设计简介

直线振动给料机

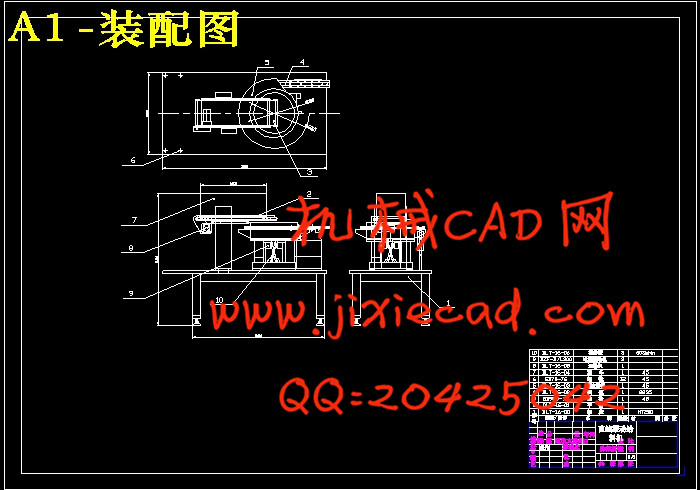

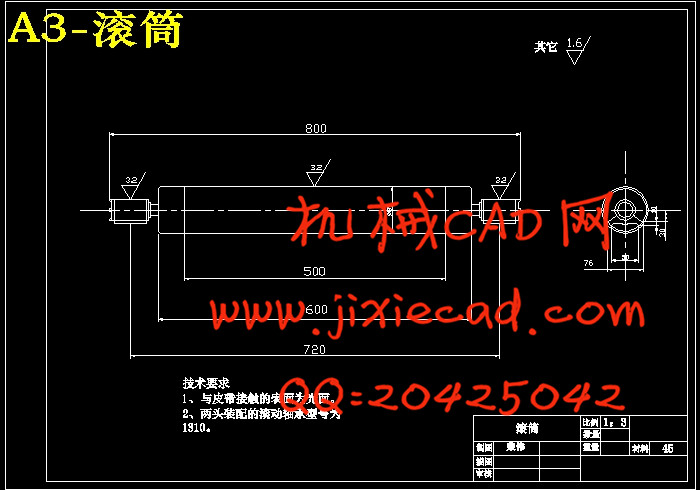

[摘要]: 本课题是针对输液袋灌装生产线输送设备部分的设计。随着医药包装材料的不断发展,目前在大输液生产中广泛使用的玻璃输液瓶有逐步被一次性软包装输液袋取代的趋势。与玻璃瓶相比较,输液袋有着众多玻璃瓶所不能比拟的、顺应医疗改革与发展的优点,如节约资源,减少环境污染,体积小,重量轻,灌装工艺简单,消毒灭菌安全,能避免交叉感染等。鉴于此,研制先进的软包装输液袋生产线已成为国内的重要课题。输送设备作为输液袋灌装生产线的重要组成部分,其主要完成灌装线输液袋灌装后瓶子输送工作,整个输送设备主要由溜槽、振动机、圆盘、皮带轮、板弹簧、直线轨道等部分组成。本设计详细阐述了大输液灌装系统的现状与前景;概述了输送设备设计的基本原则;全面剖析了输送设备的整体的结构、工作原理;具体设计了各主要组件的结构,并对相关要素进行了计算、分析与比较,主要包括溜槽尺寸设计与确定,机器内部结构的设计与确定,振动机选型与板弹簧设计、分析与介绍等;最后对输送设备的整体与主要组件绘制了详细的装配图与零件图。

关键字:输液袋、灌装线输送设备、直线轨道

Abstract:

This paper is the design of cap sealing device in the assemble line of the filling of infusing bag. With the development of the material of medical packing, currently, there comes the tendency of the replacement of glass infusing bottle which is widely used in mass infusion production by the one time soft infusion bag. Comparing with glass bottles, this bag follows the development of medical reform,and it has the advantages that the glass ones can not surpass , Such as, saving resources, reducing environment pollution, smaller volume, light weigh ,simple filling process , the safe disinfection avoiding cross-infection. Based on this, the research of the advanced assemble line of filling soft infusion bag has become the important study in our country. Cap sealing device is the main part of the line,and it main work is passing the vases after they are infused. The whole device consists of turning arm,head of perm,rotating mechanism, air mechanism, air cylinder of stretches and pendulum,air cylinder of ellipse piston。The current situation and prospect of the system are expounded detailed. And it summarizes the basic principles of the design of cap sealing device and analyzed the whole structure, movement and designed the structures of the main parts and give some calculations, analyzation and comparisons to the relative essential factors which includes and the define of the movement rotate arms and its dimensions, the dimensions of heating parts; the design of inner structure and power, and the design of air drive and vacuum system and air control valve and the brief introduction of air appendix, and also the design of air cylinder of stretches and pendulum,air cylinder of ellipse piston,The free manipulators of two degrees and then analyzation and introduction. In the end, the fix drawing, part drawing and principle drawing are dearly draw about the whole system.

Keywords: infusion bag, the device of cap sealing in filling assemble line, structure, movement.

目录

1.前言-----------------------------------------------------------------1

2. 2.直线振动给料机的设计-------------------------------------------- 2

2.1大输液灌装系统的现状与前景---------------------------------- 3

2.1.1玻璃瓶输液生产的洗灌封联动生产线--------------------------- 3

2.1.2 塑料包装输液生产发展的方向-------------------------- 4

2.1.2.1 塑包与玻璃瓶输液的简要比较--------------------------5

2.1.2.2 大输液软包装技术与药用丁基胶塞生产技术-------------- 6

2.1.2.3 三合一无菌包装技术在输液生产中的应用---------------- 6

2.1.2.4 制袋、灌装、封口软袋包装输液工艺技术的现状----------- 7

2.2 设计基本原则-------------------------------------------------- 8

2.2.1机器设计基本原则------------------------------------------- 9

2.2.2 机器零件设计基本原则--------------------------------------- 9

2.2.3机架设计准则和要求----------------------------------------- 11

2.2.3.1.机架设计的准则----------------------------------------- 11

2.2.3.2机架设计一般要求--------------------------------------- 12

2.3 灌装线输送设备---------------------------------------------- 14

2.3.1 输送设备工作原理和应用范围------------------------- 14

2.3.2结构分析和设计方案的确定--------------------------------- 14

2.3.2.1 输送设备在各部分的工作作用-------------------------- 14

2.3.2.2 设计方案的确定 ---------------------------------------- 14

2.3.3 振动溜槽结构分析和和选型--------------------------------- 15

2.3.3.1螺旋溜槽结构分析---------------------------------------- 16

2.3.3.2螺旋溜槽的选型------------------------------------------- 17

2.4设计计算------------------------------------------------------ 19

2.4.1 运动学参数的选择和计算------------------------------------ 24

2.4.2工艺参数的计算-------------------------------------------------- 26

2.4.3动力学参数的计算-------------------------------------------- 28

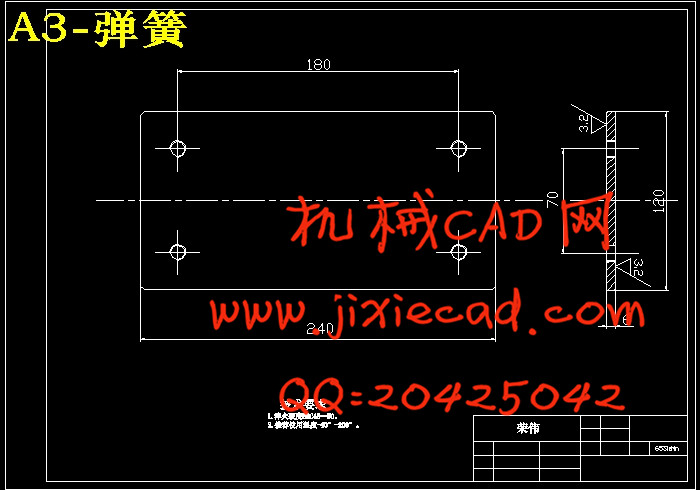

2.4.4 弹簧的选型和弹簧振动方向分析---------------------------------- 30

2.4.4.1 弹簧的选型 ----------------------------------------------- 33

2.4.3.2 弹簧振动方向分析----------------------------------------- 34

2.4.3.3 确定机架--------------------------------------------------- 35

2.4.3.4 底座机架参数:---------------------------------------------35

2.5 输送机安装与调整------------------------------------------- 36

2.5.1 安装顺序---------------------------------------------------- 37

2.5.2 安装技术要求------------------------------------------------ 37

2.5.2.1机架的安装------------------------------------------------ 38

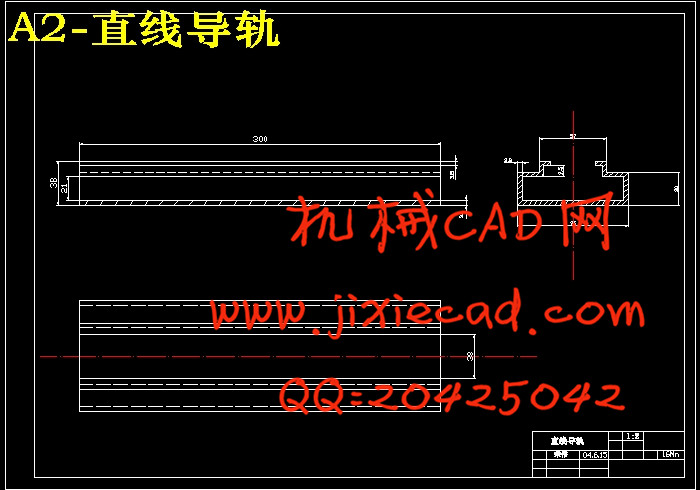

2.5.2.2 轨道的安装----------------------------------------------- 66

2.5.3输送机的调整----------------------------------------------- 66

3.总结-------------------------------------------------------------- 68

4.致谢------------------------------------------------------------- 69

5.参考文献-------------------------------------------------------- 70

[摘要]: 本课题是针对输液袋灌装生产线输送设备部分的设计。随着医药包装材料的不断发展,目前在大输液生产中广泛使用的玻璃输液瓶有逐步被一次性软包装输液袋取代的趋势。与玻璃瓶相比较,输液袋有着众多玻璃瓶所不能比拟的、顺应医疗改革与发展的优点,如节约资源,减少环境污染,体积小,重量轻,灌装工艺简单,消毒灭菌安全,能避免交叉感染等。鉴于此,研制先进的软包装输液袋生产线已成为国内的重要课题。输送设备作为输液袋灌装生产线的重要组成部分,其主要完成灌装线输液袋灌装后瓶子输送工作,整个输送设备主要由溜槽、振动机、圆盘、皮带轮、板弹簧、直线轨道等部分组成。本设计详细阐述了大输液灌装系统的现状与前景;概述了输送设备设计的基本原则;全面剖析了输送设备的整体的结构、工作原理;具体设计了各主要组件的结构,并对相关要素进行了计算、分析与比较,主要包括溜槽尺寸设计与确定,机器内部结构的设计与确定,振动机选型与板弹簧设计、分析与介绍等;最后对输送设备的整体与主要组件绘制了详细的装配图与零件图。

关键字:输液袋、灌装线输送设备、直线轨道

Abstract:

This paper is the design of cap sealing device in the assemble line of the filling of infusing bag. With the development of the material of medical packing, currently, there comes the tendency of the replacement of glass infusing bottle which is widely used in mass infusion production by the one time soft infusion bag. Comparing with glass bottles, this bag follows the development of medical reform,and it has the advantages that the glass ones can not surpass , Such as, saving resources, reducing environment pollution, smaller volume, light weigh ,simple filling process , the safe disinfection avoiding cross-infection. Based on this, the research of the advanced assemble line of filling soft infusion bag has become the important study in our country. Cap sealing device is the main part of the line,and it main work is passing the vases after they are infused. The whole device consists of turning arm,head of perm,rotating mechanism, air mechanism, air cylinder of stretches and pendulum,air cylinder of ellipse piston。The current situation and prospect of the system are expounded detailed. And it summarizes the basic principles of the design of cap sealing device and analyzed the whole structure, movement and designed the structures of the main parts and give some calculations, analyzation and comparisons to the relative essential factors which includes and the define of the movement rotate arms and its dimensions, the dimensions of heating parts; the design of inner structure and power, and the design of air drive and vacuum system and air control valve and the brief introduction of air appendix, and also the design of air cylinder of stretches and pendulum,air cylinder of ellipse piston,The free manipulators of two degrees and then analyzation and introduction. In the end, the fix drawing, part drawing and principle drawing are dearly draw about the whole system.

Keywords: infusion bag, the device of cap sealing in filling assemble line, structure, movement.

目录

1.前言-----------------------------------------------------------------1

2. 2.直线振动给料机的设计-------------------------------------------- 2

2.1大输液灌装系统的现状与前景---------------------------------- 3

2.1.1玻璃瓶输液生产的洗灌封联动生产线--------------------------- 3

2.1.2 塑料包装输液生产发展的方向-------------------------- 4

2.1.2.1 塑包与玻璃瓶输液的简要比较--------------------------5

2.1.2.2 大输液软包装技术与药用丁基胶塞生产技术-------------- 6

2.1.2.3 三合一无菌包装技术在输液生产中的应用---------------- 6

2.1.2.4 制袋、灌装、封口软袋包装输液工艺技术的现状----------- 7

2.2 设计基本原则-------------------------------------------------- 8

2.2.1机器设计基本原则------------------------------------------- 9

2.2.2 机器零件设计基本原则--------------------------------------- 9

2.2.3机架设计准则和要求----------------------------------------- 11

2.2.3.1.机架设计的准则----------------------------------------- 11

2.2.3.2机架设计一般要求--------------------------------------- 12

2.3 灌装线输送设备---------------------------------------------- 14

2.3.1 输送设备工作原理和应用范围------------------------- 14

2.3.2结构分析和设计方案的确定--------------------------------- 14

2.3.2.1 输送设备在各部分的工作作用-------------------------- 14

2.3.2.2 设计方案的确定 ---------------------------------------- 14

2.3.3 振动溜槽结构分析和和选型--------------------------------- 15

2.3.3.1螺旋溜槽结构分析---------------------------------------- 16

2.3.3.2螺旋溜槽的选型------------------------------------------- 17

2.4设计计算------------------------------------------------------ 19

2.4.1 运动学参数的选择和计算------------------------------------ 24

2.4.2工艺参数的计算-------------------------------------------------- 26

2.4.3动力学参数的计算-------------------------------------------- 28

2.4.4 弹簧的选型和弹簧振动方向分析---------------------------------- 30

2.4.4.1 弹簧的选型 ----------------------------------------------- 33

2.4.3.2 弹簧振动方向分析----------------------------------------- 34

2.4.3.3 确定机架--------------------------------------------------- 35

2.4.3.4 底座机架参数:---------------------------------------------35

2.5 输送机安装与调整------------------------------------------- 36

2.5.1 安装顺序---------------------------------------------------- 37

2.5.2 安装技术要求------------------------------------------------ 37

2.5.2.1机架的安装------------------------------------------------ 38

2.5.2.2 轨道的安装----------------------------------------------- 66

2.5.3输送机的调整----------------------------------------------- 66

3.总结-------------------------------------------------------------- 68

4.致谢------------------------------------------------------------- 69

5.参考文献-------------------------------------------------------- 70