设计简介

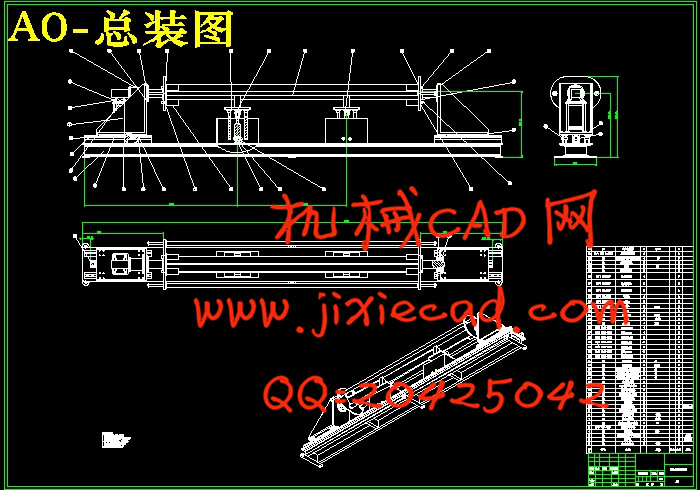

主弦杆焊接工装

摘要:

运行流程:

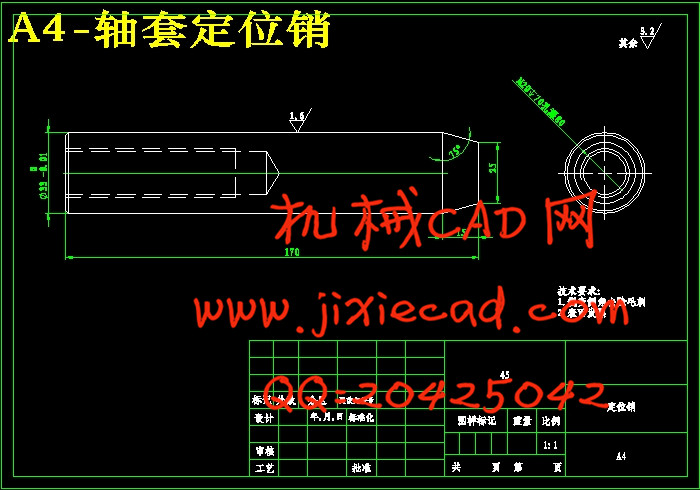

1.连接套先定位于轴套定位销

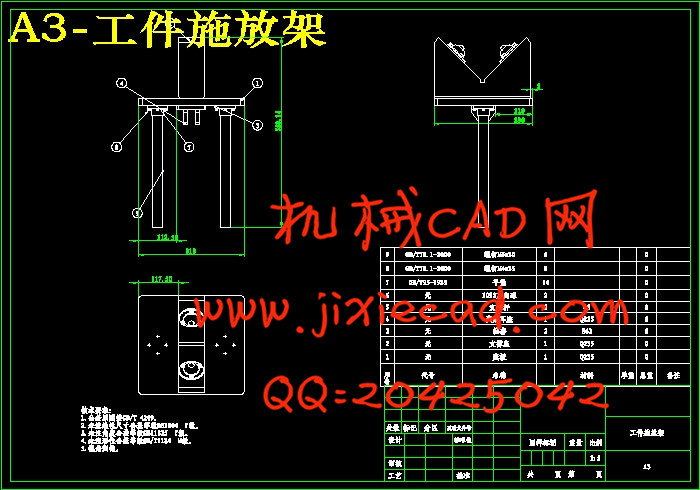

2.行车吊起主弦杆放置于工件施放架上,手动推动主弦杆实现粗定位

3.按下控制面板上的支撑汽缸顶升按钮,此时工件施放架推动主弦杆到指定位置。

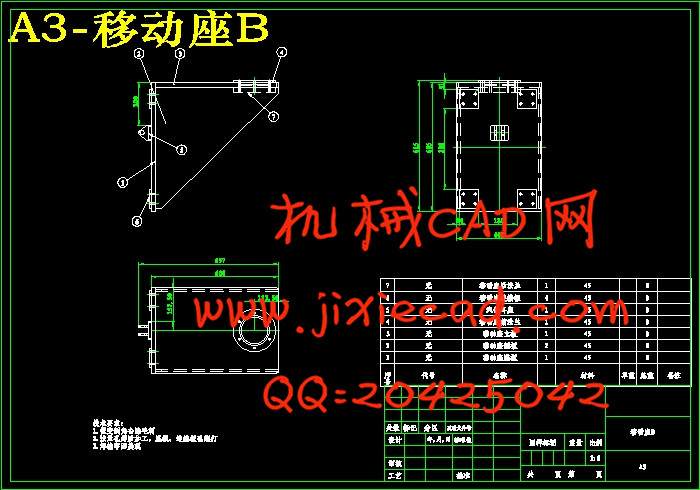

4.按下控制面板上的夹紧汽缸夹紧按钮,此时轴套定位销把连接套推送到指定位置。

5.焊工满焊位于上端的两个连接套,然后按下控制面板上的支撑汽缸回缩按钮,此时两个工件施放架回缩。

6.按下控制面板上的主弦杆翻转按钮,此时主弦杆顺时针翻转180°,位于下端的连接套翻转到了顶端。焊工满焊此连接套。

7.按下控制面板上的支撑汽缸顶升按钮,工件施放架到位后,按下夹紧汽缸回缩按钮,移动座后退,再用行车吊走主弦杆,至此此步工序到位。

设计线路:首先到现场观察工作环境,然后和现场工人展开技术交底,了解到老一套工装的弊端,以及工人们对新一代焊接工装的要求,了解清楚之后开始建模出方案,随后进行相关计算,计算完成后开始精准建模,建模完成之后审核模型,并修改。模型确定之后开始出工程图,列出外协件,加工件,以及外购件清单

方便采购部工作。

直线导轨的选用:

直线导轨简述:直线运动导轨的作用是用来支撑和引导运动部件,按给定的方向做往复直线运动。依按摩擦性质而定,直线运动导轨可以分为滑动摩擦导轨、滚动摩擦导轨、弹性摩擦导轨、流体摩擦导轨等种类。 ◎直线轴承主要用在自动化机械上比较多,像德国进口的机床,纸碗机,激光焊接机等等,当然直线轴承和直线轴是配套用的.像直线导轨主要是用在精度要求比较高的机械结构上

关键字:导轨,汽缸,主弦杆,滑动摩擦,轴承

Summary:

Running process:

Connected sets, the first positioning pin in the sleeve positioning

Lane lift the main chord placed in the workpiece cast rack, manually promote the main chord rough location

3 Press the control button panel on the support cylinder lifting workpiece cast frame to promote the main chord to the specified location.

(4) press the clamping cylinder clamping button on the control panel, the sleeve positioning pin connected sets pushed to the specified location.

Welders full welding at the top of the two connected sets, and then press the control panel on the support cylinder retraction button, two workpiece cast frame retraction.

(6) Press the control panel on the main chord flip button, the main chord of 180 ° clockwise in the bottom of the connection sets flip to the top. Welders fully welded this connection.

Press the control button panel on the support cylinder lifting, work piece cast frame in place, press the clamping cylinder retraction button, move the seat back, and then driving crane to take the main chord, thus this step-by-step process in place.

Design lines: first to the scene to observe the work environment, then expand the technical tests, and field workers to understand the drawbacks of the old tooling and workers on a new generation of welding equipment, a clear understanding to begin modeling program, followed by a related calculations, the calculations are complete, accurate modeling, modeling after the completion of the audit model and modify. Began after the model is to determine the engineering drawings, listed in the Association of machining parts, and purchased parts list

Facilitate the procurement department.

The selection of the linear guide:

Linear guide Description: the role of the linear motion guide is used to support and guide the moving parts, given the direction of reciprocating linear motion. Frictional properties, the linear motion guide rails of sliding friction, rolling friction rail, the type of elastic friction rail, fluid friction rail. Linear bearings are mainly used in automated machinery more, such as German imports of machine tools, paper bowl machine, laser welding machine, of course, linear bearings and linear axes are supporting the use of linear guide with high accuracy requirements the mechanical structure

Keywords: rails, cylinders, main chords, sliding friction, the bearings

目录

中文摘要---------------------------------------------------4

英文摘要---------------------------------------------------4

第一章------------------------------------------------4

1.1总体概

1.1.1工作环境----------------------------------------------4

1.1.2运行流程----------------------------------------------5

1.1.3操作要求----------------------------------------------5

1.1.4设备维护----------------------------------------------5

第二章------------------------------------------------6

2.1关键部件

2.1.1汽缸的选用---------------------------------------------6

2.1.2直线导轨的---------------------------------------------8

2.1.3轴承的选用---------------------------------------------10

2.1.4万向球的选用-------------------------------------------11

2.1.5电机的选用---------------------------------------------12

2.1.6减速机的选用-------------------------------------------16

参考文献----------------------------------------------------20

摘要:

运行流程:

1.连接套先定位于轴套定位销

2.行车吊起主弦杆放置于工件施放架上,手动推动主弦杆实现粗定位

3.按下控制面板上的支撑汽缸顶升按钮,此时工件施放架推动主弦杆到指定位置。

4.按下控制面板上的夹紧汽缸夹紧按钮,此时轴套定位销把连接套推送到指定位置。

5.焊工满焊位于上端的两个连接套,然后按下控制面板上的支撑汽缸回缩按钮,此时两个工件施放架回缩。

6.按下控制面板上的主弦杆翻转按钮,此时主弦杆顺时针翻转180°,位于下端的连接套翻转到了顶端。焊工满焊此连接套。

7.按下控制面板上的支撑汽缸顶升按钮,工件施放架到位后,按下夹紧汽缸回缩按钮,移动座后退,再用行车吊走主弦杆,至此此步工序到位。

设计线路:首先到现场观察工作环境,然后和现场工人展开技术交底,了解到老一套工装的弊端,以及工人们对新一代焊接工装的要求,了解清楚之后开始建模出方案,随后进行相关计算,计算完成后开始精准建模,建模完成之后审核模型,并修改。模型确定之后开始出工程图,列出外协件,加工件,以及外购件清单

方便采购部工作。

直线导轨的选用:

直线导轨简述:直线运动导轨的作用是用来支撑和引导运动部件,按给定的方向做往复直线运动。依按摩擦性质而定,直线运动导轨可以分为滑动摩擦导轨、滚动摩擦导轨、弹性摩擦导轨、流体摩擦导轨等种类。 ◎直线轴承主要用在自动化机械上比较多,像德国进口的机床,纸碗机,激光焊接机等等,当然直线轴承和直线轴是配套用的.像直线导轨主要是用在精度要求比较高的机械结构上

关键字:导轨,汽缸,主弦杆,滑动摩擦,轴承

Summary:

Running process:

Connected sets, the first positioning pin in the sleeve positioning

Lane lift the main chord placed in the workpiece cast rack, manually promote the main chord rough location

3 Press the control button panel on the support cylinder lifting workpiece cast frame to promote the main chord to the specified location.

(4) press the clamping cylinder clamping button on the control panel, the sleeve positioning pin connected sets pushed to the specified location.

Welders full welding at the top of the two connected sets, and then press the control panel on the support cylinder retraction button, two workpiece cast frame retraction.

(6) Press the control panel on the main chord flip button, the main chord of 180 ° clockwise in the bottom of the connection sets flip to the top. Welders fully welded this connection.

Press the control button panel on the support cylinder lifting, work piece cast frame in place, press the clamping cylinder retraction button, move the seat back, and then driving crane to take the main chord, thus this step-by-step process in place.

Design lines: first to the scene to observe the work environment, then expand the technical tests, and field workers to understand the drawbacks of the old tooling and workers on a new generation of welding equipment, a clear understanding to begin modeling program, followed by a related calculations, the calculations are complete, accurate modeling, modeling after the completion of the audit model and modify. Began after the model is to determine the engineering drawings, listed in the Association of machining parts, and purchased parts list

Facilitate the procurement department.

The selection of the linear guide:

Linear guide Description: the role of the linear motion guide is used to support and guide the moving parts, given the direction of reciprocating linear motion. Frictional properties, the linear motion guide rails of sliding friction, rolling friction rail, the type of elastic friction rail, fluid friction rail. Linear bearings are mainly used in automated machinery more, such as German imports of machine tools, paper bowl machine, laser welding machine, of course, linear bearings and linear axes are supporting the use of linear guide with high accuracy requirements the mechanical structure

Keywords: rails, cylinders, main chords, sliding friction, the bearings

目录

中文摘要---------------------------------------------------4

英文摘要---------------------------------------------------4

第一章------------------------------------------------4

1.1总体概

1.1.1工作环境----------------------------------------------4

1.1.2运行流程----------------------------------------------5

1.1.3操作要求----------------------------------------------5

1.1.4设备维护----------------------------------------------5

第二章------------------------------------------------6

2.1关键部件

2.1.1汽缸的选用---------------------------------------------6

2.1.2直线导轨的---------------------------------------------8

2.1.3轴承的选用---------------------------------------------10

2.1.4万向球的选用-------------------------------------------11

2.1.5电机的选用---------------------------------------------12

2.1.6减速机的选用-------------------------------------------16

参考文献----------------------------------------------------20