设计简介

摘 要

本次设计的题目是重型货车驱动桥设计。驱动桥一般由主减速器、差速器、半轴及桥壳四部分组成,其基本功用是增大由传动轴或直接由变速器传来的转矩,将转矩分配给左、右车轮,并使左、右驱动车轮具有汽车行驶运动学所要求的差速功能;此外,还要承受作用于路面和车架或车厢之间的铅垂力、纵向力和横向力。

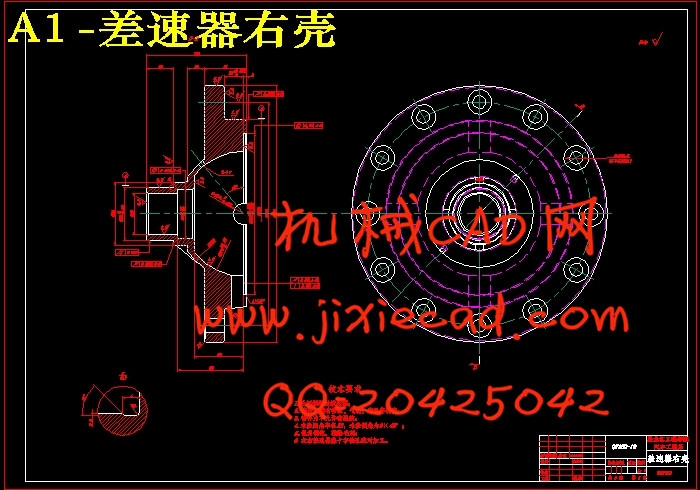

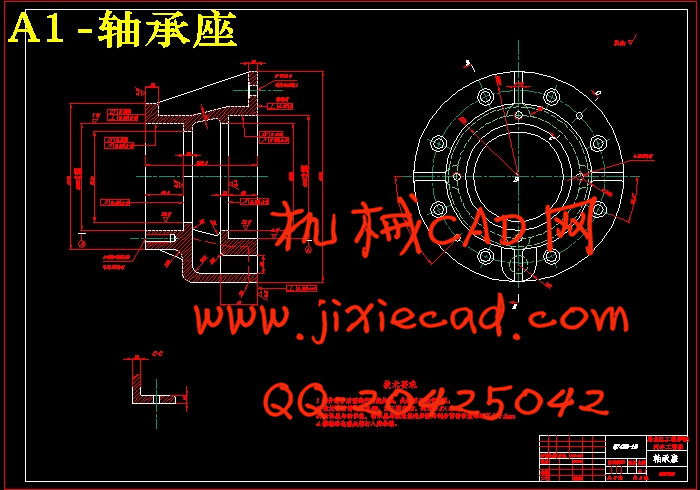

本设计首先论述了驱动桥的总体结构,在分析驱动桥各部分结构型式、发展过程及其以往形式的优缺点的基础上,确定了总体设计方案:采用整体式驱动桥,主减速器的减速型式采用双级减速器,主减速器齿轮采用螺旋锥齿轮,差速器采用普通对称式圆锥行星齿轮差速器,半轴采用全浮式型式,桥壳采用铸造整体式桥壳。在本次设计中,主要完成了双级减速器、圆锥行星齿轮差速器、全浮式半轴的设计和桥壳的校核及材料选取等工作。

关键词: 驱动桥;设计;计算;校核;材料

本次设计的题目是重型货车驱动桥设计。驱动桥一般由主减速器、差速器、半轴及桥壳四部分组成,其基本功用是增大由传动轴或直接由变速器传来的转矩,将转矩分配给左、右车轮,并使左、右驱动车轮具有汽车行驶运动学所要求的差速功能;此外,还要承受作用于路面和车架或车厢之间的铅垂力、纵向力和横向力。

本设计首先论述了驱动桥的总体结构,在分析驱动桥各部分结构型式、发展过程及其以往形式的优缺点的基础上,确定了总体设计方案:采用整体式驱动桥,主减速器的减速型式采用双级减速器,主减速器齿轮采用螺旋锥齿轮,差速器采用普通对称式圆锥行星齿轮差速器,半轴采用全浮式型式,桥壳采用铸造整体式桥壳。在本次设计中,主要完成了双级减速器、圆锥行星齿轮差速器、全浮式半轴的设计和桥壳的校核及材料选取等工作。

关键词: 驱动桥;设计;计算;校核;材料

ABSTRACT

The object of the design is The Design for Driving Axle of Heavy Truck. Driving Axle is consisted of Main Decelerator, Differential Mechanism, Half Shaft and Axle Housing. The basic function of Driving Axle is to increase the torque transmitted by Drive Shaft or directly transmitted by Gearbox, then distributes it to left and right wheel, and make these two wheels have the differential function which is required in Automobile Driving Kinematics; besides, the Driving Axle must also stand the lead hangs down strength, the longitudinal force and the transverse force acted on the road surface, the frame or the compartment lead.

The configuration of the Driving Axle is introduced in the thesis at first. On the basis of the analysis of the structure and the developing process of Driving Axle, the design adopted the Integral Driving Axle, Double Reduction Gear for Main Decelerator’s deceleration form, Spiral Bevel Gear for Main Decelerator’s gear, Full Floating for Axle and Casting Integral Axle Housing for Axle Housing. In the design, we accomplished the design for Double Reduction Gear, tapered Planetary Gear Differential Mechanism, Full Floating Axle and Axle Housing.

Keywords: Driving Axle; Design; Calculation; Check; Material

目 录The object of the design is The Design for Driving Axle of Heavy Truck. Driving Axle is consisted of Main Decelerator, Differential Mechanism, Half Shaft and Axle Housing. The basic function of Driving Axle is to increase the torque transmitted by Drive Shaft or directly transmitted by Gearbox, then distributes it to left and right wheel, and make these two wheels have the differential function which is required in Automobile Driving Kinematics; besides, the Driving Axle must also stand the lead hangs down strength, the longitudinal force and the transverse force acted on the road surface, the frame or the compartment lead.

The configuration of the Driving Axle is introduced in the thesis at first. On the basis of the analysis of the structure and the developing process of Driving Axle, the design adopted the Integral Driving Axle, Double Reduction Gear for Main Decelerator’s deceleration form, Spiral Bevel Gear for Main Decelerator’s gear, Full Floating for Axle and Casting Integral Axle Housing for Axle Housing. In the design, we accomplished the design for Double Reduction Gear, tapered Planetary Gear Differential Mechanism, Full Floating Axle and Axle Housing.

Keywords: Driving Axle; Design; Calculation; Check; Material

摘要 I

Abstract II

第1章 绪论 1

1.1 设计主要参数 1

1.2 驱动桥的结构和种类 1

1.2.1 汽车车桥的种类 1

1.2.2 驱动桥的种类 1

1.2.3 驱动桥结构组成 2

1.3 设计主要内容 6

第2章 设计方案的确定 7

2.1 主减速比的计算 7

2.2 主减速器结构方案的确定 7

2.3 差速器结构方案的确定 8

2.4 半轴型式的确定 8

2.5 桥壳型式的确定 9

2.6 本章小结 9

第3章 主减速器设计 10

3.1 主减速齿轮计算载荷的确定 10

3.2 主减速器齿轮参数的选择 11

3.3 主减速器螺旋锥齿轮的几何尺寸计算与强度计算 12

3.3.1 主减速器螺旋锥齿轮的几何尺寸计算 12

3.3.2 主减速器螺旋锥齿轮的强度计算 13

3.4 主减速器齿轮的材料及热处理 15

3.5 主减速器轴承的计算 16

3.6 主减速器的润滑 19

3.7 本章小结 19

第4章 差速器设计 20

4.1 概述 20

4.2 差速器的作用 20

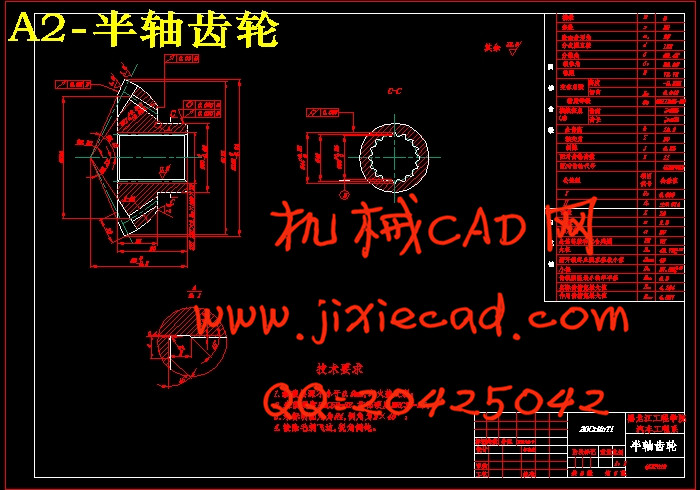

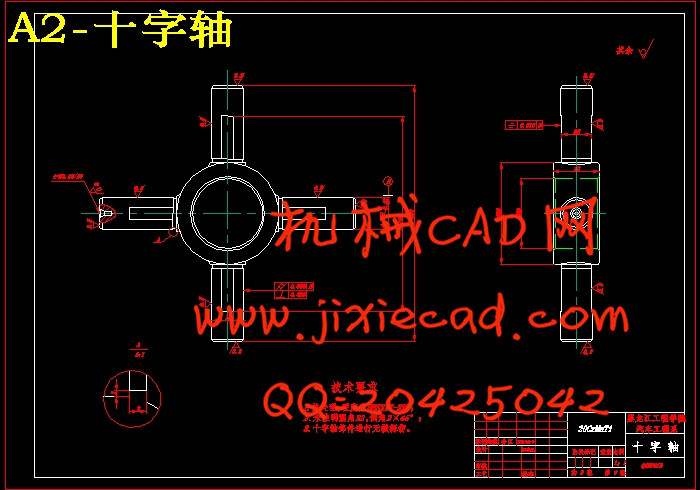

4.3 对称式圆锥行星齿轮差速器 20

4.3.1 差速器齿轮的基本参数选择 21

4.3.2 差速器齿轮的几何尺寸计算与强度计算 22

4.4 本章小结 25

第5章 半轴设计 26

5.1 概述 26

5.2 半轴的设计与计算 26

5.2.1 全浮式半轴的设计计算 26

5.2.2 半轴的结构设计及材料与热处理 28

5.3 本章小结 29

第6章 驱动桥桥壳的校核 30

6.1 概述 30

6.2 桥壳的受力分析及强度计算 30

6.2.1 桥壳的静弯曲应力计算 30

6.2.2 在不平路面冲击载荷作用下桥壳的强度计算 31

6.2.3 汽车以最大牵引力行驶时的桥壳的强度计算 31

6.2.4 汽车紧急制动时的桥壳强度计算 33

6.3 本章小结 37

结论 38

参考文献 39

致谢 40