设计简介

摘要

液压泵是向液压系统提供一定流量和压力的油液的动力元件,它是每个液压系统中不可缺少的核心元件,合理的选择液压泵对于液压系统的能耗﹑提高系统的效率﹑降低噪声﹑改善工作性能和保证系统的可靠工作都十分重要

本设计对轴向柱塞泵进行了分析,主要分析了轴向柱塞泵的分类,对其中的结构,例如,柱塞的结构型式﹑滑靴结构型式﹑配油盘结构型式等进行了分析和设计,还包括它们的受力分析与计算.还有对缸体的材料选用以及校核很关键;最后对变量机构分类型式也进行了详细的分析,比较了它们的优点和缺点.该设计最后对轴向柱塞泵的优缺点进行了整体的分析,对今后的发展也进行了展望.

关键词: 柱塞泵,液压系统,结构型式,今后发展.Abstract

液压泵是向液压系统提供一定流量和压力的油液的动力元件,它是每个液压系统中不可缺少的核心元件,合理的选择液压泵对于液压系统的能耗﹑提高系统的效率﹑降低噪声﹑改善工作性能和保证系统的可靠工作都十分重要

本设计对轴向柱塞泵进行了分析,主要分析了轴向柱塞泵的分类,对其中的结构,例如,柱塞的结构型式﹑滑靴结构型式﹑配油盘结构型式等进行了分析和设计,还包括它们的受力分析与计算.还有对缸体的材料选用以及校核很关键;最后对变量机构分类型式也进行了详细的分析,比较了它们的优点和缺点.该设计最后对轴向柱塞泵的优缺点进行了整体的分析,对今后的发展也进行了展望.

关键词: 柱塞泵,液压系统,结构型式,今后发展.Abstract

Liquid's pressing a pump is the motive component of oil liquid which presses system to provide certain discharge and pressure toward the liquid, it is each core component that the liquid presses the indispensability in the system, reasonable of choice liquid's pressing a pump can consume a ﹑ exaltation the efficiency ﹑ of the system to lower a Zao voice ﹑ an improvement work function and assurance system for liquid pressing system of of dependable work all very important

This design filled a pump to carry on toward the pillar to the stalk analytical, mainly analyzed stalk to fill the classification of pump toward the pillar, as to it's win of structure, for example, the pillar fill of the ﹑ slippery Xue structure pattern ﹑ of the structure pattern went together with the oil dish structure pattern's etc. to carry on analysis and design, also include their is analyze by dint with calculation.The material which still has a body to the urn chooses in order to and school pit very key;Finally measure an organization classification towards change, the pattern also carried on detailed analysis and compared their advantage and weakness.That design end filled the merit and shortcoming of pump to carry on whole analysis toward the pillar to the stalk and also carried on an outlook to aftertime's development.

Keyword: The pillar fills a pump, the liquid presses system, structure pattern, will develop from now on.

目 录

摘 要…………………………………………………………………………………………… ⅠThis design filled a pump to carry on toward the pillar to the stalk analytical, mainly analyzed stalk to fill the classification of pump toward the pillar, as to it's win of structure, for example, the pillar fill of the ﹑ slippery Xue structure pattern ﹑ of the structure pattern went together with the oil dish structure pattern's etc. to carry on analysis and design, also include their is analyze by dint with calculation.The material which still has a body to the urn chooses in order to and school pit very key;Finally measure an organization classification towards change, the pattern also carried on detailed analysis and compared their advantage and weakness.That design end filled the merit and shortcoming of pump to carry on whole analysis toward the pillar to the stalk and also carried on an outlook to aftertime's development.

Keyword: The pillar fills a pump, the liquid presses system, structure pattern, will develop from now on.

目 录

ABSTRACT Ⅱ

绪论……………………………………………………………………………………………4

1直轴式轴向柱塞泵工作原理与性能参数……………………………………………… 6

1.1直轴式轴向柱塞泵工作原理……………………………………………………………… 6

1.2直轴式轴向柱塞泵主要性能参数………………………………………………………… 6

1.2.3排量﹑流量与容积效率……………………………………………………………… 7

1.2.2扭矩与机械效率 8

1.2.3功率与效率…………………………………………………………………………… 9

2 直轴式轴向柱塞泵运动学及流量品质分析………………………………………… 10

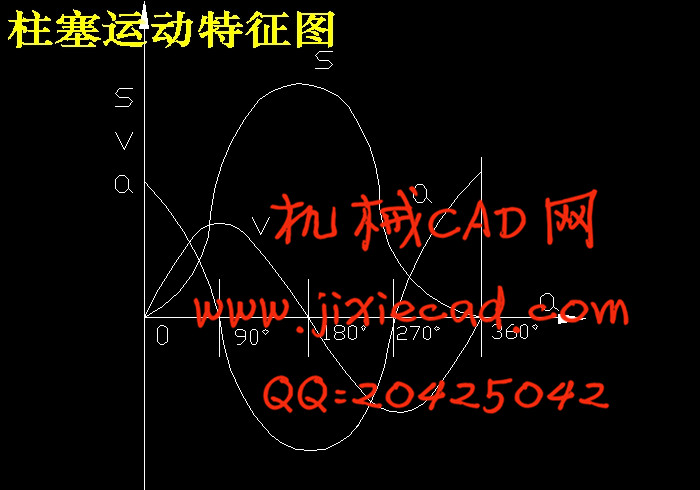

2.1柱塞运动学分析…………………………………………………………………………10

2.1.1柱塞行程S…………………………………………………………………………… 11

2.1.2柱塞运动速度分析v………………………………………………………………… 12

2.1.3柱塞运动加速度a…………………………………………………………………… 13

2.2滑靴运动分析…………………………………………………………………………… 14

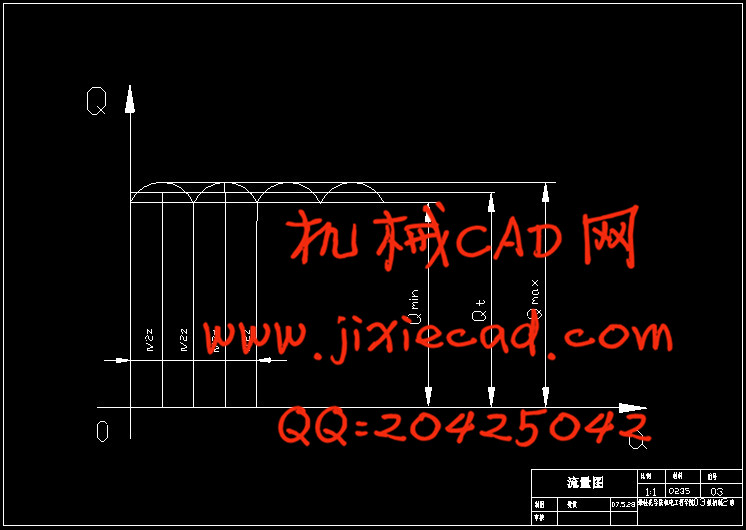

2.3瞬时流量及脉动品质分析……………………………………………………………… 15

2.3.1脉动频率…………………………………………………………………… 15

2.3.2脉动率…………………………………………………………………………………16

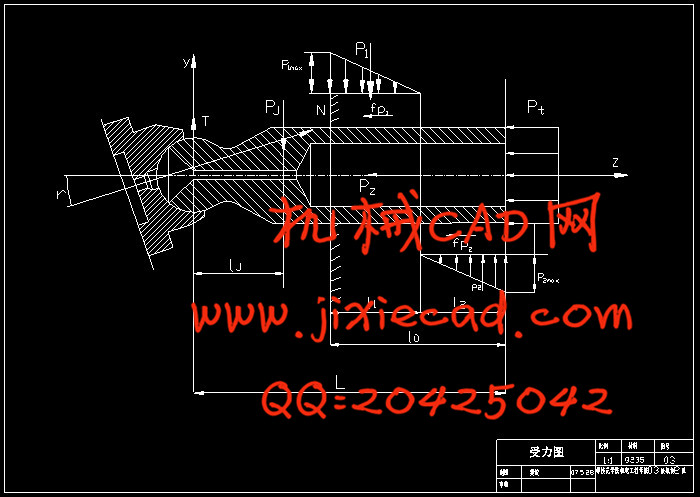

3 柱塞受力分析与设计………………………………………………………………………17

3.1柱塞受力分析……………………………………………………………………………17

3.1.1柱塞底部的液压力

3.1.2柱塞惯性力……………………………………………………………………………18

3.1.3离心反力

3.1.4斜盘反力N…………………………………………………………………………… 19

3.1.5柱塞与柱塞腔壁之间的接触应力

3.1.6摩擦力

3.2柱塞设计………………………………………………………………………………… 21

3.2.1柱塞结构型式…………………………………………………………………………22

3.2.2柱塞结构尺寸设计……………………………………………………………………23

3.2.3柱塞摩擦副比压P﹑比功

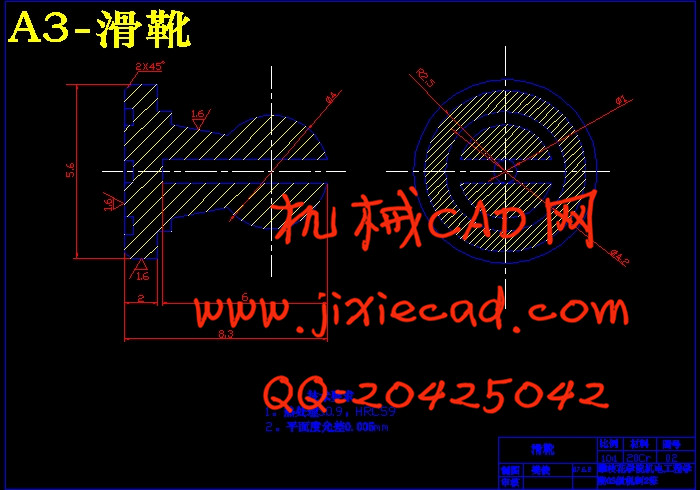

4滑靴受力分析与设计………………………………………………………………………25

4.1滑靴受力分析…………………………………………………………………………… 25

4.1.1分离力…………………………………………………………………………………26

4.1.2压紧力

4.1.3力平衡方程式…………………………………………………………………………27

4.2滑靴设计………………………………………………………………………………… 28

4.2.1剩余压紧力法…………………………………………………………………………28

4.3滑靴结构型式与结构尺寸设计…………………………………………………………29

4.3.1滑靴结构型式…………………………………………………………………………29

4.3.2结构尺寸设计……………………………………………………………………… 31

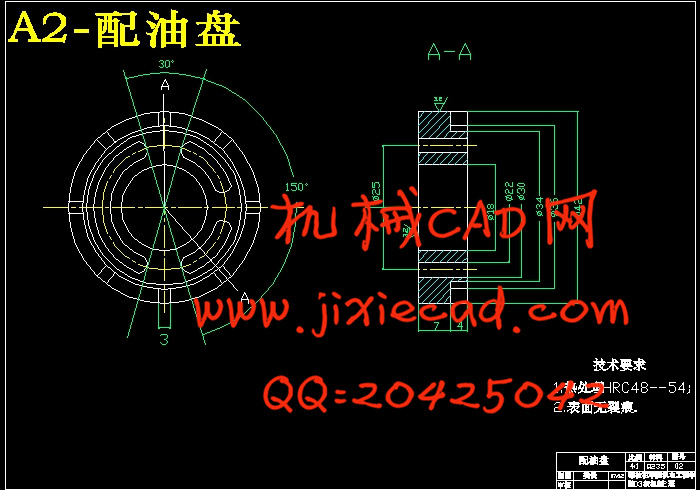

5 配油盘受力分析与设计………………………………………………………………… 32

5.1配油盘受力分析………………………………………………………………………… 32

5.1.1压紧力

5.1.2分离力

5.2配油盘设计……………………………………………………………………………… 35

5.2.1过渡区设计……………………………………………………………………………35

5.2.2配油盘主要尺寸确定…………………………………………………………………37

5.2.3验算比压p﹑比功pv………………………………………………………………… 38

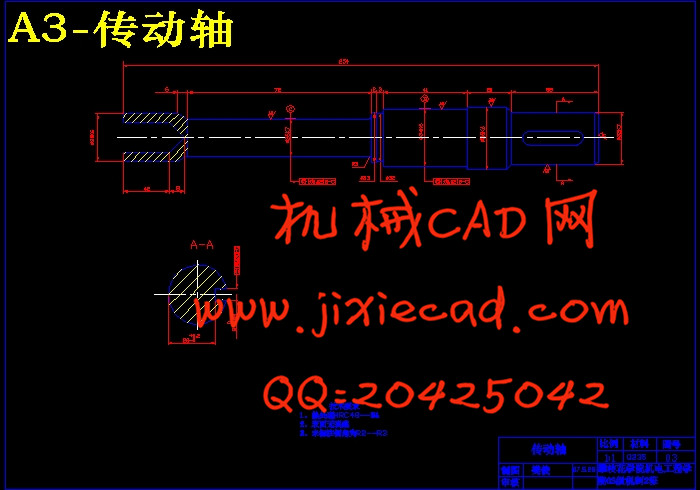

6 缸体受力分析与设计………………………………………………………………………40

6.1缸体的稳定性……………………………………………………………………………40

6.2缸体主要结构尺寸的确定………………………………………………………………40

6.2.1通油孔分布圆半径

6.2.2缸体内﹑外直径

6.2.3缸体高度H…………………………………………………………………………… 43

7柱塞回程机构设计…………………………………………………………………………44

8 斜盘力矩分析……………………………………………………………………………… 46

8.1柱塞液压力矩

8.2过渡区闭死液压力矩……………………………………………………………………46

8.2.1具有对称正重迭型配油盘……………………………………………………………46

8.2.2零重迭型配油盘………………………………………………………………………47

8.2.3带卸荷槽非对称正重迭型配油盘……………………………………………………47

8.3回程盘中心预压弹簧力矩

8.4滑靴偏转时的摩擦力矩

8.5柱塞惯性力矩

8.6柱塞与柱塞腔的摩擦力矩

8.7斜盘支承摩擦力矩

8.8斜盘与回程盘回转的转动惯性力矩

8.9斜盘自重力矩

9 变量机构……………………………………………………………………………………51

9.1手动变量机构……………………………………………………………………………51

9.2手动伺服变量机构………………………………………………………………………53

9.3恒功率变量机构…………………………………………………………………………55

9.4恒流量变量机构…………………………………………………………………………56

结论…………………………………………………………………………………………… 57

参考文献………………………………………………………………………………………58

致谢…………………………………………………………………………………………… 59