设计简介

摘 要

近年来,随着企业生产与管理的不断提高,越来越多的企业认识到物流系统的改善与合理性对企业的发展非常重要。堆垛机是自动化立体仓库中最重要的起重堆垛设备,它能够在自动化立体的巷道中来回穿梭运行,将位于巷道口的货物存入货格;或者相反取出货格内的货物运送到巷道口。

本文详细论述了在现代大多数企业中普遍使用的双立柱堆垛机的设计方案,文章的重点放在其两个部件:升降机构、货叉伸缩机构的设计上,并对安全机构和控制部分进行简单的选取和计算其中包含电机,减速器的选取,齿轮,齿条的计算,卷筒的计算,轴的校核,电器原理图的配置等。首先,提出各个机构的总体设计方案;其次,对各个机构的受力情况进行了分析并计算,然后估算初取值,再进行校核,最后确定各个实际值。

关键词:自动化立体仓库;堆垛机;升降机构;货叉伸缩机构

Abstract

In recent years, along with the unceasing raising of enterprise production and management, more and more enterprises know that thing flows out reasonability and the improvement of system, is very important for the development of enterprise. Stacker cranes is automation three-dimensional storehouse in most important take heavy crane pile up equipment, it can in the tunnel of automation cube in the shuttle operation of round trip, will locate in tunnel the goods of mouth stock goods shelf; or opposite take out the goods transit in goods shelf go to tunnel mouth.

This paper describes the majority of enterprises in the widespread use of modern double-column stacking machine design, the article focused on its two components: lifting mechanism, telescopic fork design of institutions, and security agencies and the control part simple selection and calculation including motor, reducer selection, gear, rack of calculation, the calculation of roll, axis calibration, electrical schematic diagram of the configuration. First, the proposed design programs of various agencies; Secondly, the force of the various agencies to conduct the analysis and calculation, and then estimate the initial value, and then checked, and finally establish the actual value.

Keyword:automation three-dimensional storehouse;stacker cranes;lifting mechanism; telescopic fork institutions

近年来,随着企业生产与管理的不断提高,越来越多的企业认识到物流系统的改善与合理性对企业的发展非常重要。堆垛机是自动化立体仓库中最重要的起重堆垛设备,它能够在自动化立体的巷道中来回穿梭运行,将位于巷道口的货物存入货格;或者相反取出货格内的货物运送到巷道口。

本文详细论述了在现代大多数企业中普遍使用的双立柱堆垛机的设计方案,文章的重点放在其两个部件:升降机构、货叉伸缩机构的设计上,并对安全机构和控制部分进行简单的选取和计算其中包含电机,减速器的选取,齿轮,齿条的计算,卷筒的计算,轴的校核,电器原理图的配置等。首先,提出各个机构的总体设计方案;其次,对各个机构的受力情况进行了分析并计算,然后估算初取值,再进行校核,最后确定各个实际值。

关键词:自动化立体仓库;堆垛机;升降机构;货叉伸缩机构

Abstract

In recent years, along with the unceasing raising of enterprise production and management, more and more enterprises know that thing flows out reasonability and the improvement of system, is very important for the development of enterprise. Stacker cranes is automation three-dimensional storehouse in most important take heavy crane pile up equipment, it can in the tunnel of automation cube in the shuttle operation of round trip, will locate in tunnel the goods of mouth stock goods shelf; or opposite take out the goods transit in goods shelf go to tunnel mouth.

This paper describes the majority of enterprises in the widespread use of modern double-column stacking machine design, the article focused on its two components: lifting mechanism, telescopic fork design of institutions, and security agencies and the control part simple selection and calculation including motor, reducer selection, gear, rack of calculation, the calculation of roll, axis calibration, electrical schematic diagram of the configuration. First, the proposed design programs of various agencies; Secondly, the force of the various agencies to conduct the analysis and calculation, and then estimate the initial value, and then checked, and finally establish the actual value.

Keyword:automation three-dimensional storehouse;stacker cranes;lifting mechanism; telescopic fork institutions

目 录

摘 要.......................................................................................................................................... III

ABSTRACT ................................................................................................................................. IV

目 录..........................................................................................................................................V

1 绪论.......................................................................................................................................1

1.1 研究的背景与内容............................................................................................................................. 1

1.1.1 概述..............................................................................................................................1

1.1.2 有轨巷道堆垛机的发展现状及特点........................................................................... 1

1.1.3 有轨巷道堆垛机的类型............................................................................................... 2

1.1.4 巷道堆垛机的特点....................................................................................................... 5

1.2 设计的目的和意义.............................................................................................................. 5

1.3 设计的内容及要求.............................................................................................................. 5

1.4 设计参数.............................................................................................................................. 6

2.1 堆垛机三维运动速度的确定............................................................................................. 7

2.2 堆垛机各个部分的方案选择.............................................................................................. 8

2.2.1 堆垛机起升机构传动方式的选择........................................................................................... 8

2.2.2 堆垛机行走机构传动方式的选择............................................................................... 9

2.2.3 堆垛机机架的设计思路............................................................................................... 9

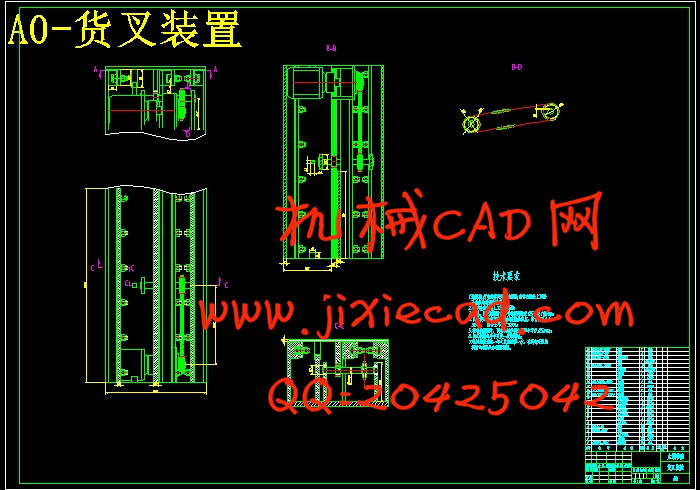

2.2.4 堆垛机货叉的设计思路............................................................................................... 9

2.2.5 堆垛机安全方案的确定............................................................................................. 11

2.3 堆垛机的技术参数............................................................................................................ 11

2.4 堆垛机的技术要求............................................................................................................ 11

3 堆垛机起升机构的设计.......................................................................................................... 15

3.1 起升机构的总体选型........................................................................................................ 15

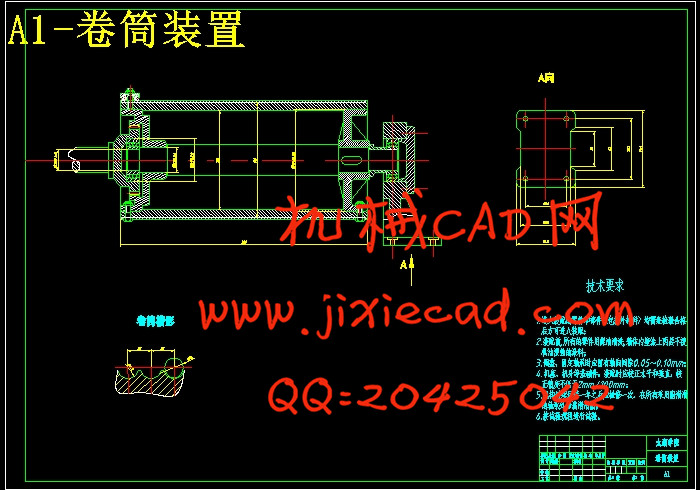

3.2 卷筒的设计........................................................................................................................ 18

3.2.1 卷筒部件计算............................................................................................................. 18

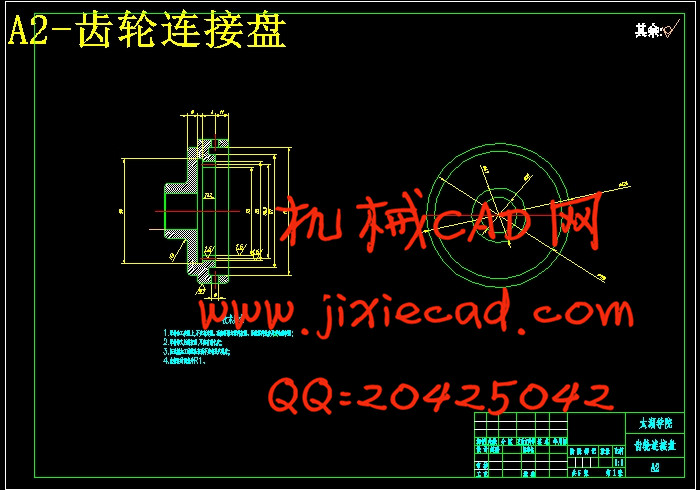

3.2.2 齿轮连接盘的计算..................................................................................................... 22

4 堆垛机行走机构和机架的选型设计...................................................................................... 25

4.1 堆垛机行走机构的选型设计........................................................................................... 25

4.2 堆垛机机架的选型设计................................................................................................... 27

5 堆垛机货叉的设计.................................................................................................................. 28

5.1 货叉传动装置的总体选型................................................................................................28

5.2 货叉传动齿轮、齿条的计算............................................................................................28

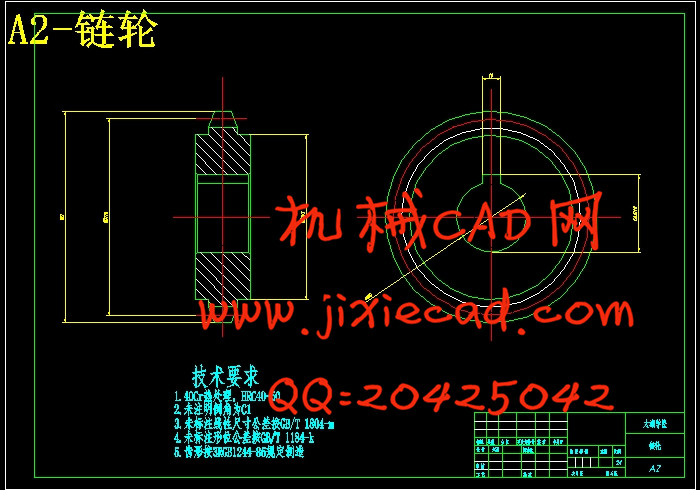

5.3 货叉传动链轮、链条的设计计算....................................................................................32

5.4 制动器的制动容量的设计................................................................................................34

6 堆垛机安全装置.......................................................................................................................35

摘 要.......................................................................................................................................... III

ABSTRACT ................................................................................................................................. IV

目 录..........................................................................................................................................V

1 绪论.......................................................................................................................................1

1.1 研究的背景与内容............................................................................................................................. 1

1.1.1 概述..............................................................................................................................1

1.1.2 有轨巷道堆垛机的发展现状及特点........................................................................... 1

1.1.3 有轨巷道堆垛机的类型............................................................................................... 2

1.1.4 巷道堆垛机的特点....................................................................................................... 5

1.2 设计的目的和意义.............................................................................................................. 5

1.3 设计的内容及要求.............................................................................................................. 5

1.4 设计参数.............................................................................................................................. 6

2.1 堆垛机三维运动速度的确定............................................................................................. 7

2.2 堆垛机各个部分的方案选择.............................................................................................. 8

2.2.1 堆垛机起升机构传动方式的选择........................................................................................... 8

2.2.2 堆垛机行走机构传动方式的选择............................................................................... 9

2.2.3 堆垛机机架的设计思路............................................................................................... 9

2.2.4 堆垛机货叉的设计思路............................................................................................... 9

2.2.5 堆垛机安全方案的确定............................................................................................. 11

2.3 堆垛机的技术参数............................................................................................................ 11

2.4 堆垛机的技术要求............................................................................................................ 11

3 堆垛机起升机构的设计.......................................................................................................... 15

3.1 起升机构的总体选型........................................................................................................ 15

3.2 卷筒的设计........................................................................................................................ 18

3.2.1 卷筒部件计算............................................................................................................. 18

3.2.2 齿轮连接盘的计算..................................................................................................... 22

4 堆垛机行走机构和机架的选型设计...................................................................................... 25

4.1 堆垛机行走机构的选型设计........................................................................................... 25

4.2 堆垛机机架的选型设计................................................................................................... 27

5 堆垛机货叉的设计.................................................................................................................. 28

5.1 货叉传动装置的总体选型................................................................................................28

5.2 货叉传动齿轮、齿条的计算............................................................................................28

5.3 货叉传动链轮、链条的设计计算....................................................................................32

5.4 制动器的制动容量的设计................................................................................................34

6 堆垛机安全装置.......................................................................................................................35

6.1 防撞保护装置.................................................................................................................... 35

6.2 钢丝绳断绳保护装置........................................................................................................ 35

7 结论与展望.............................................................................................................................. 36

7.1 结论................................................................................................................................... 36

7.2 不足之处及未来展望........................................................................................................... 36

致 谢.......................................................................................................................................... 37

参考文献...................................................................................................................................... 38

6.2 钢丝绳断绳保护装置........................................................................................................ 35

7 结论与展望.............................................................................................................................. 36

7.1 结论................................................................................................................................... 36

7.2 不足之处及未来展望........................................................................................................... 36

致 谢.......................................................................................................................................... 37

参考文献...................................................................................................................................... 38