设计简介

摘 要

随着科学技术的发展,制造技术的进步,以及社会对产品质量和品种多样化的要求越来越强烈。中、小批量生产的比例明显增加,要求现代钻孔机成为一种精密、高效、复合、集成功能和低成本的自动化加工设备。同时,为满足制造业向更高层次发展,为柔性制造单元、柔性制造系统,以及计算机集成制造系统提供基础设备,也要求钻孔机向更高水平发展。

在公交车制造中,座椅都是连接上去的。过去,一般都采用人工钻孔的方法进行拼接,人工钻孔的效率低,连接的质量不高,不适合大批量生产。现在采用的方法是:设计一个专用的钻孔机,专门用来钻公交座椅连接孔。这一连接方法的加工效率较高,连接的质量也很好。

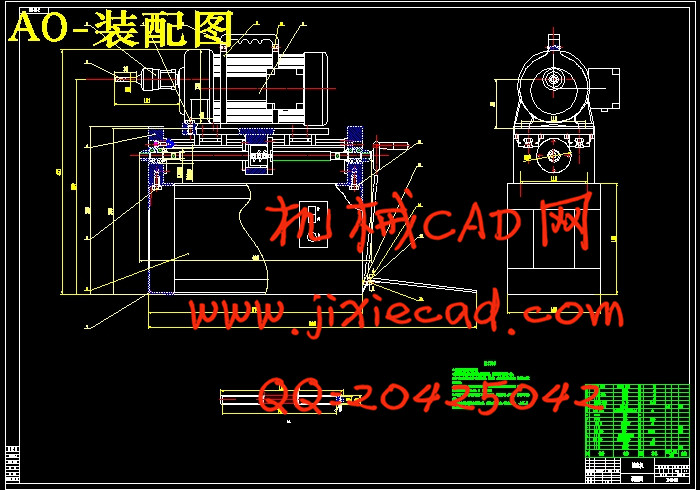

本设计通过对钻孔工艺分析,确定了卧式自动钻孔机设计方案。根据设计参数,选择了电动机,对主要结构进行了详细地设计,并对位置调节机构、联接机构等也进行了简单地设计。

关键字:钻孔机,电动机,连接

Abstract

With the development of science and technology, manufacturing technology progress, and society to product quality and the requirements of the species diversity is more and more intense. And the proportion of small batch production increased significantly, the requirements of modern drilling machine became a kind of precise, efficient, composite, the integrated function and low cost of automation processing equipment. At the same time, to meet manufacturing to a higher level, for flexible manufacturing unit, flexible manufacturing system, as well as computer integrated manufacturing system provides a basis for equipment, also calls for drilling machine to a higher level development.

In the bus manufacturing, seats are connected up. In the past, typically use the artificial drilling method for joining together, artificial drilling efficiency is low, the quality of the connection is not high, not suitable for mass production. Now the method is: to design a special drilling machine, is dedicated to the drill hole bus seat connection. The connection method of processing efficiency is higher, the connection of very good quality too.

The design of the bored through process analysis and determined the horizontal automatic drilling machine design. According to the design parameters, and choose the motor, the main structure design in detail, and the position control agencies, connecting structure and so on also of a simple design.

Key words:Drilling machine、 Electric motors、 Connection

目 录

绪 论 1

一、工艺方案的分析与设计 4

1.1工艺方案的分析与设计 4

1.2传动方案分析与钻孔工作位置示意 4

二、总体设计 5

2.1 电动机的选择 5

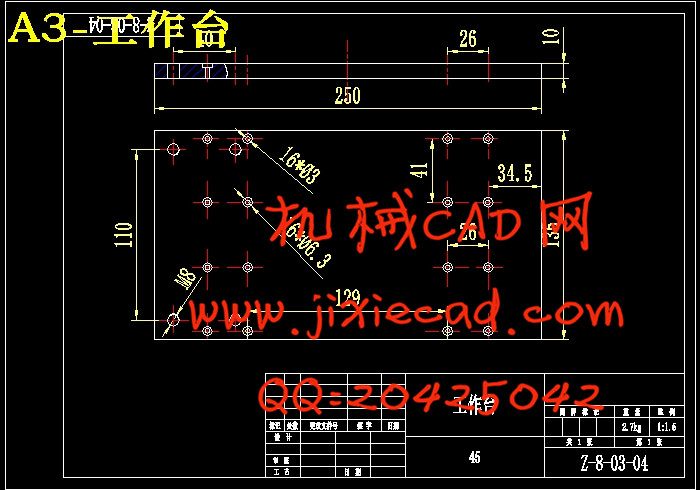

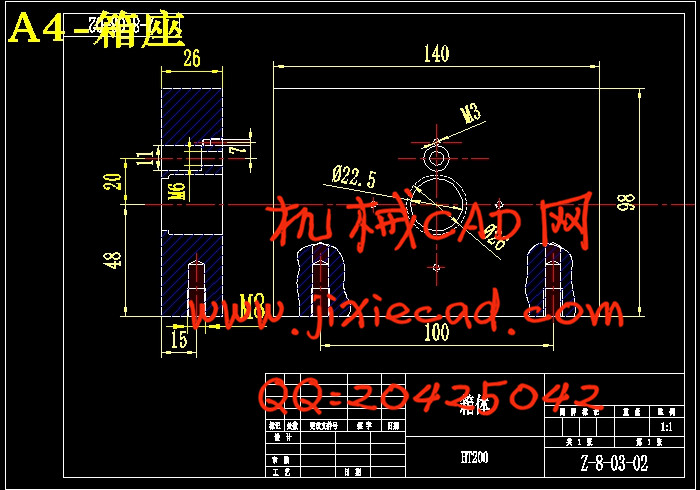

2.2工作台设计及计算 7

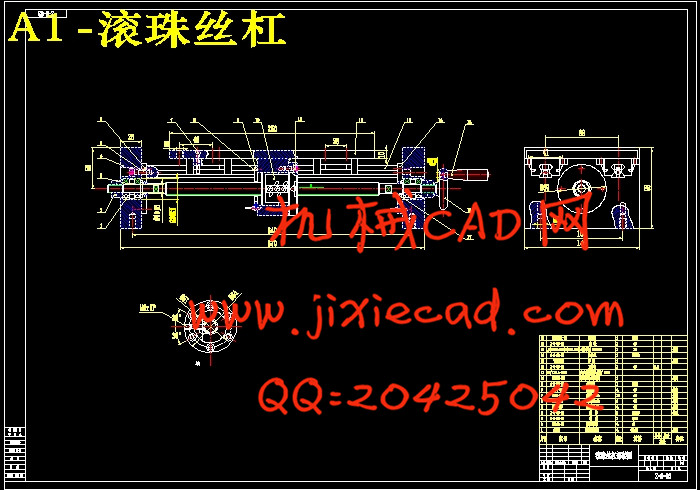

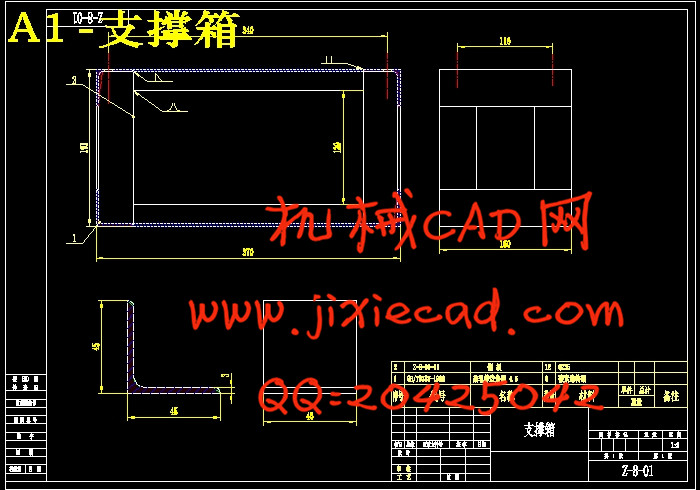

2.3进给传动系统设计计算 9

2.4脚踏板设计 16

2.5轴承的选取 16

结 论 18

致 谢 19

参考文献 20

随着科学技术的发展,制造技术的进步,以及社会对产品质量和品种多样化的要求越来越强烈。中、小批量生产的比例明显增加,要求现代钻孔机成为一种精密、高效、复合、集成功能和低成本的自动化加工设备。同时,为满足制造业向更高层次发展,为柔性制造单元、柔性制造系统,以及计算机集成制造系统提供基础设备,也要求钻孔机向更高水平发展。

在公交车制造中,座椅都是连接上去的。过去,一般都采用人工钻孔的方法进行拼接,人工钻孔的效率低,连接的质量不高,不适合大批量生产。现在采用的方法是:设计一个专用的钻孔机,专门用来钻公交座椅连接孔。这一连接方法的加工效率较高,连接的质量也很好。

本设计通过对钻孔工艺分析,确定了卧式自动钻孔机设计方案。根据设计参数,选择了电动机,对主要结构进行了详细地设计,并对位置调节机构、联接机构等也进行了简单地设计。

关键字:钻孔机,电动机,连接

Abstract

With the development of science and technology, manufacturing technology progress, and society to product quality and the requirements of the species diversity is more and more intense. And the proportion of small batch production increased significantly, the requirements of modern drilling machine became a kind of precise, efficient, composite, the integrated function and low cost of automation processing equipment. At the same time, to meet manufacturing to a higher level, for flexible manufacturing unit, flexible manufacturing system, as well as computer integrated manufacturing system provides a basis for equipment, also calls for drilling machine to a higher level development.

In the bus manufacturing, seats are connected up. In the past, typically use the artificial drilling method for joining together, artificial drilling efficiency is low, the quality of the connection is not high, not suitable for mass production. Now the method is: to design a special drilling machine, is dedicated to the drill hole bus seat connection. The connection method of processing efficiency is higher, the connection of very good quality too.

The design of the bored through process analysis and determined the horizontal automatic drilling machine design. According to the design parameters, and choose the motor, the main structure design in detail, and the position control agencies, connecting structure and so on also of a simple design.

Key words:Drilling machine、 Electric motors、 Connection

目 录

绪 论 1

一、工艺方案的分析与设计 4

1.1工艺方案的分析与设计 4

1.2传动方案分析与钻孔工作位置示意 4

二、总体设计 5

2.1 电动机的选择 5

2.2工作台设计及计算 7

2.3进给传动系统设计计算 9

2.4脚踏板设计 16

2.5轴承的选取 16

结 论 18

致 谢 19

参考文献 20