设计简介

摘 要

本次设计名为专用数控铣床自动进出料系统设计,从研究数控铣床加工中心工作台入手,借鉴国内外先进经验,设计了一个适合与加工中心工作台匹配的自动进出料装置,完成具有动作快速、定位准确以及可以长时间连续作业等优点的自动进出料装置设计,满足了生产和设计的需要,主要设计包括一套专用夹具、输送机构等主要部件。

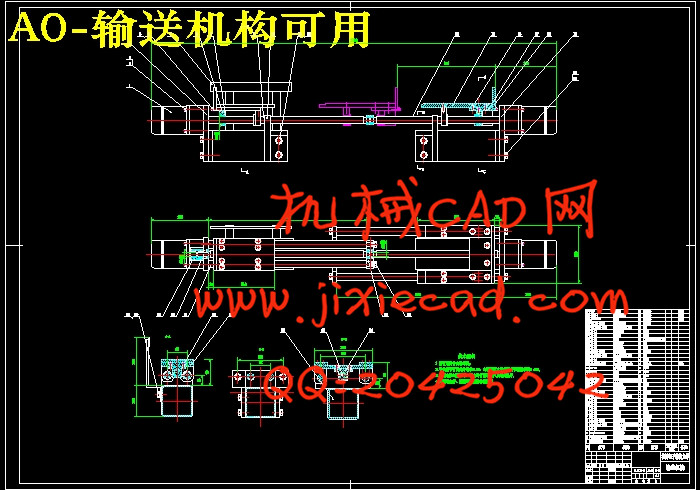

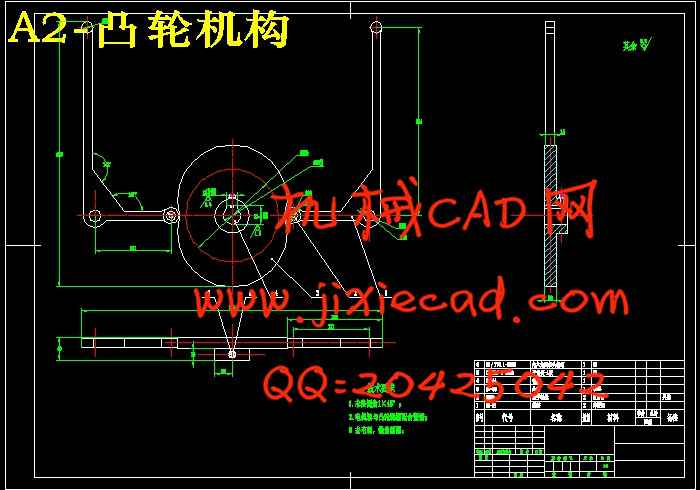

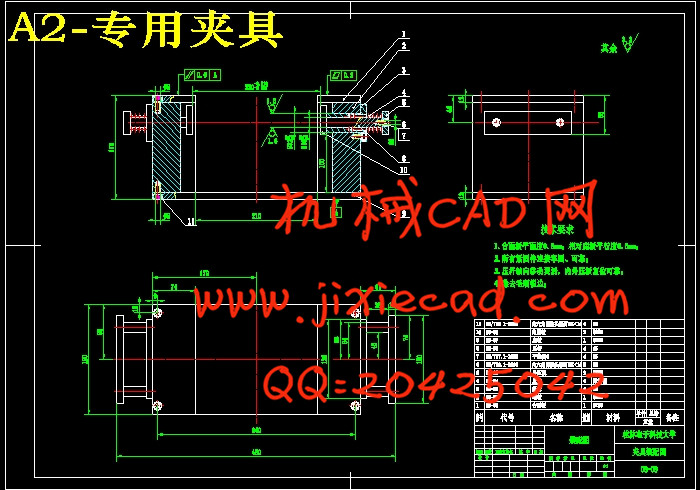

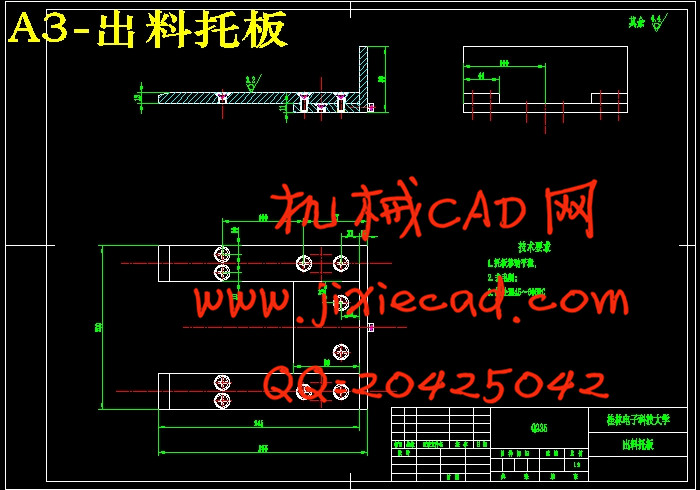

认真了考虑“实用、安全、经济”等各项因素,进行必要的方案计较后,最终确定最佳方案为专用夹具选用了电动装置作为夹紧装置,设计了压杆及内外压板进行工件的夹紧、定位。输送机构选用了机电装置,采用了步进电机、滚动直线导轨、滚珠丝杠螺母副和联轴器等进行工件的自动进出料。

设计主要进行了与加工中心工作台匹配的输送机构自动进出料装置以及专用夹具的结构设计,并进行了分析。论述了采用步进电机、滚动直线导轨、滚珠丝杠螺母副以及电动夹紧装置的优点。详细介绍了主要部件的结构设计过程及相关的计算校核。另外汇总了有关技术参数。

关键字:自动进出料;夹具;步进电机;滚珠丝杠副

Abstract

The graduation project dedicated CNC milling machine automatic feeding system design called out, starting from the research bench CNC milling machining centers, advanced experience at home and abroad, has designed a device suitable for automatic access to material processing center table with matching finish with action automatic feeding device designed out fast, accurate positioning and long-time continuous operation, etc., to meet the needs of production and design, the main components of the major design includes a dedicated fixture, transportation agencies.

Seriously considering "practical, safe and economical" and other factors, make the necessary care program after finalization.Choose the best solution for special fixtures electric device as a clamping device, designed inside and outside the bar and clamping plate workpiece positioning. Delivery mechanism chosen electromechanical device, using a stepper motor, linear guides, ball screw pair and couplings for automatic access to material of the workpiece.

The graduation project dedicated CNC milling machine automatic feeding system design called out, starting from the research bench CNC milling machining centers, advanced experience at home and abroad, has designed a device suitable for automatic access to material processing center table with matching finish with action automatic feeding device designed out fast, accurate positioning and long-time continuous operation, etc., to meet the needs of production and design, the main components of the major design includes a dedicated fixture, transportation agencies.

Keywords: automatic access to materials;fixture;stepper motor;ball screw

目 录

引言 1

1 绪论 2

1.1 国外数控机床业自动进出料的发展状况及趋势 2

1.2 国内数控机床业自动进出料的发展状况及存在问题 2

1.3 课题研究的目的及意义 3

1.4 课题主要任务 3

2 总体方案设计 3

2.1 方案拟定 3

2.1.1 输送机构的设计方案 3

2.1.2 专用夹具的设计方案 5

3 专用数控铣床自动进出料装置机械结构设计 7

3.1 滚珠丝杠副的设计 7

3.1.1滚珠丝杠副主要尺寸参数 7

3.1.2滚珠丝杠副的支承形式 8

3.1.3 滚珠丝杠副轴向间隙的调整与预紧 8

3.1.4滚珠丝杠副的计算与选型 8

3.1.5滚珠丝杠副的安装联接尺寸 11

3.2 导轨的选型 12

3.2.1直线滚动导轨副的工作原理与装配方式 13

3.2.2直线滚动导轨副的计算与选型 14

3.2.3直线滚动导轨副的安装联接尺寸 15

3.2.4导轨间隙的调整 15

3.2.5 导轨材料的热处理 15

3.2.6 导轨的润滑和防护 16

3.3 联轴器的选型 16

3.4 电机的选型 18

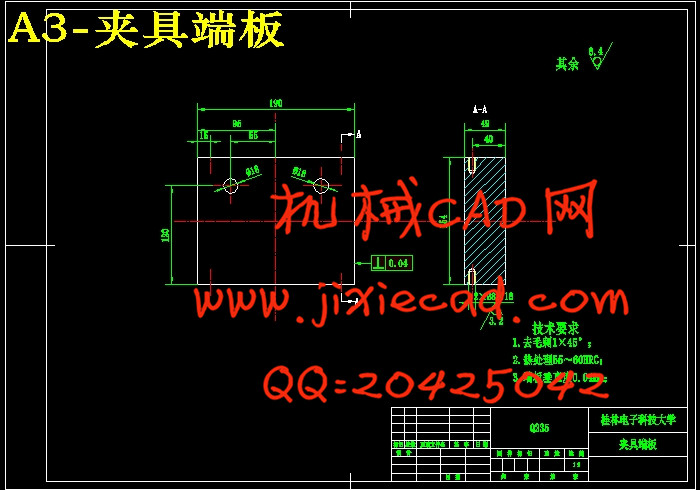

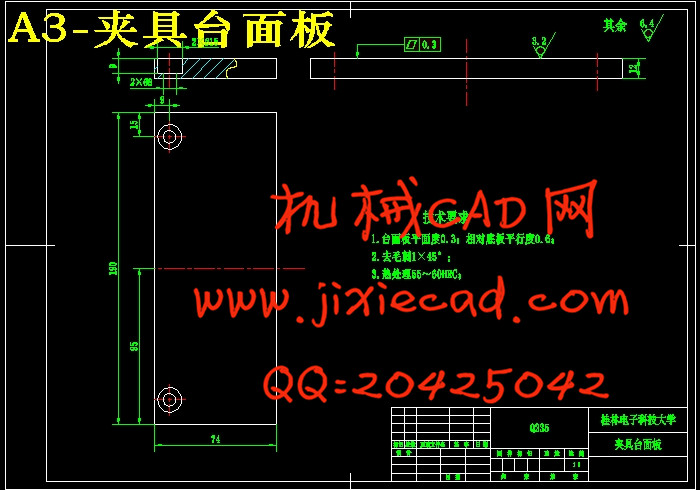

4 专用夹具设计 20

4.1 定位方案 20

4.1.1定位方案的选择 21

4.2 夹紧方案 21

4.3 夹具装配图 25

4.4夹具装配图上的尺寸、公差和技术要求 25

4.5 夹具经济性分析 26

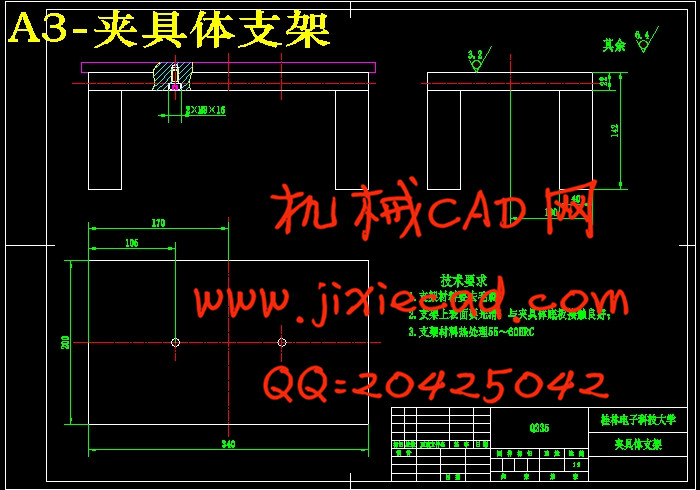

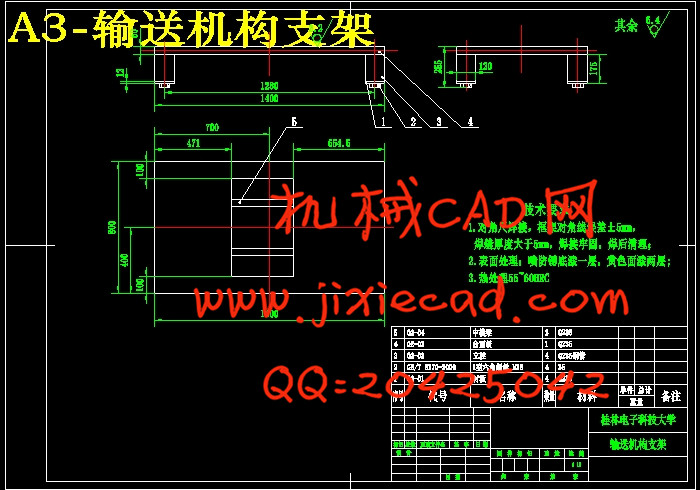

5 主机支架设计 27

6 自动进出料装置控制系统简介 29

7 总结 30

谢 辞 31

参考文献 32

本次设计名为专用数控铣床自动进出料系统设计,从研究数控铣床加工中心工作台入手,借鉴国内外先进经验,设计了一个适合与加工中心工作台匹配的自动进出料装置,完成具有动作快速、定位准确以及可以长时间连续作业等优点的自动进出料装置设计,满足了生产和设计的需要,主要设计包括一套专用夹具、输送机构等主要部件。

认真了考虑“实用、安全、经济”等各项因素,进行必要的方案计较后,最终确定最佳方案为专用夹具选用了电动装置作为夹紧装置,设计了压杆及内外压板进行工件的夹紧、定位。输送机构选用了机电装置,采用了步进电机、滚动直线导轨、滚珠丝杠螺母副和联轴器等进行工件的自动进出料。

设计主要进行了与加工中心工作台匹配的输送机构自动进出料装置以及专用夹具的结构设计,并进行了分析。论述了采用步进电机、滚动直线导轨、滚珠丝杠螺母副以及电动夹紧装置的优点。详细介绍了主要部件的结构设计过程及相关的计算校核。另外汇总了有关技术参数。

关键字:自动进出料;夹具;步进电机;滚珠丝杠副

Abstract

The graduation project dedicated CNC milling machine automatic feeding system design called out, starting from the research bench CNC milling machining centers, advanced experience at home and abroad, has designed a device suitable for automatic access to material processing center table with matching finish with action automatic feeding device designed out fast, accurate positioning and long-time continuous operation, etc., to meet the needs of production and design, the main components of the major design includes a dedicated fixture, transportation agencies.

Seriously considering "practical, safe and economical" and other factors, make the necessary care program after finalization.Choose the best solution for special fixtures electric device as a clamping device, designed inside and outside the bar and clamping plate workpiece positioning. Delivery mechanism chosen electromechanical device, using a stepper motor, linear guides, ball screw pair and couplings for automatic access to material of the workpiece.

The graduation project dedicated CNC milling machine automatic feeding system design called out, starting from the research bench CNC milling machining centers, advanced experience at home and abroad, has designed a device suitable for automatic access to material processing center table with matching finish with action automatic feeding device designed out fast, accurate positioning and long-time continuous operation, etc., to meet the needs of production and design, the main components of the major design includes a dedicated fixture, transportation agencies.

Keywords: automatic access to materials;fixture;stepper motor;ball screw

目 录

引言 1

1 绪论 2

1.1 国外数控机床业自动进出料的发展状况及趋势 2

1.2 国内数控机床业自动进出料的发展状况及存在问题 2

1.3 课题研究的目的及意义 3

1.4 课题主要任务 3

2 总体方案设计 3

2.1 方案拟定 3

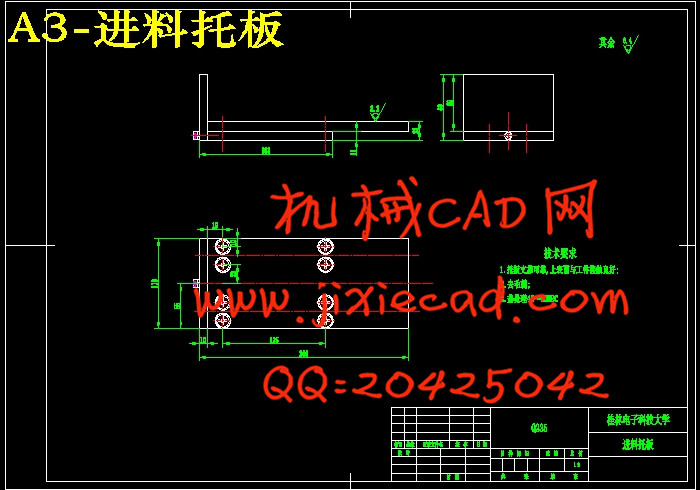

2.1.1 输送机构的设计方案 3

2.1.2 专用夹具的设计方案 5

3 专用数控铣床自动进出料装置机械结构设计 7

3.1 滚珠丝杠副的设计 7

3.1.1滚珠丝杠副主要尺寸参数 7

3.1.2滚珠丝杠副的支承形式 8

3.1.3 滚珠丝杠副轴向间隙的调整与预紧 8

3.1.4滚珠丝杠副的计算与选型 8

3.1.5滚珠丝杠副的安装联接尺寸 11

3.2 导轨的选型 12

3.2.1直线滚动导轨副的工作原理与装配方式 13

3.2.2直线滚动导轨副的计算与选型 14

3.2.3直线滚动导轨副的安装联接尺寸 15

3.2.4导轨间隙的调整 15

3.2.5 导轨材料的热处理 15

3.2.6 导轨的润滑和防护 16

3.3 联轴器的选型 16

3.4 电机的选型 18

4 专用夹具设计 20

4.1 定位方案 20

4.1.1定位方案的选择 21

4.2 夹紧方案 21

4.3 夹具装配图 25

4.4夹具装配图上的尺寸、公差和技术要求 25

4.5 夹具经济性分析 26

5 主机支架设计 27

6 自动进出料装置控制系统简介 29

7 总结 30

谢 辞 31

参考文献 32