………………53

5.6.1按强度选用减速器……………………………………………………53

5.6.2校核热功率……………………………………………………………53

5.7联轴器的选型…………………………………………………………………54

5.7.1联轴器的计算转矩……………………………………………………54

5.7.2联轴器的工作转速……………………………………………………54

5.7.3轴孔直径………………………………………………………………54

5.8进、出料端设计………………………………………………………………54

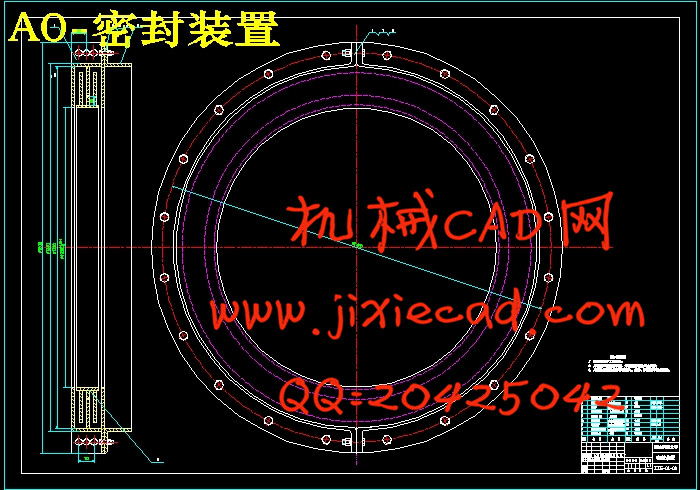

6 回转圆筒干燥器的密封………………………………………………………………56

7 回转圆筒干燥器的安装、调整和运转………………………………………………57

8 经济性分析……………………………………………………………………………58

结论与思考……………………………………………………………………………60

致谢……………………………………………………………………………………61

参考文献………………………………………………………………………………62