设计简介

摘要

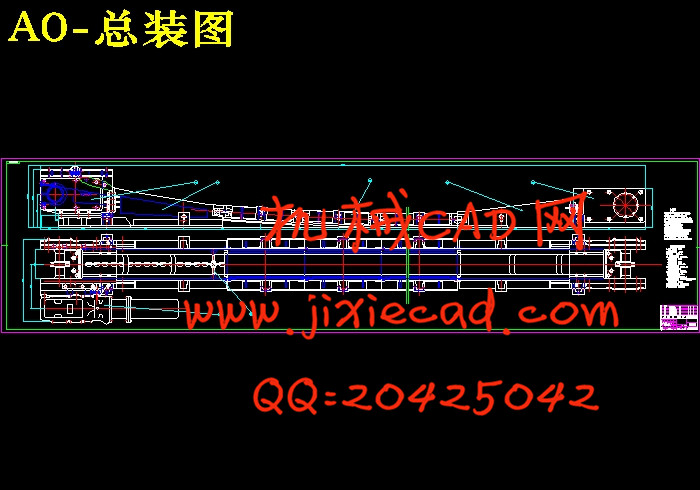

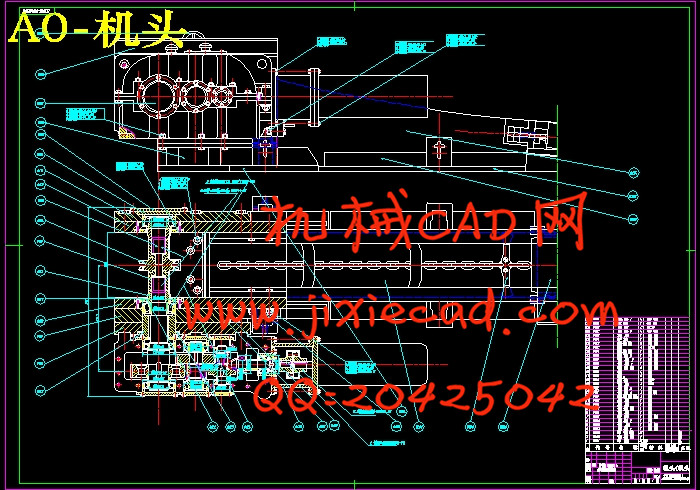

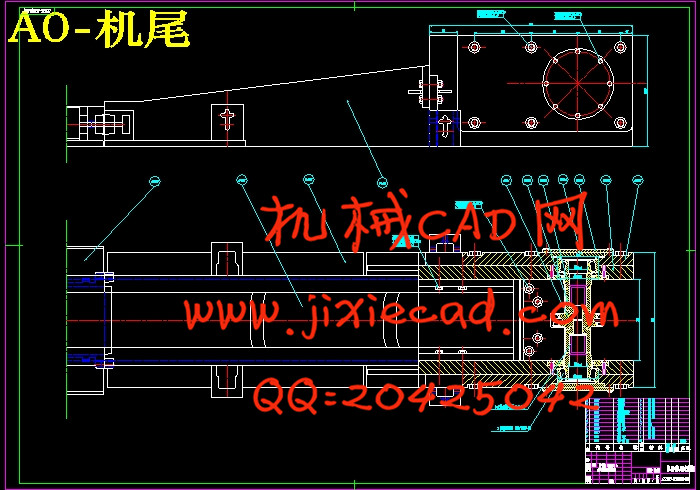

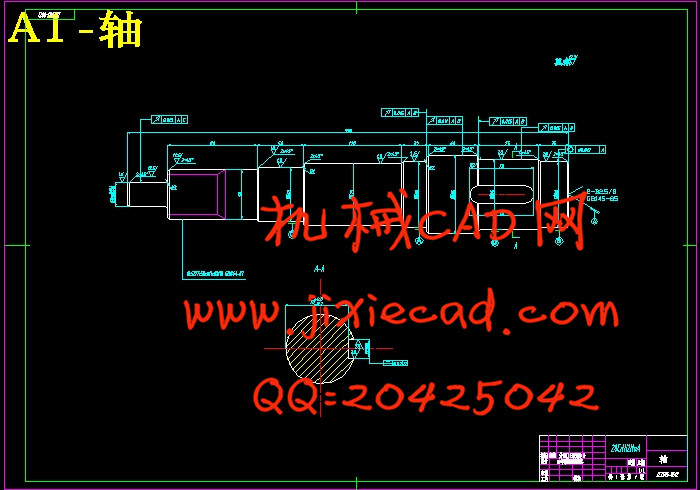

刮板输送机是综采工作面配套设备的重要组成部分,是煤炭装运的第一个环节。因此,刮板输送机的输送能力在很大程度上决定了采煤工作面的生产能力和效率。然而,我国生产技术落后,目前设计生产的刮板输送机装机功率小,输送能力低,运输距离短,耐久性差,可靠性低,寿命短。综合分析我国刮板输送机的使用现状,设计制造高性能的刮板输送机迫在眉睫。本文首先综合比较了各种类型输送机的特点,根据实际情况选用了中单链型刮板输送机。而后,对中单链型刮板输送机进行了总体结构设计。对机头传动装置、过渡槽、中部槽、刮板链、刮板、链轮、机尾等主要部件进行了技术分析和结构设计,完成了中单链型刮板输送机的整体设计。此次设计的中单链型刮板输送机左右两侧对称,可以在两侧壁上安装减速器,以适应左、右采煤工作面的需要。另外,可以很容易将机尾改装成机头,而适应各种特殊情况。此次设计的中单链型刮板输送机的特点是结构简单,受力均匀,运行平稳,摩擦阻力小,溜槽利用率高,弯曲性能好,不易出现堵塞,具有很强的适应性。

关键词:刮板输送机;中部槽;圆环链

Abstract

The scraper conveyer is the synthesis picking work surface important constituent of the supplementary equipment. It is the first link of the coal shipping. Therefore, the scraper conveyer delivery capacity has decided the mining coal working surface productivity and the efficiency in a great degree; however, our country was lagged behind at present; the scraper conveyer installing equipment power is small. The delivery capacity is low; the transportation is away from short, the durability is bad; Reliability is low; and the life is short. The generalized analysis our country scraper conveyer use present situation, the design manufacture high performance scraper conveyer is imminent. This article first synthesized has compared each kind of type conveyer characteristic, has selected center simple chain according to the actual situation the scraper conveyer. But after, the scraper conveyer has carried on the overall structural design to center simple chain. To the nose transmission device, the aqueduct, the middle trough, the scraper chain, the scraper, the chain wheel, the airplane tail and other major component has carried on the technical analysis and the structural design, has completed center simple chain the scraper conveyer overall design. This design center simple chain about the scraper conveyer two sides are symmetrical, may install the reduction gear on two sidewalls, by left meets, the right mining coal working surface need. Moreover, it may very easily reequip the airplane tail the nose, but adapts each kind of peculiar circumstance. This design of center simple chain of the scraper conveyer characteristic includes: the structure is simple, the stress is even, moves steadily, the friction drag is small, the chute use factor high, the curving performance is good, It is not easy to appear stops up, has the very strong compatibility.

Key Words: Scraper Conveyer; Middle Trough; Round Link Chain

目 录

1 前言 1

2 方案选定3

3 刮板输送机的整体设计计算5

3.1 任务书要求5

3.2 运输能力5

3.3 运行阻力6

3.4 电动机功率P 15

3.5 圆环链的选择计算 16

3.6 刮板链的安全系数 16

4 传动系统 18

5 结构设计 19

5.1 驱动装置位置的确定 19

5.2 刮板输送机结构的基本要求 22

5.3 机头部 23

5.4 机尾部 25

5.5 中部槽及附属部件 25

5.6 紧链装置 26

5.7 推移装置 27

5.8 锚固装置 27

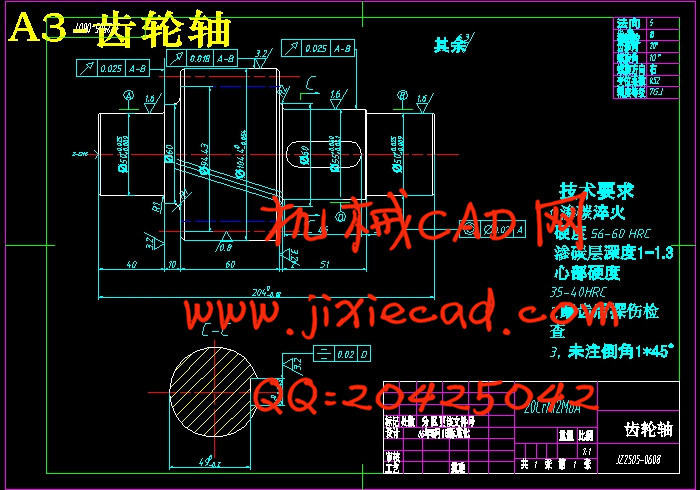

6 传动部件及其零件的设计 28

6.1 圆环链链环的结构和规格 28

6.2 圆环链接链环的结构型式 28

6.3 圆环链的性能指标 31

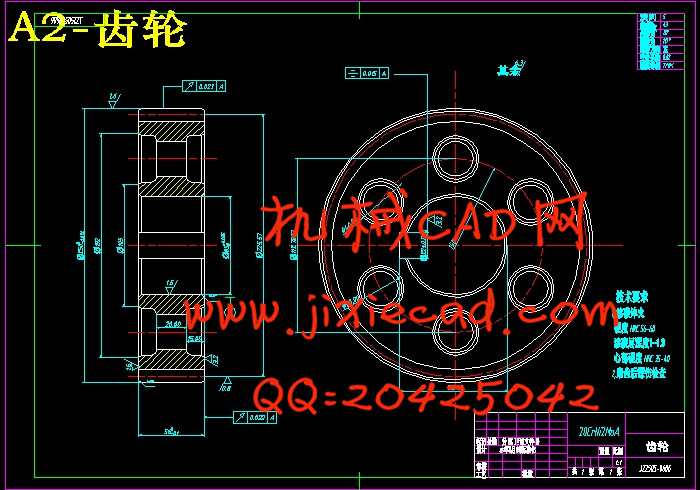

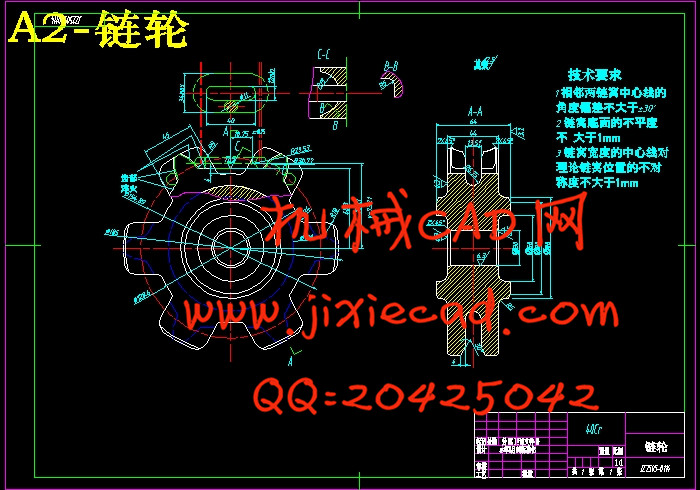

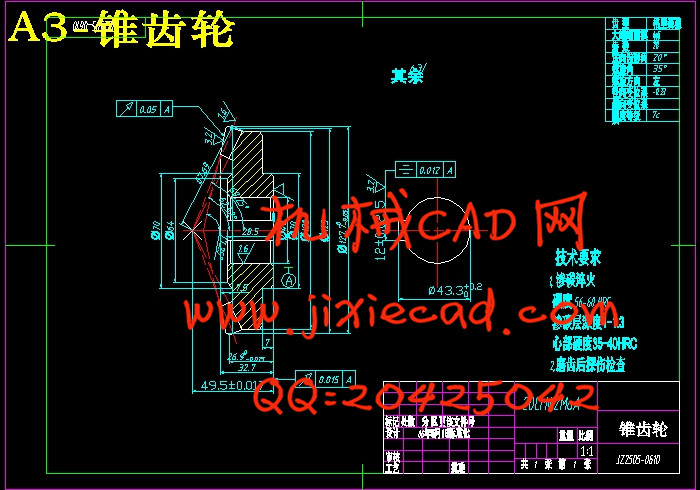

6.4 圆环链链轮的齿形参数和几何计算 33

6.5 链轮连接 38

6.6 圆环链和链轮的啮合特性 38

6.7 圆环链链轮的技术条件 41

6.8 圆环链链轮的几何计算 42

6.9 刮板 45

6.10 刮板的间距 46

6.11刮板与链条的连接 47

7 技术经济分析 48

8 总结 49

致谢 50

参考文献 51

刮板输送机是综采工作面配套设备的重要组成部分,是煤炭装运的第一个环节。因此,刮板输送机的输送能力在很大程度上决定了采煤工作面的生产能力和效率。然而,我国生产技术落后,目前设计生产的刮板输送机装机功率小,输送能力低,运输距离短,耐久性差,可靠性低,寿命短。综合分析我国刮板输送机的使用现状,设计制造高性能的刮板输送机迫在眉睫。本文首先综合比较了各种类型输送机的特点,根据实际情况选用了中单链型刮板输送机。而后,对中单链型刮板输送机进行了总体结构设计。对机头传动装置、过渡槽、中部槽、刮板链、刮板、链轮、机尾等主要部件进行了技术分析和结构设计,完成了中单链型刮板输送机的整体设计。此次设计的中单链型刮板输送机左右两侧对称,可以在两侧壁上安装减速器,以适应左、右采煤工作面的需要。另外,可以很容易将机尾改装成机头,而适应各种特殊情况。此次设计的中单链型刮板输送机的特点是结构简单,受力均匀,运行平稳,摩擦阻力小,溜槽利用率高,弯曲性能好,不易出现堵塞,具有很强的适应性。

关键词:刮板输送机;中部槽;圆环链

Abstract

The scraper conveyer is the synthesis picking work surface important constituent of the supplementary equipment. It is the first link of the coal shipping. Therefore, the scraper conveyer delivery capacity has decided the mining coal working surface productivity and the efficiency in a great degree; however, our country was lagged behind at present; the scraper conveyer installing equipment power is small. The delivery capacity is low; the transportation is away from short, the durability is bad; Reliability is low; and the life is short. The generalized analysis our country scraper conveyer use present situation, the design manufacture high performance scraper conveyer is imminent. This article first synthesized has compared each kind of type conveyer characteristic, has selected center simple chain according to the actual situation the scraper conveyer. But after, the scraper conveyer has carried on the overall structural design to center simple chain. To the nose transmission device, the aqueduct, the middle trough, the scraper chain, the scraper, the chain wheel, the airplane tail and other major component has carried on the technical analysis and the structural design, has completed center simple chain the scraper conveyer overall design. This design center simple chain about the scraper conveyer two sides are symmetrical, may install the reduction gear on two sidewalls, by left meets, the right mining coal working surface need. Moreover, it may very easily reequip the airplane tail the nose, but adapts each kind of peculiar circumstance. This design of center simple chain of the scraper conveyer characteristic includes: the structure is simple, the stress is even, moves steadily, the friction drag is small, the chute use factor high, the curving performance is good, It is not easy to appear stops up, has the very strong compatibility.

Key Words: Scraper Conveyer; Middle Trough; Round Link Chain

目 录

1 前言 1

2 方案选定3

3 刮板输送机的整体设计计算5

3.1 任务书要求5

3.2 运输能力5

3.3 运行阻力6

3.4 电动机功率P 15

3.5 圆环链的选择计算 16

3.6 刮板链的安全系数 16

4 传动系统 18

5 结构设计 19

5.1 驱动装置位置的确定 19

5.2 刮板输送机结构的基本要求 22

5.3 机头部 23

5.4 机尾部 25

5.5 中部槽及附属部件 25

5.6 紧链装置 26

5.7 推移装置 27

5.8 锚固装置 27

6 传动部件及其零件的设计 28

6.1 圆环链链环的结构和规格 28

6.2 圆环链接链环的结构型式 28

6.3 圆环链的性能指标 31

6.4 圆环链链轮的齿形参数和几何计算 33

6.5 链轮连接 38

6.6 圆环链和链轮的啮合特性 38

6.7 圆环链链轮的技术条件 41

6.8 圆环链链轮的几何计算 42

6.9 刮板 45

6.10 刮板的间距 46

6.11刮板与链条的连接 47

7 技术经济分析 48

8 总结 49

致谢 50

参考文献 51