设计简介

摘 要

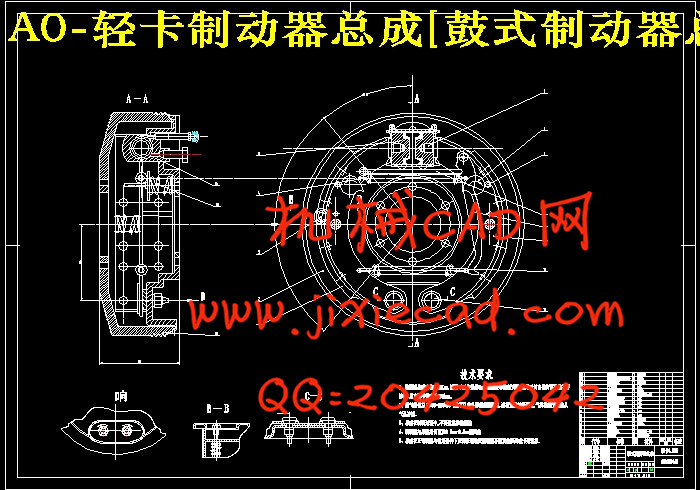

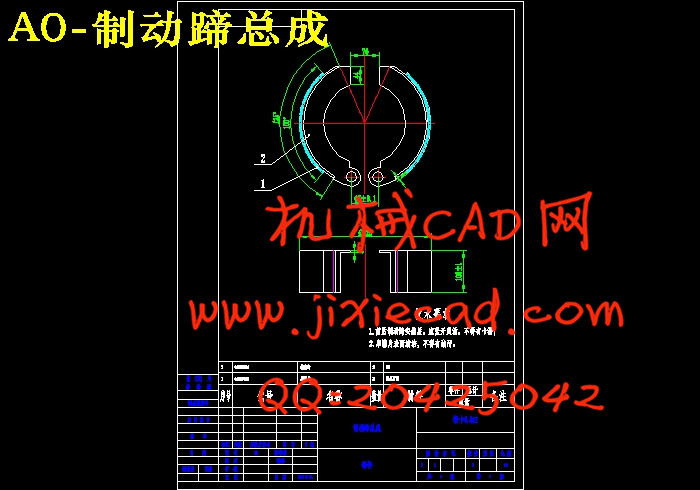

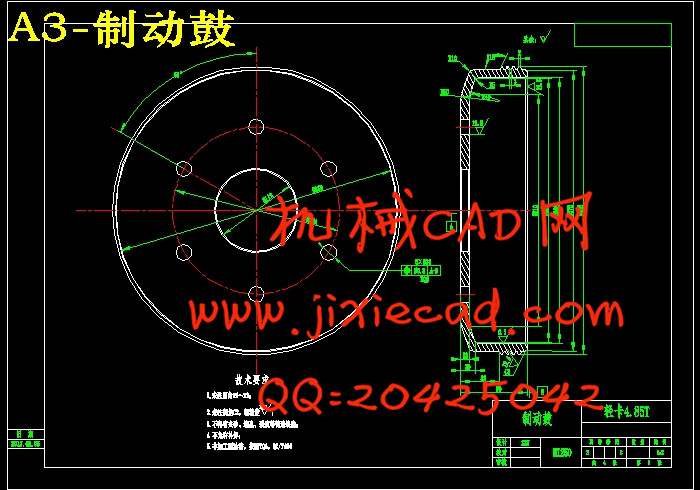

本文根据给定参数,完成了一轻型卡车鼓式制动器的设计,就摩擦式鼓式制动器进行了相关的设计和计算。首先根据给定车型的整车参数和技术要求,确定制动器的结构形式及、制动器主要参数,然后计算制动器的制动力矩、制动蹄上的压力分布、蹄片变形规律、制动效能因数、制动减速度、耐磨损特性、制动温升等,并在此基础上进行制动器主要零部件的结构设计。最后,完成装配图和零件图的绘制.关键词:轻型卡车,制动器设计,制动效能因数,制动减速度

Abstract

In the vehicle braking system has a very important role, failure will result in disaster if serious consequences. The main parts of the braking system is the brake, in the modern car is still widely used in high performance brake shoe - brake drum. The design of the friction drum brakes were related to the design and calculation., the first model of the vehicle according to the given parameter and the technical requirements, determine the brake structure and, brake main parameters, and then calculate the braking torque brake, brake shoes on the pressure distribution, deformation shoe, brake effectiveness factor, braking deceleration, wear characteristics, brake temperature, etc., and in this brake on the basis of the structural design of major components. Finally, assembly drawings and parts to complete mapping.Key word: Light truck,drum brake, braking torque, brake efficiency factor, braking deceleration.

目 录

前 言 1

1 鼓式制动器结构形式及选择 3

2制动系的主要参数及选择 4

2.1汽车制动力其分配的系数 4

2.2 同步附着系数 10

2.3制动器最大制动力矩 11

2.3.1制动鼓内径D的确定 13

2.3.2摩擦衬片宽度b和包角β 14

2.3.3摩擦衬片摩擦系数f 15

3 制动器的设计计算 16

3.1浮式领—从蹄制动器(平行支座面) 制动器因数计算 16

3.2制动驱动机构的设计计算 18

3.2.1所需制动力计算 18

3.2.2 确定制动轮缸直径 19

3.2.3 制动器所能产生的制动力计算 19

3.3 摩擦衬片的磨损特性计算 20

3.4行车制动效能计算 21

3.5驻车制动的计算 22

4 制动器优化设计 25

4.1受载静态工况 25

4.1.1启动Workbench 25

4.1.2网格的划分 25

4.1.3施加约束和载荷 27

4.1.4结果处理 27

4.1.5求解结果 27

结 论 29

致 谢 30

参考文献 31